How to Measure Kaolinite’s Heat Resistance in Sealing Products

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kaolinite Heat Resistance Testing Background and Objectives

Kaolinite, a clay mineral with the chemical composition Al₂Si₂O₅(OH)₄, has been extensively utilized in various industrial applications due to its unique properties. The evolution of kaolinite usage in sealing products has witnessed significant advancements over the past decades, transitioning from basic applications to sophisticated engineered solutions. Heat resistance measurement of kaolinite in sealing products has become increasingly critical as industrial processes demand materials capable of withstanding extreme thermal conditions while maintaining structural integrity.

The historical development of heat resistance testing methodologies for kaolinite-based sealing products reflects the growing complexity of industrial requirements. Early testing approaches primarily focused on basic thermal stability parameters, whereas contemporary methods incorporate comprehensive analyses of multiple performance indicators under various thermal stress conditions. This evolution has been driven by the expanding application of kaolinite-based seals in high-temperature environments such as automotive exhaust systems, industrial furnaces, and chemical processing equipment.

Current technological trends in this field are moving toward more precise quantification of heat resistance properties, including thermal conductivity, thermal expansion coefficient, and phase transformation behavior under extreme conditions. The integration of advanced analytical techniques such as thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), and high-temperature X-ray diffraction has revolutionized our understanding of kaolinite's thermal behavior in complex sealing systems.

The primary objective of measuring kaolinite's heat resistance in sealing products is to establish standardized testing protocols that accurately predict performance under real-world operating conditions. This includes determining the maximum temperature threshold before degradation, evaluating long-term thermal stability, and assessing the impact of thermal cycling on seal integrity. Additionally, there is a growing emphasis on understanding the interaction between kaolinite and other components in composite sealing materials when subjected to thermal stress.

Another crucial goal is to develop accelerated testing methodologies that can reliably simulate years of thermal exposure in significantly reduced timeframes, thereby expediting product development cycles while maintaining confidence in long-term performance predictions. This requires sophisticated modeling approaches that account for the complex mineralogical transformations that occur in kaolinite at elevated temperatures.

Furthermore, the industry aims to establish correlations between laboratory test results and field performance, addressing the persistent challenge of translating controlled experimental data into reliable predictions of real-world behavior. This necessitates the development of testing regimes that incorporate multiple environmental factors simultaneously, such as thermal fluctuations, mechanical stress, and chemical exposure.

The historical development of heat resistance testing methodologies for kaolinite-based sealing products reflects the growing complexity of industrial requirements. Early testing approaches primarily focused on basic thermal stability parameters, whereas contemporary methods incorporate comprehensive analyses of multiple performance indicators under various thermal stress conditions. This evolution has been driven by the expanding application of kaolinite-based seals in high-temperature environments such as automotive exhaust systems, industrial furnaces, and chemical processing equipment.

Current technological trends in this field are moving toward more precise quantification of heat resistance properties, including thermal conductivity, thermal expansion coefficient, and phase transformation behavior under extreme conditions. The integration of advanced analytical techniques such as thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), and high-temperature X-ray diffraction has revolutionized our understanding of kaolinite's thermal behavior in complex sealing systems.

The primary objective of measuring kaolinite's heat resistance in sealing products is to establish standardized testing protocols that accurately predict performance under real-world operating conditions. This includes determining the maximum temperature threshold before degradation, evaluating long-term thermal stability, and assessing the impact of thermal cycling on seal integrity. Additionally, there is a growing emphasis on understanding the interaction between kaolinite and other components in composite sealing materials when subjected to thermal stress.

Another crucial goal is to develop accelerated testing methodologies that can reliably simulate years of thermal exposure in significantly reduced timeframes, thereby expediting product development cycles while maintaining confidence in long-term performance predictions. This requires sophisticated modeling approaches that account for the complex mineralogical transformations that occur in kaolinite at elevated temperatures.

