Evaluate Kaolinite’s Role in Cementitious Materials for Strength

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Kaolinite in Cementitious Materials: Background and Objectives

Kaolinite, a clay mineral with the chemical composition Al₂Si₂O₅(OH)₄, has emerged as a significant component in cementitious materials research over the past several decades. The evolution of this technology can be traced back to the 1970s when researchers began exploring alternative supplementary cementitious materials (SCMs) to reduce the environmental impact of traditional Portland cement production, which accounts for approximately 8% of global CO₂ emissions.

The technological trajectory of kaolinite in cementitious applications has accelerated significantly since the early 2000s, with particular emphasis on metakaolin—the dehydroxylated form of kaolinite produced through calcination at temperatures between 650-800°C. This thermal activation process transforms the crystalline structure of kaolinite into a highly reactive amorphous material with enhanced pozzolanic properties.

Recent technological advancements have focused on optimizing the calcination process to maximize reactivity while minimizing energy consumption. Innovations in flash calcination and mechanochemical activation have emerged as promising approaches to enhance the performance of kaolinite-derived materials in cement systems.

The integration of kaolinite-based materials in cement formulations aligns with the construction industry's growing emphasis on sustainability and performance enhancement. Global initiatives such as the Paris Agreement and various national carbon reduction strategies have accelerated research into SCMs, positioning kaolinite as a strategic material for future cementitious systems.

The primary technical objectives for kaolinite in cementitious materials include: enhancing mechanical strength through pozzolanic reactions and filler effects; improving durability against chemical attacks, particularly sulfate and chloride penetration; reducing permeability to extend service life in aggressive environments; and decreasing the carbon footprint of concrete production through clinker factor reduction.

Current research trends indicate growing interest in understanding the synergistic effects between kaolinite-derived materials and other SCMs such as fly ash, slag, and silica fume. Additionally, investigations into the nano-scale mechanisms of kaolinite's contribution to strength development are providing new insights for optimized material design.

The technological goals for future development include establishing standardized processing parameters for consistent performance, developing cost-effective activation methods suitable for large-scale production, and quantifying the long-term performance benefits in various exposure conditions. These objectives collectively aim to position kaolinite-based materials as essential components in next-generation sustainable construction materials that balance performance requirements with environmental imperatives.

The technological trajectory of kaolinite in cementitious applications has accelerated significantly since the early 2000s, with particular emphasis on metakaolin—the dehydroxylated form of kaolinite produced through calcination at temperatures between 650-800°C. This thermal activation process transforms the crystalline structure of kaolinite into a highly reactive amorphous material with enhanced pozzolanic properties.

Recent technological advancements have focused on optimizing the calcination process to maximize reactivity while minimizing energy consumption. Innovations in flash calcination and mechanochemical activation have emerged as promising approaches to enhance the performance of kaolinite-derived materials in cement systems.

The integration of kaolinite-based materials in cement formulations aligns with the construction industry's growing emphasis on sustainability and performance enhancement. Global initiatives such as the Paris Agreement and various national carbon reduction strategies have accelerated research into SCMs, positioning kaolinite as a strategic material for future cementitious systems.

The primary technical objectives for kaolinite in cementitious materials include: enhancing mechanical strength through pozzolanic reactions and filler effects; improving durability against chemical attacks, particularly sulfate and chloride penetration; reducing permeability to extend service life in aggressive environments; and decreasing the carbon footprint of concrete production through clinker factor reduction.

Current research trends indicate growing interest in understanding the synergistic effects between kaolinite-derived materials and other SCMs such as fly ash, slag, and silica fume. Additionally, investigations into the nano-scale mechanisms of kaolinite's contribution to strength development are providing new insights for optimized material design.

The technological goals for future development include establishing standardized processing parameters for consistent performance, developing cost-effective activation methods suitable for large-scale production, and quantifying the long-term performance benefits in various exposure conditions. These objectives collectively aim to position kaolinite-based materials as essential components in next-generation sustainable construction materials that balance performance requirements with environmental imperatives.

