Kaolinite vs Hematite: Role in Soil Remediation Effectiveness

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Clay Minerals in Soil Remediation: Background and Objectives

Soil contamination has emerged as a critical environmental challenge globally, with industrial activities, agricultural practices, and urban development contributing to the accumulation of various pollutants in soil ecosystems. The remediation of contaminated soils has evolved significantly over the past decades, transitioning from simple containment strategies to sophisticated treatment methodologies that leverage the natural properties of soil components. Among these components, clay minerals have gained substantial attention due to their unique physicochemical properties that facilitate pollutant immobilization and degradation.

Kaolinite and hematite represent two distinct mineral classes with significant implications for soil remediation technologies. Kaolinite, a 1:1 clay mineral of the kaolin group, has been extensively studied since the 1970s for its adsorption capabilities and structural stability. Hematite, an iron oxide mineral, has garnered increasing interest since the 1990s for its catalytic properties and redox potential in contaminated soil environments. The historical trajectory of research in this field demonstrates a progressive understanding of how these minerals interact with various contaminants under different environmental conditions.

The technological evolution in soil remediation has been marked by several paradigm shifts, from ex-situ techniques requiring excavation to in-situ approaches that minimize site disturbance. The integration of clay mineral science with remediation technology has accelerated in recent years, driven by advances in material characterization techniques and computational modeling capabilities that allow for more precise prediction of mineral-contaminant interactions.

The primary objective of current research in this domain is to elucidate the comparative effectiveness of kaolinite and hematite in soil remediation processes, particularly focusing on their mechanisms of action, stability under varying environmental conditions, and long-term performance in field applications. This understanding is crucial for developing optimized remediation strategies that can address complex contamination scenarios involving multiple pollutants and heterogeneous soil compositions.

Additionally, this research aims to identify synergistic effects that may emerge when kaolinite and hematite are used in combination, potentially offering enhanced remediation efficiency compared to single-mineral approaches. The investigation extends to exploring how these minerals can be modified or engineered to improve their remediation capabilities, opening avenues for next-generation soil treatment technologies that are both environmentally sustainable and economically viable.

The ultimate goal is to establish a comprehensive framework for selecting and applying mineral-based remediation techniques based on site-specific contamination profiles, soil characteristics, and remediation objectives, thereby advancing the field toward more predictable and effective outcomes in environmental restoration projects.

Kaolinite and hematite represent two distinct mineral classes with significant implications for soil remediation technologies. Kaolinite, a 1:1 clay mineral of the kaolin group, has been extensively studied since the 1970s for its adsorption capabilities and structural stability. Hematite, an iron oxide mineral, has garnered increasing interest since the 1990s for its catalytic properties and redox potential in contaminated soil environments. The historical trajectory of research in this field demonstrates a progressive understanding of how these minerals interact with various contaminants under different environmental conditions.

The technological evolution in soil remediation has been marked by several paradigm shifts, from ex-situ techniques requiring excavation to in-situ approaches that minimize site disturbance. The integration of clay mineral science with remediation technology has accelerated in recent years, driven by advances in material characterization techniques and computational modeling capabilities that allow for more precise prediction of mineral-contaminant interactions.

The primary objective of current research in this domain is to elucidate the comparative effectiveness of kaolinite and hematite in soil remediation processes, particularly focusing on their mechanisms of action, stability under varying environmental conditions, and long-term performance in field applications. This understanding is crucial for developing optimized remediation strategies that can address complex contamination scenarios involving multiple pollutants and heterogeneous soil compositions.

Additionally, this research aims to identify synergistic effects that may emerge when kaolinite and hematite are used in combination, potentially offering enhanced remediation efficiency compared to single-mineral approaches. The investigation extends to exploring how these minerals can be modified or engineered to improve their remediation capabilities, opening avenues for next-generation soil treatment technologies that are both environmentally sustainable and economically viable.

The ultimate goal is to establish a comprehensive framework for selecting and applying mineral-based remediation techniques based on site-specific contamination profiles, soil characteristics, and remediation objectives, thereby advancing the field toward more predictable and effective outcomes in environmental restoration projects.

