Optimizing Kaolinite Use in Refractory Materials: Durability Tips

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kaolinite Refractory Evolution and Objectives

Kaolinite has been a cornerstone material in refractory applications since the early industrial era, with its evolution closely tied to advancements in high-temperature manufacturing processes. The historical trajectory of kaolinite in refractories began in the 18th century with rudimentary applications in brick kilns and expanded significantly during the industrial revolution when higher temperature processes demanded more sophisticated refractory solutions.

The chemical composition of kaolinite (Al₂Si₂O₅(OH)₄) provides inherent properties that make it valuable for refractory applications, including its high fusion point, thermal stability, and relatively low thermal expansion. These characteristics have positioned kaolinite as a critical component in various refractory formulations throughout technological development periods.

By the mid-20th century, significant research efforts focused on enhancing kaolinite's performance through calcination processes, resulting in the development of metakaolin and mullite-based refractories with superior thermal resistance. The 1970s and 1980s witnessed further refinements in processing techniques, including the introduction of high-purity kaolinite extraction methods that substantially improved refractory performance in demanding industrial environments.

Recent technological advancements have centered on nano-engineering kaolinite structures to optimize specific properties. Modern processing techniques now allow for precise control over particle size distribution, surface area, and purity levels, enabling customized kaolinite formulations for specific refractory applications. This evolution represents a shift from kaolinite as a basic raw material to a sophisticated engineered component.

The primary objective in contemporary kaolinite refractory development is achieving enhanced durability under extreme thermal cycling conditions while maintaining cost-effectiveness. Specific technical goals include increasing the thermal shock resistance coefficient by at least 15-20%, extending service life in corrosive environments by 30-40%, and reducing thermal conductivity without compromising structural integrity.

Additional objectives focus on developing environmentally sustainable kaolinite processing methods that reduce energy consumption during manufacturing while maintaining or improving performance characteristics. The industry also aims to create hybrid kaolinite-based composites that combine traditional benefits with advanced material properties such as improved crack propagation resistance and reduced spalling under thermal stress.

The technological trajectory suggests that future kaolinite refractories will increasingly incorporate precision engineering at the microstructural level, potentially utilizing artificial intelligence for formulation optimization. This evolution path aligns with broader industry trends toward more durable, energy-efficient, and environmentally responsible high-temperature materials that can withstand increasingly demanding industrial processes.

The chemical composition of kaolinite (Al₂Si₂O₅(OH)₄) provides inherent properties that make it valuable for refractory applications, including its high fusion point, thermal stability, and relatively low thermal expansion. These characteristics have positioned kaolinite as a critical component in various refractory formulations throughout technological development periods.

By the mid-20th century, significant research efforts focused on enhancing kaolinite's performance through calcination processes, resulting in the development of metakaolin and mullite-based refractories with superior thermal resistance. The 1970s and 1980s witnessed further refinements in processing techniques, including the introduction of high-purity kaolinite extraction methods that substantially improved refractory performance in demanding industrial environments.

Recent technological advancements have centered on nano-engineering kaolinite structures to optimize specific properties. Modern processing techniques now allow for precise control over particle size distribution, surface area, and purity levels, enabling customized kaolinite formulations for specific refractory applications. This evolution represents a shift from kaolinite as a basic raw material to a sophisticated engineered component.

The primary objective in contemporary kaolinite refractory development is achieving enhanced durability under extreme thermal cycling conditions while maintaining cost-effectiveness. Specific technical goals include increasing the thermal shock resistance coefficient by at least 15-20%, extending service life in corrosive environments by 30-40%, and reducing thermal conductivity without compromising structural integrity.

Additional objectives focus on developing environmentally sustainable kaolinite processing methods that reduce energy consumption during manufacturing while maintaining or improving performance characteristics. The industry also aims to create hybrid kaolinite-based composites that combine traditional benefits with advanced material properties such as improved crack propagation resistance and reduced spalling under thermal stress.

The technological trajectory suggests that future kaolinite refractories will increasingly incorporate precision engineering at the microstructural level, potentially utilizing artificial intelligence for formulation optimization. This evolution path aligns with broader industry trends toward more durable, energy-efficient, and environmentally responsible high-temperature materials that can withstand increasingly demanding industrial processes.