Market Analysis of Kaolinite-Enhanced Cement Products

The global market for kaolinite-enhanced cement products has witnessed substantial growth over the past decade, driven primarily by increasing construction activities in developing economies and growing awareness about sustainable building materials. The current market size is estimated at $12.5 billion, with a compound annual growth rate of 6.8% projected through 2028, significantly outpacing traditional cement products which grow at approximately 4.2% annually.

Asia-Pacific dominates the market landscape, accounting for over 42% of global consumption, with China and India being the primary contributors due to their massive infrastructure development initiatives. North America and Europe collectively represent about 35% of the market, where demand is primarily driven by the renovation and retrofitting sectors rather than new construction.

Consumer preferences are increasingly shifting toward high-performance construction materials that offer enhanced durability and reduced environmental impact. Kaolinite-enhanced cement products align perfectly with this trend, as they typically reduce carbon emissions by 15-20% compared to conventional Portland cement while offering superior strength characteristics. This sustainability aspect has become a significant market differentiator, particularly in regions with stringent environmental regulations.

The commercial construction segment currently represents the largest application area, consuming approximately 38% of kaolinite-enhanced cement products, followed by residential construction at 32% and infrastructure projects at 25%. The remaining 5% is utilized in specialized applications such as marine structures and high-temperature environments where conventional cement products underperform.

Price sensitivity varies significantly across different market segments. While premium construction projects readily absorb the 10-15% price premium of kaolinite-enhanced products due to their performance benefits, mass housing and basic infrastructure projects remain more cost-conscious, creating a bifurcated market structure.

Distribution channels for these products have evolved considerably, with direct-to-contractor sales growing at twice the rate of traditional retail channels. This shift reflects the increasing technical sophistication of these products and the need for specialized application knowledge, driving manufacturers to establish closer relationships with professional users.

Market penetration rates show substantial regional variation, reaching as high as 28% in environmentally progressive markets like Scandinavia and parts of Western Europe, while remaining below 8% in many developing economies where cost considerations often outweigh performance benefits. This disparity highlights significant growth potential as awareness increases and economies of scale improve cost competitiveness.

Asia-Pacific dominates the market landscape, accounting for over 42% of global consumption, with China and India being the primary contributors due to their massive infrastructure development initiatives. North America and Europe collectively represent about 35% of the market, where demand is primarily driven by the renovation and retrofitting sectors rather than new construction.

Consumer preferences are increasingly shifting toward high-performance construction materials that offer enhanced durability and reduced environmental impact. Kaolinite-enhanced cement products align perfectly with this trend, as they typically reduce carbon emissions by 15-20% compared to conventional Portland cement while offering superior strength characteristics. This sustainability aspect has become a significant market differentiator, particularly in regions with stringent environmental regulations.

The commercial construction segment currently represents the largest application area, consuming approximately 38% of kaolinite-enhanced cement products, followed by residential construction at 32% and infrastructure projects at 25%. The remaining 5% is utilized in specialized applications such as marine structures and high-temperature environments where conventional cement products underperform.

Price sensitivity varies significantly across different market segments. While premium construction projects readily absorb the 10-15% price premium of kaolinite-enhanced products due to their performance benefits, mass housing and basic infrastructure projects remain more cost-conscious, creating a bifurcated market structure.

Distribution channels for these products have evolved considerably, with direct-to-contractor sales growing at twice the rate of traditional retail channels. This shift reflects the increasing technical sophistication of these products and the need for specialized application knowledge, driving manufacturers to establish closer relationships with professional users.

Market penetration rates show substantial regional variation, reaching as high as 28% in environmentally progressive markets like Scandinavia and parts of Western Europe, while remaining below 8% in many developing economies where cost considerations often outweigh performance benefits. This disparity highlights significant growth potential as awareness increases and economies of scale improve cost competitiveness.

Current Status and Challenges in Kaolinite Application

The global utilization of kaolinite in cementitious materials has witnessed significant growth over the past decade. Currently, kaolinite is primarily employed as a supplementary cementitious material (SCM) in various construction applications, with its adoption varying considerably across different regions. In developed economies such as North America and Western Europe, kaolinite-based products have achieved moderate market penetration, while emerging economies in Asia and Africa show rapidly increasing adoption rates due to their abundant natural kaolinite deposits.

