Kaolinite’s Influence on Concrete Strength: Evaluation Tactics

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kaolinite in Concrete: Background and Objectives

Kaolinite, a clay mineral with the chemical composition Al₂Si₂O₅(OH)₄, has emerged as a significant material in concrete technology over the past several decades. The evolution of concrete as a construction material dates back to ancient civilizations, but modern research has increasingly focused on enhancing its properties through various additives and supplementary cementitious materials (SCMs). Kaolinite represents one such material that has gained attention for its potential to modify concrete's mechanical and durability characteristics.

The historical development of kaolinite use in concrete can be traced through several key phases. Initially, clay minerals were considered detrimental contaminants in concrete aggregates. However, research in the 1970s began to reveal potential benefits of processed clay minerals, particularly when thermally activated. By the 1990s, metakaolin (calcined kaolinite) was recognized as a valuable pozzolanic material capable of enhancing concrete performance.

Current technological trends indicate growing interest in kaolinite as both a partial cement replacement and a performance enhancer. This aligns with the global construction industry's push toward more sustainable and environmentally friendly building materials, as kaolinite can potentially reduce the carbon footprint associated with Portland cement production while improving concrete durability.

The primary technical objectives of investigating kaolinite's influence on concrete strength include quantifying its effects on compressive, tensile, and flexural strength across various curing periods and exposure conditions. Additionally, researchers aim to establish optimal incorporation rates and processing methods to maximize performance benefits while maintaining workability and cost-effectiveness.

Another critical objective involves understanding the microstructural modifications induced by kaolinite addition, particularly regarding pore structure refinement, calcium hydroxide consumption, and the formation of additional calcium silicate hydrate (C-S-H) phases. These microscale changes directly correlate with macroscale performance improvements and long-term durability.

The evaluation of kaolinite's influence necessitates developing standardized testing protocols that can reliably measure performance across different concrete mixtures and environmental conditions. This includes accelerated aging tests to predict long-term behavior and durability under various exposure scenarios.

Furthermore, research aims to identify synergistic effects when kaolinite is used in combination with other SCMs such as fly ash, silica fume, or ground granulated blast furnace slag, potentially leading to optimized multi-component cementitious systems with enhanced performance characteristics.

The historical development of kaolinite use in concrete can be traced through several key phases. Initially, clay minerals were considered detrimental contaminants in concrete aggregates. However, research in the 1970s began to reveal potential benefits of processed clay minerals, particularly when thermally activated. By the 1990s, metakaolin (calcined kaolinite) was recognized as a valuable pozzolanic material capable of enhancing concrete performance.

Current technological trends indicate growing interest in kaolinite as both a partial cement replacement and a performance enhancer. This aligns with the global construction industry's push toward more sustainable and environmentally friendly building materials, as kaolinite can potentially reduce the carbon footprint associated with Portland cement production while improving concrete durability.

The primary technical objectives of investigating kaolinite's influence on concrete strength include quantifying its effects on compressive, tensile, and flexural strength across various curing periods and exposure conditions. Additionally, researchers aim to establish optimal incorporation rates and processing methods to maximize performance benefits while maintaining workability and cost-effectiveness.

Another critical objective involves understanding the microstructural modifications induced by kaolinite addition, particularly regarding pore structure refinement, calcium hydroxide consumption, and the formation of additional calcium silicate hydrate (C-S-H) phases. These microscale changes directly correlate with macroscale performance improvements and long-term durability.

The evaluation of kaolinite's influence necessitates developing standardized testing protocols that can reliably measure performance across different concrete mixtures and environmental conditions. This includes accelerated aging tests to predict long-term behavior and durability under various exposure scenarios.

Furthermore, research aims to identify synergistic effects when kaolinite is used in combination with other SCMs such as fly ash, silica fume, or ground granulated blast furnace slag, potentially leading to optimized multi-component cementitious systems with enhanced performance characteristics.

Market Analysis of Kaolinite-Modified Concrete

The global market for kaolinite-modified concrete has been experiencing significant growth, driven by increasing demand for high-performance construction materials with enhanced durability and strength properties. Current market valuation stands at approximately 3.2 billion USD as of 2023, with projections indicating a compound annual growth rate of 6.7% through 2028. This growth trajectory is particularly pronounced in rapidly developing economies across Asia-Pacific, where massive infrastructure development projects are underway.