Market Analysis of High-Performance Refractory Materials

The global high-performance refractory materials market has been experiencing steady growth, driven primarily by expanding metallurgical, glass, cement, and petrochemical industries. Currently valued at approximately 26 billion USD, the market is projected to reach 34 billion USD by 2027, representing a compound annual growth rate of 5.5%. This growth trajectory is particularly evident in regions with robust industrial manufacturing bases, including China, India, Japan, Germany, and the United States.

Kaolinite-based refractories constitute a significant segment within this market, accounting for roughly 18% of the total refractory materials consumption. Their popularity stems from kaolinite's excellent thermal stability, low thermal expansion, and superior resistance to chemical attack, making these materials particularly valuable in applications requiring prolonged exposure to extreme temperatures and corrosive environments.

Market demand analysis reveals several key trends influencing the high-performance refractory sector. First, there is increasing preference for refractories offering extended service life and reduced maintenance requirements, directly addressing the industry's focus on operational efficiency and cost reduction. Second, environmental regulations are driving demand for cleaner production processes and more sustainable refractory solutions, with kaolinite gaining favor due to its natural origin and relatively low environmental impact compared to synthetic alternatives.

The steel industry remains the largest consumer of high-performance refractories, accounting for approximately 60% of total consumption. However, emerging applications in advanced ceramics, aerospace components, and specialized glass manufacturing are creating new market opportunities for optimized kaolinite-based materials. These sectors demand refractories with enhanced durability characteristics and precise performance parameters.

Regional market analysis indicates that Asia-Pacific dominates the global consumption of high-performance refractories, representing nearly 65% of the market share, with China alone accounting for 40%. This regional concentration aligns with the distribution of heavy industries and manufacturing facilities. North America and Europe follow with approximately 15% and 12% market share respectively, primarily driven by replacement demand and technological upgrades in established industrial facilities.

Customer requirements are increasingly sophisticated, with specifications extending beyond basic thermal resistance to include parameters such as thermal shock resistance, abrasion resistance, and chemical inertness. This evolution in demand is creating premium market segments where optimized kaolinite formulations can command price premiums of 30-40% over standard refractory products, presenting significant value creation opportunities for manufacturers who can effectively enhance kaolinite's durability characteristics.

Kaolinite-based refractories constitute a significant segment within this market, accounting for roughly 18% of the total refractory materials consumption. Their popularity stems from kaolinite's excellent thermal stability, low thermal expansion, and superior resistance to chemical attack, making these materials particularly valuable in applications requiring prolonged exposure to extreme temperatures and corrosive environments.

Market demand analysis reveals several key trends influencing the high-performance refractory sector. First, there is increasing preference for refractories offering extended service life and reduced maintenance requirements, directly addressing the industry's focus on operational efficiency and cost reduction. Second, environmental regulations are driving demand for cleaner production processes and more sustainable refractory solutions, with kaolinite gaining favor due to its natural origin and relatively low environmental impact compared to synthetic alternatives.

The steel industry remains the largest consumer of high-performance refractories, accounting for approximately 60% of total consumption. However, emerging applications in advanced ceramics, aerospace components, and specialized glass manufacturing are creating new market opportunities for optimized kaolinite-based materials. These sectors demand refractories with enhanced durability characteristics and precise performance parameters.

Regional market analysis indicates that Asia-Pacific dominates the global consumption of high-performance refractories, representing nearly 65% of the market share, with China alone accounting for 40%. This regional concentration aligns with the distribution of heavy industries and manufacturing facilities. North America and Europe follow with approximately 15% and 12% market share respectively, primarily driven by replacement demand and technological upgrades in established industrial facilities.

Customer requirements are increasingly sophisticated, with specifications extending beyond basic thermal resistance to include parameters such as thermal shock resistance, abrasion resistance, and chemical inertness. This evolution in demand is creating premium market segments where optimized kaolinite formulations can command price premiums of 30-40% over standard refractory products, presenting significant value creation opportunities for manufacturers who can effectively enhance kaolinite's durability characteristics.

