Development of Battery Management Systems for Flywheel Energy Storage

AUG 8, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flywheel BMS Background and Objectives

Flywheel energy storage systems have emerged as a promising technology for grid-scale energy storage, offering high power density, long cycle life, and rapid response times. The development of Battery Management Systems (BMS) for flywheel energy storage represents a critical advancement in this field, aiming to optimize the performance, efficiency, and safety of these systems.

The evolution of flywheel technology can be traced back to ancient times, with its modern applications in energy storage gaining traction in the late 20th century. Initially used in mechanical systems, flywheels have transitioned into high-tech energy storage devices, incorporating advanced materials, magnetic bearings, and vacuum enclosures to minimize friction and energy losses.

The primary objective of developing BMS for flywheel energy storage is to address the unique challenges posed by these systems. Unlike traditional chemical batteries, flywheels store energy in the form of rotational kinetic energy, requiring specialized management techniques. The BMS must monitor and control various parameters such as rotational speed, temperature, vibration, and power flow to ensure optimal operation and longevity of the flywheel system.

One of the key goals is to enhance the overall efficiency of flywheel energy storage. This involves minimizing standby losses, optimizing charge and discharge cycles, and ensuring precise control of the flywheel's rotational speed. The BMS plays a crucial role in achieving these objectives by implementing advanced control algorithms and real-time monitoring systems.

Safety is another critical aspect driving the development of flywheel BMS. Given the high rotational speeds involved, typically ranging from 20,000 to 50,000 RPM, ensuring the structural integrity and containment of the flywheel is paramount. The BMS must incorporate robust safety features, including emergency shutdown mechanisms and continuous monitoring of critical parameters to prevent catastrophic failures.

The integration of flywheel energy storage systems into the broader energy landscape presents both opportunities and challenges. As renewable energy sources become more prevalent, the need for fast-responding, high-power energy storage solutions grows. Flywheels, with their ability to rapidly absorb and release energy, are well-suited to provide grid stabilization services, frequency regulation, and short-term power quality improvement.

The development of BMS for flywheel energy storage also aims to address the scalability and modularity of these systems. By creating standardized management interfaces and protocols, the goal is to facilitate the integration of flywheel storage units into larger energy storage arrays or hybrid systems combining different storage technologies.

As the technology progresses, there is a growing focus on improving the energy density and reducing the cost of flywheel systems. The BMS plays a crucial role in this endeavor by optimizing the performance of existing hardware and enabling the implementation of more advanced flywheel designs. This includes exploring the use of novel materials, such as carbon fiber composites, and pushing the boundaries of rotational speeds to increase energy storage capacity.

The evolution of flywheel technology can be traced back to ancient times, with its modern applications in energy storage gaining traction in the late 20th century. Initially used in mechanical systems, flywheels have transitioned into high-tech energy storage devices, incorporating advanced materials, magnetic bearings, and vacuum enclosures to minimize friction and energy losses.

The primary objective of developing BMS for flywheel energy storage is to address the unique challenges posed by these systems. Unlike traditional chemical batteries, flywheels store energy in the form of rotational kinetic energy, requiring specialized management techniques. The BMS must monitor and control various parameters such as rotational speed, temperature, vibration, and power flow to ensure optimal operation and longevity of the flywheel system.

One of the key goals is to enhance the overall efficiency of flywheel energy storage. This involves minimizing standby losses, optimizing charge and discharge cycles, and ensuring precise control of the flywheel's rotational speed. The BMS plays a crucial role in achieving these objectives by implementing advanced control algorithms and real-time monitoring systems.

Safety is another critical aspect driving the development of flywheel BMS. Given the high rotational speeds involved, typically ranging from 20,000 to 50,000 RPM, ensuring the structural integrity and containment of the flywheel is paramount. The BMS must incorporate robust safety features, including emergency shutdown mechanisms and continuous monitoring of critical parameters to prevent catastrophic failures.

The integration of flywheel energy storage systems into the broader energy landscape presents both opportunities and challenges. As renewable energy sources become more prevalent, the need for fast-responding, high-power energy storage solutions grows. Flywheels, with their ability to rapidly absorb and release energy, are well-suited to provide grid stabilization services, frequency regulation, and short-term power quality improvement.

The development of BMS for flywheel energy storage also aims to address the scalability and modularity of these systems. By creating standardized management interfaces and protocols, the goal is to facilitate the integration of flywheel storage units into larger energy storage arrays or hybrid systems combining different storage technologies.