The technical landscape reveals that calcined kaolinite (metakaolin) has emerged as the predominant form utilized in high-performance concrete applications. Research indicates that optimal replacement levels typically range between 5-20% of cement weight, with higher substitution rates often leading to workability challenges. Recent advancements have focused on optimizing calcination temperatures (typically 650-800°C) to maximize pozzolanic reactivity while minimizing energy consumption.

Despite promising results, several significant technical challenges persist in kaolinite application. The variability in natural kaolinite deposits creates inconsistency in performance, with impurities significantly affecting reactivity and strength development. This heterogeneity complicates standardization efforts and quality control protocols. Additionally, the energy-intensive calcination process contributes substantially to the carbon footprint, partially offsetting the environmental benefits gained from cement reduction.

Water demand represents another critical challenge, as metakaolin typically increases water requirements in concrete mixtures, necessitating higher superplasticizer dosages to maintain workability. This increased admixture demand impacts production economics and can introduce compatibility issues with other concrete components. Furthermore, long-term durability data remains limited, particularly regarding alkali-silica reaction mitigation and sulfate resistance in aggressive environments.

The geographical distribution of kaolinite research and application reveals interesting patterns. China, India, and Brazil have emerged as leaders in kaolinite-based cement research, leveraging their substantial natural deposits. European research has concentrated on high-performance applications, while North American efforts focus on durability enhancement and standardization.

Recent technological barriers include the development of cost-effective processing methods to remove impurities from lower-grade kaolinite sources and the optimization of particle size distribution to enhance reactivity. Additionally, the industry faces challenges in establishing reliable quality assessment methods that can predict performance in diverse cementitious systems and environmental conditions.

The technical landscape reveals that calcined kaolinite (metakaolin) has emerged as the predominant form utilized in high-performance concrete applications. Research indicates that optimal replacement levels typically range between 5-20% of cement weight, with higher substitution rates often leading to workability challenges. Recent advancements have focused on optimizing calcination temperatures (typically 650-800°C) to maximize pozzolanic reactivity while minimizing energy consumption.

Despite promising results, several significant technical challenges persist in kaolinite application. The variability in natural kaolinite deposits creates inconsistency in performance, with impurities significantly affecting reactivity and strength development. This heterogeneity complicates standardization efforts and quality control protocols. Additionally, the energy-intensive calcination process contributes substantially to the carbon footprint, partially offsetting the environmental benefits gained from cement reduction.

Water demand represents another critical challenge, as metakaolin typically increases water requirements in concrete mixtures, necessitating higher superplasticizer dosages to maintain workability. This increased admixture demand impacts production economics and can introduce compatibility issues with other concrete components. Furthermore, long-term durability data remains limited, particularly regarding alkali-silica reaction mitigation and sulfate resistance in aggressive environments.

The geographical distribution of kaolinite research and application reveals interesting patterns. China, India, and Brazil have emerged as leaders in kaolinite-based cement research, leveraging their substantial natural deposits. European research has concentrated on high-performance applications, while North American efforts focus on durability enhancement and standardization.

Recent technological barriers include the development of cost-effective processing methods to remove impurities from lower-grade kaolinite sources and the optimization of particle size distribution to enhance reactivity. Additionally, the industry faces challenges in establishing reliable quality assessment methods that can predict performance in diverse cementitious systems and environmental conditions.

Current Methodologies for Incorporating Kaolinite in Cement

01 Kaolinite reinforcement with additives

Various additives can be incorporated into kaolinite to enhance its strength properties. These include polymers, resins, and other binding agents that create stronger bonds between kaolinite particles. The reinforcement process typically involves mixing these additives with kaolinite under controlled conditions to achieve optimal strength characteristics. This approach is particularly useful in applications requiring high mechanical performance such as ceramics and construction materials.- Methods to enhance kaolinite strength through chemical modification: Chemical treatments can significantly improve the strength properties of kaolinite. These include the use of various binding agents, chemical activators, and surface modifiers that alter the molecular structure of kaolinite clay. Such modifications can enhance the mechanical properties, including compressive strength, tensile strength, and overall durability of kaolinite-based materials. These treatments often involve the use of alkaline solutions, silicates, or organic compounds that react with the alumina-silicate structure of kaolinite.

