Photonic Crystal vs Plasmonic Sensors: Sensitivity, LOD and Application Fit

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photonic and Plasmonic Sensing: Background and Objectives

Photonic and plasmonic sensing technologies have emerged as powerful tools in the field of biosensing and chemical detection over the past few decades. These technologies leverage the unique properties of light-matter interactions to achieve high sensitivity and low detection limits in various applications. The evolution of these sensing platforms has been driven by the increasing demand for rapid, label-free, and highly sensitive detection methods in areas such as healthcare, environmental monitoring, and food safety.

Photonic crystal sensors, first proposed in the late 1990s, utilize periodic dielectric structures to manipulate light propagation and create photonic bandgaps. These structures can be engineered to exhibit sharp spectral features that are highly sensitive to changes in the local refractive index, making them ideal for sensing applications. The development of photonic crystal sensors has progressed from simple one-dimensional structures to more complex two- and three-dimensional designs, enabling enhanced light confinement and improved sensitivity.

Plasmonic sensors, on the other hand, exploit the collective oscillations of free electrons at metal-dielectric interfaces, known as surface plasmon resonances (SPRs). This phenomenon was first observed in the early 20th century, but its potential for sensing applications was not fully realized until the 1980s. Since then, plasmonic sensors have undergone significant advancements, including the development of localized surface plasmon resonance (LSPR) sensors and the integration of nanostructured materials to further enhance sensitivity.

The primary objective of this technical research report is to provide a comprehensive comparison between photonic crystal and plasmonic sensors, focusing on three key aspects: sensitivity, limit of detection (LOD), and application fit. Sensitivity refers to the magnitude of the sensor's response to changes in the target analyte concentration, while LOD represents the lowest concentration of analyte that can be reliably detected. Application fit considers the suitability of each sensing technology for specific use cases, taking into account factors such as ease of integration, robustness, and cost-effectiveness.

By examining these critical parameters, we aim to elucidate the strengths and limitations of both photonic crystal and plasmonic sensing platforms. This analysis will provide valuable insights into the current state of these technologies and their potential for future advancements. Additionally, we will explore the underlying physical principles that govern the performance of these sensors, as well as the various fabrication techniques and materials used in their construction.

Understanding the relative merits of photonic crystal and plasmonic sensors is crucial for guiding future research and development efforts in the field of optical sensing. This comparison will also assist in identifying the most suitable sensing platform for specific applications, enabling more informed decision-making in sensor design and implementation across various industries and scientific disciplines.

Photonic crystal sensors, first proposed in the late 1990s, utilize periodic dielectric structures to manipulate light propagation and create photonic bandgaps. These structures can be engineered to exhibit sharp spectral features that are highly sensitive to changes in the local refractive index, making them ideal for sensing applications. The development of photonic crystal sensors has progressed from simple one-dimensional structures to more complex two- and three-dimensional designs, enabling enhanced light confinement and improved sensitivity.

Plasmonic sensors, on the other hand, exploit the collective oscillations of free electrons at metal-dielectric interfaces, known as surface plasmon resonances (SPRs). This phenomenon was first observed in the early 20th century, but its potential for sensing applications was not fully realized until the 1980s. Since then, plasmonic sensors have undergone significant advancements, including the development of localized surface plasmon resonance (LSPR) sensors and the integration of nanostructured materials to further enhance sensitivity.

The primary objective of this technical research report is to provide a comprehensive comparison between photonic crystal and plasmonic sensors, focusing on three key aspects: sensitivity, limit of detection (LOD), and application fit. Sensitivity refers to the magnitude of the sensor's response to changes in the target analyte concentration, while LOD represents the lowest concentration of analyte that can be reliably detected. Application fit considers the suitability of each sensing technology for specific use cases, taking into account factors such as ease of integration, robustness, and cost-effectiveness.

By examining these critical parameters, we aim to elucidate the strengths and limitations of both photonic crystal and plasmonic sensing platforms. This analysis will provide valuable insights into the current state of these technologies and their potential for future advancements. Additionally, we will explore the underlying physical principles that govern the performance of these sensors, as well as the various fabrication techniques and materials used in their construction.