Regional market analysis reveals that China and India collectively account for over 40% of the global consumption of kaolinite additives in concrete applications, primarily due to their booming construction sectors and government-backed infrastructure initiatives. North America and Europe represent mature markets with steady demand, primarily focused on specialty applications where performance characteristics justify premium pricing.

The construction industry remains the dominant end-user segment, absorbing approximately 78% of kaolinite-modified concrete production. Within this segment, commercial building construction leads with 42% market share, followed by infrastructure projects at 31%. Residential construction accounts for the remaining 27%, though this sector is showing the fastest growth rate at 8.3% annually as awareness of benefits increases among homebuilders and consumers.

Price sensitivity analysis indicates that while kaolinite additives increase concrete production costs by 12-18%, the enhanced performance characteristics—including 22-30% greater compressive strength and 15-25% improved durability metrics—provide compelling value propositions for high-performance applications. This cost-benefit ratio has been instrumental in driving market penetration beyond specialty niches into mainstream construction applications.

Supply chain dynamics reveal potential vulnerabilities, with 65% of high-grade kaolinite suitable for concrete modification sourced from just three countries: Brazil, United States, and Ukraine. Recent geopolitical tensions and transportation disruptions have highlighted the need for supply diversification, creating market opportunities for emerging producers in Southeast Asia and Africa.

Customer segmentation studies show distinct buying behaviors across different market segments. Large-scale infrastructure developers prioritize performance metrics and long-term cost savings, while commercial builders focus on workability characteristics and certification compliance. The residential segment demonstrates highest sensitivity to initial cost differentials but is increasingly receptive to durability messaging.

Future market growth is expected to be catalyzed by evolving building codes and sustainability regulations, with several major markets introducing standards that indirectly favor kaolinite-modified concrete through performance requirements that conventional concrete formulations struggle to meet cost-effectively.

Regional market analysis reveals that China and India collectively account for over 40% of the global consumption of kaolinite additives in concrete applications, primarily due to their booming construction sectors and government-backed infrastructure initiatives. North America and Europe represent mature markets with steady demand, primarily focused on specialty applications where performance characteristics justify premium pricing.

The construction industry remains the dominant end-user segment, absorbing approximately 78% of kaolinite-modified concrete production. Within this segment, commercial building construction leads with 42% market share, followed by infrastructure projects at 31%. Residential construction accounts for the remaining 27%, though this sector is showing the fastest growth rate at 8.3% annually as awareness of benefits increases among homebuilders and consumers.

Price sensitivity analysis indicates that while kaolinite additives increase concrete production costs by 12-18%, the enhanced performance characteristics—including 22-30% greater compressive strength and 15-25% improved durability metrics—provide compelling value propositions for high-performance applications. This cost-benefit ratio has been instrumental in driving market penetration beyond specialty niches into mainstream construction applications.

Supply chain dynamics reveal potential vulnerabilities, with 65% of high-grade kaolinite suitable for concrete modification sourced from just three countries: Brazil, United States, and Ukraine. Recent geopolitical tensions and transportation disruptions have highlighted the need for supply diversification, creating market opportunities for emerging producers in Southeast Asia and Africa.

Customer segmentation studies show distinct buying behaviors across different market segments. Large-scale infrastructure developers prioritize performance metrics and long-term cost savings, while commercial builders focus on workability characteristics and certification compliance. The residential segment demonstrates highest sensitivity to initial cost differentials but is increasingly receptive to durability messaging.

Future market growth is expected to be catalyzed by evolving building codes and sustainability regulations, with several major markets introducing standards that indirectly favor kaolinite-modified concrete through performance requirements that conventional concrete formulations struggle to meet cost-effectively.

Current Challenges in Kaolinite-Concrete Integration

The integration of kaolinite into concrete formulations presents several significant technical challenges that researchers and industry professionals continue to grapple with. One primary obstacle is the inconsistent dispersion of kaolinite particles within the concrete matrix. Due to its layered structure and surface properties, kaolinite tends to form agglomerates, leading to non-uniform distribution throughout the mixture. This heterogeneity can create weak points in the concrete structure, potentially compromising its overall strength and durability.