Furthermore, the industry aims to establish correlations between laboratory test results and field performance, addressing the persistent challenge of translating controlled experimental data into reliable predictions of real-world behavior. This necessitates the development of testing regimes that incorporate multiple environmental factors simultaneously, such as thermal fluctuations, mechanical stress, and chemical exposure.

Market Demand Analysis for Heat-Resistant Sealing Materials

The global market for heat-resistant sealing materials has experienced significant growth in recent years, driven by increasing demands across multiple industries including automotive, aerospace, chemical processing, and energy production. The market value for high-temperature sealing solutions reached approximately $7.2 billion in 2022, with projections indicating a compound annual growth rate of 6.3% through 2028.

Kaolinite-based sealing products represent a growing segment within this market due to their excellent thermal stability, chemical resistance, and cost-effectiveness compared to other ceramic materials. Industries requiring sealing solutions that can withstand temperatures above 800°C have shown particular interest in kaolinite composites, with the automotive sector leading adoption for exhaust system applications.

Market research indicates that end-users prioritize three key performance attributes in heat-resistant sealing materials: consistent performance under thermal cycling conditions, longevity at sustained high temperatures, and predictable degradation patterns. This has created specific demand for standardized testing methodologies that can accurately measure and predict kaolinite's heat resistance properties in real-world applications.

The energy sector presents the fastest-growing market opportunity, with demand increasing at 8.7% annually as power generation facilities seek more durable sealing solutions for high-temperature environments. This growth is particularly pronounced in regions investing heavily in energy infrastructure, including East Asia and North America.

Regulatory trends are significantly influencing market dynamics, with stricter emissions standards and safety regulations driving manufacturers to develop and validate more heat-resistant sealing solutions. The European Union's industrial emissions directives and similar regulations in North America have created substantial demand for sealing materials with verifiable thermal performance characteristics.

Customer feedback from industrial surveys reveals a significant gap between laboratory testing results and field performance of heat-resistant sealing materials. This discrepancy has created market demand for more sophisticated measurement techniques that can better simulate real-world conditions, particularly for materials like kaolinite that exhibit complex behavior under varying thermal loads.

The competitive landscape shows increasing investment in research and development of testing methodologies, with major players allocating an average of 12% of revenue to advance measurement technologies for material performance. This trend underscores the market's recognition that accurate measurement of heat resistance properties directly correlates with product value proposition and pricing power in the industrial sealing segment.

Kaolinite-based sealing products represent a growing segment within this market due to their excellent thermal stability, chemical resistance, and cost-effectiveness compared to other ceramic materials. Industries requiring sealing solutions that can withstand temperatures above 800°C have shown particular interest in kaolinite composites, with the automotive sector leading adoption for exhaust system applications.

Market research indicates that end-users prioritize three key performance attributes in heat-resistant sealing materials: consistent performance under thermal cycling conditions, longevity at sustained high temperatures, and predictable degradation patterns. This has created specific demand for standardized testing methodologies that can accurately measure and predict kaolinite's heat resistance properties in real-world applications.

The energy sector presents the fastest-growing market opportunity, with demand increasing at 8.7% annually as power generation facilities seek more durable sealing solutions for high-temperature environments. This growth is particularly pronounced in regions investing heavily in energy infrastructure, including East Asia and North America.

Regulatory trends are significantly influencing market dynamics, with stricter emissions standards and safety regulations driving manufacturers to develop and validate more heat-resistant sealing solutions. The European Union's industrial emissions directives and similar regulations in North America have created substantial demand for sealing materials with verifiable thermal performance characteristics.

Customer feedback from industrial surveys reveals a significant gap between laboratory testing results and field performance of heat-resistant sealing materials. This discrepancy has created market demand for more sophisticated measurement techniques that can better simulate real-world conditions, particularly for materials like kaolinite that exhibit complex behavior under varying thermal loads.

The competitive landscape shows increasing investment in research and development of testing methodologies, with major players allocating an average of 12% of revenue to advance measurement technologies for material performance. This trend underscores the market's recognition that accurate measurement of heat resistance properties directly correlates with product value proposition and pricing power in the industrial sealing segment.