As the technology progresses, there is a growing focus on improving the energy density and reducing the cost of flywheel systems. The BMS plays a crucial role in this endeavor by optimizing the performance of existing hardware and enabling the implementation of more advanced flywheel designs. This includes exploring the use of novel materials, such as carbon fiber composites, and pushing the boundaries of rotational speeds to increase energy storage capacity.

Market Analysis for Flywheel Energy Storage

The market for flywheel energy storage systems has been experiencing significant growth in recent years, driven by the increasing demand for efficient and sustainable energy storage solutions. As renewable energy sources become more prevalent, the need for reliable energy storage technologies to balance grid fluctuations and provide backup power has intensified. Flywheel energy storage systems have emerged as a promising solution due to their high power density, long cycle life, and rapid response times.

The global flywheel energy storage market is projected to expand at a compound annual growth rate (CAGR) of over 8% from 2021 to 2026. This growth is primarily attributed to the rising adoption of renewable energy sources, the need for grid stabilization, and the increasing focus on energy efficiency across various industries. The market is segmented based on application, including uninterruptible power supply (UPS), distributed energy generation, transport, and data centers.

In the UPS segment, flywheels are gaining traction as a reliable alternative to traditional battery-based systems, particularly in mission-critical applications such as healthcare facilities and data centers. The distributed energy generation sector is also driving market growth, as flywheels can effectively smooth out power fluctuations from intermittent renewable sources like solar and wind.

Geographically, North America currently holds the largest market share, followed by Europe and Asia-Pacific. The United States, in particular, has seen significant investments in flywheel energy storage projects, supported by government initiatives promoting clean energy technologies. Europe's market growth is driven by stringent environmental regulations and the push for grid modernization.

Key market players in the flywheel energy storage industry include Active Power, Beacon Power, Calnetix Technologies, and Vycon Energy. These companies are focusing on technological advancements to improve the efficiency and cost-effectiveness of flywheel systems. Innovations in materials science, such as the development of high-strength composite materials for rotor construction, are expected to further enhance the performance and market appeal of flywheel energy storage solutions.

Despite the positive market outlook, challenges remain. The high initial capital costs associated with flywheel systems compared to some traditional energy storage technologies can be a barrier to widespread adoption. Additionally, the limited energy storage capacity of flywheels compared to large-scale battery systems may restrict their application in certain long-duration storage scenarios.

Looking ahead, the integration of advanced battery management systems with flywheel energy storage is expected to open new market opportunities. This combination can leverage the strengths of both technologies, providing a more comprehensive energy storage solution that addresses a wider range of applications and customer needs.

The global flywheel energy storage market is projected to expand at a compound annual growth rate (CAGR) of over 8% from 2021 to 2026. This growth is primarily attributed to the rising adoption of renewable energy sources, the need for grid stabilization, and the increasing focus on energy efficiency across various industries. The market is segmented based on application, including uninterruptible power supply (UPS), distributed energy generation, transport, and data centers.

In the UPS segment, flywheels are gaining traction as a reliable alternative to traditional battery-based systems, particularly in mission-critical applications such as healthcare facilities and data centers. The distributed energy generation sector is also driving market growth, as flywheels can effectively smooth out power fluctuations from intermittent renewable sources like solar and wind.

Geographically, North America currently holds the largest market share, followed by Europe and Asia-Pacific. The United States, in particular, has seen significant investments in flywheel energy storage projects, supported by government initiatives promoting clean energy technologies. Europe's market growth is driven by stringent environmental regulations and the push for grid modernization.

Key market players in the flywheel energy storage industry include Active Power, Beacon Power, Calnetix Technologies, and Vycon Energy. These companies are focusing on technological advancements to improve the efficiency and cost-effectiveness of flywheel systems. Innovations in materials science, such as the development of high-strength composite materials for rotor construction, are expected to further enhance the performance and market appeal of flywheel energy storage solutions.

Despite the positive market outlook, challenges remain. The high initial capital costs associated with flywheel systems compared to some traditional energy storage technologies can be a barrier to widespread adoption. Additionally, the limited energy storage capacity of flywheels compared to large-scale battery systems may restrict their application in certain long-duration storage scenarios.

Looking ahead, the integration of advanced battery management systems with flywheel energy storage is expected to open new market opportunities. This combination can leverage the strengths of both technologies, providing a more comprehensive energy storage solution that addresses a wider range of applications and customer needs.

