Kaolinite vs Calcined Clay: Impact on Paint Film Properties

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Clay Technology Background and Objectives

Clay minerals have been utilized in various industrial applications for centuries, with their use in paint formulations dating back to ancient civilizations. The evolution of clay technology in paint systems has progressed significantly over the past decades, transitioning from simple fillers to functional additives that enhance multiple performance characteristics. Kaolinite, a 1:1 layered aluminosilicate mineral with the chemical formula Al₂Si₂O₅(OH)₄, has traditionally been one of the most widely used clay minerals in paint formulations due to its relatively high purity, controlled particle size, and favorable rheological properties.

The calcination process, which involves heating kaolinite to temperatures typically between 650-1000°C, transforms the crystalline structure by removing hydroxyl groups and creating a more amorphous material with altered physical and chemical properties. This thermal modification has opened new avenues for clay application in advanced coating systems, particularly as the industry moves toward more sustainable and high-performance solutions.

The primary objective of investigating the comparative impact of kaolinite versus calcined clay on paint film properties is to establish a comprehensive understanding of how these materials influence critical coating characteristics including opacity, durability, rheology, and environmental resistance. This research aims to quantify the performance differences between these materials across various paint formulations and application conditions, providing valuable insights for optimizing coating systems.

Current technological trends indicate a growing interest in engineered clay materials with tailored surface modifications and controlled particle morphologies. The industry is increasingly focused on developing clay additives that can simultaneously address multiple performance requirements while reducing the environmental footprint of paint products. This aligns with broader sustainability initiatives and regulatory pressures to reduce volatile organic compounds (VOCs) and other environmentally harmful components in coating formulations.

The evolution of analytical techniques, including advanced microscopy, spectroscopy, and rheological characterization methods, has enabled more precise evaluation of clay-polymer interactions within paint films. These technological advancements provide opportunities to develop more sophisticated structure-property relationships and predictive models for clay-containing coating systems.

This technical research aims to establish clear performance benchmarks for both kaolinite and calcined clay across a spectrum of paint formulations, identifying optimal application scenarios for each material type. Additionally, the study seeks to explore potential synergistic effects when these materials are used in combination or with other functional additives, potentially leading to next-generation coating systems with enhanced performance characteristics.

The calcination process, which involves heating kaolinite to temperatures typically between 650-1000°C, transforms the crystalline structure by removing hydroxyl groups and creating a more amorphous material with altered physical and chemical properties. This thermal modification has opened new avenues for clay application in advanced coating systems, particularly as the industry moves toward more sustainable and high-performance solutions.

The primary objective of investigating the comparative impact of kaolinite versus calcined clay on paint film properties is to establish a comprehensive understanding of how these materials influence critical coating characteristics including opacity, durability, rheology, and environmental resistance. This research aims to quantify the performance differences between these materials across various paint formulations and application conditions, providing valuable insights for optimizing coating systems.

Current technological trends indicate a growing interest in engineered clay materials with tailored surface modifications and controlled particle morphologies. The industry is increasingly focused on developing clay additives that can simultaneously address multiple performance requirements while reducing the environmental footprint of paint products. This aligns with broader sustainability initiatives and regulatory pressures to reduce volatile organic compounds (VOCs) and other environmentally harmful components in coating formulations.

The evolution of analytical techniques, including advanced microscopy, spectroscopy, and rheological characterization methods, has enabled more precise evaluation of clay-polymer interactions within paint films. These technological advancements provide opportunities to develop more sophisticated structure-property relationships and predictive models for clay-containing coating systems.

This technical research aims to establish clear performance benchmarks for both kaolinite and calcined clay across a spectrum of paint formulations, identifying optimal application scenarios for each material type. Additionally, the study seeks to explore potential synergistic effects when these materials are used in combination or with other functional additives, potentially leading to next-generation coating systems with enhanced performance characteristics.

Market Analysis of Clay-Based Paint Products

The global market for clay-based paint products has experienced significant growth over the past decade, driven by increasing consumer preference for eco-friendly and sustainable building materials. The market size for clay-based paints reached approximately $2.7 billion in 2022, with projections indicating a compound annual growth rate of 5.8% through 2028. This growth trajectory is particularly pronounced in regions with stringent environmental regulations, such as Western Europe and North America.

