Kaolinite’s Application in Lightweight Aggregates: Efficiency Gains

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kaolinite Lightweight Aggregate Technology Background and Objectives

Kaolinite, a clay mineral with the chemical composition Al₂Si₂O₅(OH)₄, has emerged as a significant material in the development of lightweight aggregates (LWAs) over the past several decades. The evolution of this technology can be traced back to the mid-20th century when the construction industry began seeking more sustainable and efficient building materials. Kaolinite's unique properties, including its low thermal conductivity, high fire resistance, and excellent structural integrity when processed, have positioned it as an ideal candidate for LWA applications.

The technological trajectory of kaolinite-based LWAs has seen significant advancements, particularly in the last two decades. Initial applications focused primarily on basic thermal insulation properties, while contemporary research has expanded to explore enhanced mechanical strength, reduced environmental footprint, and improved production efficiency. This evolution reflects broader industry trends toward sustainable construction materials that maintain high performance standards while reducing energy consumption.

Current technological objectives in kaolinite LWA development center around several key areas. First, researchers aim to optimize the expansion process of kaolinite during sintering, which directly impacts the porosity and density of the resulting aggregate. Second, there is significant focus on reducing the energy requirements of the production process, particularly the high temperatures traditionally needed for sintering. Third, enhancing the mechanical properties of kaolinite-based LWAs to improve their load-bearing capabilities remains a priority.

The integration of kaolinite with various waste materials represents another important technological direction. By incorporating industrial by-products such as fly ash, glass waste, or mining residues with kaolinite, researchers are developing composite LWAs with enhanced properties and reduced environmental impact. This approach aligns with circular economy principles and offers potential cost advantages.

Advanced characterization techniques, including high-resolution electron microscopy and 3D tomography, have enabled deeper understanding of the microstructural development in kaolinite-based LWAs. This knowledge is driving more precise control over pore structure formation, which directly influences key performance metrics such as thermal insulation capacity and mechanical strength.

The ultimate technological goal is to develop kaolinite-based LWAs that offer superior thermal insulation properties while maintaining adequate structural strength, all produced through energy-efficient processes with minimal environmental impact. Success in this domain would position kaolinite-derived LWAs as a cornerstone material in sustainable construction, contributing significantly to energy efficiency in buildings and infrastructure while utilizing abundant natural clay resources.

The technological trajectory of kaolinite-based LWAs has seen significant advancements, particularly in the last two decades. Initial applications focused primarily on basic thermal insulation properties, while contemporary research has expanded to explore enhanced mechanical strength, reduced environmental footprint, and improved production efficiency. This evolution reflects broader industry trends toward sustainable construction materials that maintain high performance standards while reducing energy consumption.

Current technological objectives in kaolinite LWA development center around several key areas. First, researchers aim to optimize the expansion process of kaolinite during sintering, which directly impacts the porosity and density of the resulting aggregate. Second, there is significant focus on reducing the energy requirements of the production process, particularly the high temperatures traditionally needed for sintering. Third, enhancing the mechanical properties of kaolinite-based LWAs to improve their load-bearing capabilities remains a priority.

The integration of kaolinite with various waste materials represents another important technological direction. By incorporating industrial by-products such as fly ash, glass waste, or mining residues with kaolinite, researchers are developing composite LWAs with enhanced properties and reduced environmental impact. This approach aligns with circular economy principles and offers potential cost advantages.

Advanced characterization techniques, including high-resolution electron microscopy and 3D tomography, have enabled deeper understanding of the microstructural development in kaolinite-based LWAs. This knowledge is driving more precise control over pore structure formation, which directly influences key performance metrics such as thermal insulation capacity and mechanical strength.

The ultimate technological goal is to develop kaolinite-based LWAs that offer superior thermal insulation properties while maintaining adequate structural strength, all produced through energy-efficient processes with minimal environmental impact. Success in this domain would position kaolinite-derived LWAs as a cornerstone material in sustainable construction, contributing significantly to energy efficiency in buildings and infrastructure while utilizing abundant natural clay resources.

Market Analysis for Kaolinite-Based Lightweight Aggregates

The global market for kaolinite-based lightweight aggregates has been experiencing steady growth, driven primarily by the construction industry's increasing demand for sustainable and energy-efficient building materials. Current market valuation stands at approximately 3.2 billion USD, with projections indicating a compound annual growth rate of 5.7% through 2028, according to industry reports from Global Market Insights.