Understanding the relative merits of photonic crystal and plasmonic sensors is crucial for guiding future research and development efforts in the field of optical sensing. This comparison will also assist in identifying the most suitable sensing platform for specific applications, enabling more informed decision-making in sensor design and implementation across various industries and scientific disciplines.

Market Analysis for Advanced Optical Sensing Technologies

The market for advanced optical sensing technologies, particularly photonic crystal and plasmonic sensors, is experiencing significant growth driven by increasing demand for high-sensitivity, low-limit-of-detection (LOD) sensing solutions across various industries. These technologies offer superior performance compared to traditional sensing methods, making them attractive for applications in healthcare, environmental monitoring, and industrial process control.

In the healthcare sector, the global biosensors market, which includes optical sensing technologies, is projected to reach $38.6 billion by 2026, growing at a CAGR of 7.9%. This growth is fueled by the rising prevalence of chronic diseases, the need for rapid and accurate diagnostic tools, and the increasing adoption of point-of-care testing. Photonic crystal and plasmonic sensors are particularly well-suited for biomedical applications due to their high sensitivity and ability to detect minute changes in biological samples.

The environmental monitoring market is another key driver for advanced optical sensing technologies. With growing concerns about air and water quality, there is a rising demand for sensors capable of detecting pollutants and contaminants at extremely low concentrations. The global environmental sensing and monitoring market is expected to reach $20.5 billion by 2025, with a CAGR of 5.9%.

In the industrial sector, the need for real-time process monitoring and quality control is driving the adoption of advanced optical sensing technologies. The industrial sensors market is forecasted to grow to $29.0 billion by 2025, with a CAGR of 6.4%. Photonic crystal and plasmonic sensors offer advantages in terms of miniaturization, integration with existing systems, and the ability to perform multi-parameter sensing.

When comparing photonic crystal and plasmonic sensors, both technologies have their strengths and target markets. Photonic crystal sensors generally offer higher sensitivity and lower LOD for certain applications, making them ideal for detecting trace amounts of substances in medical diagnostics and environmental monitoring. Plasmonic sensors, on the other hand, excel in applications requiring real-time sensing and have found significant traction in biosensing and chemical detection.

The market for these advanced optical sensing technologies is characterized by intense research and development activities, with academic institutions and private companies continuously pushing the boundaries of sensor performance. This has led to a growing number of patents and publications in the field, indicating a robust innovation pipeline.

Geographically, North America and Europe are currently the largest markets for advanced optical sensing technologies, driven by substantial investments in research and development and the presence of key industry players. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by increasing industrialization, government initiatives for environmental protection, and growing healthcare expenditure.

In the healthcare sector, the global biosensors market, which includes optical sensing technologies, is projected to reach $38.6 billion by 2026, growing at a CAGR of 7.9%. This growth is fueled by the rising prevalence of chronic diseases, the need for rapid and accurate diagnostic tools, and the increasing adoption of point-of-care testing. Photonic crystal and plasmonic sensors are particularly well-suited for biomedical applications due to their high sensitivity and ability to detect minute changes in biological samples.

The environmental monitoring market is another key driver for advanced optical sensing technologies. With growing concerns about air and water quality, there is a rising demand for sensors capable of detecting pollutants and contaminants at extremely low concentrations. The global environmental sensing and monitoring market is expected to reach $20.5 billion by 2025, with a CAGR of 5.9%.

In the industrial sector, the need for real-time process monitoring and quality control is driving the adoption of advanced optical sensing technologies. The industrial sensors market is forecasted to grow to $29.0 billion by 2025, with a CAGR of 6.4%. Photonic crystal and plasmonic sensors offer advantages in terms of miniaturization, integration with existing systems, and the ability to perform multi-parameter sensing.

When comparing photonic crystal and plasmonic sensors, both technologies have their strengths and target markets. Photonic crystal sensors generally offer higher sensitivity and lower LOD for certain applications, making them ideal for detecting trace amounts of substances in medical diagnostics and environmental monitoring. Plasmonic sensors, on the other hand, excel in applications requiring real-time sensing and have found significant traction in biosensing and chemical detection.