Current BMS Challenges in Flywheel Systems

Battery Management Systems (BMS) for Flywheel Energy Storage face several significant challenges in their development and implementation. One of the primary issues is the high-speed rotation of flywheels, which can reach up to 100,000 RPM. This extreme rotational speed creates unique thermal management challenges for the BMS, as the heat generated can significantly impact battery performance and lifespan.

Another critical challenge is the need for precise state of charge (SOC) and state of health (SOH) estimation. Unlike traditional battery systems, flywheel energy storage systems experience rapid charge and discharge cycles, making accurate SOC and SOH calculations more complex. The BMS must adapt to these quick energy fluctuations while maintaining reliable estimations to ensure optimal system performance and longevity.

The integration of advanced sensors and monitoring systems poses another hurdle for BMS development in flywheel applications. The high-speed rotation and potential vibrations require robust and highly sensitive sensors capable of withstanding these extreme conditions while providing accurate real-time data. This requirement often leads to increased costs and complexity in BMS design and implementation.

Safety considerations present a significant challenge for BMS in flywheel systems. The high rotational energy stored in flywheels can pose serious risks if not properly managed. The BMS must incorporate advanced safety features, including emergency shutdown mechanisms and containment strategies, to mitigate potential hazards associated with system failures or unexpected events.

Balancing energy efficiency with system reliability is another ongoing challenge. While maximizing energy storage and discharge efficiency is crucial, the BMS must also ensure consistent and reliable operation under various conditions. This balance often requires sophisticated control algorithms and predictive maintenance capabilities, adding to the complexity of BMS development.

The scalability of BMS solutions for different flywheel sizes and applications presents additional challenges. As flywheel energy storage systems can vary significantly in size and capacity, developing a versatile BMS that can be easily adapted to different configurations while maintaining optimal performance is a complex task.

Lastly, the integration of flywheel energy storage systems with existing power grids and renewable energy sources introduces interoperability challenges for BMS. Ensuring seamless communication and coordination between the flywheel system, its BMS, and the broader energy infrastructure requires advanced communication protocols and grid integration strategies.

Another critical challenge is the need for precise state of charge (SOC) and state of health (SOH) estimation. Unlike traditional battery systems, flywheel energy storage systems experience rapid charge and discharge cycles, making accurate SOC and SOH calculations more complex. The BMS must adapt to these quick energy fluctuations while maintaining reliable estimations to ensure optimal system performance and longevity.

The integration of advanced sensors and monitoring systems poses another hurdle for BMS development in flywheel applications. The high-speed rotation and potential vibrations require robust and highly sensitive sensors capable of withstanding these extreme conditions while providing accurate real-time data. This requirement often leads to increased costs and complexity in BMS design and implementation.

Safety considerations present a significant challenge for BMS in flywheel systems. The high rotational energy stored in flywheels can pose serious risks if not properly managed. The BMS must incorporate advanced safety features, including emergency shutdown mechanisms and containment strategies, to mitigate potential hazards associated with system failures or unexpected events.

Balancing energy efficiency with system reliability is another ongoing challenge. While maximizing energy storage and discharge efficiency is crucial, the BMS must also ensure consistent and reliable operation under various conditions. This balance often requires sophisticated control algorithms and predictive maintenance capabilities, adding to the complexity of BMS development.

The scalability of BMS solutions for different flywheel sizes and applications presents additional challenges. As flywheel energy storage systems can vary significantly in size and capacity, developing a versatile BMS that can be easily adapted to different configurations while maintaining optimal performance is a complex task.

Lastly, the integration of flywheel energy storage systems with existing power grids and renewable energy sources introduces interoperability challenges for BMS. Ensuring seamless communication and coordination between the flywheel system, its BMS, and the broader energy infrastructure requires advanced communication protocols and grid integration strategies.

Existing BMS Solutions for Flywheels

01 Battery monitoring and control systems

These systems monitor various parameters of batteries, such as voltage, current, temperature, and state of charge. They use this information to optimize battery performance, extend battery life, and ensure safe operation. Advanced algorithms are employed to estimate battery health and predict remaining useful life.- Battery monitoring and control systems: These systems monitor various parameters of battery cells or packs, such as voltage, current, temperature, and state of charge. They use this data to optimize battery performance, ensure safe operation, and extend battery life through intelligent charging and discharging strategies.

- Thermal management in battery systems: Thermal management is crucial for battery performance and longevity. This involves techniques for heat dissipation, temperature regulation, and cooling systems to maintain optimal operating conditions for battery cells and packs, especially in high-power applications.

- Battery balancing techniques: Battery balancing ensures that all cells in a battery pack maintain similar voltage levels, preventing overcharging or undercharging of individual cells. This includes passive and active balancing methods to equalize charge distribution and improve overall battery performance and lifespan.