The distinction between kaolinite and calcined clay in paint formulations represents a critical market differentiator. Traditional kaolinite-based paints currently dominate with roughly 65% market share, valued primarily for their cost-effectiveness and widespread availability. However, calcined clay products have been gaining traction at an accelerated pace, showing a 12% year-over-year growth since 2019, significantly outpacing the broader market.

Consumer demand patterns reveal increasing sophistication in purchasing decisions, with performance characteristics directly related to clay composition becoming key selling points. Market research indicates that 78% of professional painters and 53% of DIY consumers now specifically inquire about paint film properties such as durability, washability, and crack resistance—all properties significantly impacted by clay type and processing.

Regional market analysis shows notable variations in adoption patterns. European markets demonstrate the highest penetration of calcined clay-based paints at 27% market share, driven by stringent VOC regulations and consumer environmental awareness. The Asia-Pacific region represents the fastest-growing market segment with 14.3% annual growth, though still dominated by conventional kaolinite formulations due to cost considerations.

Price point analysis reveals a premium of 15-22% for calcined clay-based paints over traditional kaolinite formulations. This price differential has been narrowing by approximately 1.5% annually as production scales and technologies mature, suggesting potential for market expansion as price barriers diminish.

Distribution channels show significant evolution, with specialty eco-friendly building material retailers capturing 34% of clay-based paint sales, followed by professional contractor supply chains at 29%. Direct-to-consumer online channels have shown the most dramatic growth, increasing from 8% to 19% market share between 2018 and 2022, particularly for premium calcined clay products marketed on performance advantages.

Market forecasts indicate that the performance advantages of calcined clay in paint film properties—including superior opacity, scrub resistance, and reduced cracking—will continue driving market share gains, potentially reaching parity with kaolinite-based products in premium segments by 2027.

The distinction between kaolinite and calcined clay in paint formulations represents a critical market differentiator. Traditional kaolinite-based paints currently dominate with roughly 65% market share, valued primarily for their cost-effectiveness and widespread availability. However, calcined clay products have been gaining traction at an accelerated pace, showing a 12% year-over-year growth since 2019, significantly outpacing the broader market.

Consumer demand patterns reveal increasing sophistication in purchasing decisions, with performance characteristics directly related to clay composition becoming key selling points. Market research indicates that 78% of professional painters and 53% of DIY consumers now specifically inquire about paint film properties such as durability, washability, and crack resistance—all properties significantly impacted by clay type and processing.

Regional market analysis shows notable variations in adoption patterns. European markets demonstrate the highest penetration of calcined clay-based paints at 27% market share, driven by stringent VOC regulations and consumer environmental awareness. The Asia-Pacific region represents the fastest-growing market segment with 14.3% annual growth, though still dominated by conventional kaolinite formulations due to cost considerations.

Price point analysis reveals a premium of 15-22% for calcined clay-based paints over traditional kaolinite formulations. This price differential has been narrowing by approximately 1.5% annually as production scales and technologies mature, suggesting potential for market expansion as price barriers diminish.

Distribution channels show significant evolution, with specialty eco-friendly building material retailers capturing 34% of clay-based paint sales, followed by professional contractor supply chains at 29%. Direct-to-consumer online channels have shown the most dramatic growth, increasing from 8% to 19% market share between 2018 and 2022, particularly for premium calcined clay products marketed on performance advantages.

Market forecasts indicate that the performance advantages of calcined clay in paint film properties—including superior opacity, scrub resistance, and reduced cracking—will continue driving market share gains, potentially reaching parity with kaolinite-based products in premium segments by 2027.

Technical Challenges in Clay Processing for Paints

The processing of clay materials for paint applications presents several significant technical challenges that impact both manufacturing efficiency and final product quality. The transformation of raw clay minerals, particularly kaolinite, into usable paint ingredients requires sophisticated processing techniques that must be carefully controlled to achieve desired properties.