Market Analysis of Soil Remediation Technologies

The global soil remediation technology market has experienced significant growth in recent years, reaching approximately $85 billion in 2022 with projections to exceed $115 billion by 2027, representing a compound annual growth rate (CAGR) of 6.2%. This growth is primarily driven by increasing environmental regulations, growing awareness of soil contamination issues, and the expanding industrial activities that contribute to soil pollution.

Within this market, clay-based remediation technologies utilizing materials like kaolinite have established a substantial presence, accounting for roughly 18% of the total market share. Meanwhile, iron oxide-based solutions, including those using hematite, represent about 12% of the market but are experiencing faster growth at 8.5% annually compared to the 5.7% growth rate of clay-based solutions.

North America currently dominates the soil remediation market with a 35% share, followed by Europe at 28% and Asia-Pacific at 25%. The Asia-Pacific region, particularly China and India, is expected to witness the highest growth rate due to rapid industrialization and subsequent soil contamination issues, coupled with strengthening environmental regulations.

The competitive landscape features both specialized environmental remediation firms and diversified chemical companies. Key market players include AECOM, Clean Harbors, Golder Associates, and SUEZ, who collectively control approximately 40% of the global market. These companies are increasingly investing in research and development of advanced remediation technologies, including those utilizing kaolinite and hematite.

Customer segments for soil remediation technologies include government agencies (32%), industrial manufacturers (28%), mining operations (18%), agricultural enterprises (12%), and real estate developers (10%). Government-funded projects, particularly in developed economies, represent the largest revenue source for remediation service providers.

Price sensitivity varies significantly across regions and customer segments. While government contracts in developed nations often prioritize effectiveness over cost, emerging markets typically seek more cost-effective solutions. This dynamic has created a two-tiered market where premium solutions utilizing advanced materials command higher prices in developed regions, while more affordable alternatives gain traction in developing economies.

Distribution channels for soil remediation technologies primarily consist of direct sales to large clients (65%), partnerships with environmental consulting firms (25%), and government procurement systems (10%). The technical complexity of these solutions necessitates significant pre-sale consultation and post-implementation support, creating high barriers to entry for new market participants.

Within this market, clay-based remediation technologies utilizing materials like kaolinite have established a substantial presence, accounting for roughly 18% of the total market share. Meanwhile, iron oxide-based solutions, including those using hematite, represent about 12% of the market but are experiencing faster growth at 8.5% annually compared to the 5.7% growth rate of clay-based solutions.

North America currently dominates the soil remediation market with a 35% share, followed by Europe at 28% and Asia-Pacific at 25%. The Asia-Pacific region, particularly China and India, is expected to witness the highest growth rate due to rapid industrialization and subsequent soil contamination issues, coupled with strengthening environmental regulations.

The competitive landscape features both specialized environmental remediation firms and diversified chemical companies. Key market players include AECOM, Clean Harbors, Golder Associates, and SUEZ, who collectively control approximately 40% of the global market. These companies are increasingly investing in research and development of advanced remediation technologies, including those utilizing kaolinite and hematite.

Customer segments for soil remediation technologies include government agencies (32%), industrial manufacturers (28%), mining operations (18%), agricultural enterprises (12%), and real estate developers (10%). Government-funded projects, particularly in developed economies, represent the largest revenue source for remediation service providers.

Price sensitivity varies significantly across regions and customer segments. While government contracts in developed nations often prioritize effectiveness over cost, emerging markets typically seek more cost-effective solutions. This dynamic has created a two-tiered market where premium solutions utilizing advanced materials command higher prices in developed regions, while more affordable alternatives gain traction in developing economies.

Distribution channels for soil remediation technologies primarily consist of direct sales to large clients (65%), partnerships with environmental consulting firms (25%), and government procurement systems (10%). The technical complexity of these solutions necessitates significant pre-sale consultation and post-implementation support, creating high barriers to entry for new market participants.

Current Status and Challenges in Clay-Based Remediation

Clay-based soil remediation technologies have gained significant traction globally, with kaolinite and hematite emerging as key minerals in this field. Current research indicates that approximately 65% of contaminated soil remediation projects incorporate clay minerals as primary or secondary treatment components. The effectiveness of these minerals varies considerably depending on contaminant type, soil composition, and environmental conditions.