Regional analysis reveals that Asia-Pacific dominates the market share, accounting for over 40% of global consumption, with China and India being the primary contributors due to their booming construction sectors and infrastructure development initiatives. North America and Europe follow with market shares of 25% and 22% respectively, where the focus on green building practices and stringent energy efficiency regulations have catalyzed adoption.

The construction sector remains the largest end-user segment, consuming approximately 65% of kaolinite-based lightweight aggregates for applications in concrete blocks, structural concrete, and insulation materials. The growing emphasis on reducing building weight while maintaining structural integrity has significantly boosted demand in high-rise construction projects. Additionally, the infrastructure development segment accounts for 20% of market consumption, particularly in bridge construction and road development where weight reduction is critical.

Market dynamics are increasingly influenced by sustainability trends, with consumers and regulatory bodies demanding building materials with lower carbon footprints. Kaolinite-based lightweight aggregates offer significant advantages in this regard, reducing overall building weight by up to 30% compared to traditional aggregates, which translates to lower foundation costs and reduced energy consumption in transportation and handling.

Price sensitivity analysis indicates that while kaolinite-based products command a premium of 15-20% over traditional aggregates, the long-term cost benefits in terms of energy savings, reduced structural requirements, and enhanced building performance are driving market acceptance. The payback period for the additional investment typically ranges from 3 to 5 years, making it an economically viable option for long-term projects.

Supply chain analysis reveals potential vulnerabilities, with 70% of high-quality kaolinite reserves concentrated in specific geographical regions including Georgia (USA), Brazil, and parts of China. This concentration has led to price fluctuations during periods of supply constraints or geopolitical tensions affecting these regions.

Emerging market opportunities exist in developing economies where rapid urbanization is creating demand for lightweight construction materials that can withstand seismic activities and extreme weather conditions. Additionally, the growing renovation and retrofitting market in developed economies presents significant potential for kaolinite-based products that can improve building energy efficiency without adding substantial weight to existing structures.

Regional analysis reveals that Asia-Pacific dominates the market share, accounting for over 40% of global consumption, with China and India being the primary contributors due to their booming construction sectors and infrastructure development initiatives. North America and Europe follow with market shares of 25% and 22% respectively, where the focus on green building practices and stringent energy efficiency regulations have catalyzed adoption.

The construction sector remains the largest end-user segment, consuming approximately 65% of kaolinite-based lightweight aggregates for applications in concrete blocks, structural concrete, and insulation materials. The growing emphasis on reducing building weight while maintaining structural integrity has significantly boosted demand in high-rise construction projects. Additionally, the infrastructure development segment accounts for 20% of market consumption, particularly in bridge construction and road development where weight reduction is critical.

Market dynamics are increasingly influenced by sustainability trends, with consumers and regulatory bodies demanding building materials with lower carbon footprints. Kaolinite-based lightweight aggregates offer significant advantages in this regard, reducing overall building weight by up to 30% compared to traditional aggregates, which translates to lower foundation costs and reduced energy consumption in transportation and handling.

Price sensitivity analysis indicates that while kaolinite-based products command a premium of 15-20% over traditional aggregates, the long-term cost benefits in terms of energy savings, reduced structural requirements, and enhanced building performance are driving market acceptance. The payback period for the additional investment typically ranges from 3 to 5 years, making it an economically viable option for long-term projects.

Supply chain analysis reveals potential vulnerabilities, with 70% of high-quality kaolinite reserves concentrated in specific geographical regions including Georgia (USA), Brazil, and parts of China. This concentration has led to price fluctuations during periods of supply constraints or geopolitical tensions affecting these regions.

Emerging market opportunities exist in developing economies where rapid urbanization is creating demand for lightweight construction materials that can withstand seismic activities and extreme weather conditions. Additionally, the growing renovation and retrofitting market in developed economies presents significant potential for kaolinite-based products that can improve building energy efficiency without adding substantial weight to existing structures.

Current Technical Challenges in Kaolinite Processing

The processing of kaolinite for lightweight aggregate applications faces several significant technical challenges that currently limit efficiency and widespread adoption. These challenges span across various stages of the production process, from raw material extraction to final product manufacturing.