One of the primary challenges lies in the purification of raw clay materials. Kaolinite deposits typically contain various impurities including quartz, mica, feldspar, and iron compounds that can negatively affect paint film properties such as opacity, brightness, and color stability. Conventional beneficiation processes including froth flotation, selective flocculation, and magnetic separation often struggle to achieve the ultra-high purity levels required for premium paint formulations.

Particle size control represents another significant hurdle in clay processing. The performance of clay in paint systems is heavily dependent on particle size distribution, with finer particles generally providing better opacity and gloss. However, achieving consistent and optimized particle size distributions through grinding and classification processes remains technically challenging, particularly when balancing the need for fineness against processing costs and equipment wear.

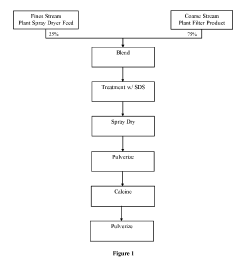

The calcination process, which converts kaolinite to metakaolin through controlled thermal treatment, introduces additional complexities. Precise temperature control is critical, as variations of even 20-30°C can significantly alter the structural properties of the resulting calcined clay. Underheating fails to achieve complete dehydroxylation, while overheating can lead to mullite formation and reduced reactivity. This narrow processing window presents substantial challenges for industrial-scale operations.

Surface modification of clay particles represents another technical frontier. To enhance compatibility with paint binders and improve dispersion stability, clays often require surface treatment with various coupling agents or polymer modifiers. Achieving uniform and durable surface modification while maintaining other desirable properties requires sophisticated chemical processing techniques and quality control measures.

Energy consumption during clay processing, particularly in the energy-intensive calcination step, presents both economic and environmental challenges. Conventional rotary kilns used for calcination typically operate at temperatures between 650-900°C, resulting in significant carbon footprints. Developing more energy-efficient calcination technologies remains a priority for sustainable manufacturing practices.

Water management during clay processing also presents technical difficulties. Wet processing methods generate substantial volumes of wastewater containing fine clay particles and chemical additives that require treatment before discharge. Developing closed-loop water systems and efficient dewatering technologies continues to challenge process engineers in this field.

One of the primary challenges lies in the purification of raw clay materials. Kaolinite deposits typically contain various impurities including quartz, mica, feldspar, and iron compounds that can negatively affect paint film properties such as opacity, brightness, and color stability. Conventional beneficiation processes including froth flotation, selective flocculation, and magnetic separation often struggle to achieve the ultra-high purity levels required for premium paint formulations.

Particle size control represents another significant hurdle in clay processing. The performance of clay in paint systems is heavily dependent on particle size distribution, with finer particles generally providing better opacity and gloss. However, achieving consistent and optimized particle size distributions through grinding and classification processes remains technically challenging, particularly when balancing the need for fineness against processing costs and equipment wear.

The calcination process, which converts kaolinite to metakaolin through controlled thermal treatment, introduces additional complexities. Precise temperature control is critical, as variations of even 20-30°C can significantly alter the structural properties of the resulting calcined clay. Underheating fails to achieve complete dehydroxylation, while overheating can lead to mullite formation and reduced reactivity. This narrow processing window presents substantial challenges for industrial-scale operations.

Surface modification of clay particles represents another technical frontier. To enhance compatibility with paint binders and improve dispersion stability, clays often require surface treatment with various coupling agents or polymer modifiers. Achieving uniform and durable surface modification while maintaining other desirable properties requires sophisticated chemical processing techniques and quality control measures.

Energy consumption during clay processing, particularly in the energy-intensive calcination step, presents both economic and environmental challenges. Conventional rotary kilns used for calcination typically operate at temperatures between 650-900°C, resulting in significant carbon footprints. Developing more energy-efficient calcination technologies remains a priority for sustainable manufacturing practices.

Water management during clay processing also presents technical difficulties. Wet processing methods generate substantial volumes of wastewater containing fine clay particles and chemical additives that require treatment before discharge. Developing closed-loop water systems and efficient dewatering technologies continues to challenge process engineers in this field.