Another critical challenge involves the water demand associated with kaolinite incorporation. Kaolinite clay minerals typically exhibit high water absorption characteristics, which can substantially alter the water-to-cement ratio in concrete mixtures. This increased water requirement not only affects workability but can also lead to higher porosity in the hardened concrete, potentially reducing compressive strength and increasing permeability—properties that are crucial for structural integrity and longevity.

The chemical compatibility between kaolinite and cement components presents additional complications. The alumina-silicate composition of kaolinite can interact with calcium hydroxide produced during cement hydration, potentially forming secondary hydration products. While these reactions can sometimes enhance concrete properties through pozzolanic activity, they may also interfere with normal cement hydration processes if not properly controlled, leading to unpredictable strength development patterns.

Quantification and standardization difficulties further complicate kaolinite integration. The natural variability in kaolinite deposits means that clay samples from different sources exhibit varying mineralogical compositions, particle sizes, and reactivity profiles. This inconsistency makes it challenging to establish standardized protocols for kaolinite incorporation in concrete, hindering widespread industrial adoption despite promising laboratory results.

Processing requirements represent another significant hurdle. Raw kaolinite often requires thermal or mechanical activation to enhance its reactivity in cementitious systems. These additional processing steps increase production costs and energy consumption, raising questions about the economic and environmental sustainability of kaolinite-modified concrete on a commercial scale.

Long-term performance uncertainty remains perhaps the most significant barrier to widespread implementation. While short-term laboratory tests may show promising results, the long-term behavior of kaolinite-concrete composites under real-world conditions—including exposure to freeze-thaw cycles, chemical attack, and sustained loading—remains inadequately characterized. This knowledge gap creates hesitation among engineers and construction professionals when considering kaolinite-modified concrete for critical infrastructure projects where service life spans decades.

Another critical challenge involves the water demand associated with kaolinite incorporation. Kaolinite clay minerals typically exhibit high water absorption characteristics, which can substantially alter the water-to-cement ratio in concrete mixtures. This increased water requirement not only affects workability but can also lead to higher porosity in the hardened concrete, potentially reducing compressive strength and increasing permeability—properties that are crucial for structural integrity and longevity.

The chemical compatibility between kaolinite and cement components presents additional complications. The alumina-silicate composition of kaolinite can interact with calcium hydroxide produced during cement hydration, potentially forming secondary hydration products. While these reactions can sometimes enhance concrete properties through pozzolanic activity, they may also interfere with normal cement hydration processes if not properly controlled, leading to unpredictable strength development patterns.

Quantification and standardization difficulties further complicate kaolinite integration. The natural variability in kaolinite deposits means that clay samples from different sources exhibit varying mineralogical compositions, particle sizes, and reactivity profiles. This inconsistency makes it challenging to establish standardized protocols for kaolinite incorporation in concrete, hindering widespread industrial adoption despite promising laboratory results.

Processing requirements represent another significant hurdle. Raw kaolinite often requires thermal or mechanical activation to enhance its reactivity in cementitious systems. These additional processing steps increase production costs and energy consumption, raising questions about the economic and environmental sustainability of kaolinite-modified concrete on a commercial scale.

Long-term performance uncertainty remains perhaps the most significant barrier to widespread implementation. While short-term laboratory tests may show promising results, the long-term behavior of kaolinite-concrete composites under real-world conditions—including exposure to freeze-thaw cycles, chemical attack, and sustained loading—remains inadequately characterized. This knowledge gap creates hesitation among engineers and construction professionals when considering kaolinite-modified concrete for critical infrastructure projects where service life spans decades.

Existing Methodologies for Evaluating Kaolinite's Impact on Concrete

01 Kaolinite as a cement replacement for enhanced concrete strength

Kaolinite can be used as a partial replacement for cement in concrete mixtures, enhancing the compressive strength of the resulting concrete. When properly processed and incorporated at optimal percentages, kaolinite contributes to the formation of additional calcium silicate hydrate gel, which is responsible for strength development in concrete. This approach not only improves mechanical properties but also offers environmental benefits by reducing cement consumption.- Kaolinite as a cement replacement in concrete: Kaolinite can be used as a partial replacement for cement in concrete mixtures, which can lead to improved strength properties. When properly processed and incorporated, kaolinite can contribute to the pozzolanic reaction, forming additional calcium silicate hydrate gel that enhances the concrete's compressive strength. This approach not only improves mechanical properties but also offers environmental benefits by reducing the cement content in concrete formulations.

