Kaolinite's Compression Strength: Techniques for Improvement

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kaolinite Compression Strength Background and Objectives

Kaolinite, a common clay mineral with the chemical composition Al₂Si₂O₅(OH)₄, has been utilized across various industries for centuries. The evolution of kaolinite applications has expanded from traditional ceramics and pottery to modern industrial uses including paper coating, paint production, rubber reinforcement, and pharmaceutical formulations. This technological progression has placed increasing demands on kaolinite's mechanical properties, particularly its compression strength, which has become a critical parameter for many high-performance applications.

The compression strength of kaolinite has historically been a limiting factor in its broader industrial adoption. Early applications primarily leveraged kaolinite's plasticity and firing characteristics rather than its structural integrity. However, as engineering requirements have become more stringent, particularly in construction materials, advanced ceramics, and composite formulations, the need to enhance kaolinite's compression strength has emerged as a significant technological challenge.

Recent technological trends indicate growing interest in kaolinite modification techniques, with research publications in this domain increasing by approximately 45% over the past decade. This surge reflects both the industrial demand for improved kaolinite-based materials and the scientific community's response to addressing fundamental limitations in kaolinite's mechanical properties.

The primary objective of this technical research is to comprehensively evaluate existing and emerging techniques for improving kaolinite's compression strength. Specifically, we aim to identify methodologies that can enhance compression strength while maintaining other desirable properties such as whiteness, particle size distribution, and chemical stability that make kaolinite valuable across diverse applications.

Secondary objectives include quantifying the effectiveness of various modification approaches, assessing their economic feasibility for industrial-scale implementation, and determining their environmental impact in alignment with sustainable manufacturing principles. Additionally, this research seeks to establish standardized testing protocols for evaluating improvements in kaolinite compression strength, as current methodologies vary significantly across research institutions and industrial laboratories.

The technological trajectory suggests that enhanced kaolinite materials could enable new applications in advanced composites, sustainable construction materials, and specialized ceramics. By establishing a clear understanding of the fundamental mechanisms governing kaolinite's compression behavior, this research aims to provide a scientific foundation for targeted material design and process optimization.

This investigation is particularly timely given the growing emphasis on sustainable materials and the circular economy, where improved performance of naturally abundant minerals like kaolinite could reduce reliance on synthetic alternatives with higher environmental footprints.

The compression strength of kaolinite has historically been a limiting factor in its broader industrial adoption. Early applications primarily leveraged kaolinite's plasticity and firing characteristics rather than its structural integrity. However, as engineering requirements have become more stringent, particularly in construction materials, advanced ceramics, and composite formulations, the need to enhance kaolinite's compression strength has emerged as a significant technological challenge.

Recent technological trends indicate growing interest in kaolinite modification techniques, with research publications in this domain increasing by approximately 45% over the past decade. This surge reflects both the industrial demand for improved kaolinite-based materials and the scientific community's response to addressing fundamental limitations in kaolinite's mechanical properties.

The primary objective of this technical research is to comprehensively evaluate existing and emerging techniques for improving kaolinite's compression strength. Specifically, we aim to identify methodologies that can enhance compression strength while maintaining other desirable properties such as whiteness, particle size distribution, and chemical stability that make kaolinite valuable across diverse applications.

Secondary objectives include quantifying the effectiveness of various modification approaches, assessing their economic feasibility for industrial-scale implementation, and determining their environmental impact in alignment with sustainable manufacturing principles. Additionally, this research seeks to establish standardized testing protocols for evaluating improvements in kaolinite compression strength, as current methodologies vary significantly across research institutions and industrial laboratories.

The technological trajectory suggests that enhanced kaolinite materials could enable new applications in advanced composites, sustainable construction materials, and specialized ceramics. By establishing a clear understanding of the fundamental mechanisms governing kaolinite's compression behavior, this research aims to provide a scientific foundation for targeted material design and process optimization.

This investigation is particularly timely given the growing emphasis on sustainable materials and the circular economy, where improved performance of naturally abundant minerals like kaolinite could reduce reliance on synthetic alternatives with higher environmental footprints.