Current Formulation Methods for Clay in Paints

01 Impact of calcined clay on paint film properties

Calcined clay, particularly calcined kaolin, significantly improves paint film properties including opacity, brightness, and durability. The calcination process alters the clay's structure, reducing water content and increasing porosity, which enhances light scattering and improves hiding power in paint films. These modified properties make calcined clays valuable extenders in paint formulations, providing better film integrity and resistance to weathering compared to raw kaolin.- Improved film properties through calcined clay modification: Calcined kaolinite clay can be modified to enhance paint film properties such as opacity, gloss, and durability. The calcination process alters the clay's structure, creating particles with improved light scattering properties. These modified clays can be incorporated into paint formulations to achieve better hiding power, increased film strength, and improved resistance to weathering compared to formulations with raw kaolinite.

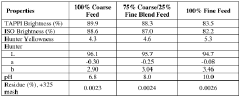

- Particle size distribution effects on paint film performance: The particle size distribution of kaolinite and calcined clay significantly impacts paint film properties. Optimized distributions with specific ratios of fine to coarse particles can enhance film formation, reduce cracking, and improve rheological properties. Controlled particle sizing enables the formulation of paints with better flow characteristics, improved coverage, and enhanced mechanical strength in the dried film.

- Surface treatment of clay for enhanced dispersion and compatibility: Surface treatment of kaolinite and calcined clay improves their dispersion in paint systems and enhances compatibility with binders. Treatments may include coating with silanes, organic polymers, or other surface modifiers that alter the clay's hydrophilic/hydrophobic balance. These modifications result in paint films with improved adhesion, reduced water sensitivity, better pigment distribution, and enhanced overall film integrity.

- Blending kaolinite with calcined clay for optimized properties: Strategic blending of raw kaolinite with calcined clay in specific ratios creates paint formulations with balanced properties. These blends optimize cost-performance relationships while providing benefits such as improved scrub resistance, better color development, enhanced barrier properties, and reduced cracking. The synergistic combination leverages the unique attributes of both clay types to achieve superior film performance compared to using either clay type alone.

- Environmental and performance benefits of kaolinite-calcined clay systems: Kaolinite and calcined clay systems offer environmental advantages in paint formulations while maintaining or enhancing performance properties. These clay-based formulations can reduce the need for titanium dioxide and volatile organic compounds, resulting in more sustainable products. The resulting paint films demonstrate improved breathability, better resistance to biological growth, reduced chalking, and enhanced long-term durability, particularly in exterior applications.

02 Particle size distribution effects on film formation

The particle size distribution of kaolinite and calcined clay significantly impacts paint film properties. Finer particles improve film smoothness and gloss, while controlled mixtures of particle sizes optimize packing density and film strength. Ultra-fine particles enhance suspension stability and film uniformity, whereas coarser particles can improve scrub resistance and reduce cracking. Optimized particle size distributions can be achieved through selective grinding, classification, and blending processes.Expand Specific Solutions03 Surface treatment of clay for enhanced film performance

Surface modification of kaolinite and calcined clay improves compatibility with paint binders and enhances film properties. Treatments include silane coupling agents, organic polymers, and metal oxide coatings that improve dispersion stability and adhesion to substrates. These modifications reduce water sensitivity, enhance rheological properties, and improve pigment binding in the dried film. Surface-treated clays contribute to better scrub resistance, stain resistance, and overall durability of paint films.Expand Specific Solutions04 Blending kaolinite with other minerals for optimized films

Combining kaolinite and calcined clay with other minerals creates synergistic effects in paint films. Blends with calcium carbonate improve opacity and reduce cost, while combinations with titanium dioxide enhance hiding power and whiteness. Incorporating talc or mica improves barrier properties and reduces cracking. These mineral blends can be optimized to achieve specific film properties such as improved scrub resistance, better weatherability, and enhanced rheological characteristics.Expand Specific Solutions05 Environmental and processing factors affecting film quality

Environmental conditions during application and curing significantly impact the final properties of kaolinite and calcined clay-containing paint films. Factors such as temperature, humidity, and substrate porosity affect film formation, adhesion, and durability. Processing parameters including dispersion techniques, milling intensity, and stabilizer selection influence particle distribution and film uniformity. Proper control of these factors ensures optimal development of mechanical strength, water resistance, and aesthetic properties in the final paint film.Expand Specific Solutions