Current Kaolinite Refractory Technology Challenges

The global refractory materials industry currently faces significant challenges in optimizing kaolinite utilization, particularly regarding durability enhancement. A comprehensive assessment reveals that traditional kaolinite-based refractories struggle with thermal shock resistance limitations, especially in high-temperature industrial applications exceeding 1600°C. This constraint has become increasingly problematic as modern metallurgical, cement, and glass manufacturing processes demand materials capable of withstanding more extreme thermal cycling conditions.

Chemical degradation presents another substantial challenge, with kaolinite-based refractories showing vulnerability to alkali attack in cement kilns and slag penetration in steel ladles. Research indicates that up to 30% reduction in service life occurs when these materials face aggressive chemical environments without proper modifications or protective measures.

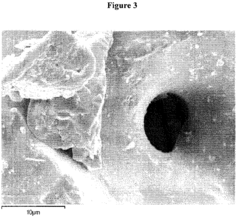

Microstructural stability issues manifest as premature cracking and spalling during thermal cycling. Current manufacturing techniques have not fully resolved the challenge of maintaining consistent porosity distribution throughout kaolinite-based refractory products, leading to uneven thermal expansion and subsequent structural failures. Advanced imaging studies demonstrate that conventional processing methods create inherent microstructural weaknesses at grain boundaries.

The environmental sustainability of kaolinite extraction and processing represents an emerging challenge. Traditional beneficiation methods consume significant water resources and generate substantial waste streams. Regulatory pressures in major manufacturing regions increasingly demand reduced environmental footprints, necessitating technological innovations in raw material processing.

Cost-effectiveness remains a persistent obstacle, with high-purity kaolinite sources becoming scarcer and more expensive. The industry faces a 15-20% increase in raw material costs over the past five years, compelling manufacturers to explore alternative formulations or processing techniques that maximize performance while minimizing pure kaolinite content.

Technical standardization across global markets presents additional complications. Divergent testing protocols and performance specifications between North American, European, and Asian markets create barriers to technology transfer and product optimization. This fragmentation impedes the development of universally applicable solutions for enhancing kaolinite refractory durability.

Research infrastructure limitations further constrain innovation, with insufficient collaboration between academic institutions and industrial partners. The specialized equipment required for high-temperature testing and microstructural analysis remains concentrated in a few research centers, limiting broader experimental validation of new formulations and processing techniques.

Chemical degradation presents another substantial challenge, with kaolinite-based refractories showing vulnerability to alkali attack in cement kilns and slag penetration in steel ladles. Research indicates that up to 30% reduction in service life occurs when these materials face aggressive chemical environments without proper modifications or protective measures.

Microstructural stability issues manifest as premature cracking and spalling during thermal cycling. Current manufacturing techniques have not fully resolved the challenge of maintaining consistent porosity distribution throughout kaolinite-based refractory products, leading to uneven thermal expansion and subsequent structural failures. Advanced imaging studies demonstrate that conventional processing methods create inherent microstructural weaknesses at grain boundaries.

The environmental sustainability of kaolinite extraction and processing represents an emerging challenge. Traditional beneficiation methods consume significant water resources and generate substantial waste streams. Regulatory pressures in major manufacturing regions increasingly demand reduced environmental footprints, necessitating technological innovations in raw material processing.

Cost-effectiveness remains a persistent obstacle, with high-purity kaolinite sources becoming scarcer and more expensive. The industry faces a 15-20% increase in raw material costs over the past five years, compelling manufacturers to explore alternative formulations or processing techniques that maximize performance while minimizing pure kaolinite content.

Technical standardization across global markets presents additional complications. Divergent testing protocols and performance specifications between North American, European, and Asian markets create barriers to technology transfer and product optimization. This fragmentation impedes the development of universally applicable solutions for enhancing kaolinite refractory durability.

Research infrastructure limitations further constrain innovation, with insufficient collaboration between academic institutions and industrial partners. The specialized equipment required for high-temperature testing and microstructural analysis remains concentrated in a few research centers, limiting broader experimental validation of new formulations and processing techniques.