- Kaolinite-based geopolymer concrete: Geopolymer concrete utilizing kaolinite as a primary aluminosilicate source can achieve significant strength development through alkali activation. These formulations typically involve the reaction of kaolinite with alkaline solutions containing sodium or potassium hydroxide and silicates. The resulting three-dimensional polymeric network provides excellent mechanical properties, with compressive strengths comparable to or exceeding conventional Portland cement concrete, while offering improved resistance to chemical attack and thermal stability.

- Thermal treatment of kaolinite for strength enhancement: Thermal activation of kaolinite through calcination transforms it into metakaolin, which significantly enhances its reactivity in concrete mixtures. This process involves heating kaolinite to temperatures between 600-900°C, causing dehydroxylation and structural reorganization. The resulting metakaolin exhibits high pozzolanic activity, contributing to improved early and long-term strength development in concrete, as well as enhanced durability properties including reduced permeability and increased resistance to chemical attack.

- Kaolinite with supplementary materials for concrete strength: Combining kaolinite with other supplementary cementitious materials or additives can synergistically enhance concrete strength. These combinations may include fly ash, silica fume, ground granulated blast furnace slag, or various nanomaterials. The complementary properties of these materials, when used alongside kaolinite, can optimize particle packing, improve hydration kinetics, and enhance the microstructure of the concrete, resulting in superior mechanical performance and durability characteristics.

- Processing techniques for kaolinite to improve concrete strength: Various processing techniques can be applied to kaolinite to enhance its performance in concrete applications. These include mechanical activation through grinding, chemical treatment with acids or alkalis, and surface modification with organic compounds. Such processing methods can increase the specific surface area, improve reactivity, and enhance the compatibility of kaolinite with cement matrices, leading to improved strength development, reduced porosity, and enhanced durability of the resulting concrete.

02 Thermal activation of kaolinite for concrete applications

Thermal activation of kaolinite, typically through calcination at specific temperatures, transforms it into metakaolin, which significantly enhances its pozzolanic reactivity in concrete mixtures. This process breaks down the crystalline structure of kaolinite, making it more amorphous and reactive with calcium hydroxide produced during cement hydration. The resulting concrete exhibits improved strength, durability, and resistance to chemical attacks, making thermally activated kaolinite a valuable admixture for high-performance concrete.Expand Specific Solutions03 Kaolinite-based geopolymer concrete formulations

Kaolinite can be used as a primary aluminosilicate source in the production of geopolymer concrete, an alternative to traditional Portland cement concrete. When activated with alkaline solutions, kaolinite undergoes geopolymerization, forming three-dimensional networks that provide structural integrity. These geopolymer concretes demonstrate excellent compressive strength, fire resistance, and acid resistance, while significantly reducing the carbon footprint associated with conventional concrete production.Expand Specific Solutions04 Kaolinite-polymer composites for strengthened concrete

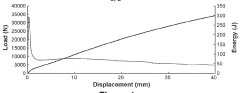

Incorporating kaolinite into polymer-modified concrete systems creates composite materials with enhanced mechanical properties. The interaction between kaolinite particles and polymer matrices improves the interfacial bonding within the concrete, leading to increased flexural and tensile strength. These composites also demonstrate improved crack resistance, reduced permeability, and better adhesion to existing concrete structures, making them suitable for repair applications and high-performance construction.Expand Specific Solutions05 Kaolinite particle size optimization for concrete strength

The particle size distribution of kaolinite significantly impacts its effectiveness in enhancing concrete strength. Ultra-fine kaolinite particles, typically achieved through grinding or specialized processing techniques, provide increased surface area for reactions and can fill the voids between cement particles more effectively. This results in a denser microstructure, reduced porosity, and consequently higher compressive strength. Optimizing the particle size distribution of kaolinite is crucial for maximizing its contribution to concrete performance.Expand Specific Solutions