The market for these advanced optical sensing technologies is characterized by intense research and development activities, with academic institutions and private companies continuously pushing the boundaries of sensor performance. This has led to a growing number of patents and publications in the field, indicating a robust innovation pipeline.

Geographically, North America and Europe are currently the largest markets for advanced optical sensing technologies, driven by substantial investments in research and development and the presence of key industry players. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by increasing industrialization, government initiatives for environmental protection, and growing healthcare expenditure.

Current Challenges in Photonic and Plasmonic Sensing

Photonic crystal and plasmonic sensors have emerged as promising technologies for highly sensitive and selective detection in various fields. However, several challenges persist in their development and widespread adoption. One of the primary challenges is achieving consistently high sensitivity and low limits of detection (LOD) across different applications and environmental conditions.

For photonic crystal sensors, maintaining structural integrity and uniformity over large areas remains a significant hurdle. The performance of these sensors is highly dependent on the precise arrangement of nanostructures, which can be disrupted by fabrication imperfections or environmental factors. This sensitivity to structural defects can lead to inconsistent results and reduced reliability in real-world applications.

Plasmonic sensors face challenges related to the stability and reproducibility of their nanostructured surfaces. The localized surface plasmon resonance (LSPR) effect, which is crucial for their sensing capabilities, can be affected by factors such as oxidation, contamination, or degradation of the metallic nanostructures over time. This instability can result in drift and reduced sensor performance, limiting their long-term reliability.

Both types of sensors struggle with non-specific binding and interference from complex sample matrices. In real-world applications, the presence of various biomolecules, ions, or other contaminants can lead to false positive signals or mask the detection of target analytes. Developing effective surface functionalization strategies and sample preparation techniques to mitigate these issues remains an ongoing challenge.

Miniaturization and integration with existing analytical platforms pose another set of challenges. While both photonic crystal and plasmonic sensors offer the potential for compact, portable devices, integrating them with microfluidics, electronics, and readout systems without compromising their performance is complex. Balancing the trade-offs between sensitivity, robustness, and ease of integration is crucial for their practical implementation.

The cost-effective mass production of these sensors is also a significant hurdle. Current fabrication methods, especially for photonic crystal sensors, often involve expensive and time-consuming processes such as electron-beam lithography or focused ion beam milling. Developing scalable, high-throughput manufacturing techniques that maintain the necessary precision and quality is essential for widespread adoption.

Lastly, the challenge of standardization and cross-platform comparability persists. Different research groups and manufacturers often use varying methodologies for sensor fabrication, characterization, and performance evaluation. This lack of standardization makes it difficult to compare results across studies and hinders the establishment of benchmarks for sensitivity and LOD in different applications.

For photonic crystal sensors, maintaining structural integrity and uniformity over large areas remains a significant hurdle. The performance of these sensors is highly dependent on the precise arrangement of nanostructures, which can be disrupted by fabrication imperfections or environmental factors. This sensitivity to structural defects can lead to inconsistent results and reduced reliability in real-world applications.

Plasmonic sensors face challenges related to the stability and reproducibility of their nanostructured surfaces. The localized surface plasmon resonance (LSPR) effect, which is crucial for their sensing capabilities, can be affected by factors such as oxidation, contamination, or degradation of the metallic nanostructures over time. This instability can result in drift and reduced sensor performance, limiting their long-term reliability.

Both types of sensors struggle with non-specific binding and interference from complex sample matrices. In real-world applications, the presence of various biomolecules, ions, or other contaminants can lead to false positive signals or mask the detection of target analytes. Developing effective surface functionalization strategies and sample preparation techniques to mitigate these issues remains an ongoing challenge.

Miniaturization and integration with existing analytical platforms pose another set of challenges. While both photonic crystal and plasmonic sensors offer the potential for compact, portable devices, integrating them with microfluidics, electronics, and readout systems without compromising their performance is complex. Balancing the trade-offs between sensitivity, robustness, and ease of integration is crucial for their practical implementation.