Established Kaolinite Optimization Techniques

01 Kaolinite modification for enhanced durability

Various modification techniques can be applied to kaolinite to enhance its durability properties. These modifications may include surface treatments, chemical functionalization, or physical alterations that improve the clay's resistance to weathering, chemical attack, and mechanical stress. Modified kaolinite exhibits improved stability in harsh environments and can maintain its structural integrity over extended periods, making it suitable for applications requiring long-term durability.- Kaolinite modification for enhanced durability: Kaolinite can be modified through various chemical treatments to enhance its durability properties. These modifications often involve surface treatments that improve the clay's resistance to weathering, moisture, and chemical degradation. Modified kaolinite exhibits superior mechanical strength and longevity in various applications, making it more suitable for demanding environmental conditions.

- Kaolinite composites for improved structural stability: Combining kaolinite with other materials to form composites significantly enhances its durability characteristics. These composites often incorporate polymers, resins, or other mineral components that work synergistically with kaolinite to create materials with improved tensile strength, impact resistance, and dimensional stability. The resulting composites demonstrate extended service life and reduced degradation under stress conditions.

- Thermal treatment processes for kaolinite durability: Various thermal treatment processes can be applied to kaolinite to transform its crystalline structure and enhance durability. These processes include calcination, sintering, and controlled heating regimes that alter the mineral's physical and chemical properties. Thermally treated kaolinite exhibits improved hardness, chemical resistance, and stability in high-temperature applications, making it suitable for refractory and ceramic applications requiring long-term durability.

- Kaolinite in cement and construction materials: Incorporating kaolinite into cement and construction materials can enhance their durability and performance characteristics. When properly processed and added to concrete mixtures, kaolinite improves resistance to weathering, reduces permeability, and enhances long-term structural integrity. These formulations demonstrate superior resistance to freeze-thaw cycles, chemical attack, and environmental degradation, resulting in construction materials with extended service life.

- Environmental factors affecting kaolinite durability: The durability of kaolinite is significantly influenced by various environmental factors including moisture exposure, pH variations, temperature fluctuations, and chemical contaminants. Research has focused on understanding these degradation mechanisms and developing protective measures to mitigate their effects. Strategies include surface coatings, stabilizing additives, and controlled processing conditions that enhance kaolinite's resistance to environmental stressors and extend its functional lifespan in various applications.

02 Kaolinite composites for improved mechanical properties

Combining kaolinite with other materials to form composites significantly enhances its durability characteristics. These composites typically incorporate polymers, resins, or other mineral components that work synergistically with kaolinite to improve mechanical strength, abrasion resistance, and dimensional stability. The resulting materials demonstrate superior durability under mechanical stress and environmental exposure compared to unmodified kaolinite.Expand Specific Solutions03 Thermal treatment methods for kaolinite stabilization

Specific thermal processing techniques can be applied to kaolinite to transform its crystalline structure and enhance durability. These processes include controlled calcination, sintering, or heat treatment under specific conditions that alter the mineral's physical and chemical properties. Thermally treated kaolinite exhibits improved resistance to thermal cycling, chemical degradation, and mechanical wear, making it suitable for applications in harsh environments.Expand Specific Solutions04 Chemical stabilization of kaolinite for environmental resistance

Chemical treatments can be applied to kaolinite to improve its resistance to environmental factors such as moisture, pH variations, and chemical exposure. These treatments may involve the use of specific reagents, catalysts, or binding agents that interact with the clay's surface to create protective barriers or alter its chemical reactivity. Chemically stabilized kaolinite demonstrates enhanced durability in aggressive environments and maintains its functional properties over extended periods.Expand Specific Solutions05 Kaolinite durability enhancement for specific industrial applications

Specialized formulations and processing techniques have been developed to enhance kaolinite durability for specific industrial applications such as construction materials, coatings, ceramics, and paper products. These application-specific approaches optimize the clay's performance characteristics to meet the durability requirements of particular industries. The enhanced kaolinite materials demonstrate improved longevity, resistance to degradation, and maintained functionality under the specific conditions encountered in these applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The refractory materials market utilizing kaolinite is currently in a growth phase, driven by increasing demand in steel, cement, and petrochemical industries. The global market size is estimated to exceed $30 billion, with a projected CAGR of 3-4% through 2027. Technologically, established players like NIPPON STEEL, Krosaki Harima, and Allied Mineral Products demonstrate high maturity in kaolinite application for high-temperature environments, while companies such as NGK Insulators and Calderys France are advancing innovative formulations to enhance durability. Research institutions including University of Science & Technology Beijing and Indian Institute of Technology Madras are developing next-generation refractory solutions, focusing on nano-additives and composite structures to optimize kaolinite's thermal resistance properties.