Current Methodologies and Challenges in Thermal Testing

The evaluation of kaolinite's heat resistance in sealing products requires sophisticated testing methodologies that have evolved significantly over recent decades. Currently, the industry employs several standardized testing protocols, with thermogravimetric analysis (TGA) being among the most prevalent. TGA measures weight changes in kaolinite samples as they are subjected to controlled temperature increases, typically ranging from ambient temperature to 1000°C or higher. This method provides valuable data on dehydroxylation temperatures and thermal stability thresholds specific to kaolinite-based sealing materials.

Differential scanning calorimetry (DSC) complements TGA by measuring heat flow into or out of the kaolinite sample during temperature variations. This technique is particularly valuable for identifying phase transitions and quantifying the energy associated with thermal events in kaolinite, offering insights into its behavior under different thermal conditions in sealing applications.

Hot disk thermal constants analyzers have gained prominence for measuring thermal conductivity and diffusivity of kaolinite composites in sealing products. These parameters are crucial for predicting how sealing materials will perform under thermal stress in real-world applications, especially in industrial settings where temperature fluctuations are common.

Despite these advanced methodologies, significant challenges persist in thermal testing of kaolinite-based sealing products. Sample preparation inconsistencies represent a major hurdle, as variations in particle size distribution, moisture content, and compaction can significantly alter test results. The heterogeneous nature of industrial kaolinite further complicates standardization efforts, making it difficult to establish universally applicable testing protocols.

Environmental factors during testing introduce additional variables that can compromise result reliability. Humidity levels, atmospheric composition, and pressure conditions must be carefully controlled to ensure reproducible measurements. Many laboratories struggle to maintain these precise conditions throughout extended testing periods, leading to data variability across different testing facilities.

The translation of laboratory results to real-world performance presents perhaps the most significant challenge. Accelerated aging tests attempt to simulate years of thermal cycling in compressed timeframes, but these simulations often fail to account for complex interactions between kaolinite and other components in sealing assemblies. The industry lacks consensus on correlation factors between accelerated testing and actual service life predictions.

Recent innovations have introduced in-situ testing methods that monitor kaolinite's thermal properties while simultaneously subjecting samples to mechanical stress, better mimicking actual application conditions. However, these advanced techniques require sophisticated equipment and expertise not yet widely available in quality control laboratories, limiting their industrial adoption.

Differential scanning calorimetry (DSC) complements TGA by measuring heat flow into or out of the kaolinite sample during temperature variations. This technique is particularly valuable for identifying phase transitions and quantifying the energy associated with thermal events in kaolinite, offering insights into its behavior under different thermal conditions in sealing applications.

Hot disk thermal constants analyzers have gained prominence for measuring thermal conductivity and diffusivity of kaolinite composites in sealing products. These parameters are crucial for predicting how sealing materials will perform under thermal stress in real-world applications, especially in industrial settings where temperature fluctuations are common.

Despite these advanced methodologies, significant challenges persist in thermal testing of kaolinite-based sealing products. Sample preparation inconsistencies represent a major hurdle, as variations in particle size distribution, moisture content, and compaction can significantly alter test results. The heterogeneous nature of industrial kaolinite further complicates standardization efforts, making it difficult to establish universally applicable testing protocols.

Environmental factors during testing introduce additional variables that can compromise result reliability. Humidity levels, atmospheric composition, and pressure conditions must be carefully controlled to ensure reproducible measurements. Many laboratories struggle to maintain these precise conditions throughout extended testing periods, leading to data variability across different testing facilities.

The translation of laboratory results to real-world performance presents perhaps the most significant challenge. Accelerated aging tests attempt to simulate years of thermal cycling in compressed timeframes, but these simulations often fail to account for complex interactions between kaolinite and other components in sealing assemblies. The industry lacks consensus on correlation factors between accelerated testing and actual service life predictions.