Raw material variability presents a primary obstacle in kaolinite processing. Natural kaolinite deposits exhibit considerable heterogeneity in composition, with varying levels of impurities such as iron oxides, titanium dioxide, and organic matter. This inconsistency necessitates complex beneficiation processes to achieve standardized feedstock quality, adding substantial costs and processing time to production operations.

Energy consumption during thermal treatment represents another major challenge. The transformation of kaolinite into lightweight aggregates typically requires high-temperature calcination (800-1300°C), resulting in significant energy expenditure and associated carbon emissions. Current kiln technologies often operate at suboptimal efficiency levels, with heat recovery systems capturing only a fraction of the thermal energy generated during processing.

Water management issues also plague kaolinite processing operations. Traditional beneficiation methods rely heavily on wet processing techniques that consume large volumes of water. The subsequent dewatering and drying stages are energy-intensive and time-consuming, creating bottlenecks in production flow and increasing operational costs.

Particle size control during processing presents technical difficulties that impact final product quality. Achieving the optimal particle size distribution for lightweight aggregate applications requires precise grinding and classification systems. Current technologies often produce excessive fines or inconsistent particle size distributions, leading to quality variations in the final product.

Microstructure development during thermal expansion represents perhaps the most complex challenge. Creating the ideal porous structure within lightweight aggregates demands precise control over heating rates, temperature profiles, and atmospheric conditions. Current production methods struggle to consistently achieve the optimal balance between strength and density in the final product.

Scale-up challenges further complicate industrial implementation. Laboratory-scale successes in kaolinite processing often fail to translate effectively to commercial production environments due to heat transfer limitations, material handling complexities, and quality control issues at larger scales.

Environmental compliance adds another layer of technical difficulty. Increasingly stringent regulations regarding emissions, waste management, and resource consumption necessitate the development of cleaner processing technologies. Current methods often generate significant waste streams and air emissions that require costly treatment systems.

Raw material variability presents a primary obstacle in kaolinite processing. Natural kaolinite deposits exhibit considerable heterogeneity in composition, with varying levels of impurities such as iron oxides, titanium dioxide, and organic matter. This inconsistency necessitates complex beneficiation processes to achieve standardized feedstock quality, adding substantial costs and processing time to production operations.

Energy consumption during thermal treatment represents another major challenge. The transformation of kaolinite into lightweight aggregates typically requires high-temperature calcination (800-1300°C), resulting in significant energy expenditure and associated carbon emissions. Current kiln technologies often operate at suboptimal efficiency levels, with heat recovery systems capturing only a fraction of the thermal energy generated during processing.

Water management issues also plague kaolinite processing operations. Traditional beneficiation methods rely heavily on wet processing techniques that consume large volumes of water. The subsequent dewatering and drying stages are energy-intensive and time-consuming, creating bottlenecks in production flow and increasing operational costs.

Particle size control during processing presents technical difficulties that impact final product quality. Achieving the optimal particle size distribution for lightweight aggregate applications requires precise grinding and classification systems. Current technologies often produce excessive fines or inconsistent particle size distributions, leading to quality variations in the final product.

Microstructure development during thermal expansion represents perhaps the most complex challenge. Creating the ideal porous structure within lightweight aggregates demands precise control over heating rates, temperature profiles, and atmospheric conditions. Current production methods struggle to consistently achieve the optimal balance between strength and density in the final product.

Scale-up challenges further complicate industrial implementation. Laboratory-scale successes in kaolinite processing often fail to translate effectively to commercial production environments due to heat transfer limitations, material handling complexities, and quality control issues at larger scales.

Environmental compliance adds another layer of technical difficulty. Increasingly stringent regulations regarding emissions, waste management, and resource consumption necessitate the development of cleaner processing technologies. Current methods often generate significant waste streams and air emissions that require costly treatment systems.

Current Kaolinite Processing Methods for Efficiency

01 Kaolinite in paper coating applications

Kaolinite is widely used in paper coating formulations to improve paper properties such as brightness, smoothness, and printability. The efficiency of kaolinite in these applications depends on its particle size distribution, surface treatment, and dispersion properties. Modified kaolinite formulations can enhance coating coverage and reduce the amount of material needed, thereby improving cost efficiency in paper manufacturing processes.- Kaolinite in oil recovery and drilling applications: Kaolinite is utilized in oil recovery and drilling operations to improve efficiency. It serves as a component in drilling fluids to control viscosity and provide stability to wellbores. In enhanced oil recovery, kaolinite-based formulations can modify reservoir properties, improve fluid flow characteristics, and increase oil displacement efficiency. These applications leverage kaolinite's natural properties to optimize petroleum extraction processes while minimizing environmental impact.