NIPPON STEEL CORP.

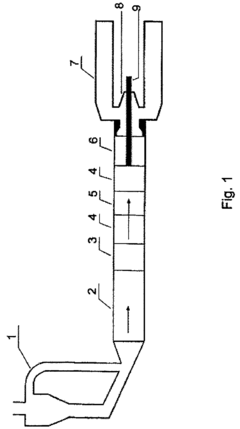

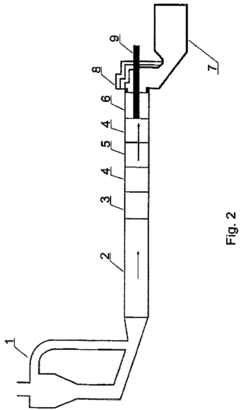

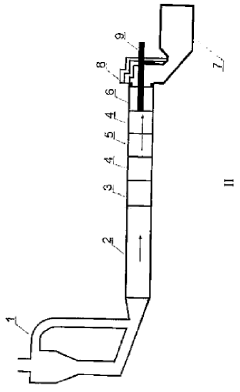

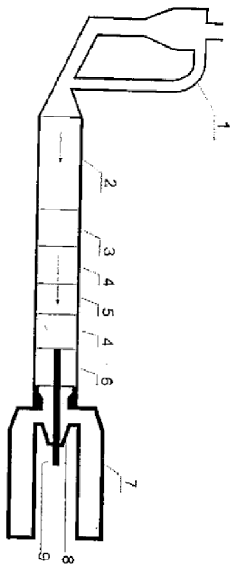

Technical Solution: NIPPON STEEL has developed advanced kaolinite-based refractory materials with enhanced durability through their proprietary multi-phase binding system. Their technology involves precise control of kaolinite particle size distribution (typically maintaining 45-75μm as optimal range) and incorporating alumina-rich additives to form mullite phases during sintering. The company's approach includes a specialized heat treatment process at 1350-1450°C that promotes controlled crystallization, resulting in refractories with superior thermal shock resistance. NIPPON STEEL's materials feature a unique microstructure where kaolinite-derived mullite needles interlock with the matrix, creating a reinforced structure that significantly improves mechanical strength and erosion resistance in harsh industrial environments such as blast furnaces and steel ladles.

Strengths: Superior thermal shock resistance due to engineered microstructure; excellent resistance to slag penetration; longer service life in extreme temperature cycling conditions. Weaknesses: Higher production costs compared to conventional refractories; requires precise control of manufacturing parameters; limited flexibility for on-site adjustments.

Krosaki Harima Corp.

Technical Solution: Krosaki Harima has pioneered an innovative approach to kaolinite utilization in refractory materials through their "Controlled Porosity Technology" (CPT). This technique precisely engineers the pore structure of kaolinite-based refractories by incorporating specific organic pore-forming agents that burn out during firing, creating a network of micro and macro pores with optimized distribution. Their process involves treating raw kaolinite with proprietary surface modifiers to enhance its dispersion and bonding characteristics, followed by a specialized firing regime that includes a holding period at 950-1050°C to facilitate mullite formation while maintaining structural integrity. The resulting materials exhibit exceptional thermal insulation properties while maintaining mechanical strength. Krosaki Harima's refractories also incorporate nano-scale additives that fill intergranular spaces, significantly reducing permeability to molten metals and slags.

Strengths: Exceptional thermal insulation properties; superior resistance to thermal spalling; reduced energy consumption in industrial applications due to better insulation. Weaknesses: More complex manufacturing process requiring specialized equipment; potentially higher initial cost; may have lower mechanical strength at room temperature compared to denser alternatives.

Critical Patents in Kaolinite Durability Enhancement

Refractory material for cement industry kilns and use thereof

PatentInactiveUS7531476B2

Innovation

- A refractory material composition comprising 55% andalusite, 35% silicon carbide, and 10% clay, or variations thereof, providing enhanced hardness and resistance to thermal, physical, and chemical deformation, configured as bricks or mortar for lining cement kilns.