Recent innovations have introduced in-situ testing methods that monitor kaolinite's thermal properties while simultaneously subjecting samples to mechanical stress, better mimicking actual application conditions. However, these advanced techniques require sophisticated equipment and expertise not yet widely available in quality control laboratories, limiting their industrial adoption.

Established Protocols for Evaluating Kaolinite Thermal Properties

01 Heat-resistant kaolinite composites

Kaolinite can be combined with other materials to form composites with enhanced heat resistance properties. These composites often incorporate materials like polymers, resins, or other minerals to create structures that can withstand high temperatures while maintaining structural integrity. The resulting materials show improved thermal stability and can be used in various high-temperature applications including industrial furnaces, kilns, and thermal insulation systems.- Heat-resistant kaolinite composites: Kaolinite can be incorporated into composite materials to enhance their heat resistance properties. These composites typically combine kaolinite with other materials such as polymers, resins, or ceramics to create products that can withstand high temperatures. The addition of kaolinite improves thermal stability, reduces thermal expansion, and enhances the overall heat resistance of the composite material, making it suitable for applications in high-temperature environments.

- Thermal modification of kaolinite: Kaolinite can undergo thermal modification processes to enhance its heat resistance properties. These processes involve heating kaolinite to specific temperatures, which causes structural changes that improve its thermal stability. The modified kaolinite exhibits improved resistance to high temperatures, making it suitable for applications requiring materials that can withstand thermal stress without degradation.

- Kaolinite in refractory materials: Kaolinite is widely used in the production of refractory materials due to its excellent heat resistance properties. When incorporated into refractory formulations, kaolinite contributes to the material's ability to withstand high temperatures without significant deformation or degradation. These refractory materials are used in various high-temperature applications, including furnace linings, kilns, and other industrial equipment exposed to extreme heat.

- Chemical treatment to enhance kaolinite heat resistance: Various chemical treatments can be applied to kaolinite to enhance its heat resistance properties. These treatments may involve the addition of specific chemicals or compounds that modify the surface or structure of kaolinite, resulting in improved thermal stability. Chemically treated kaolinite exhibits better resistance to high temperatures and can maintain its structural integrity under thermal stress, making it valuable for applications requiring materials with enhanced heat resistance.

- Kaolinite in fire-resistant applications: Kaolinite is utilized in various fire-resistant applications due to its inherent heat resistance properties. When incorporated into fire-resistant formulations, kaolinite helps to improve the material's ability to withstand fire and high temperatures. These applications include fire-resistant coatings, barriers, and construction materials designed to provide protection against fire hazards and to maintain structural integrity during fire events.

02 Thermal modification of kaolinite

Kaolinite can undergo thermal modification processes to enhance its heat resistance properties. These processes include calcination at specific temperatures, which transforms the crystal structure of kaolinite and improves its thermal stability. The modified kaolinite exhibits better resistance to thermal degradation and can maintain its properties at higher temperatures, making it suitable for applications requiring materials that can withstand extreme heat conditions.Expand Specific Solutions03 Kaolinite in refractory materials

Kaolinite is widely used as a key component in refractory materials due to its inherent heat resistance properties. When properly formulated, kaolinite-based refractories can withstand extremely high temperatures without significant degradation. These materials are commonly used in furnace linings, kiln construction, and other high-temperature industrial applications where thermal stability is critical for operational safety and efficiency.Expand Specific Solutions04 Surface treatment of kaolinite for heat resistance

Various surface treatment methods can be applied to kaolinite to enhance its heat resistance properties. These treatments include coating with heat-resistant compounds, chemical modification of the surface structure, and application of specialized additives. The treated kaolinite shows improved thermal stability, reduced thermal expansion, and better performance in high-temperature environments, making it suitable for advanced thermal management applications.Expand Specific Solutions05 Kaolinite in heat-resistant ceramic formulations

Kaolinite serves as a fundamental ingredient in heat-resistant ceramic formulations. When processed and fired under controlled conditions, kaolinite-based ceramics demonstrate exceptional thermal stability and mechanical strength at high temperatures. These ceramics can be engineered to have specific thermal properties by adjusting the composition and processing parameters, resulting in materials suitable for applications ranging from household ceramics to advanced industrial components exposed to extreme thermal conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Thermal Testing