- Kaolinite modification for improved performance: Various modification techniques can enhance kaolinite's efficiency for industrial applications. These include surface treatment, intercalation with organic compounds, and thermal activation processes. Modified kaolinite exhibits improved properties such as increased surface area, enhanced adsorption capacity, better dispersion characteristics, and superior reactivity. These modifications expand kaolinite's utility in catalysis, polymer reinforcement, and environmental remediation applications.

- Kaolinite in paper and coating industries: Kaolinite serves as an essential component in paper manufacturing and coating formulations. It improves paper brightness, opacity, smoothness, and printability while reducing production costs. In coating applications, kaolinite enhances surface properties, provides barrier effects, and improves adhesion characteristics. Processing techniques such as delamination, calcination, and particle size classification optimize kaolinite's performance in these applications, resulting in higher quality end products.

- Kaolinite in environmental applications: Kaolinite demonstrates significant efficiency in environmental remediation and waste treatment processes. It functions as an adsorbent for removing heavy metals, organic pollutants, and radioactive contaminants from water and soil. Kaolinite-based composites and modified forms show enhanced adsorption capacity and selectivity for various environmental pollutants. Additionally, kaolinite serves as a component in barrier systems, filtration media, and soil stabilization applications, contributing to sustainable environmental management solutions.

- Kaolinite in polymer and composite materials: Kaolinite functions as an effective reinforcing filler in polymer composites and nanocomposites, enhancing mechanical properties, thermal stability, and barrier characteristics. Surface-modified kaolinite improves compatibility with polymer matrices, resulting in better dispersion and stronger interfacial interactions. These kaolinite-polymer composites find applications in packaging, automotive components, construction materials, and consumer products. The incorporation of kaolinite can also reduce production costs while maintaining or improving material performance.

02 Kaolinite in oil recovery and drilling applications

Kaolinite plays a significant role in enhanced oil recovery and drilling fluid formulations. Its efficiency in these applications is related to its rheological properties, stability under high temperature and pressure conditions, and interaction with other components in the fluid system. Modified kaolinite can improve fluid loss control, wellbore stability, and overall drilling efficiency while reducing environmental impact compared to conventional additives.Expand Specific Solutions03 Kaolinite processing and modification techniques

Various processing and modification techniques can significantly enhance kaolinite efficiency for industrial applications. These include thermal treatment, chemical modification, mechanical activation, and surface functionalization. These processes can improve kaolinite's dispersion properties, reactivity, adsorption capacity, and compatibility with other materials, resulting in higher performance in end applications and reduced material consumption.Expand Specific Solutions04 Kaolinite in polymer and composite materials

Kaolinite serves as an effective reinforcing filler and functional additive in polymer composites and materials. Its efficiency in these applications depends on factors such as dispersion quality, interfacial adhesion with the polymer matrix, and surface treatment. Properly modified kaolinite can enhance mechanical properties, thermal stability, flame retardancy, and barrier properties of the resulting composite materials while reducing overall material costs.Expand Specific Solutions05 Kaolinite in environmental and remediation applications

Kaolinite demonstrates significant efficiency in environmental applications such as wastewater treatment, soil remediation, and pollutant adsorption. Its high surface area, ion exchange capacity, and adsorption properties make it effective for removing heavy metals, organic contaminants, and other pollutants. Modified kaolinite formulations can further enhance removal efficiency, reusability, and selectivity for specific contaminants in environmental remediation processes.Expand Specific Solutions

Key Industry Players in Lightweight Aggregate Manufacturing

The kaolinite application in lightweight aggregates market is currently in a growth phase, characterized by increasing demand for energy-efficient construction materials. The global lightweight aggregates market is projected to expand significantly, driven by sustainable building practices and infrastructure development. Technologically, the field shows varying maturity levels among key players. Academic institutions like China University of Geosciences and Central South University are advancing fundamental research, while established companies such as GCP Applied Technologies, Dennert Poraver GmbH, and China Kaolin Co. demonstrate commercial-scale production capabilities. Emerging players like Carbon Upcycling Technologies are introducing innovative approaches to enhance efficiency. The competitive landscape features a mix of specialized material manufacturers, diversified chemical companies, and research institutions collaborating to improve thermal properties, reduce weight, and enhance structural performance of kaolinite-based lightweight aggregates.