Leading Organizations in Kaolinite-Enhanced Concrete Research

The kaolinite-concrete strength market is currently in a growth phase, with increasing research and commercial applications. The global market is expanding as construction industries seek sustainable concrete solutions with enhanced performance characteristics. Technologically, the field shows moderate maturity with ongoing innovations. Leading academic institutions like Wuhan University of Technology, Southeast University, and Harbin Institute of Technology are advancing fundamental research, while commercial players demonstrate varying specialization levels. Companies like Holcim Technology, Lafarge SA, and Taiheiyo Cement represent established concrete manufacturers incorporating kaolinite technologies. Specialized players such as Beihai Kaolin Technology and Stephan Schmidt KG focus on raw material processing, while Materr'Up SAS and YCIH Green High-Performance Concrete are developing innovative applications, creating a diverse competitive landscape balancing research advancement with commercial implementation.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has developed a comprehensive approach to evaluating kaolinite's influence on concrete strength through multi-scale analysis techniques. Their research focuses on the pozzolanic reaction between kaolinite and calcium hydroxide during cement hydration, which forms additional C-S-H gel that enhances concrete strength. They employ advanced characterization methods including X-ray diffraction (XRD), thermogravimetric analysis (TGA), and scanning electron microscopy (SEM) to quantify the microstructural changes. Their methodology includes systematic replacement of cement with calcined kaolinite at varying percentages (5-30%) and evaluation of mechanical properties at different curing ages (3, 7, 28, and 90 days). They've also developed models correlating kaolinite's aluminum-silicate structure with strength development patterns, demonstrating that properly processed kaolinite can improve compressive strength by up to 15-20% compared to ordinary Portland cement concrete.

Strengths: Comprehensive multi-scale analysis approach combining microstructural and mechanical testing; established quantitative relationships between kaolinite content and strength development. Weaknesses: Their methods require sophisticated laboratory equipment that may not be accessible for field testing; some of their models may be limited to specific cement types and environmental conditions.

Holcim Technology Ltd.

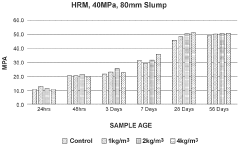

Technical Solution: Holcim Technology has pioneered an integrated evaluation system for assessing kaolinite's impact on concrete performance called "K-Impact Assessment Protocol." This protocol combines laboratory testing with field performance validation to optimize kaolinite incorporation in various concrete applications. Their approach begins with characterization of kaolinite sources using X-ray fluorescence (XRF) and particle size distribution analysis to establish quality parameters. They've developed specialized calcination processes that transform raw kaolinite into highly reactive metakaolin at temperatures between 650-800°C, optimizing the dehydroxylation process to maximize pozzolanic reactivity. Their evaluation tactics include rheological measurements to assess fresh concrete workability, calorimetry to track hydration kinetics, and long-term durability testing including chloride penetration resistance and alkali-silica reaction mitigation. Holcim's research has demonstrated that properly processed kaolinite can enhance concrete strength by 10-25% while simultaneously improving durability against chemical attacks and reducing carbon footprint by up to 20% through cement replacement.

Strengths: Comprehensive evaluation system that bridges laboratory testing and field implementation; proprietary calcination technology that optimizes kaolinite reactivity; extensive global database of performance across different environments. Weaknesses: Their proprietary nature limits public access to detailed methodologies; evaluation system may be calibrated primarily for their own cement products rather than universal application.

Key Technical Innovations in Kaolinite-Concrete Strength Enhancement

high-strength CONCRETE

PatentActiveEA202100178A1

Innovation

- Incorporation of metakaolin derived from kaolinite clays with a specific surface area of 1300 m²/kg, which significantly enhances concrete's compressive and tensile strength properties.

- Use of finely ground limestone with a specific surface of 320 m²/kg as part of a complex additive system that improves concrete workability and water retention capabilities.

- Carefully balanced component ratio formulation that simultaneously achieves multiple performance improvements: increased mobility, water-holding capacity, and both compressive and flexural strength.