- Reinforcement of kaolinite with composite materials: Incorporating kaolinite into composite materials can significantly enhance its strength characteristics. By combining kaolinite with materials such as polymers, fibers, or other mineral additives, the resulting composites demonstrate improved mechanical properties. These composite structures benefit from the synergistic effects of the different components, where kaolinite provides specific properties like thermal stability while the reinforcing materials contribute to increased tensile strength, flexural strength, and impact resistance.

- Thermal treatment processes for strengthening kaolinite: Various thermal treatment processes can be employed to enhance the strength of kaolinite-based materials. These include calcination, sintering, and controlled heating regimes that transform the crystal structure of kaolinite. When subjected to specific temperature ranges, kaolinite undergoes phase transformations that can result in materials with significantly improved mechanical properties. The dehydroxylation process and subsequent recrystallization contribute to the formation of stronger ceramic-like materials with enhanced hardness and compressive strength.

- Kaolinite strength enhancement through particle size optimization: The strength properties of kaolinite can be significantly influenced by controlling and optimizing particle size distribution. Fine-grained kaolinite typically exhibits different strength characteristics compared to coarser varieties. Methods such as grinding, classification, and selective fractionation can be employed to achieve specific particle size distributions that maximize strength properties. The increased surface area of finer particles can lead to stronger interparticle bonding, while controlled mixtures of different size fractions can optimize packing density and consequently improve mechanical strength.

- Kaolinite strength improvement through additives and blending: The incorporation of various additives and blending with other materials can significantly enhance the strength properties of kaolinite. These additives may include binders, plasticizers, dispersants, and other functional materials that improve the cohesion and mechanical properties of kaolinite-based formulations. The strategic blending of kaolinite with other clays, minerals, or synthetic materials can create mixtures with optimized strength characteristics for specific applications, such as in ceramics, paper coatings, or construction materials.

02 Heat treatment methods for strength enhancement

Thermal processing techniques can significantly improve the strength of kaolinite-based materials. Controlled calcination at specific temperature ranges transforms the crystal structure of kaolinite, resulting in improved mechanical properties. The heat treatment process can include sintering, firing, or other thermal methods that promote particle fusion and densification. These methods are essential in producing high-strength kaolinite products for industrial applications.Expand Specific Solutions03 Composite formulations with kaolinite

Kaolinite can be combined with other materials to form composites with enhanced strength properties. These composites often incorporate materials such as fibers, nanoparticles, or other minerals that work synergistically with kaolinite to improve overall mechanical performance. The formulation process typically involves careful selection of complementary materials and optimization of mixing ratios to achieve desired strength characteristics. These composites find applications in various industries including construction, paper manufacturing, and ceramics.Expand Specific Solutions04 Chemical modification of kaolinite structure

Chemical treatments can be applied to modify the surface and internal structure of kaolinite, resulting in improved strength properties. These modifications include intercalation, functionalization, and other chemical processes that alter the bonding characteristics of kaolinite particles. By introducing specific chemical agents, the interaction between kaolinite layers can be enhanced, leading to stronger materials. These chemically modified kaolinites exhibit superior mechanical properties compared to their unmodified counterparts.Expand Specific Solutions05 Processing techniques for optimizing kaolinite strength

Specialized processing techniques can be employed to optimize the strength of kaolinite-based materials. These include advanced milling methods, pressure application during formation, and controlled drying processes that enhance particle alignment and packing density. The processing conditions significantly influence the microstructure of the final material, which directly affects its strength properties. By carefully controlling these processing parameters, manufacturers can produce kaolinite materials with tailored strength characteristics for specific applications.Expand Specific Solutions