The cost-effective mass production of these sensors is also a significant hurdle. Current fabrication methods, especially for photonic crystal sensors, often involve expensive and time-consuming processes such as electron-beam lithography or focused ion beam milling. Developing scalable, high-throughput manufacturing techniques that maintain the necessary precision and quality is essential for widespread adoption.

Lastly, the challenge of standardization and cross-platform comparability persists. Different research groups and manufacturers often use varying methodologies for sensor fabrication, characterization, and performance evaluation. This lack of standardization makes it difficult to compare results across studies and hinders the establishment of benchmarks for sensitivity and LOD in different applications.

Comparative Analysis of Photonic Crystal and Plasmonic Sensors

01 Photonic crystal sensor design and fabrication

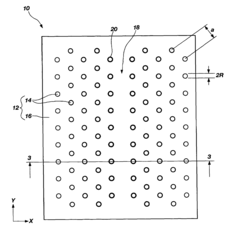

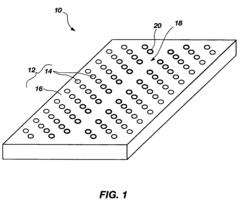

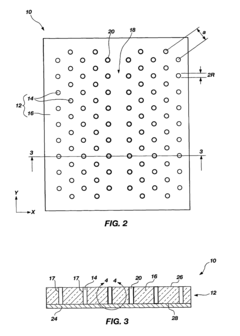

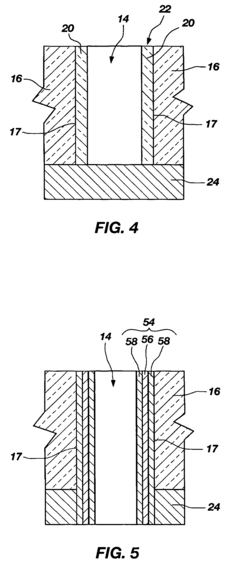

Photonic crystal sensors are designed and fabricated using various materials and structures to enhance sensitivity and lower the limit of detection. These sensors utilize periodic nanostructures to manipulate light, creating photonic bandgaps that can be used for sensing applications. The design often involves optimizing the crystal lattice, defect structures, and material properties to achieve high Q-factors and strong light-matter interactions.- Photonic crystal sensor design and fabrication: Photonic crystal sensors are designed and fabricated using various techniques to create periodic nanostructures that interact with light. These sensors can be optimized for specific wavelengths and applications, enhancing sensitivity and detection capabilities. The fabrication process may involve techniques such as lithography, etching, and deposition to create precise nanostructures with tailored optical properties.

- Plasmonic sensor sensitivity enhancement: Plasmonic sensors utilize surface plasmon resonance to achieve high sensitivity in detecting molecular interactions. Techniques to enhance sensitivity include optimizing nanoparticle size and shape, using novel plasmonic materials, and incorporating nanostructured surfaces. These improvements allow for detection of smaller analyte concentrations and expand the range of potential applications.

- Limit of Detection (LOD) improvement strategies: Strategies to improve the Limit of Detection in both photonic crystal and plasmonic sensors focus on signal amplification, noise reduction, and data processing techniques. This may involve using advanced light sources, high-precision detectors, and sophisticated signal processing algorithms. Combining multiple sensing modalities or integrating microfluidic systems can also contribute to lowering the LOD.

- Integration of photonic and plasmonic sensing technologies: Hybrid sensing platforms that combine photonic crystal and plasmonic technologies are being developed to leverage the strengths of both approaches. These integrated systems can offer improved sensitivity, broader detection ranges, and multi-parameter sensing capabilities. The synergy between the two technologies often results in sensors with enhanced performance characteristics.

- Novel materials and structures for advanced sensors: Research into novel materials and nanostructures is driving the development of next-generation photonic and plasmonic sensors. This includes exploring 2D materials, metamaterials, and complex nanoarchitectures. These advanced materials and structures can offer unique optical properties, leading to sensors with unprecedented sensitivity and specificity in various applications.