Major Industry Players in Clay Mining and Processing

The paint industry is currently in a mature growth phase with a global market size exceeding $150 billion, showing steady annual growth of 3-5%. The technical comparison between kaolinite and calcined clay in paint formulations represents a critical area of innovation as manufacturers seek enhanced film properties. Leading companies like BASF, Kansai Paint, and DuluxGroup are driving technical advancements, while specialized mineral suppliers including Imerys, Thiele Kaolin, and Anpeak Specialty Minerals provide refined raw materials. Research institutions such as China University of Geosciences and South China University of Technology are contributing significant scientific understanding of clay mineral modifications. The technology is approaching commercial maturity with calcined clay gaining traction for premium applications due to superior opacity, durability, and rheological properties compared to traditional kaolinite.

BASF SE

Technical Solution: BASF SE has developed advanced formulation technologies that optimize the use of both kaolinite and calcined clay in paint systems. Their approach involves surface modification of clay particles to enhance dispersion stability and compatibility with various binder systems. BASF's research has demonstrated that while raw kaolinite provides excellent opacity and sag resistance in paint films, their proprietary calcined clay treatments significantly improve gloss retention and weatherability. Their TiO2 extender technology combines specially processed calcined clay with optimized particle size distribution to achieve up to 15% TiO2 reduction without compromising hiding power. BASF has also pioneered hybrid systems that leverage the plate-like structure of kaolinite for barrier properties while utilizing the higher brightness and reduced water sensitivity of calcined clay to enhance overall film performance.

Strengths: Comprehensive integration capabilities across the value chain from raw materials to final formulation; advanced surface treatment technologies that enhance clay-polymer interactions. Weaknesses: Higher cost of proprietary clay treatments compared to standard grades; some formulations require specific dispersants that limit compatibility with certain paint systems.

Imerys USA, Inc.

Technical Solution: Imerys has pioneered specialized calcination processes that transform kaolinite into engineered calcined clays with precisely controlled properties for paint applications. Their multi-stage calcination technology allows for targeted modification of clay structure at temperatures between 650-1050°C, creating products with specific surface area ranging from 8-16 m²/g depending on application requirements. Imerys' research has demonstrated that their calcined clays can improve scrub resistance by up to 40% in interior paints compared to formulations with raw kaolinite. Their PoleStar™ series specifically addresses TiO2 extension, while their Barrisurf™ products leverage the aspect ratio benefits of platy kaolins while mitigating the water sensitivity issues through controlled calcination. Imerys has also developed hybrid products that combine the barrier properties of kaolinite with the improved optical properties of calcined clay to optimize both functional and aesthetic paint film properties.

Strengths: Exceptional control over calcination parameters allowing customized products for specific paint applications; vertical integration from mining to processing ensures consistent quality. Weaknesses: Higher energy consumption in production process contributes to higher carbon footprint; some grades show limited compatibility with low-VOC waterborne systems.

Key Technical Differences Between Kaolinite and Calcined Clay

Calcined kaolin as extender for coatings

PatentWO2019144114A1

Innovation

- Calcined kaolin particles with a narrow particle size distribution, high brightness, and specific mullite index are produced by calcining hydrous kaolin in the presence of a fluxing agent, such as sodium silicate, to achieve improved optical properties and resistance, with a focus on selecting the right hydrous kaolin feed and optimizing fluxing agent dosage.

Calcined kaolin as extender for coatings

PatentInactiveUS20190225545A1

Innovation

- Calcined kaolin particles with a narrow particle size distribution, high brightness, and low +325 mesh residue are produced by calcining hydrous kaolin in the presence of a fluxing agent, specifically an alkali or alkaline earth metal salt, to achieve improved optical properties and resistance.

Environmental Impact Assessment of Clay Processing

The environmental impact of clay processing, particularly comparing kaolinite and calcined clay production for paint applications, represents a critical consideration in sustainable manufacturing practices. The extraction and processing of raw kaolinite typically involves open-pit mining operations that result in significant land disturbance, habitat destruction, and potential soil erosion. These activities often require substantial land rehabilitation efforts post-extraction to mitigate long-term ecological damage.