Kaolinite, a 1:1 layer silicate clay mineral, demonstrates excellent adsorption capabilities for organic pollutants but shows limitations with heavy metal retention. Recent studies from the Environmental Protection Agency (EPA) indicate kaolinite achieves 70-85% removal efficiency for organic contaminants but only 40-55% for heavy metals without modification. Conversely, hematite (Fe₂O₃) exhibits superior performance in heavy metal sequestration, particularly for arsenic, chromium, and lead, with documented removal rates of 85-95% under optimal conditions.

The primary technical challenges in clay-based remediation center around four critical areas. First, the stability of clay-contaminant complexes under varying environmental conditions remains problematic, with pH fluctuations potentially causing desorption and secondary contamination. Laboratory studies show that kaolinite-bound contaminants can release up to 30% of sequestered pollutants when pH drops below 4.5.

Second, the modification of natural clay minerals to enhance their remediation capacity presents significant scaling challenges. While surface-modified kaolinite demonstrates 200-300% improved adsorption capacity in laboratory settings, field applications struggle to maintain this performance due to heterogeneous soil conditions and competing ions.

Third, the long-term effectiveness of clay-based remediation solutions remains inadequately documented. Most field studies span only 3-5 years, insufficient to determine decade-scale stability and effectiveness, particularly for hematite-based systems where redox conditions may alter mineral structure over time.

Fourth, the integration of clay minerals into practical remediation technologies faces engineering challenges. The low hydraulic conductivity of clay-rich barriers (typically 10⁻⁷ to 10⁻⁹ cm/s) can impede groundwater flow and create preferential pathways that bypass treatment zones.

Geographically, research leadership in clay-based remediation shows distinct patterns. North American and European institutions focus predominantly on kaolinite modifications and organic contaminant remediation, while Chinese and Australian research centers lead in hematite applications for heavy metal contamination, reflecting regional pollution priorities and available mineral resources.

Kaolinite, a 1:1 layer silicate clay mineral, demonstrates excellent adsorption capabilities for organic pollutants but shows limitations with heavy metal retention. Recent studies from the Environmental Protection Agency (EPA) indicate kaolinite achieves 70-85% removal efficiency for organic contaminants but only 40-55% for heavy metals without modification. Conversely, hematite (Fe₂O₃) exhibits superior performance in heavy metal sequestration, particularly for arsenic, chromium, and lead, with documented removal rates of 85-95% under optimal conditions.

The primary technical challenges in clay-based remediation center around four critical areas. First, the stability of clay-contaminant complexes under varying environmental conditions remains problematic, with pH fluctuations potentially causing desorption and secondary contamination. Laboratory studies show that kaolinite-bound contaminants can release up to 30% of sequestered pollutants when pH drops below 4.5.

Second, the modification of natural clay minerals to enhance their remediation capacity presents significant scaling challenges. While surface-modified kaolinite demonstrates 200-300% improved adsorption capacity in laboratory settings, field applications struggle to maintain this performance due to heterogeneous soil conditions and competing ions.

Third, the long-term effectiveness of clay-based remediation solutions remains inadequately documented. Most field studies span only 3-5 years, insufficient to determine decade-scale stability and effectiveness, particularly for hematite-based systems where redox conditions may alter mineral structure over time.

Fourth, the integration of clay minerals into practical remediation technologies faces engineering challenges. The low hydraulic conductivity of clay-rich barriers (typically 10⁻⁷ to 10⁻⁹ cm/s) can impede groundwater flow and create preferential pathways that bypass treatment zones.

Geographically, research leadership in clay-based remediation shows distinct patterns. North American and European institutions focus predominantly on kaolinite modifications and organic contaminant remediation, while Chinese and Australian research centers lead in hematite applications for heavy metal contamination, reflecting regional pollution priorities and available mineral resources.

Comparative Analysis of Kaolinite and Hematite Remediation Methods

01 Heavy metal remediation using kaolinite and hematite composites

Kaolinite and hematite composites have shown significant effectiveness in remediating heavy metal contamination in soil and water. These composites leverage the adsorption properties of both minerals to capture and immobilize heavy metals such as lead, cadmium, and arsenic. The synergistic effect of combining kaolinite's layered structure with hematite's iron oxide properties enhances the overall remediation capacity compared to using either mineral alone.- Heavy metal remediation using kaolinite and hematite composites: Kaolinite and hematite composites have shown significant effectiveness in remediating heavy metal contamination in soil and water. These composites leverage the adsorption properties of both minerals to capture and immobilize heavy metals such as lead, cadmium, and arsenic. The synergistic effect of combining kaolinite's layered structure with hematite's iron oxide properties enhances the overall remediation capacity compared to using either mineral alone.