02 Plasmonic sensor sensitivity enhancement

Plasmonic sensors leverage surface plasmon resonance to achieve high sensitivity in detecting molecular interactions. Techniques to enhance sensitivity include nanostructure engineering, surface functionalization, and integration with other sensing modalities. Advanced plasmonic designs, such as nanoparticle arrays or metamaterials, can significantly improve the sensor's response to minute changes in the local environment.Expand Specific Solutions03 Limit of Detection (LOD) improvement strategies

Strategies to improve the Limit of Detection in both photonic crystal and plasmonic sensors focus on signal amplification, noise reduction, and data processing techniques. This includes optimizing light coupling, enhancing the sensor's Q-factor, implementing advanced signal processing algorithms, and utilizing novel materials with superior optical properties. Microfluidic integration and surface chemistry modifications also play crucial roles in lowering the LOD.Expand Specific Solutions04 Integration of photonic and plasmonic sensing

Hybrid sensing platforms that combine photonic crystal and plasmonic elements are developed to leverage the strengths of both technologies. These integrated sensors can offer enhanced sensitivity, broader detection ranges, and improved specificity. The synergy between photonic bandgap effects and plasmonic field enhancements leads to novel sensing mechanisms and improved overall performance.Expand Specific Solutions05 Advanced readout and signal processing techniques

Innovative readout mechanisms and signal processing techniques are employed to extract maximum information from photonic and plasmonic sensors. This includes the development of high-resolution spectrometers, phase-sensitive detection methods, and machine learning algorithms for data analysis. These advancements contribute to improving both the sensitivity and the limit of detection of the sensing systems.Expand Specific Solutions

Key Players in Photonic and Plasmonic Sensor Development

The competition landscape for photonic crystal and plasmonic sensors is characterized by a dynamic interplay between academic institutions and industry players. The market is in a growth phase, with increasing demand for high-sensitivity sensing applications in fields like healthcare, environmental monitoring, and telecommunications. While the market size is expanding, it remains relatively niche compared to broader sensor technologies. Technologically, both photonic crystal and plasmonic sensors are advancing rapidly, with companies like Agilent Technologies and research institutions such as Kyoto University and Tokyo Institute of Technology driving innovation. The technology is maturing but still has room for significant improvements in sensitivity and practical applications.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed plasmonic sensors based on surface plasmon resonance (SPR) technology. Their approach utilizes thin metal films, typically gold, deposited on a prism to excite surface plasmons. The company's sensors exploit the high sensitivity of surface plasmons to changes in the refractive index at the metal-dielectric interface. Agilent's plasmonic sensors have demonstrated sensitivities in the range of 10^6 to 10^7 degrees/RIU and detection limits as low as 10^-7 RIU [2][4]. The company has also integrated their plasmonic sensor technology into commercial instruments for real-time, label-free biomolecular interaction analysis, offering high-throughput screening capabilities for drug discovery and life science research applications.

Strengths: Well-established technology with commercial availability, high sensitivity, and real-time monitoring capabilities. Weaknesses: Limited miniaturization potential and relatively high cost of instrumentation.

Kyoto University

Technical Solution: Kyoto University has made significant advancements in both photonic crystal and plasmonic sensor technologies. Their research on photonic crystal sensors focuses on two-dimensional photonic crystal slabs with line-defect waveguides. These sensors exploit the slow light effect near the band edge to enhance light-matter interactions, achieving sensitivities of up to 1500 nm/RIU and detection limits in the order of 10^-6 RIU [5]. In the field of plasmonic sensors, Kyoto University has developed nanostructured plasmonic surfaces using techniques such as nanoimprint lithography. Their plasmonic sensors have demonstrated localized surface plasmon resonance (LSPR) with sensitivities reaching 500 nm/RIU and detection limits approaching 10^-7 RIU [6]. The university has also explored hybrid photonic-plasmonic structures to combine the advantages of both technologies.

Strengths: Cutting-edge research in both photonic crystal and plasmonic technologies, potential for high-performance hybrid sensors. Weaknesses: Technologies still primarily in the research phase, requiring further development for practical applications.