The heat resistance measurement of kaolinite in sealing products is currently in a growth phase, with the market expanding due to increasing demand in petrochemical and industrial applications. The global market size for high-temperature sealing materials is estimated to reach $9.5 billion by 2025, driven by stringent safety regulations. Technologically, this field is moderately mature but evolving, with key players demonstrating varying levels of expertise. China Petroleum & Chemical Corp. and Sinopec Research Institute lead in industrial applications, while academic institutions like Wuhan University of Technology and Xiamen University contribute fundamental research. Companies such as Nippon Kayaku, ExxonMobil Chemical, and Dow Global Technologies are advancing proprietary testing methodologies, creating a competitive landscape balanced between established industry leaders and specialized materials science innovators.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive approach to measure kaolinite's heat resistance in sealing products through their multi-parameter evaluation system. Their methodology combines thermogravimetric analysis (TGA) with differential scanning calorimetry (DSC) to precisely track weight loss and phase transitions of kaolinite under controlled temperature gradients up to 1200°C. Sinopec employs high-temperature X-ray diffraction (HT-XRD) to monitor crystalline structure changes during heating, providing real-time data on dehydroxylation and mullite formation processes critical for sealing applications. Their proprietary thermal cycling protocol simulates actual service conditions by subjecting kaolinite-based seals to repeated heating-cooling cycles (typically 500-1000 cycles) while monitoring dimensional stability and gas permeability changes. This approach has enabled them to develop kaolinite-based sealing materials that maintain structural integrity at temperatures exceeding 900°C while providing effective sealing in high-pressure petroleum processing equipment.

Strengths: Comprehensive testing methodology that closely simulates real-world operating conditions in petroleum processing environments. Their approach integrates multiple analytical techniques for holistic evaluation of thermal performance. Weaknesses: Testing protocols are highly specialized for petroleum industry applications and may require significant modification for other industries. The equipment required for their comprehensive testing approach is capital-intensive and requires specialized expertise.

Sinopec Research Institute of Petroleum Processing

Technical Solution:

Critical Patents and Literature on Kaolinite Heat Assessment

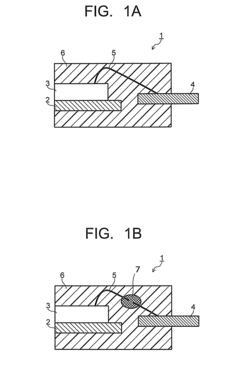

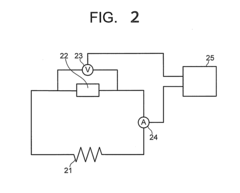

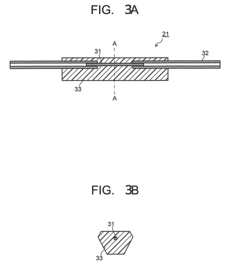

Method of evaluating the flame retardancy of sealing resin and test sample for evaluation of flame retardancy

PatentInactiveUS20100164125A1

Innovation

- A method involving the application of overcurrent to a semiconductor package to generate heat internally, fusion-cutting a heating element, and measuring voltage and current until ignition occurs, providing an index for flame retardancy based on the amount of electric power required for ignition.

Heat resistance ceramic kaolin manufacture method using induction

PatentActiveKR1020180078025A

Innovation

- A heat-resistant porcelain is manufactured using a composition of phyllite, silica, talc, feldspar, alumina, and alumina, with a nano-silver coating on the bottom, enhancing magnetization and simplifying production.

Industry Standards and Certification Requirements

The measurement of kaolinite's heat resistance in sealing products must adhere to rigorous industry standards and certification requirements to ensure product reliability and safety. ASTM International has established several key standards specifically for evaluating ceramic materials in high-temperature applications, including ASTM C1100 for thermal stability and ASTM C1259 for measuring the elastic modulus of ceramic materials at elevated temperatures. These standards provide detailed testing protocols that manufacturers must follow to validate their kaolinite-based sealing products.