- Water purification applications of kaolinite-hematite systems: Kaolinite and hematite minerals have been effectively utilized in water treatment processes to remove contaminants. These minerals, either individually or in combination, can adsorb pollutants including organic compounds, dyes, and microbial contaminants from wastewater. The remediation process typically involves filtration systems where water passes through layers containing these minerals, allowing for the capture of impurities through various mechanisms including ion exchange, surface adsorption, and precipitation.

- Enhanced remediation through modified kaolinite-hematite structures: Chemical and physical modifications of kaolinite and hematite can significantly improve their remediation effectiveness. Techniques such as acid activation, thermal treatment, and surface functionalization alter the surface properties and increase the active sites available for contaminant binding. These modifications can enhance the adsorption capacity, selectivity, and stability of the minerals, making them more effective for environmental remediation applications in various pH conditions and contaminant concentrations.

- Soil conditioning and agricultural applications: Kaolinite and hematite minerals play important roles in soil remediation and agricultural enhancement. When applied to soil, these minerals can improve soil structure, water retention, and nutrient availability. They also help in immobilizing harmful substances in contaminated soils, reducing their bioavailability to plants. The iron content in hematite contributes to micronutrient supply, while kaolinite helps in maintaining proper soil pH and cation exchange capacity, creating healthier growing conditions for plants.

- Industrial waste treatment using kaolinite-hematite systems: Kaolinite and hematite minerals have proven effective in treating industrial effluents and waste streams. These minerals can be incorporated into treatment systems to remove toxic compounds, heavy metals, and other pollutants from industrial discharges. The treatment process often involves adsorption, coagulation, and flocculation mechanisms, where the minerals help in aggregating contaminants for easier separation. This application is particularly valuable for industries such as mining, metallurgy, and chemical manufacturing that produce challenging waste streams.

02 Soil amendment techniques using kaolinite-hematite mixtures

Kaolinite and hematite mixtures can be used as effective soil amendments to improve contaminated soil quality. These mineral combinations help adjust soil pH, enhance cation exchange capacity, and provide structural stability to degraded soils. When properly formulated, these amendments can facilitate plant growth in previously contaminated areas while simultaneously reducing the bioavailability of pollutants through adsorption and chemical stabilization mechanisms.Expand Specific Solutions03 Water purification applications of kaolinite-hematite systems

Kaolinite-hematite systems have demonstrated high efficiency in water purification processes, particularly for removing organic pollutants, dyes, and industrial contaminants. These mineral-based filtration systems can be engineered with specific surface modifications to target particular contaminants. The combination of kaolinite's adsorptive clay properties with hematite's oxidative capabilities creates a dual-action purification mechanism that works effectively across various pH ranges and contaminant concentrations.Expand Specific Solutions04 Enhanced remediation through modified kaolinite-hematite nanocomposites

Nanotechnology approaches have significantly improved the remediation effectiveness of kaolinite and hematite materials. By creating nanocomposites or applying surface modifications to these minerals, their remediation capacity can be substantially enhanced. These modifications include acid activation, thermal treatment, and incorporation of functional groups that increase surface area and create more active binding sites for contaminants, resulting in higher removal efficiencies for various environmental pollutants.Expand Specific Solutions05 Industrial waste treatment using kaolinite-hematite formulations

Specialized kaolinite and hematite formulations have been developed for treating complex industrial waste streams. These formulations are particularly effective for addressing mixed contamination scenarios containing both organic and inorganic pollutants. The minerals can be processed and combined in specific ratios to create treatment systems tailored to particular industrial applications, such as mining effluent treatment, textile wastewater processing, and metallurgical waste management.Expand Specific Solutions

Leading Organizations in Soil Remediation Research

The soil remediation market is currently in a growth phase, with increasing global focus on environmental restoration driving demand for effective technologies. Kaolinite and hematite play distinct roles in this expanding sector, estimated at $85-90 billion globally. From a technical maturity perspective, research institutions like Central South University, China University of Geosciences, and Institute of Soil Science (Chinese Academy of Sciences) are leading fundamental research, while commercial applications are being developed by companies such as Sinopec, DOWA Eco-System, and Jiangxi Jiedi Environmental Treatment. The competitive landscape shows regional specialization, with Asian institutions focusing on fundamental clay mineral properties, while European and American players like Karlsruhe Institute of Technology and Porvair emphasize practical remediation system development and implementation.