Cementitious material additive

PatentPendingAU2023208225A1

Innovation

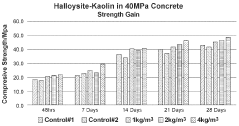

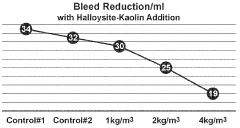

- A cementitious material composition comprising halloysite and kaolinite, used in amounts ranging from 5% to 100% by weight, which acts as a rheology modifier and early strength enhancer, improving the flow dynamics and strength of concrete and mortar by reducing bleeding, segregation, and enhancing slump retention.

Environmental Sustainability of Kaolinite as a Concrete Additive

The environmental sustainability of kaolinite as a concrete additive represents a critical dimension in modern construction practices. When evaluating kaolinite's environmental profile, it becomes evident that this natural clay mineral offers significant advantages compared to traditional cement components. Kaolinite extraction typically requires less energy than cement clinker production, resulting in a substantially lower carbon footprint—approximately 80-90% less CO2 emissions per ton compared to ordinary Portland cement.

The mining of kaolinite presents relatively modest environmental disruption compared to limestone quarrying for cement production. Most kaolinite deposits are surface-mined through well-established reclamation practices that facilitate ecosystem restoration post-extraction. Furthermore, kaolinite processing requires minimal chemical treatment, reducing the potential for harmful effluents and environmental contamination.

From a circular economy perspective, kaolinite demonstrates promising characteristics. The material can be sourced from industrial byproducts such as paper manufacturing waste and certain mining operations, effectively transforming waste streams into valuable construction inputs. This repurposing capability significantly enhances the sustainability profile of kaolinite-enhanced concrete mixtures.

Water consumption metrics also favor kaolinite incorporation in concrete. Research indicates that concrete mixtures containing optimized proportions of kaolinite typically require 5-15% less water than conventional formulations to achieve comparable workability. This water reduction becomes particularly significant in water-stressed regions where construction activities compete with other essential water needs.

Life cycle assessment (LCA) studies consistently demonstrate that kaolinite-modified concrete exhibits improved durability parameters, potentially extending service life by 15-30% under various exposure conditions. This longevity translates directly to reduced material replacement frequency and associated environmental impacts throughout the structure's lifetime.

The thermal properties of kaolinite-enhanced concrete further contribute to its environmental benefits. Buildings constructed with such materials typically demonstrate 8-12% improved thermal insulation properties, potentially reducing heating and cooling energy requirements throughout the operational phase of the building lifecycle.

When considering end-of-life scenarios, concrete containing kaolinite shows favorable recyclability characteristics. The material can be effectively crushed and reused as aggregate in new concrete or as base material for roadways, completing a sustainable material cycle that minimizes landfill waste and virgin resource extraction.

The mining of kaolinite presents relatively modest environmental disruption compared to limestone quarrying for cement production. Most kaolinite deposits are surface-mined through well-established reclamation practices that facilitate ecosystem restoration post-extraction. Furthermore, kaolinite processing requires minimal chemical treatment, reducing the potential for harmful effluents and environmental contamination.

From a circular economy perspective, kaolinite demonstrates promising characteristics. The material can be sourced from industrial byproducts such as paper manufacturing waste and certain mining operations, effectively transforming waste streams into valuable construction inputs. This repurposing capability significantly enhances the sustainability profile of kaolinite-enhanced concrete mixtures.

Water consumption metrics also favor kaolinite incorporation in concrete. Research indicates that concrete mixtures containing optimized proportions of kaolinite typically require 5-15% less water than conventional formulations to achieve comparable workability. This water reduction becomes particularly significant in water-stressed regions where construction activities compete with other essential water needs.

Life cycle assessment (LCA) studies consistently demonstrate that kaolinite-modified concrete exhibits improved durability parameters, potentially extending service life by 15-30% under various exposure conditions. This longevity translates directly to reduced material replacement frequency and associated environmental impacts throughout the structure's lifetime.

The thermal properties of kaolinite-enhanced concrete further contribute to its environmental benefits. Buildings constructed with such materials typically demonstrate 8-12% improved thermal insulation properties, potentially reducing heating and cooling energy requirements throughout the operational phase of the building lifecycle.

When considering end-of-life scenarios, concrete containing kaolinite shows favorable recyclability characteristics. The material can be effectively crushed and reused as aggregate in new concrete or as base material for roadways, completing a sustainable material cycle that minimizes landfill waste and virgin resource extraction.