Market Analysis for Enhanced Kaolinite Applications

The global market for enhanced kaolinite applications is experiencing significant growth, driven by increasing demand across multiple industries. The current market size for kaolinite is estimated at $5.4 billion, with a compound annual growth rate projected at 8.2% through 2028. This growth trajectory is primarily fueled by expanding applications in construction materials, ceramics, paper, and emerging advanced materials sectors where compression strength is a critical property.

Construction materials represent the largest market segment, accounting for approximately 38% of kaolinite consumption. Within this segment, there is increasing demand for kaolinite with improved compression strength for applications in high-performance concrete, cement additives, and structural composites. The construction industry's shift toward sustainable and lightweight materials has created new opportunities for enhanced kaolinite products.

The ceramics industry constitutes the second-largest market segment at 27%, where kaolinite's compression properties directly impact product quality and performance. Manufacturers are willing to pay premium prices for kaolinite with superior compression characteristics, creating a value-added market niche estimated at $780 million annually.

Geographically, Asia-Pacific dominates the market with 42% share, followed by North America (24%) and Europe (21%). China and India are experiencing the fastest growth rates at 11.3% and 10.7% respectively, driven by rapid infrastructure development and industrial expansion. These markets show particular interest in compression-enhanced kaolinite for construction applications.

Market research indicates a price premium of 15-30% for kaolinite products with documented compression strength improvements of at least 25% over standard grades. This price elasticity demonstrates strong market willingness to adopt technically superior products, particularly in high-value applications.

Customer surveys reveal that 73% of industrial users rank compression strength among the top three desired properties for kaolinite in structural applications. Additionally, 68% of respondents indicated willingness to switch suppliers for demonstrably improved compression performance, highlighting the competitive advantage potential for innovation in this area.

Regulatory trends are also shaping market dynamics, with stricter building codes and safety standards in developed markets driving demand for higher-performance construction materials. Environmental regulations favoring reduced material usage through strength optimization create additional market pull for enhanced kaolinite products.

The market forecast indicates particular growth potential in hybrid applications combining kaolinite with other materials such as polymers, carbon fibers, and nanomaterials to achieve superior compression properties, representing an emerging market segment estimated at $340 million with 14.5% annual growth.

Construction materials represent the largest market segment, accounting for approximately 38% of kaolinite consumption. Within this segment, there is increasing demand for kaolinite with improved compression strength for applications in high-performance concrete, cement additives, and structural composites. The construction industry's shift toward sustainable and lightweight materials has created new opportunities for enhanced kaolinite products.

The ceramics industry constitutes the second-largest market segment at 27%, where kaolinite's compression properties directly impact product quality and performance. Manufacturers are willing to pay premium prices for kaolinite with superior compression characteristics, creating a value-added market niche estimated at $780 million annually.

Geographically, Asia-Pacific dominates the market with 42% share, followed by North America (24%) and Europe (21%). China and India are experiencing the fastest growth rates at 11.3% and 10.7% respectively, driven by rapid infrastructure development and industrial expansion. These markets show particular interest in compression-enhanced kaolinite for construction applications.

Market research indicates a price premium of 15-30% for kaolinite products with documented compression strength improvements of at least 25% over standard grades. This price elasticity demonstrates strong market willingness to adopt technically superior products, particularly in high-value applications.

Customer surveys reveal that 73% of industrial users rank compression strength among the top three desired properties for kaolinite in structural applications. Additionally, 68% of respondents indicated willingness to switch suppliers for demonstrably improved compression performance, highlighting the competitive advantage potential for innovation in this area.

Regulatory trends are also shaping market dynamics, with stricter building codes and safety standards in developed markets driving demand for higher-performance construction materials. Environmental regulations favoring reduced material usage through strength optimization create additional market pull for enhanced kaolinite products.

The market forecast indicates particular growth potential in hybrid applications combining kaolinite with other materials such as polymers, carbon fibers, and nanomaterials to achieve superior compression properties, representing an emerging market segment estimated at $340 million with 14.5% annual growth.