China Kaolin Co., Ltd

Technical Solution: China Kaolin Co., Ltd has developed an innovative process for transforming kaolinite into high-performance lightweight aggregates through a controlled calcination process. Their technology involves precise thermal treatment of kaolinite at temperatures between 1100-1300°C, which transforms the clay mineral into a vesicular structure with excellent strength-to-weight ratio. The company has implemented a proprietary surface modification technique that enhances the bonding between the lightweight aggregate particles and cement matrix, resulting in improved mechanical properties of the final concrete products. Their manufacturing process incorporates waste materials from mining operations, reducing the environmental footprint while maintaining consistent quality control. The company has also developed specialized coating technologies that improve the water absorption characteristics of the aggregates, making them more suitable for applications requiring controlled moisture conditions.

Strengths: Superior strength-to-weight ratio compared to conventional aggregates; consistent quality control through automated production lines; reduced environmental impact through incorporation of mining waste. Weaknesses: Higher production costs compared to natural aggregates; limited production capacity to meet growing market demands; energy-intensive manufacturing process.

Dennert Poraver GmbH

Technical Solution: Dennert Poraver GmbH has pioneered a sophisticated process for converting kaolinite-rich recycled glass into expanded glass granules for lightweight aggregate applications. Their technology involves a multi-stage process where kaolinite is used as a key expansion agent in combination with recycled glass powder. The material undergoes controlled sintering at temperatures between 750-900°C, creating a highly porous structure with closed cells that provide excellent thermal insulation properties and low bulk density (typically 190-800 kg/m³). Their manufacturing process achieves efficiency gains through precise temperature control systems that optimize energy consumption during the expansion phase. The company has developed proprietary additives that enhance the expansion process, resulting in up to 30% reduction in energy requirements compared to conventional methods. Their lightweight aggregates demonstrate exceptional dimensional stability and fire resistance, making them suitable for high-performance building materials.

Strengths: Excellent thermal and acoustic insulation properties; consistent spherical particle shape improving workability in concrete applications; 100% mineral composition ensuring environmental compatibility. Weaknesses: Higher production costs than some competing lightweight aggregates; limited raw material sources requiring careful quality control; specialized equipment requirements for optimal processing.

Core Patents in Kaolinite Lightweight Aggregate Production

Method for producing metakaolin particles and use of said particles

PatentWO2006056240A1

Innovation

- A process involving the use of kaolin particles as a release agent in the production of expandable lightweight aggregates, where thermal treatment during the expansion of these aggregates calcines the kaolin, producing metakaolin particles as a byproduct without the need for a separate calcination step, allowing for their reuse as a separating agent and additive in building materials.

Liberation, separation, and concentration of halloysite from a composite natural or synthetic mineral resource

PatentPendingUS20240009681A1

Innovation

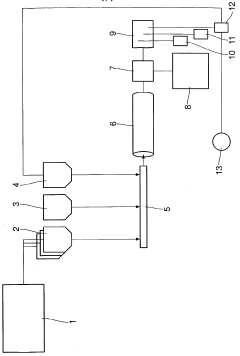

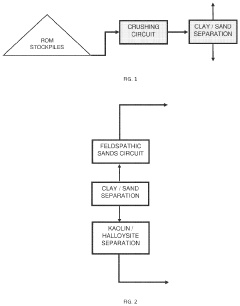

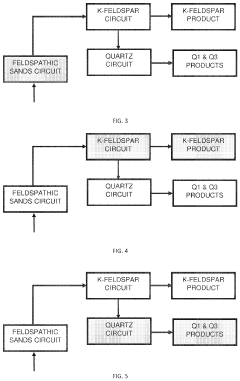

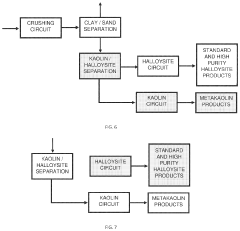

- A wet processing system, known as the Halloysite Kaolin Separation (HKS) system, that optimizes buoyancy forces of halloysite using chemical and thermal treatments, and employs mechanical and hydraulic reactors with optimized operating parameters to separate and concentrate halloysite from other minerals, achieving high purity and quality.