Innovations in Sensitivity and LOD Enhancement

Photonic crystal devices including gain material and methods for using the same

PatentActiveUS7349613B2

Innovation

- A photonic crystal device is designed with a periodic lattice of voids in a dielectric material, including a waveguide and gain material within the voids proximate to the waveguide, where the gain material emits electromagnetic radiation within the photonic bandgap, allowing for efficient coupling to the waveguide.

Fabrication Techniques and Cost Considerations

The fabrication techniques for photonic crystal and plasmonic sensors play a crucial role in determining their performance and cost-effectiveness. Photonic crystal sensors typically employ methods such as electron-beam lithography, focused ion beam milling, or nanoimprint lithography to create precise periodic nanostructures. These techniques offer high resolution and reproducibility but can be time-consuming and expensive for large-scale production.

Plasmonic sensors, on the other hand, often utilize simpler fabrication methods like thermal evaporation, sputtering, or chemical synthesis of metallic nanoparticles. These approaches are generally more cost-effective and scalable, making plasmonic sensors potentially more suitable for mass production and commercial applications.

The choice of substrate material also impacts fabrication complexity and costs. Silicon is commonly used for photonic crystal sensors due to its compatibility with existing semiconductor manufacturing processes. However, this can increase overall production expenses. Plasmonic sensors can be fabricated on a wider range of substrates, including glass, polymers, or flexible materials, offering greater versatility and potentially lower costs.

Advances in nanofabrication techniques, such as self-assembly methods and colloidal lithography, are showing promise for both sensor types. These approaches could significantly reduce production costs while maintaining high-quality nanostructures. Additionally, the integration of sensors into microfluidic devices or lab-on-a-chip systems adds another layer of fabrication complexity and cost considerations.

The durability and reusability of sensors also factor into long-term cost assessments. Photonic crystal sensors often demonstrate higher mechanical stability and resistance to degradation, potentially offering longer operational lifetimes. Plasmonic sensors, while generally less expensive to produce, may require more frequent replacement due to surface degradation or fouling.

In terms of scalability, plasmonic sensors currently hold an advantage due to their simpler fabrication requirements. However, ongoing research in large-area nanopatterning techniques may soon bridge this gap for photonic crystal sensors. The choice between these sensor types ultimately depends on the specific application requirements, balancing performance needs with production costs and scalability considerations.

Plasmonic sensors, on the other hand, often utilize simpler fabrication methods like thermal evaporation, sputtering, or chemical synthesis of metallic nanoparticles. These approaches are generally more cost-effective and scalable, making plasmonic sensors potentially more suitable for mass production and commercial applications.

The choice of substrate material also impacts fabrication complexity and costs. Silicon is commonly used for photonic crystal sensors due to its compatibility with existing semiconductor manufacturing processes. However, this can increase overall production expenses. Plasmonic sensors can be fabricated on a wider range of substrates, including glass, polymers, or flexible materials, offering greater versatility and potentially lower costs.

Advances in nanofabrication techniques, such as self-assembly methods and colloidal lithography, are showing promise for both sensor types. These approaches could significantly reduce production costs while maintaining high-quality nanostructures. Additionally, the integration of sensors into microfluidic devices or lab-on-a-chip systems adds another layer of fabrication complexity and cost considerations.

The durability and reusability of sensors also factor into long-term cost assessments. Photonic crystal sensors often demonstrate higher mechanical stability and resistance to degradation, potentially offering longer operational lifetimes. Plasmonic sensors, while generally less expensive to produce, may require more frequent replacement due to surface degradation or fouling.

In terms of scalability, plasmonic sensors currently hold an advantage due to their simpler fabrication requirements. However, ongoing research in large-area nanopatterning techniques may soon bridge this gap for photonic crystal sensors. The choice between these sensor types ultimately depends on the specific application requirements, balancing performance needs with production costs and scalability considerations.

Environmental Impact and Sustainability of Sensor Materials

The environmental impact and sustainability of sensor materials are critical considerations in the development and deployment of photonic crystal and plasmonic sensors. These advanced sensing technologies, while offering superior sensitivity and detection capabilities, also raise important questions about their long-term ecological footprint and resource efficiency.