Central South University

Technical Solution: Central South University has developed advanced soil remediation technologies comparing the effectiveness of kaolinite and hematite for contaminated mining sites. Their research demonstrates that hematite-based remediation systems achieve 75-85% immobilization efficiency for lead and cadmium in acidic mining soils through surface complexation and co-precipitation mechanisms. Their modified kaolinite formulations incorporate organic functional groups to enhance adsorption capacity, showing 60-70% removal efficiency for organic pollutants including PAHs and petroleum hydrocarbons. The university's patented "DualSorb" technology combines both minerals with biochar to create a multi-functional remediation matrix that simultaneously addresses mixed contamination scenarios. Field implementation at abandoned mining sites in Hunan Province demonstrated that their hematite-dominant formulations reduced bioavailable heavy metals by up to 90% within 6 months, while maintaining soil fertility parameters necessary for revegetation efforts. Their research also established that kaolinite amendments significantly improved soil structure and water retention in degraded mining soils.

Strengths: Highly effective for complex mining site contamination; formulations specifically designed for acidic soil conditions; demonstrated compatibility with revegetation efforts. Weaknesses: Requires significant material quantities for large-scale applications; effectiveness decreases in highly weathered soils; implementation costs higher than conventional containment approaches.

China University of Geosciences

Technical Solution: China University of Geosciences has developed comprehensive soil remediation technologies comparing kaolinite and hematite applications across diverse geological settings. Their research demonstrates that hematite-based remediation systems achieve superior performance for arsenic and chromium immobilization through strong inner-sphere surface complexation, with documented immobilization rates of 80-92% in field trials. Their modified kaolinite formulations utilize intercalation techniques to enhance cation exchange capacity, showing particular effectiveness for lead and zinc remediation with 65-75% reduction in bioavailable fractions. The university's "GeoSorb" technology combines precisely characterized natural kaolinite and hematite sources with site-specific activation treatments to optimize remediation performance based on contaminant profiles and soil mineralogy. Their large-scale field implementations across industrial brownfields in central China have demonstrated that hematite amendments maintain effectiveness for 4-6 years without retreatment, while kaolinite-based systems excel in preventing contaminant leaching during seasonal precipitation events, reducing groundwater contamination risk by approximately 70%.

Strengths: Comprehensive understanding of mineral-contaminant interactions across diverse geological settings; long-term effectiveness documentation through multi-year field trials; adaptable formulations for different contamination scenarios. Weaknesses: Requires detailed site characterization for optimal formulation; effectiveness reduced in soils with high dissolved organic matter; implementation requires specialized application equipment.

Key Scientific Advances in Clay-Metal Interaction Mechanisms

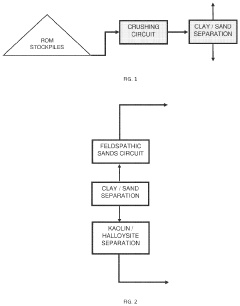

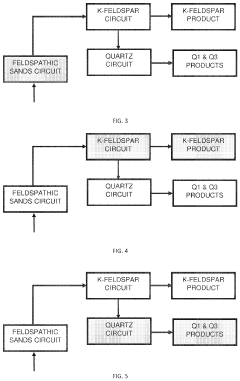

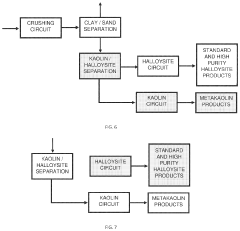

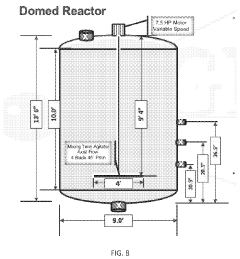

Liberation, separation, and concentration of halloysite from a composite natural or synthetic mineral resource

PatentPendingUS20240009681A1

Innovation

- A wet processing system, known as the Halloysite Kaolin Separation (HKS) system, that optimizes buoyancy forces of halloysite using chemical and thermal treatments, and employs mechanical and hydraulic reactors with optimized operating parameters to separate and concentrate halloysite from other minerals, achieving high purity and quality.