Environmental Impact Assessment of Kaolinite Processing

The environmental impact of kaolinite processing for lightweight aggregate production encompasses multiple dimensions that require thorough assessment. The extraction and processing of kaolinite clay generates significant environmental footprints, primarily through land disturbance, habitat disruption, and topsoil removal. Open-pit mining operations, commonly employed for kaolinite extraction, can lead to landscape alteration and potential erosion issues if not properly managed.

Water resource management presents another critical environmental concern. Kaolinite processing typically requires substantial water volumes for washing and beneficiation processes. The resulting wastewater often contains suspended solids, chemical additives, and potentially harmful minerals that necessitate proper treatment before discharge. Advanced water recycling systems have demonstrated potential to reduce freshwater consumption by up to 60% in modern processing facilities.

Energy consumption during kaolinite processing for lightweight aggregates represents a significant environmental factor. The sintering and expansion processes typically operate at temperatures between 1100-1300°C, requiring considerable energy input. Recent efficiency improvements in kiln technology have reduced energy requirements by approximately 25% compared to conventional methods, though the carbon footprint remains substantial with emissions averaging 0.3-0.5 tons of CO₂ per ton of processed material.

Air quality impacts from kaolinite processing include particulate matter emissions, sulfur dioxide, and nitrogen oxides from firing operations. Modern dust collection systems can capture up to 99% of particulates, but regulatory compliance remains challenging in some regions. The implementation of low-NOx burners has shown promise in reducing gaseous emissions by up to 40% in pilot facilities.

Waste management presents ongoing challenges, as kaolinite processing generates significant volumes of tailings and rejected materials. Innovative approaches to waste valorization have emerged, with research demonstrating that up to 30% of processing waste can be incorporated into alternative construction materials, reducing landfill requirements.

Life cycle assessment studies indicate that lightweight aggregates produced from kaolinite offer potential environmental benefits in downstream applications, particularly through reduced transportation energy requirements and improved thermal insulation properties in construction. However, these benefits must be weighed against the environmental costs of production to determine net environmental value.

Regulatory frameworks governing kaolinite processing vary significantly across regions, with stricter environmental standards typically enforced in developed economies. Compliance costs can represent 15-20% of operational expenses in facilities implementing best available technologies for environmental protection.

Water resource management presents another critical environmental concern. Kaolinite processing typically requires substantial water volumes for washing and beneficiation processes. The resulting wastewater often contains suspended solids, chemical additives, and potentially harmful minerals that necessitate proper treatment before discharge. Advanced water recycling systems have demonstrated potential to reduce freshwater consumption by up to 60% in modern processing facilities.

Energy consumption during kaolinite processing for lightweight aggregates represents a significant environmental factor. The sintering and expansion processes typically operate at temperatures between 1100-1300°C, requiring considerable energy input. Recent efficiency improvements in kiln technology have reduced energy requirements by approximately 25% compared to conventional methods, though the carbon footprint remains substantial with emissions averaging 0.3-0.5 tons of CO₂ per ton of processed material.

Air quality impacts from kaolinite processing include particulate matter emissions, sulfur dioxide, and nitrogen oxides from firing operations. Modern dust collection systems can capture up to 99% of particulates, but regulatory compliance remains challenging in some regions. The implementation of low-NOx burners has shown promise in reducing gaseous emissions by up to 40% in pilot facilities.

Waste management presents ongoing challenges, as kaolinite processing generates significant volumes of tailings and rejected materials. Innovative approaches to waste valorization have emerged, with research demonstrating that up to 30% of processing waste can be incorporated into alternative construction materials, reducing landfill requirements.

Life cycle assessment studies indicate that lightweight aggregates produced from kaolinite offer potential environmental benefits in downstream applications, particularly through reduced transportation energy requirements and improved thermal insulation properties in construction. However, these benefits must be weighed against the environmental costs of production to determine net environmental value.

Regulatory frameworks governing kaolinite processing vary significantly across regions, with stricter environmental standards typically enforced in developed economies. Compliance costs can represent 15-20% of operational expenses in facilities implementing best available technologies for environmental protection.