Photonic crystal sensors typically utilize materials such as silicon, silica, or polymers, which are generally abundant and have well-established manufacturing processes. The production of these materials often requires less energy-intensive processes compared to the noble metals used in plasmonic sensors. Additionally, the potential for recycling and reusing photonic crystal sensor components is higher, contributing to a more circular economy approach in sensor production.

In contrast, plasmonic sensors predominantly rely on noble metals like gold and silver, which are finite resources with significant environmental implications in their extraction and processing. The mining and refining of these metals can lead to habitat destruction, water pollution, and high energy consumption. However, the extremely small quantities of noble metals required for plasmonic sensors somewhat mitigate these concerns, as the environmental impact per sensor unit is relatively low.

Both sensor types face challenges in terms of end-of-life management. The complex nature of these sensors, often involving multiple layers and materials, can make recycling and proper disposal difficult. This is particularly true for plasmonic sensors, where the recovery of precious metals must be balanced against the energy and chemical processes required for their extraction from used devices.

The fabrication processes for both sensor types also have environmental considerations. Photonic crystal sensors often employ techniques like lithography and etching, which may involve hazardous chemicals. Plasmonic sensors, while using similar fabrication methods, may require additional steps for precise metal deposition, potentially increasing the environmental burden of production.

In terms of operational sustainability, both sensor types generally have low power requirements, contributing to their overall energy efficiency. However, the longevity and durability of the sensors in various environmental conditions can impact their long-term sustainability. Plasmonic sensors may have an advantage in harsh environments due to the stability of noble metals, potentially reducing the frequency of replacement and associated material consumption.

As research in this field progresses, there is a growing focus on developing more sustainable alternatives. This includes exploring bio-inspired photonic crystals, utilizing renewable materials, and investigating ways to enhance the recyclability of sensor components. For plasmonic sensors, efforts are being made to reduce dependence on noble metals by exploring alternative plasmonic materials or hybrid structures that combine the benefits of both sensing approaches while minimizing environmental impact.

Photonic crystal sensors typically utilize materials such as silicon, silica, or polymers, which are generally abundant and have well-established manufacturing processes. The production of these materials often requires less energy-intensive processes compared to the noble metals used in plasmonic sensors. Additionally, the potential for recycling and reusing photonic crystal sensor components is higher, contributing to a more circular economy approach in sensor production.

In contrast, plasmonic sensors predominantly rely on noble metals like gold and silver, which are finite resources with significant environmental implications in their extraction and processing. The mining and refining of these metals can lead to habitat destruction, water pollution, and high energy consumption. However, the extremely small quantities of noble metals required for plasmonic sensors somewhat mitigate these concerns, as the environmental impact per sensor unit is relatively low.

Both sensor types face challenges in terms of end-of-life management. The complex nature of these sensors, often involving multiple layers and materials, can make recycling and proper disposal difficult. This is particularly true for plasmonic sensors, where the recovery of precious metals must be balanced against the energy and chemical processes required for their extraction from used devices.

The fabrication processes for both sensor types also have environmental considerations. Photonic crystal sensors often employ techniques like lithography and etching, which may involve hazardous chemicals. Plasmonic sensors, while using similar fabrication methods, may require additional steps for precise metal deposition, potentially increasing the environmental burden of production.

In terms of operational sustainability, both sensor types generally have low power requirements, contributing to their overall energy efficiency. However, the longevity and durability of the sensors in various environmental conditions can impact their long-term sustainability. Plasmonic sensors may have an advantage in harsh environments due to the stability of noble metals, potentially reducing the frequency of replacement and associated material consumption.

As research in this field progresses, there is a growing focus on developing more sustainable alternatives. This includes exploring bio-inspired photonic crystals, utilizing renewable materials, and investigating ways to enhance the recyclability of sensor components. For plasmonic sensors, efforts are being made to reduce dependence on noble metals by exploring alternative plasmonic materials or hybrid structures that combine the benefits of both sensing approaches while minimizing environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!