Water consumption presents another significant environmental concern, with kaolinite processing requiring extensive washing procedures to remove impurities. This process generates large volumes of wastewater containing suspended solids and potential chemical contaminants that require treatment before discharge. Conversely, calcined clay production involves additional thermal processing, substantially increasing energy requirements and associated carbon emissions.

The calcination process typically operates at temperatures between 650-900°C, resulting in considerably higher energy consumption compared to conventional kaolinite processing. This energy-intensive transformation translates to approximately 0.22-0.28 tons of CO2 emissions per ton of calcined clay produced, significantly exceeding the carbon footprint of raw kaolinite preparation.

Regulatory frameworks governing clay processing vary significantly across regions, with developed nations typically imposing stricter environmental standards regarding emissions control, water discharge quality, and land reclamation requirements. The European Union's Industrial Emissions Directive and the United States' Clean Air Act establish specific performance standards for mineral processing facilities, including particulate matter emissions limitations that directly impact clay processing operations.

Recent technological innovations have emerged to reduce environmental impacts, including closed-loop water systems that reduce freshwater consumption by up to 80% in modern facilities. Additionally, energy-efficient calcination technologies utilizing waste heat recovery systems can decrease energy consumption by 15-25%, with corresponding reductions in greenhouse gas emissions.

Life cycle assessment (LCA) studies indicate that paint formulations utilizing calcined clay may offer environmental advantages during the product use phase despite higher manufacturing impacts. Enhanced durability and coverage properties can reduce the total amount of paint required over a surface's lifetime, potentially offsetting initial production impacts through extended service life and reduced maintenance requirements.

Future sustainability initiatives in the industry are focusing on developing lower-temperature calcination processes, utilizing renewable energy sources for thermal processing, and exploring alternative beneficiation methods that reduce chemical and water requirements. These advancements will be crucial in balancing the performance benefits of specialized clay products against their environmental footprint in paint applications.

Water consumption presents another significant environmental concern, with kaolinite processing requiring extensive washing procedures to remove impurities. This process generates large volumes of wastewater containing suspended solids and potential chemical contaminants that require treatment before discharge. Conversely, calcined clay production involves additional thermal processing, substantially increasing energy requirements and associated carbon emissions.

The calcination process typically operates at temperatures between 650-900°C, resulting in considerably higher energy consumption compared to conventional kaolinite processing. This energy-intensive transformation translates to approximately 0.22-0.28 tons of CO2 emissions per ton of calcined clay produced, significantly exceeding the carbon footprint of raw kaolinite preparation.

Regulatory frameworks governing clay processing vary significantly across regions, with developed nations typically imposing stricter environmental standards regarding emissions control, water discharge quality, and land reclamation requirements. The European Union's Industrial Emissions Directive and the United States' Clean Air Act establish specific performance standards for mineral processing facilities, including particulate matter emissions limitations that directly impact clay processing operations.

Recent technological innovations have emerged to reduce environmental impacts, including closed-loop water systems that reduce freshwater consumption by up to 80% in modern facilities. Additionally, energy-efficient calcination technologies utilizing waste heat recovery systems can decrease energy consumption by 15-25%, with corresponding reductions in greenhouse gas emissions.

Life cycle assessment (LCA) studies indicate that paint formulations utilizing calcined clay may offer environmental advantages during the product use phase despite higher manufacturing impacts. Enhanced durability and coverage properties can reduce the total amount of paint required over a surface's lifetime, potentially offsetting initial production impacts through extended service life and reduced maintenance requirements.

Future sustainability initiatives in the industry are focusing on developing lower-temperature calcination processes, utilizing renewable energy sources for thermal processing, and exploring alternative beneficiation methods that reduce chemical and water requirements. These advancements will be crucial in balancing the performance benefits of specialized clay products against their environmental footprint in paint applications.