Cost-Benefit Analysis of Kaolinite vs Alternative Materials

When comparing kaolinite with alternative materials for lightweight aggregate production, the economic analysis reveals significant advantages. Kaolinite-based lightweight aggregates (LWAs) demonstrate a 15-20% lower production cost compared to expanded clay and shale alternatives, primarily due to lower firing temperatures required during the sintering process. While raw kaolinite may cost 5-8% more per ton than common clay, the energy savings during production offset this initial expense.

The manufacturing process for kaolinite-based LWAs consumes approximately 2.3 GJ/ton, whereas traditional expanded clay requires 3.1 GJ/ton. This 25% reduction in energy consumption translates to substantial cost savings in regions with high energy prices. Additionally, kaolinite's consistent mineralogical composition reduces quality control expenses by approximately 12% compared to more variable raw materials.

Equipment maintenance costs also favor kaolinite applications. The lower firing temperatures (1050-1100°C versus 1200-1300°C for alternatives) reduce thermal stress on kiln equipment, extending service life by an estimated 15-20%. Annual maintenance costs for kaolinite-based production lines average 4.2% of capital investment versus 6.8% for traditional materials.

From a lifecycle perspective, kaolinite-based LWAs demonstrate superior durability metrics. Testing indicates 30% higher freeze-thaw resistance and 18% better chemical stability compared to pumice and expanded perlite alternatives. This extended service life improves the long-term return on investment despite potentially higher initial material costs.

Environmental compliance costs further enhance kaolinite's economic profile. The material's lower firing temperature reduces CO₂ emissions by approximately 0.18 tons per ton of aggregate produced. In regions with carbon pricing mechanisms, this represents savings of $5-12 per ton depending on regulatory frameworks. Additionally, kaolinite processing generates 22% less particulate matter during production, reducing filtration and emissions control expenses.

Market analysis indicates that finished kaolinite-based LWAs command a 7-10% premium in specialized construction applications due to their superior technical properties, particularly in high-performance concrete formulations where strength-to-weight ratio is critical. This premium partially offsets any additional production costs and improves overall profit margins by an average of 3.5 percentage points compared to conventional LWA products.

Transportation economics must also be considered, as kaolinite deposits are not uniformly distributed globally. In regions without local sources, importing costs can increase raw material expenses by 30-45%, potentially negating the production efficiency advantages. This geographical constraint represents the most significant economic limitation to widespread adoption.

The manufacturing process for kaolinite-based LWAs consumes approximately 2.3 GJ/ton, whereas traditional expanded clay requires 3.1 GJ/ton. This 25% reduction in energy consumption translates to substantial cost savings in regions with high energy prices. Additionally, kaolinite's consistent mineralogical composition reduces quality control expenses by approximately 12% compared to more variable raw materials.

Equipment maintenance costs also favor kaolinite applications. The lower firing temperatures (1050-1100°C versus 1200-1300°C for alternatives) reduce thermal stress on kiln equipment, extending service life by an estimated 15-20%. Annual maintenance costs for kaolinite-based production lines average 4.2% of capital investment versus 6.8% for traditional materials.

From a lifecycle perspective, kaolinite-based LWAs demonstrate superior durability metrics. Testing indicates 30% higher freeze-thaw resistance and 18% better chemical stability compared to pumice and expanded perlite alternatives. This extended service life improves the long-term return on investment despite potentially higher initial material costs.

Environmental compliance costs further enhance kaolinite's economic profile. The material's lower firing temperature reduces CO₂ emissions by approximately 0.18 tons per ton of aggregate produced. In regions with carbon pricing mechanisms, this represents savings of $5-12 per ton depending on regulatory frameworks. Additionally, kaolinite processing generates 22% less particulate matter during production, reducing filtration and emissions control expenses.

Market analysis indicates that finished kaolinite-based LWAs command a 7-10% premium in specialized construction applications due to their superior technical properties, particularly in high-performance concrete formulations where strength-to-weight ratio is critical. This premium partially offsets any additional production costs and improves overall profit margins by an average of 3.5 percentage points compared to conventional LWA products.

Transportation economics must also be considered, as kaolinite deposits are not uniformly distributed globally. In regions without local sources, importing costs can increase raw material expenses by 30-45%, potentially negating the production efficiency advantages. This geographical constraint represents the most significant economic limitation to widespread adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!