In the European market, the EN 1366 series of standards governs fire resistance testing for service installations, with specific sections addressing sealing systems. Manufacturers seeking to enter the European market must demonstrate compliance with these standards through testing at accredited laboratories. Similarly, ISO 834 provides international guidelines for fire resistance tests on building elements, including those containing kaolinite components.

For automotive and aerospace applications, more stringent certification requirements apply. The SAE AS8660 standard specifically addresses high-temperature sealing materials, requiring them to maintain integrity under extreme thermal cycling conditions. Products must undergo thermal shock testing according to MIL-STD-810G Method 503.6, which subjects materials to rapid temperature changes to simulate real-world operational environments.

Certification bodies such as Underwriters Laboratories (UL) and Factory Mutual (FM) have developed their own testing protocols for heat-resistant sealing products. UL 1709, for instance, evaluates the performance of protective materials for structural steel under rapid temperature rise fire conditions. Obtaining UL or FM certification significantly enhances market acceptance of kaolinite-based sealing products, particularly in safety-critical applications.

The American Petroleum Institute (API) has established specific requirements for sealing materials used in oil and gas applications through standards like API 6FB, which evaluates fire resistance of valves and related components. For nuclear applications, ASME Section III standards impose additional requirements regarding radiation resistance alongside thermal stability.

Emerging standards are beginning to address the environmental impact of heat-resistant materials, with ISO 14040 series providing frameworks for life cycle assessment. Manufacturers are increasingly required to document the environmental footprint of their kaolinite processing methods alongside traditional performance metrics.

Compliance with these standards typically requires specialized testing equipment, including differential scanning calorimeters, thermogravimetric analyzers, and high-temperature mechanical testing apparatus. Certification processes often involve third-party verification and periodic re-certification to ensure ongoing compliance as standards evolve to address new safety concerns and technological developments.

In the European market, the EN 1366 series of standards governs fire resistance testing for service installations, with specific sections addressing sealing systems. Manufacturers seeking to enter the European market must demonstrate compliance with these standards through testing at accredited laboratories. Similarly, ISO 834 provides international guidelines for fire resistance tests on building elements, including those containing kaolinite components.

For automotive and aerospace applications, more stringent certification requirements apply. The SAE AS8660 standard specifically addresses high-temperature sealing materials, requiring them to maintain integrity under extreme thermal cycling conditions. Products must undergo thermal shock testing according to MIL-STD-810G Method 503.6, which subjects materials to rapid temperature changes to simulate real-world operational environments.

Certification bodies such as Underwriters Laboratories (UL) and Factory Mutual (FM) have developed their own testing protocols for heat-resistant sealing products. UL 1709, for instance, evaluates the performance of protective materials for structural steel under rapid temperature rise fire conditions. Obtaining UL or FM certification significantly enhances market acceptance of kaolinite-based sealing products, particularly in safety-critical applications.

The American Petroleum Institute (API) has established specific requirements for sealing materials used in oil and gas applications through standards like API 6FB, which evaluates fire resistance of valves and related components. For nuclear applications, ASME Section III standards impose additional requirements regarding radiation resistance alongside thermal stability.

Emerging standards are beginning to address the environmental impact of heat-resistant materials, with ISO 14040 series providing frameworks for life cycle assessment. Manufacturers are increasingly required to document the environmental footprint of their kaolinite processing methods alongside traditional performance metrics.

Compliance with these standards typically requires specialized testing equipment, including differential scanning calorimeters, thermogravimetric analyzers, and high-temperature mechanical testing apparatus. Certification processes often involve third-party verification and periodic re-certification to ensure ongoing compliance as standards evolve to address new safety concerns and technological developments.