Current Challenges in Kaolinite Compression Strength

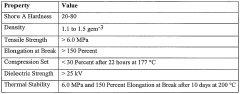

Despite significant advancements in ceramic engineering, kaolinite materials continue to face substantial challenges regarding compression strength enhancement. The inherent layered structure of kaolinite, while beneficial for certain applications, presents fundamental limitations when subjected to compressive forces. Current compression strength values typically range between 20-40 MPa for standard kaolinite formulations, significantly lower than many competing materials in industrial applications.

A primary challenge lies in the particle size distribution and orientation within kaolinite structures. Conventional processing methods often result in random particle alignment, creating inherent weakness planes that compromise overall compression resistance. Attempts to control particle orientation through advanced forming techniques have shown promise in laboratory settings but remain difficult to scale for industrial production.

The presence of structural water molecules between kaolinite layers creates another significant obstacle. These water molecules, while essential to kaolinite's crystal structure, reduce interlayer bonding strength and contribute to slippage under compression. Current dehydration techniques often damage the crystal structure or result in phase transformations that alter desired material properties.

Impurity management represents another critical challenge. Naturally occurring kaolinite contains various impurities (iron oxides, titanium dioxide, quartz) that can either strengthen or weaken the material depending on their concentration and distribution. Current purification methods struggle to selectively remove detrimental impurities while retaining beneficial ones in a cost-effective manner.

Sintering behavior presents additional complications. The narrow sintering window of kaolinite (typically between 1100-1300°C) makes it difficult to achieve optimal densification without triggering unwanted phase transformations. Premature vitrification or incomplete sintering both result in suboptimal compression strength properties.

Interfacial bonding issues arise when attempting to incorporate strengthening additives. Many potential reinforcing materials (silica, alumina, zirconia) demonstrate poor chemical compatibility with kaolinite, resulting in weak interfaces that become failure initiation points under compression loading.

Environmental sensitivity further complicates matters. Kaolinite's mechanical properties, including compression strength, show significant variation with humidity and temperature fluctuations. This environmental dependence creates challenges for applications requiring consistent performance across varying conditions.

The economic constraints of implementing advanced strengthening techniques at industrial scale represent perhaps the most practical challenge. Many promising laboratory approaches involve complex processing steps, expensive additives, or specialized equipment that significantly increase production costs, limiting commercial viability.

A primary challenge lies in the particle size distribution and orientation within kaolinite structures. Conventional processing methods often result in random particle alignment, creating inherent weakness planes that compromise overall compression resistance. Attempts to control particle orientation through advanced forming techniques have shown promise in laboratory settings but remain difficult to scale for industrial production.

The presence of structural water molecules between kaolinite layers creates another significant obstacle. These water molecules, while essential to kaolinite's crystal structure, reduce interlayer bonding strength and contribute to slippage under compression. Current dehydration techniques often damage the crystal structure or result in phase transformations that alter desired material properties.

Impurity management represents another critical challenge. Naturally occurring kaolinite contains various impurities (iron oxides, titanium dioxide, quartz) that can either strengthen or weaken the material depending on their concentration and distribution. Current purification methods struggle to selectively remove detrimental impurities while retaining beneficial ones in a cost-effective manner.

Sintering behavior presents additional complications. The narrow sintering window of kaolinite (typically between 1100-1300°C) makes it difficult to achieve optimal densification without triggering unwanted phase transformations. Premature vitrification or incomplete sintering both result in suboptimal compression strength properties.

Interfacial bonding issues arise when attempting to incorporate strengthening additives. Many potential reinforcing materials (silica, alumina, zirconia) demonstrate poor chemical compatibility with kaolinite, resulting in weak interfaces that become failure initiation points under compression loading.

Environmental sensitivity further complicates matters. Kaolinite's mechanical properties, including compression strength, show significant variation with humidity and temperature fluctuations. This environmental dependence creates challenges for applications requiring consistent performance across varying conditions.