Refractory material for cement industry kilns and use thereof

PatentInactiveIN181KOL2006A

Innovation

- A refractory material composed of andalusite (Al11SiO4), silicon carbide (SiC), and clay, combined in specific proportions to enhance hardness, resistance, and thermal conductivity, tailored for the unique demands of cement kilns, including the use of kaolinite as a substitute for andalusite.

Environmental Impact and Sustainability Considerations

The extraction and processing of kaolinite for refractory materials carries significant environmental implications that must be addressed for sustainable industry practices. Mining operations for kaolinite typically involve open-pit extraction, which leads to habitat disruption, soil erosion, and potential water contamination. The processing phase further contributes to environmental concerns through energy consumption and chemical treatments that generate waste streams requiring proper management.

Recent advancements in mining techniques have introduced more environmentally responsible approaches, including selective mining and improved site rehabilitation protocols. These practices minimize the footprint of extraction activities while facilitating faster ecosystem recovery post-mining. Additionally, closed-loop water systems in processing facilities have demonstrated substantial reductions in freshwater consumption, with some operations achieving up to 80% water recycling rates.

Carbon emissions represent another critical environmental consideration in kaolinite processing for refractories. The calcination process, which typically occurs at temperatures between 600-900°C, contributes significantly to the carbon footprint of refractory production. Industry leaders have begun implementing alternative energy sources and optimized firing schedules to reduce these emissions. Biomass-derived fuels and electric calcination powered by renewable energy show promising results, potentially reducing carbon emissions by 30-45% compared to conventional methods.

Waste valorization strategies have emerged as a cornerstone of sustainability efforts in the refractory sector. Kaolinite processing by-products and end-of-life refractory materials can be repurposed into secondary applications, including cement production, ceramic manufacturing, and soil amendment. This circular economy approach not only reduces landfill burden but also decreases the demand for virgin raw materials, creating a more sustainable material lifecycle.

Regulatory frameworks worldwide are increasingly emphasizing environmental performance in mining and manufacturing operations. Companies optimizing kaolinite use in refractories must navigate complex compliance requirements while proactively adopting best practices that exceed minimum standards. Environmental certification programs like ISO 14001 and industry-specific sustainability initiatives provide frameworks for continuous improvement and transparent reporting of environmental metrics.

Water quality protection deserves particular attention in kaolinite operations, as processing often involves chemical additives that could impact aquatic ecosystems if improperly managed. Advanced filtration systems and chemical recovery technologies enable facilities to minimize harmful discharges while recovering valuable process chemicals for reuse, creating both environmental and economic benefits in the refractory production chain.

Recent advancements in mining techniques have introduced more environmentally responsible approaches, including selective mining and improved site rehabilitation protocols. These practices minimize the footprint of extraction activities while facilitating faster ecosystem recovery post-mining. Additionally, closed-loop water systems in processing facilities have demonstrated substantial reductions in freshwater consumption, with some operations achieving up to 80% water recycling rates.

Carbon emissions represent another critical environmental consideration in kaolinite processing for refractories. The calcination process, which typically occurs at temperatures between 600-900°C, contributes significantly to the carbon footprint of refractory production. Industry leaders have begun implementing alternative energy sources and optimized firing schedules to reduce these emissions. Biomass-derived fuels and electric calcination powered by renewable energy show promising results, potentially reducing carbon emissions by 30-45% compared to conventional methods.

Waste valorization strategies have emerged as a cornerstone of sustainability efforts in the refractory sector. Kaolinite processing by-products and end-of-life refractory materials can be repurposed into secondary applications, including cement production, ceramic manufacturing, and soil amendment. This circular economy approach not only reduces landfill burden but also decreases the demand for virgin raw materials, creating a more sustainable material lifecycle.

Regulatory frameworks worldwide are increasingly emphasizing environmental performance in mining and manufacturing operations. Companies optimizing kaolinite use in refractories must navigate complex compliance requirements while proactively adopting best practices that exceed minimum standards. Environmental certification programs like ISO 14001 and industry-specific sustainability initiatives provide frameworks for continuous improvement and transparent reporting of environmental metrics.