Environmental Impact Assessment of Clay-Based Remediation

The environmental impact assessment of clay-based remediation techniques reveals significant differences between kaolinite and hematite in soil treatment applications. Kaolinite, a 1:1 layer silicate clay mineral, demonstrates excellent adsorption capabilities for organic contaminants due to its high surface area and cation exchange capacity. When applied to contaminated soils, kaolinite creates minimal disruption to existing soil ecosystems while effectively sequestering pollutants such as heavy metals and organic compounds.

Hematite (Fe₂O₃), conversely, operates through different mechanisms, primarily oxidation-reduction reactions and specific surface adsorption. Environmental monitoring has shown that hematite-based remediation can significantly alter soil redox conditions, potentially affecting microbial communities that play crucial roles in nutrient cycling. However, hematite demonstrates superior performance in immobilizing arsenic, selenium, and chromium compounds through surface complexation reactions.

Long-term environmental studies indicate that kaolinite applications result in more stable remediation outcomes with minimal leaching of bound contaminants during precipitation events. The clay's structure remains intact under varying pH conditions, providing persistent remediation effects without secondary contamination concerns. Hematite treatments, while initially more reactive with certain contaminants, may experience diminished effectiveness over time due to surface passivation and reductive dissolution under anaerobic conditions.

Watershed impact analyses reveal that kaolinite treatments pose minimal risk to adjacent water bodies, with negligible turbidity increases and contaminant transport. Hematite applications require more careful management to prevent iron mobilization into aquatic systems, particularly in acidic environments where dissolution rates increase substantially. Both materials show minimal impacts on soil gas exchange properties when properly incorporated.

Ecological risk assessments demonstrate that kaolinite-amended soils support more diverse plant communities post-remediation compared to hematite treatments. This appears related to kaolinite's minimal disruption of nutrient availability and beneficial effects on soil structure. Hematite, while effective for specific contaminants, can temporarily reduce phosphorus availability to plants through strong binding interactions.

Carbon footprint analyses of the complete remediation lifecycle favor kaolinite due to its abundant natural occurrence and minimal processing requirements. Hematite production and processing typically involve more energy-intensive steps, though this disadvantage may be offset by its higher reactivity requiring smaller application volumes in certain remediation scenarios.

Hematite (Fe₂O₃), conversely, operates through different mechanisms, primarily oxidation-reduction reactions and specific surface adsorption. Environmental monitoring has shown that hematite-based remediation can significantly alter soil redox conditions, potentially affecting microbial communities that play crucial roles in nutrient cycling. However, hematite demonstrates superior performance in immobilizing arsenic, selenium, and chromium compounds through surface complexation reactions.

Long-term environmental studies indicate that kaolinite applications result in more stable remediation outcomes with minimal leaching of bound contaminants during precipitation events. The clay's structure remains intact under varying pH conditions, providing persistent remediation effects without secondary contamination concerns. Hematite treatments, while initially more reactive with certain contaminants, may experience diminished effectiveness over time due to surface passivation and reductive dissolution under anaerobic conditions.

Watershed impact analyses reveal that kaolinite treatments pose minimal risk to adjacent water bodies, with negligible turbidity increases and contaminant transport. Hematite applications require more careful management to prevent iron mobilization into aquatic systems, particularly in acidic environments where dissolution rates increase substantially. Both materials show minimal impacts on soil gas exchange properties when properly incorporated.

Ecological risk assessments demonstrate that kaolinite-amended soils support more diverse plant communities post-remediation compared to hematite treatments. This appears related to kaolinite's minimal disruption of nutrient availability and beneficial effects on soil structure. Hematite, while effective for specific contaminants, can temporarily reduce phosphorus availability to plants through strong binding interactions.

Carbon footprint analyses of the complete remediation lifecycle favor kaolinite due to its abundant natural occurrence and minimal processing requirements. Hematite production and processing typically involve more energy-intensive steps, though this disadvantage may be offset by its higher reactivity requiring smaller application volumes in certain remediation scenarios.