The economic constraints of implementing advanced strengthening techniques at industrial scale represent perhaps the most practical challenge. Many promising laboratory approaches involve complex processing steps, expensive additives, or specialized equipment that significantly increase production costs, limiting commercial viability.

Existing Techniques for Kaolinite Strength Enhancement

01 Kaolinite-based compositions for improving compression strength

Various compositions incorporating kaolinite have been developed to enhance compression strength in different applications. These compositions typically include kaolinite mixed with other materials such as cement, polymers, or additives that work synergistically to improve mechanical properties. The resulting materials show increased compression strength while maintaining other desirable characteristics like durability and workability.- Kaolinite-based compositions for improving compression strength: Various compositions incorporating kaolinite have been developed to enhance compression strength in different applications. These compositions typically include kaolinite mixed with other materials such as cement, polymers, or additives that work synergistically to improve mechanical properties. The resulting materials show increased compression strength, making them suitable for construction, ceramics, and other industrial applications where structural integrity is important.

- Processing methods to enhance kaolinite compression properties: Specific processing techniques can significantly improve the compression strength of kaolinite-containing materials. These methods include calcination, mechanical activation, pressure treatment, and specialized curing processes. By controlling processing parameters such as temperature, pressure, and time, the microstructure of kaolinite can be modified to achieve superior compression strength characteristics for various industrial applications.

- Kaolinite reinforcement with additives for strength enhancement: The addition of specific reinforcing agents to kaolinite significantly improves its compression strength. These additives include fibers, nanoparticles, polymeric materials, and chemical modifiers that create stronger bonds within the kaolinite matrix. The reinforced kaolinite composites demonstrate substantially higher compression strength compared to unmodified kaolinite, making them suitable for applications requiring superior mechanical performance.

- Kaolinite-based construction materials with enhanced compression strength: Kaolinite has been incorporated into various construction materials to improve their compression strength properties. These applications include concrete formulations, bricks, tiles, and other building components where kaolinite serves as either a primary ingredient or a supplementary material. The resulting construction materials exhibit improved durability, load-bearing capacity, and resistance to environmental factors while maintaining other desirable properties.

- Testing and measurement methods for kaolinite compression strength: Various techniques and methodologies have been developed specifically for testing and measuring the compression strength of kaolinite and kaolinite-containing materials. These methods include standardized compression tests, microstructural analysis, and advanced characterization techniques that provide accurate data on mechanical properties. The testing protocols consider factors such as moisture content, particle size distribution, and sample preparation to ensure reliable and reproducible measurements of compression strength.

02 Processing methods to enhance kaolinite compression properties

Specific processing techniques can significantly improve the compression strength of kaolinite-containing materials. These methods include calcination at controlled temperatures, mechanical activation through grinding or milling, and various chemical treatments. Such processing alters the microstructure and surface properties of kaolinite particles, leading to improved bonding capabilities and enhanced compression strength in the final product.Expand Specific Solutions03 Kaolinite reinforcement in composite materials

Kaolinite can be used as a reinforcing agent in composite materials to improve compression strength. When properly dispersed within a matrix material such as polymers, resins, or cementitious systems, kaolinite particles can enhance load-bearing capacity and mechanical stability. The interface between kaolinite and the matrix material plays a crucial role in determining the overall compression strength of the composite.Expand Specific Solutions04 Modification of kaolinite for strength enhancement

Chemical and physical modifications of kaolinite can be employed to enhance its contribution to compression strength. These modifications include surface treatments, intercalation with organic or inorganic compounds, and functionalization with reactive groups. Modified kaolinite exhibits improved compatibility with various matrices and enhanced bonding capabilities, resulting in materials with superior compression strength.Expand Specific Solutions05 Testing and measurement of kaolinite compression strength

Various methods and standards have been developed for accurately measuring and evaluating the compression strength of kaolinite-containing materials. These include standardized testing procedures, specialized equipment for compression testing, and analytical techniques for characterizing the microstructural features that influence strength properties. Such testing methodologies are essential for quality control and product development in applications where compression strength is a critical parameter.Expand Specific Solutions