Water quality protection deserves particular attention in kaolinite operations, as processing often involves chemical additives that could impact aquatic ecosystems if improperly managed. Advanced filtration systems and chemical recovery technologies enable facilities to minimize harmful discharges while recovering valuable process chemicals for reuse, creating both environmental and economic benefits in the refractory production chain.

Quality Control and Testing Methodologies

Quality control and testing methodologies are critical components in optimizing kaolinite use for refractory materials. Effective quality assessment begins with raw material characterization, where kaolinite samples undergo rigorous chemical composition analysis using X-ray fluorescence (XRF) and X-ray diffraction (XRD) techniques. These methods provide precise data on alumina-silica ratios and crystallinity levels, which directly correlate with refractory performance.

Physical property testing represents another essential dimension of quality control. Particle size distribution analysis using laser diffraction technology enables manufacturers to ensure consistent granulometry, which significantly impacts the final product's thermal shock resistance. Bulk density and porosity measurements, conducted through mercury porosimetry or gas adsorption techniques, provide critical insights into the material's structural integrity under extreme temperature conditions.

Thermal performance evaluation constitutes perhaps the most crucial testing methodology for kaolinite-based refractories. Pyrometric cone equivalent (PCE) tests determine the material's refractoriness, while dilatometry measurements track dimensional stability during thermal cycling. Hot modulus of rupture (HMOR) testing assesses mechanical strength at elevated temperatures, providing valuable data on how the material will perform in industrial applications.

Standardization of testing protocols follows internationally recognized frameworks such as ASTM C133 for cold crushing strength and ASTM C583 for modulus of rupture. These standardized approaches ensure consistency across different production batches and facilitate meaningful comparisons between different kaolinite formulations. Additionally, ISO 1893 standards for refractoriness determination provide globally accepted benchmarks for quality assessment.

Advanced analytical techniques have recently enhanced quality control capabilities. Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) allows for microstructural analysis and elemental mapping at microscopic scales. Thermogravimetric analysis (TGA) provides insights into dehydroxylation behavior and phase transformations during firing, which directly impact the refractory's performance characteristics.

In-process monitoring systems represent the frontier of quality control methodologies. Real-time sensors measuring viscosity, temperature profiles, and mineralogical transformations during production enable immediate adjustments to processing parameters. This approach minimizes variability and ensures consistent quality across production runs, ultimately extending the service life of kaolinite-based refractory products in demanding industrial environments.

Physical property testing represents another essential dimension of quality control. Particle size distribution analysis using laser diffraction technology enables manufacturers to ensure consistent granulometry, which significantly impacts the final product's thermal shock resistance. Bulk density and porosity measurements, conducted through mercury porosimetry or gas adsorption techniques, provide critical insights into the material's structural integrity under extreme temperature conditions.

Thermal performance evaluation constitutes perhaps the most crucial testing methodology for kaolinite-based refractories. Pyrometric cone equivalent (PCE) tests determine the material's refractoriness, while dilatometry measurements track dimensional stability during thermal cycling. Hot modulus of rupture (HMOR) testing assesses mechanical strength at elevated temperatures, providing valuable data on how the material will perform in industrial applications.

Standardization of testing protocols follows internationally recognized frameworks such as ASTM C133 for cold crushing strength and ASTM C583 for modulus of rupture. These standardized approaches ensure consistency across different production batches and facilitate meaningful comparisons between different kaolinite formulations. Additionally, ISO 1893 standards for refractoriness determination provide globally accepted benchmarks for quality assessment.

Advanced analytical techniques have recently enhanced quality control capabilities. Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) allows for microstructural analysis and elemental mapping at microscopic scales. Thermogravimetric analysis (TGA) provides insights into dehydroxylation behavior and phase transformations during firing, which directly impact the refractory's performance characteristics.

In-process monitoring systems represent the frontier of quality control methodologies. Real-time sensors measuring viscosity, temperature profiles, and mineralogical transformations during production enable immediate adjustments to processing parameters. This approach minimizes variability and ensures consistent quality across production runs, ultimately extending the service life of kaolinite-based refractory products in demanding industrial environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!