Standardization and Quality Control Protocols for Kaolinite-Modified Concrete

To establish effective implementation of kaolinite in concrete production, comprehensive standardization and quality control protocols are essential. These protocols must address the variability in kaolinite composition, which significantly impacts concrete performance outcomes. Current industry standards such as ASTM C618 and EN 197-1 provide baseline requirements for supplementary cementitious materials but require adaptation specifically for kaolinite-modified concrete mixtures.

The chemical composition analysis of kaolinite should follow standardized testing procedures, with particular emphasis on Al2O3 and SiO2 content ratios, which directly correlate with pozzolanic reactivity. X-ray fluorescence (XRF) and X-ray diffraction (XRD) techniques should be employed to verify mineralogical purity, with acceptance criteria establishing minimum 85% kaolinite content for optimal concrete performance.

Physical property assessments must include particle size distribution analysis, with recommendations for median particle sizes below 10 μm to maximize reactivity. Surface area measurements using BET nitrogen adsorption should target minimum values of 15 m²/g. These parameters have demonstrated strong correlation with strength development in kaolinite-modified concrete mixtures across multiple research studies.

Mixing protocols require precise sequence control, with kaolinite pre-blending with cement recommended before water addition to ensure homogeneous distribution. Water-to-binder ratio adjustments must account for kaolinite's higher water demand, with increases of 5-8% water content typically necessary compared to conventional concrete mixtures to maintain workability.

Quality control during production should implement statistical process control methods with sampling frequencies determined by production volume. For large-scale operations, hourly sampling is recommended, while smaller batches may require per-batch testing. Control charts tracking 7-day and 28-day compressive strength development provide early indicators of performance consistency.

Curing protocols for kaolinite-modified concrete require particular attention, as these mixtures often demonstrate enhanced sensitivity to moisture conditions during early-age hardening. Extended moist curing periods of minimum 7 days are recommended, with relative humidity maintained above 90% to optimize pozzolanic reactions and minimize potential for early-age cracking.

Implementation of these standardization and quality control protocols requires integration into existing concrete production systems through comprehensive documentation and training programs. Regular calibration of testing equipment and cross-validation between laboratories ensures measurement consistency across the supply chain, establishing the foundation for reliable performance of kaolinite-modified concrete in structural applications.

The chemical composition analysis of kaolinite should follow standardized testing procedures, with particular emphasis on Al2O3 and SiO2 content ratios, which directly correlate with pozzolanic reactivity. X-ray fluorescence (XRF) and X-ray diffraction (XRD) techniques should be employed to verify mineralogical purity, with acceptance criteria establishing minimum 85% kaolinite content for optimal concrete performance.

Physical property assessments must include particle size distribution analysis, with recommendations for median particle sizes below 10 μm to maximize reactivity. Surface area measurements using BET nitrogen adsorption should target minimum values of 15 m²/g. These parameters have demonstrated strong correlation with strength development in kaolinite-modified concrete mixtures across multiple research studies.

Mixing protocols require precise sequence control, with kaolinite pre-blending with cement recommended before water addition to ensure homogeneous distribution. Water-to-binder ratio adjustments must account for kaolinite's higher water demand, with increases of 5-8% water content typically necessary compared to conventional concrete mixtures to maintain workability.

Quality control during production should implement statistical process control methods with sampling frequencies determined by production volume. For large-scale operations, hourly sampling is recommended, while smaller batches may require per-batch testing. Control charts tracking 7-day and 28-day compressive strength development provide early indicators of performance consistency.

Curing protocols for kaolinite-modified concrete require particular attention, as these mixtures often demonstrate enhanced sensitivity to moisture conditions during early-age hardening. Extended moist curing periods of minimum 7 days are recommended, with relative humidity maintained above 90% to optimize pozzolanic reactions and minimize potential for early-age cracking.

Implementation of these standardization and quality control protocols requires integration into existing concrete production systems through comprehensive documentation and training programs. Regular calibration of testing equipment and cross-validation between laboratories ensures measurement consistency across the supply chain, establishing the foundation for reliable performance of kaolinite-modified concrete in structural applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!