Leading Companies and Research Institutions in Kaolinite Cement

The kaolinite market in cementitious materials is currently in a growth phase, driven by increasing demand for sustainable construction solutions. The global market size is expanding steadily, with projections indicating significant growth due to infrastructure development in emerging economies. Technologically, kaolinite applications in cement are advancing from experimental to commercial implementation, with varying maturity levels across companies. Leading players like Tianjin Cement Industry Design & Research Institute and Wuhan University of Technology are pioneering advanced applications, while established corporations such as Cementos Argos, Vicat SA, and Saudi Aramco are integrating kaolinite into their cement formulations. Carbon Upcycling Technologies represents the innovative edge, developing proprietary methods for enhancing kaolinite's strength-contributing properties in cementitious materials.

Tianjin Cement Industry Design & Research Institute Co., Ltd.

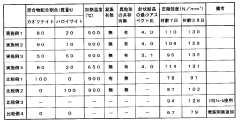

Technical Solution: Tianjin Cement Industry Design & Research Institute has developed an integrated approach to kaolinite utilization in cement manufacturing through their "K-Cement" technology platform. Their system incorporates kaolinite both as a raw material component in clinker production and as a supplementary cementitious material. The institute's research demonstrates that controlled introduction of kaolinite in the raw mix can modify clinker mineralogy, enhancing the formation of hydraulic calcium aluminates while reducing energy-intensive belite phases. Additionally, their process includes a parallel stream where kaolinite undergoes flash calcination (residence time <5 seconds at 750-800°C) to produce highly reactive metakaolin that is interground with the clinker. This dual-stream approach has been implemented in several cement plants across China, showing 10-15% reduction in carbon emissions while maintaining cement performance standards according to GB175-2007.

Strengths: Holistic approach addressing both clinker production and supplementary cementitious material applications; industrial-scale implementation experience; demonstrated carbon reduction benefits. Weaknesses: Complex implementation requiring modifications to existing cement production infrastructure; optimization challenges when raw materials vary in composition; higher technical expertise requirements for operation.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has pioneered research on kaolinite's role in cementitious materials through calcined clay cement technology. Their approach involves thermal activation of kaolinite at temperatures between 600-850°C to produce metakaolin, which significantly enhances pozzolanic reactivity. Their research demonstrates that properly calcined kaolinite can replace up to 30% of ordinary Portland cement while maintaining or improving compressive strength development. The university has developed a proprietary processing method that optimizes the dehydroxylation of kaolinite's octahedral layer, creating an amorphous phase with high surface area (15-20 m²/g) that readily reacts with calcium hydroxide during cement hydration. Their studies show that the resulting C-S-H and C-A-S-H gel formations contribute to refined pore structure and enhanced mechanical properties in the hardened cement matrix.

Strengths: Advanced thermal activation techniques that maximize pozzolanic reactivity; comprehensive understanding of reaction mechanisms between metakaolin and cement components; proven ability to maintain strength while significantly reducing clinker factor. Weaknesses: Energy requirements for calcination process may impact cost-effectiveness; performance highly dependent on kaolinite purity and processing parameters.

Key Patents and Research on Kaolinite Strength Enhancement

Method of producing a pozzolanic material for use in a low-carbon cement

PatentWO2025078560A1

Innovation

- A method is developed to produce a pozzolanic material by co-calcining an argillaceous material with a kaolinite content of 1-49 wt.% and a source of calcium oxide, which includes calcite or calcium oxide, at a temperature of 700-900°C to transform kaolinite into metakaolin, thereby enhancing the cement's compressive strength.

Strength-enhancing material for cement composition and method for producing thereof

PatentInactiveJP2011136888A

Innovation

- A cement composition containing granular metakaolin with a particle size of 10 μm or less and acicular metakaolin with an aspect ratio of 3 or more, produced by heating a mixture of granular kaolinite and halloysite at 600 to 900°C, effectively suppressing agglomeration and enhancing strength.