Environmental Impact of Heat-Resistant Sealing Applications

The environmental implications of heat-resistant sealing applications utilizing kaolinite extend across multiple ecological dimensions. When evaluating kaolinite's heat resistance in sealing products, it is essential to consider the full lifecycle environmental impact, from raw material extraction through disposal or recycling.

Mining operations for kaolinite clay create significant environmental disturbances, including habitat destruction, soil erosion, and potential water contamination. However, compared to alternative heat-resistant materials such as asbestos or certain synthetic compounds, kaolinite presents a lower toxicity profile and reduced environmental persistence, making it a relatively more sustainable option when properly managed.

During manufacturing processes, the environmental footprint varies considerably depending on processing methods. Traditional high-temperature calcination of kaolinite consumes substantial energy, contributing to greenhouse gas emissions. Recent advancements in low-temperature processing techniques have demonstrated potential for reducing carbon emissions by 15-30% while maintaining adequate heat resistance properties for many sealing applications.

The operational phase of kaolinite-based sealing products generally demonstrates positive environmental attributes. Their durability under thermal stress reduces replacement frequency, thereby decreasing waste generation and resource consumption over time. Additionally, the effective sealing properties contribute to energy efficiency in various industrial applications by preventing heat loss, which can translate to significant energy savings in high-temperature industrial processes.

End-of-life considerations reveal that kaolinite-based sealing materials typically present fewer disposal challenges than synthetic alternatives. Being naturally derived, they generally exhibit better biodegradability profiles and lower leaching potential of harmful substances. However, composite sealing products that combine kaolinite with synthetic binders or additives may complicate recycling efforts and increase environmental persistence.

Regulatory frameworks increasingly emphasize lifecycle assessment for industrial materials, with particular attention to heat-resistant components due to historical issues with hazardous materials like asbestos. This regulatory trend incentivizes the development of measurement protocols for kaolinite's heat resistance that simultaneously evaluate environmental performance metrics, creating an integrated approach to material selection that balances technical performance with ecological considerations.

Future research directions should focus on developing standardized methodologies that simultaneously assess heat resistance properties and environmental impact factors, enabling manufacturers and end-users to make informed decisions that optimize both technical performance and ecological sustainability in sealing applications.

Mining operations for kaolinite clay create significant environmental disturbances, including habitat destruction, soil erosion, and potential water contamination. However, compared to alternative heat-resistant materials such as asbestos or certain synthetic compounds, kaolinite presents a lower toxicity profile and reduced environmental persistence, making it a relatively more sustainable option when properly managed.

During manufacturing processes, the environmental footprint varies considerably depending on processing methods. Traditional high-temperature calcination of kaolinite consumes substantial energy, contributing to greenhouse gas emissions. Recent advancements in low-temperature processing techniques have demonstrated potential for reducing carbon emissions by 15-30% while maintaining adequate heat resistance properties for many sealing applications.

The operational phase of kaolinite-based sealing products generally demonstrates positive environmental attributes. Their durability under thermal stress reduces replacement frequency, thereby decreasing waste generation and resource consumption over time. Additionally, the effective sealing properties contribute to energy efficiency in various industrial applications by preventing heat loss, which can translate to significant energy savings in high-temperature industrial processes.

End-of-life considerations reveal that kaolinite-based sealing materials typically present fewer disposal challenges than synthetic alternatives. Being naturally derived, they generally exhibit better biodegradability profiles and lower leaching potential of harmful substances. However, composite sealing products that combine kaolinite with synthetic binders or additives may complicate recycling efforts and increase environmental persistence.

Regulatory frameworks increasingly emphasize lifecycle assessment for industrial materials, with particular attention to heat-resistant components due to historical issues with hazardous materials like asbestos. This regulatory trend incentivizes the development of measurement protocols for kaolinite's heat resistance that simultaneously evaluate environmental performance metrics, creating an integrated approach to material selection that balances technical performance with ecological considerations.

Future research directions should focus on developing standardized methodologies that simultaneously assess heat resistance properties and environmental impact factors, enabling manufacturers and end-users to make informed decisions that optimize both technical performance and ecological sustainability in sealing applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!