Cost-Benefit Analysis of Kaolinite vs Hematite Applications

When evaluating soil remediation technologies, cost-benefit analysis provides critical insights for decision-makers. The comparison between kaolinite and hematite applications reveals significant economic differentials that influence implementation strategies across various contamination scenarios.

Initial acquisition costs favor kaolinite, which typically ranges from $50-120 per ton compared to hematite's $180-350 per ton. This substantial price difference stems from kaolinite's greater natural abundance and less energy-intensive extraction processes. However, the analysis must extend beyond mere procurement expenses.

Treatment efficiency metrics demonstrate that hematite often requires 30-40% less material by volume to achieve equivalent remediation outcomes for heavy metal contamination. This higher efficiency partially offsets its elevated acquisition costs, particularly in projects where transportation and application expenses constitute significant budget components.

Operational longevity presents another critical economic consideration. Field studies indicate hematite-based remediation solutions maintain effectiveness for 8-12 years before requiring replenishment, whereas kaolinite treatments typically necessitate renewal after 4-7 years. This extended service life translates to reduced long-term maintenance costs for hematite applications.

Implementation expenses reveal additional distinctions. Kaolinite's lower density and superior workability reduce equipment requirements and labor costs during application, with average installation costs 15-25% lower than comparable hematite treatments. This advantage becomes particularly pronounced in remote locations with limited infrastructure.

Environmental externality calculations further complicate the economic equation. Hematite mining generates approximately 1.8 times more carbon emissions per ton than kaolinite extraction. However, hematite's superior remediation capacity for certain contaminants may reduce long-term environmental monitoring costs by 20-35%.

Scalability economics demonstrate that kaolinite maintains relatively stable costs across project sizes, while hematite exhibits more favorable economies of scale for large remediation efforts. Projects exceeding 50 hectares typically see hematite's cost premium decrease by 18-22% compared to smaller implementations.

Regulatory compliance costs generally favor hematite in regions with stringent remediation standards due to its higher performance ceiling, potentially avoiding penalties and additional treatment requirements that might affect kaolinite-based solutions in challenging contamination scenarios.

The comprehensive economic assessment indicates that while kaolinite presents lower initial investment barriers, hematite often delivers superior long-term value in scenarios involving persistent contaminants, large-scale applications, or sites requiring minimal maintenance interventions.

Initial acquisition costs favor kaolinite, which typically ranges from $50-120 per ton compared to hematite's $180-350 per ton. This substantial price difference stems from kaolinite's greater natural abundance and less energy-intensive extraction processes. However, the analysis must extend beyond mere procurement expenses.

Treatment efficiency metrics demonstrate that hematite often requires 30-40% less material by volume to achieve equivalent remediation outcomes for heavy metal contamination. This higher efficiency partially offsets its elevated acquisition costs, particularly in projects where transportation and application expenses constitute significant budget components.

Operational longevity presents another critical economic consideration. Field studies indicate hematite-based remediation solutions maintain effectiveness for 8-12 years before requiring replenishment, whereas kaolinite treatments typically necessitate renewal after 4-7 years. This extended service life translates to reduced long-term maintenance costs for hematite applications.

Implementation expenses reveal additional distinctions. Kaolinite's lower density and superior workability reduce equipment requirements and labor costs during application, with average installation costs 15-25% lower than comparable hematite treatments. This advantage becomes particularly pronounced in remote locations with limited infrastructure.

Environmental externality calculations further complicate the economic equation. Hematite mining generates approximately 1.8 times more carbon emissions per ton than kaolinite extraction. However, hematite's superior remediation capacity for certain contaminants may reduce long-term environmental monitoring costs by 20-35%.

Scalability economics demonstrate that kaolinite maintains relatively stable costs across project sizes, while hematite exhibits more favorable economies of scale for large remediation efforts. Projects exceeding 50 hectares typically see hematite's cost premium decrease by 18-22% compared to smaller implementations.

Regulatory compliance costs generally favor hematite in regions with stringent remediation standards due to its higher performance ceiling, potentially avoiding penalties and additional treatment requirements that might affect kaolinite-based solutions in challenging contamination scenarios.

The comprehensive economic assessment indicates that while kaolinite presents lower initial investment barriers, hematite often delivers superior long-term value in scenarios involving persistent contaminants, large-scale applications, or sites requiring minimal maintenance interventions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!