Environmental Impact and Sustainability Considerations

The incorporation of kaolinite into cementitious materials presents significant environmental and sustainability advantages that align with global efforts to reduce the carbon footprint of construction industries. Cement production traditionally accounts for approximately 8% of global CO2 emissions, making any reduction in cement content through supplementary materials like kaolinite environmentally beneficial. When kaolinite is calcined to produce metakaolin, it requires substantially lower processing temperatures (650-800°C) compared to Portland cement clinker (1450°C), resulting in approximately 80-90% lower carbon emissions per ton of material produced.

Kaolinite's abundance as a natural clay mineral provides opportunities for localized sourcing, potentially reducing transportation-related emissions in construction supply chains. Furthermore, the utilization of kaolinite from industrial byproducts and waste streams, such as paper industry residues or mining tailings, represents a circular economy approach that diverts materials from landfills while reducing the demand for virgin resources.

Life cycle assessment (LCA) studies indicate that partial replacement of cement with properly processed kaolinite can reduce the environmental impact of concrete by 15-30% across multiple indicators, including global warming potential, acidification, and resource depletion. The enhanced durability of kaolinite-modified cementitious materials also contributes to sustainability by extending service life and reducing maintenance requirements, thereby conserving resources over time.

Water consumption represents another critical environmental consideration. Research demonstrates that while initial water demand may increase with some kaolinite formulations due to their higher specific surface area, the improved microstructure ultimately leads to reduced permeability and better water conservation during the service life of the material. This characteristic is particularly valuable in water-scarce regions where construction activities compete with other essential water needs.

From a regulatory perspective, the inclusion of kaolinite in cementitious materials aligns with emerging green building standards and carbon reduction policies. Many countries now offer incentives for construction materials with reduced environmental footprints, positioning kaolinite-based solutions favorably in evolving markets. The material's natural origin also addresses growing consumer preferences for bio-based and minimally processed construction materials.

Future sustainability improvements may come from optimizing kaolinite processing methods, such as mechanical activation or lower-temperature thermal treatments, which could further reduce the already favorable environmental profile of this supplementary cementitious material. Research into hybrid systems combining kaolinite with other sustainable additives like agricultural ashes or recycled glass powder shows promise for maximizing environmental benefits while maintaining or enhancing strength properties.

Kaolinite's abundance as a natural clay mineral provides opportunities for localized sourcing, potentially reducing transportation-related emissions in construction supply chains. Furthermore, the utilization of kaolinite from industrial byproducts and waste streams, such as paper industry residues or mining tailings, represents a circular economy approach that diverts materials from landfills while reducing the demand for virgin resources.

Life cycle assessment (LCA) studies indicate that partial replacement of cement with properly processed kaolinite can reduce the environmental impact of concrete by 15-30% across multiple indicators, including global warming potential, acidification, and resource depletion. The enhanced durability of kaolinite-modified cementitious materials also contributes to sustainability by extending service life and reducing maintenance requirements, thereby conserving resources over time.

Water consumption represents another critical environmental consideration. Research demonstrates that while initial water demand may increase with some kaolinite formulations due to their higher specific surface area, the improved microstructure ultimately leads to reduced permeability and better water conservation during the service life of the material. This characteristic is particularly valuable in water-scarce regions where construction activities compete with other essential water needs.

From a regulatory perspective, the inclusion of kaolinite in cementitious materials aligns with emerging green building standards and carbon reduction policies. Many countries now offer incentives for construction materials with reduced environmental footprints, positioning kaolinite-based solutions favorably in evolving markets. The material's natural origin also addresses growing consumer preferences for bio-based and minimally processed construction materials.

Future sustainability improvements may come from optimizing kaolinite processing methods, such as mechanical activation or lower-temperature thermal treatments, which could further reduce the already favorable environmental profile of this supplementary cementitious material. Research into hybrid systems combining kaolinite with other sustainable additives like agricultural ashes or recycled glass powder shows promise for maximizing environmental benefits while maintaining or enhancing strength properties.

Performance Testing Standards and Quality Control Methods

The evaluation of kaolinite's performance in cementitious materials requires standardized testing protocols to ensure consistent and reliable results. ASTM C618 serves as the primary standard for assessing pozzolanic materials, including kaolinite, establishing specifications for chemical composition, physical properties, and performance requirements. This standard mandates that supplementary cementitious materials containing kaolinite must meet minimum strength activity indices when compared to control samples.