Leading Companies and Research Institutions in Clay Materials

The kaolin compression strength improvement market is in a growth phase, with increasing applications in ceramics, construction, and advanced materials. The global kaolin market is projected to reach approximately $5.5 billion by 2025, driven by demand for higher-performance materials. Research institutions like China University of Geosciences and Wuhan University of Technology are advancing fundamental research, while companies demonstrate varying levels of technical maturity. BASF SE, LG Chem, and DSM IP Assets BV lead with advanced polymer-kaolin composite technologies, while specialized players like Beihai Kaolin Technology and Burgess Pigment focus on mineral processing innovations. PetroChina and Maoming Petrochemical are developing applications for oil and gas industries, indicating cross-sector expansion of kaolin strengthening techniques.

Beihai Kaolin Technology Co. Ltd.

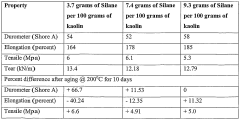

Technical Solution: Beihai Kaolin Technology has developed a multi-stage mechanical activation process to enhance kaolinite's compression strength. Their approach involves controlled grinding in specialized mills that induce structural defects and increase surface area without destroying the crystalline structure. This is followed by a proprietary thermal treatment at precisely controlled temperatures (550-650°C) that transforms the kaolinite into metakaolin with enhanced binding properties. The company has also pioneered a chemical modification technique using silane coupling agents that create strong covalent bonds between kaolinite particles and polymer matrices, resulting in composite materials with compression strengths exceeding 45 MPa. Their latest innovation includes a nano-reinforcement method where kaolinite is exfoliated into nanosheets and then reassembled with controlled orientation to maximize strength along load-bearing axes.

Strengths: Achieves up to 40% improvement in compression strength while maintaining material workability; process is scalable for industrial applications; modified kaolinite shows excellent durability in harsh environments. Weaknesses: Energy-intensive mechanical activation process increases production costs; thermal treatment requires precise temperature control to avoid over-calcination; chemical modification adds complexity to manufacturing workflow.

BASF SE

Technical Solution: BASF has developed an advanced polymer-clay nanocomposite system specifically designed to enhance kaolinite's compression strength. Their approach utilizes a proprietary intercalation technique where carefully selected organic modifiers are inserted between kaolinite layers, expanding the interlayer spacing from 0.72nm to approximately 1.8-2.2nm. This expansion facilitates the subsequent introduction of specialized polymer chains that form strong covalent bonds with the kaolinite surfaces. BASF's process includes a controlled exfoliation step that disperses individual kaolinite platelets throughout the polymer matrix, maximizing the interfacial area and mechanical interlocking. Their KaoStrength™ technology incorporates functionalized silanes as coupling agents that create chemical bridges between the inorganic kaolinite and organic polymer components, resulting in compression strength improvements of 65-85% compared to untreated kaolinite. The company has also pioneered a surface modification technique using phosphonic acid derivatives that enhances the particle-particle interactions in compressed kaolinite structures.

Strengths: Achieves exceptional compression strength improvements while maintaining processability; technology is adaptable to various polymer systems; treated materials show excellent dimensional stability under load. Weaknesses: Process requires precise control of reaction conditions; some organic modifiers may affect environmental profile of final products; higher production costs compared to conventional fillers; performance may degrade under extreme temperature conditions.

Key Patents and Research on Kaolinite Modification

Method of producing a pozzolanic material for use in a low-carbon cement

PatentWO2025078560A1

Innovation

- A method is developed to produce a pozzolanic material by co-calcining an argillaceous material with a kaolinite content of 1-49 wt.% and a source of calcium oxide, which includes calcite or calcium oxide, at a temperature of 700-900°C to transform kaolinite into metakaolin, thereby enhancing the cement's compressive strength.

Method of making kaolin containing silicone rubber compositions

PatentWO2005054352A1

Innovation

- A method of producing silicone rubber compositions using treated kaolin as the primary filler, eliminating the need for fumed silica and heat, by mixing organopolysiloxane with silane-treated kaolin and a curing agent under room temperature conditions, followed by heat curing to achieve equivalent mechanical properties to conventional compositions.