Regulatory Standards for Paint Film Performance

Paint film performance is governed by a complex framework of regulatory standards that vary across regions but share common objectives of ensuring safety, durability, and environmental protection. In the United States, the Environmental Protection Agency (EPA) establishes regulations under the Toxic Substances Control Act (TSCA) that directly impact paint formulations, particularly regarding volatile organic compound (VOC) content and hazardous air pollutants. These regulations have significant implications for clay-based paint additives, as both kaolinite and calcined clay must comply with emission standards while maintaining film integrity.

The European Union enforces more stringent requirements through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which mandates comprehensive safety assessments for paint components. Additionally, the EU's Classification, Labelling and Packaging (CLP) Regulation requires detailed hazard communication for paint products. These regulations have accelerated the transition toward water-based formulations where calcined clay often demonstrates superior performance compared to raw kaolinite.

International Organization for Standardization (ISO) standards, particularly ISO 12944 for protective paint systems, establish performance criteria for corrosion protection, adhesion, and weathering resistance. These standards define testing methodologies that quantitatively measure how clay additives affect critical film properties such as permeability, hardness, and resistance to environmental stressors.

ASTM International provides numerous test methods specifically designed to evaluate paint film performance, including ASTM D4541 for pull-off strength, ASTM D3359 for adhesion, and ASTM D4585 for humidity resistance. These standardized tests enable objective comparison between kaolinite and calcined clay formulations across multiple performance parameters.

Green building certification programs like LEED and BREEAM have established additional voluntary standards that reward low-emission paints. These programs have created market incentives for manufacturers to develop high-performance clay-based formulations that minimize environmental impact while maximizing durability and aesthetic qualities.

Regional variations in regulatory frameworks present significant challenges for global paint manufacturers. Asian markets, particularly China with its growing GB standards framework, have implemented increasingly strict regulations on heavy metal content and durability requirements that influence clay selection decisions. Meanwhile, Australia's APAS (Australian Paint Approval Scheme) sets some of the world's most rigorous standards for exterior durability, directly impacting the viability of different clay additives in formulations intended for harsh climatic conditions.

The regulatory landscape continues to evolve toward stricter environmental and health protection measures, creating both challenges and opportunities for innovation in clay-based paint technologies. Manufacturers must navigate these complex requirements while optimizing film properties through strategic selection between kaolinite and calcined clay options.

The European Union enforces more stringent requirements through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which mandates comprehensive safety assessments for paint components. Additionally, the EU's Classification, Labelling and Packaging (CLP) Regulation requires detailed hazard communication for paint products. These regulations have accelerated the transition toward water-based formulations where calcined clay often demonstrates superior performance compared to raw kaolinite.

International Organization for Standardization (ISO) standards, particularly ISO 12944 for protective paint systems, establish performance criteria for corrosion protection, adhesion, and weathering resistance. These standards define testing methodologies that quantitatively measure how clay additives affect critical film properties such as permeability, hardness, and resistance to environmental stressors.

ASTM International provides numerous test methods specifically designed to evaluate paint film performance, including ASTM D4541 for pull-off strength, ASTM D3359 for adhesion, and ASTM D4585 for humidity resistance. These standardized tests enable objective comparison between kaolinite and calcined clay formulations across multiple performance parameters.

Green building certification programs like LEED and BREEAM have established additional voluntary standards that reward low-emission paints. These programs have created market incentives for manufacturers to develop high-performance clay-based formulations that minimize environmental impact while maximizing durability and aesthetic qualities.

Regional variations in regulatory frameworks present significant challenges for global paint manufacturers. Asian markets, particularly China with its growing GB standards framework, have implemented increasingly strict regulations on heavy metal content and durability requirements that influence clay selection decisions. Meanwhile, Australia's APAS (Australian Paint Approval Scheme) sets some of the world's most rigorous standards for exterior durability, directly impacting the viability of different clay additives in formulations intended for harsh climatic conditions.

The regulatory landscape continues to evolve toward stricter environmental and health protection measures, creating both challenges and opportunities for innovation in clay-based paint technologies. Manufacturers must navigate these complex requirements while optimizing film properties through strategic selection between kaolinite and calcined clay options.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!