Compressive strength testing, governed by ASTM C109, represents the cornerstone of performance assessment for kaolinite-modified cement. This method involves preparing standardized mortar cubes with varying kaolinite percentages and measuring their compressive strength at different curing ages (typically 7, 28, and 90 days). The strength activity index calculation provides a quantitative measure of kaolinite's contribution to mechanical performance.

For durability assessment, ASTM C1012 evaluates sulfate resistance through expansion measurements of mortar bars containing kaolinite over extended periods. Additionally, ASTM C1202 (Rapid Chloride Permeability Test) quantifies the electrical conductance of concrete as an indirect measure of chloride ion penetration resistance, a critical parameter for structures exposed to marine environments or deicing salts.

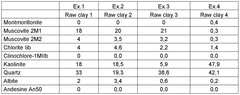

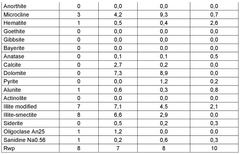

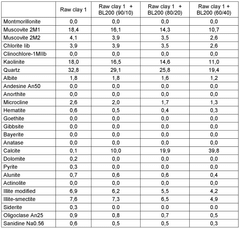

Quality control methods for kaolinite in cementitious applications begin with raw material characterization. X-ray diffraction (XRD) analysis confirms mineralogical composition and purity, while particle size distribution analysis ensures consistent fineness. Thermogravimetric analysis (TGA) provides information about dehydroxylation temperature ranges, which correlate with kaolinite's reactivity when calcined to form metakaolin.

Statistical process control techniques are essential for monitoring kaolinite performance in production environments. Control charts tracking strength development, setting time variations, and workability parameters help identify process deviations before they impact final product quality. Acceptance sampling plans based on ISO 2859 establish criteria for lot acceptance or rejection based on predetermined quality levels.

Field testing protocols complement laboratory assessments by evaluating real-world performance under actual construction and service conditions. Non-destructive testing methods such as ultrasonic pulse velocity measurements and rebound hammer tests provide in-situ strength estimations for kaolinite-modified concrete structures, while core sampling allows for direct strength verification and microstructural analysis of hardened concrete containing kaolinite.

Compressive strength testing, governed by ASTM C109, represents the cornerstone of performance assessment for kaolinite-modified cement. This method involves preparing standardized mortar cubes with varying kaolinite percentages and measuring their compressive strength at different curing ages (typically 7, 28, and 90 days). The strength activity index calculation provides a quantitative measure of kaolinite's contribution to mechanical performance.

For durability assessment, ASTM C1012 evaluates sulfate resistance through expansion measurements of mortar bars containing kaolinite over extended periods. Additionally, ASTM C1202 (Rapid Chloride Permeability Test) quantifies the electrical conductance of concrete as an indirect measure of chloride ion penetration resistance, a critical parameter for structures exposed to marine environments or deicing salts.

Quality control methods for kaolinite in cementitious applications begin with raw material characterization. X-ray diffraction (XRD) analysis confirms mineralogical composition and purity, while particle size distribution analysis ensures consistent fineness. Thermogravimetric analysis (TGA) provides information about dehydroxylation temperature ranges, which correlate with kaolinite's reactivity when calcined to form metakaolin.

Statistical process control techniques are essential for monitoring kaolinite performance in production environments. Control charts tracking strength development, setting time variations, and workability parameters help identify process deviations before they impact final product quality. Acceptance sampling plans based on ISO 2859 establish criteria for lot acceptance or rejection based on predetermined quality levels.

Field testing protocols complement laboratory assessments by evaluating real-world performance under actual construction and service conditions. Non-destructive testing methods such as ultrasonic pulse velocity measurements and rebound hammer tests provide in-situ strength estimations for kaolinite-modified concrete structures, while core sampling allows for direct strength verification and microstructural analysis of hardened concrete containing kaolinite.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!