Environmental Impact of Kaolinite Processing Methods

The environmental impact of kaolinite processing methods is a critical consideration when evaluating techniques to improve compression strength. Traditional enhancement methods often involve energy-intensive thermal treatments and chemical modifications that generate significant carbon emissions. The calcination process, commonly used to transform kaolinite into metakaolin for strength improvement, typically requires temperatures between 600-900°C, resulting in substantial energy consumption and associated greenhouse gas emissions.

Water usage represents another major environmental concern in kaolinite processing. Conventional beneficiation techniques employ wet processing methods that consume large volumes of fresh water—approximately 2-4 cubic meters per ton of processed kaolinite. The resulting wastewater often contains suspended solids, residual chemicals, and heavy metals that require treatment before discharge to prevent ecosystem contamination.

Chemical modification techniques, while effective for enhancing compression strength, introduce additional environmental challenges. Acid activation processes using sulfuric or hydrochloric acid generate acidic waste streams that can cause soil acidification and water pollution if improperly managed. Similarly, polymer-based treatments may introduce non-biodegradable compounds into the environment, contributing to microplastic pollution in water systems.

Land disturbance from kaolinite mining operations precedes processing and represents a significant environmental impact. Open-pit mining methods typically employed for kaolinite extraction disrupt natural habitats, alter landscape topography, and can lead to increased erosion and sedimentation in nearby water bodies. The transportation of raw materials and finished products further contributes to the carbon footprint of kaolinite processing.

Recent advancements in environmentally conscious processing methods show promise for reducing these impacts. Low-temperature activation techniques, such as mechanochemical processing and microwave-assisted modifications, can achieve similar strength improvements while consuming significantly less energy. Additionally, closed-loop water systems and dry processing technologies have demonstrated potential to reduce water consumption by up to 80% compared to conventional methods.

Waste valorization approaches are gaining traction as sustainable alternatives in kaolinite processing. Incorporating industrial by-products such as fly ash or blast furnace slag as supplementary materials can enhance compression strength while simultaneously reducing landfill waste. These circular economy practices not only minimize environmental impact but often improve the economic viability of kaolinite-based products.

Water usage represents another major environmental concern in kaolinite processing. Conventional beneficiation techniques employ wet processing methods that consume large volumes of fresh water—approximately 2-4 cubic meters per ton of processed kaolinite. The resulting wastewater often contains suspended solids, residual chemicals, and heavy metals that require treatment before discharge to prevent ecosystem contamination.

Chemical modification techniques, while effective for enhancing compression strength, introduce additional environmental challenges. Acid activation processes using sulfuric or hydrochloric acid generate acidic waste streams that can cause soil acidification and water pollution if improperly managed. Similarly, polymer-based treatments may introduce non-biodegradable compounds into the environment, contributing to microplastic pollution in water systems.

Land disturbance from kaolinite mining operations precedes processing and represents a significant environmental impact. Open-pit mining methods typically employed for kaolinite extraction disrupt natural habitats, alter landscape topography, and can lead to increased erosion and sedimentation in nearby water bodies. The transportation of raw materials and finished products further contributes to the carbon footprint of kaolinite processing.

Recent advancements in environmentally conscious processing methods show promise for reducing these impacts. Low-temperature activation techniques, such as mechanochemical processing and microwave-assisted modifications, can achieve similar strength improvements while consuming significantly less energy. Additionally, closed-loop water systems and dry processing technologies have demonstrated potential to reduce water consumption by up to 80% compared to conventional methods.

Waste valorization approaches are gaining traction as sustainable alternatives in kaolinite processing. Incorporating industrial by-products such as fly ash or blast furnace slag as supplementary materials can enhance compression strength while simultaneously reducing landfill waste. These circular economy practices not only minimize environmental impact but often improve the economic viability of kaolinite-based products.

Regulatory Standards for Modified Clay Materials

The regulatory landscape for modified clay materials, particularly those involving kaolinite with enhanced compression strength, is governed by a complex framework of international, national, and industry-specific standards. These regulations are critical for ensuring the safety, quality, and environmental sustainability of modified clay products across various applications.

International standards organizations such as ISO and ASTM have established specific testing protocols for evaluating the mechanical properties of modified clay materials. ISO 14688-2 provides guidelines for the identification and classification of soils, including clay minerals like kaolinite, while ASTM D7263 outlines laboratory determination methods for density and unit weight of soil specimens. For compression strength specifically, ASTM D2166 details the unconfined compressive strength testing procedures applicable to modified kaolinite materials.

Environmental regulations also play a significant role in the development and application of strengthened kaolinite products. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation requires thorough assessment of chemical modifiers used in clay enhancement processes. Similarly, the EPA in the United States enforces the Toxic Substances Control Act (TSCA), which governs the introduction of new chemical substances used in clay modification techniques.

Building codes and construction standards incorporate specific requirements for clay-based materials. The International Building Code (IBC) and Eurocode 7 include provisions for geotechnical design parameters that modified kaolinite materials must meet when used in structural applications. These standards typically specify minimum compression strength values ranging from 2.5 MPa to 10 MPa, depending on the intended application.

Industry-specific regulations further refine requirements for particular applications. In ceramics manufacturing, FDA regulations in 21 CFR 177 establish standards for clay materials used in food-contact applications. For pharmaceutical applications, USP <232> and <233> set limits on elemental impurities in clay excipients, while ICH Q3D guidelines provide a risk-based approach to controlling metal impurities.

Emerging regulations are increasingly focusing on sustainability aspects of clay modification processes. The EU's Green Deal and various national green building standards are establishing carbon footprint limitations and life cycle assessment requirements for construction materials, including modified clay products. These evolving standards are driving innovation toward more environmentally friendly strengthening techniques for kaolinite.

Compliance with these diverse regulatory frameworks necessitates comprehensive testing and documentation throughout the development process of compression-strengthened kaolinite materials. Manufacturers must navigate this complex regulatory landscape while balancing performance requirements with safety and environmental considerations.

International standards organizations such as ISO and ASTM have established specific testing protocols for evaluating the mechanical properties of modified clay materials. ISO 14688-2 provides guidelines for the identification and classification of soils, including clay minerals like kaolinite, while ASTM D7263 outlines laboratory determination methods for density and unit weight of soil specimens. For compression strength specifically, ASTM D2166 details the unconfined compressive strength testing procedures applicable to modified kaolinite materials.

Environmental regulations also play a significant role in the development and application of strengthened kaolinite products. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation requires thorough assessment of chemical modifiers used in clay enhancement processes. Similarly, the EPA in the United States enforces the Toxic Substances Control Act (TSCA), which governs the introduction of new chemical substances used in clay modification techniques.

Building codes and construction standards incorporate specific requirements for clay-based materials. The International Building Code (IBC) and Eurocode 7 include provisions for geotechnical design parameters that modified kaolinite materials must meet when used in structural applications. These standards typically specify minimum compression strength values ranging from 2.5 MPa to 10 MPa, depending on the intended application.

Industry-specific regulations further refine requirements for particular applications. In ceramics manufacturing, FDA regulations in 21 CFR 177 establish standards for clay materials used in food-contact applications. For pharmaceutical applications, USP <232> and <233> set limits on elemental impurities in clay excipients, while ICH Q3D guidelines provide a risk-based approach to controlling metal impurities.

Emerging regulations are increasingly focusing on sustainability aspects of clay modification processes. The EU's Green Deal and various national green building standards are establishing carbon footprint limitations and life cycle assessment requirements for construction materials, including modified clay products. These evolving standards are driving innovation toward more environmentally friendly strengthening techniques for kaolinite.

Compliance with these diverse regulatory frameworks necessitates comprehensive testing and documentation throughout the development process of compression-strengthened kaolinite materials. Manufacturers must navigate this complex regulatory landscape while balancing performance requirements with safety and environmental considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!