- State of charge and health estimation: Advanced algorithms and techniques are used to accurately estimate the state of charge (SoC) and state of health (SoH) of batteries. This information is crucial for predicting remaining battery life, optimizing charging cycles, and scheduling maintenance.

- Integration with power electronics and energy systems: Battery management systems are increasingly integrated with power electronics and broader energy management systems. This integration allows for more efficient energy distribution, grid interaction, and optimization of renewable energy sources in conjunction with battery storage.

02 Thermal management in battery systems

Thermal management is crucial for maintaining optimal battery performance and longevity. These systems employ various cooling and heating mechanisms to keep batteries within their ideal temperature range. They may include active cooling systems, passive heat dissipation methods, or a combination of both to regulate battery temperature effectively.Expand Specific Solutions03 Cell balancing techniques

Cell balancing is essential for maintaining uniform charge levels across all cells in a battery pack. This process helps to maximize overall battery capacity and lifespan. Various balancing methods are used, including passive and active balancing techniques, to ensure optimal performance of the entire battery system.Expand Specific Solutions04 Integration with energy management systems

Battery management systems are increasingly integrated with broader energy management systems in applications such as electric vehicles and renewable energy storage. This integration allows for optimized energy distribution, improved efficiency, and better coordination between power sources and loads.Expand Specific Solutions05 Safety features and fault detection

Advanced safety features are incorporated into battery management systems to detect and mitigate potential hazards. These include overcharge protection, over-discharge prevention, short circuit detection, and thermal runaway prevention. Sophisticated fault detection algorithms are employed to identify and isolate issues before they escalate.Expand Specific Solutions

Key Players in Flywheel BMS Industry

The development of Battery Management Systems for Flywheel Energy Storage is in a growth phase, with increasing market size due to rising demand for efficient energy storage solutions. The technology is maturing, with companies like Torus, Inc. and Helix Power Corp. leading innovation in flywheel systems. Established players such as YASKAWA Electric Corp. and Embraer SA are also entering the market, indicating growing industry interest. Academic institutions like Tianjin University and Harbin Institute of Technology are contributing to research and development, further advancing the technology. The competitive landscape is diverse, with startups, large corporations, and research institutions all vying for market share in this promising field.

American Flywheel Systems, Inc.

Technical Solution: American Flywheel Systems, Inc. has developed advanced Battery Management Systems (BMS) for Flywheel Energy Storage Systems (FESS). Their BMS utilizes a multi-level control architecture, integrating high-speed microcontrollers for real-time monitoring and control of individual flywheel cells. The system employs sophisticated algorithms for state estimation, including State of Charge (SoC) and State of Health (SoH) calculations, which are crucial for optimizing the performance and longevity of FESS[1]. The BMS also incorporates advanced thermal management techniques, using a combination of active and passive cooling methods to maintain optimal operating temperatures for the flywheel system[3]. Additionally, their BMS features a predictive maintenance module that uses machine learning algorithms to anticipate potential failures and schedule maintenance activities, thereby reducing downtime and extending the system's lifespan[5].

Strengths: Highly specialized in flywheel technology, advanced control algorithms, and predictive maintenance capabilities. Weaknesses: May have limited scalability for larger grid-scale applications and potentially higher costs due to specialized components.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed a comprehensive Battery Management System for Flywheel Energy Storage that integrates seamlessly with their broader energy management solutions. Their BMS utilizes advanced sensor technology and proprietary algorithms to monitor and control the flywheel's rotational speed, energy input/output, and system health in real-time[2]. The system incorporates a distributed architecture, allowing for scalability and redundancy in large-scale FESS installations. Honeywell's BMS also features adaptive control strategies that optimize charge and discharge cycles based on historical usage patterns and predicted energy demands, improving overall system efficiency[4]. Furthermore, their solution includes a robust safety management system that can quickly detect and respond to anomalies, ensuring safe operation even under extreme conditions[6].

Strengths: Extensive experience in industrial control systems, strong integration capabilities with other energy management systems, and global support network. Weaknesses: May not be as specialized in flywheel technology compared to dedicated flywheel companies.

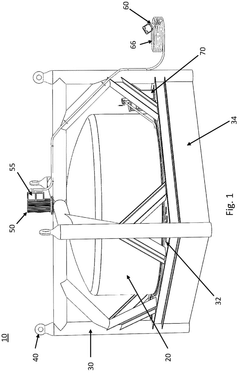

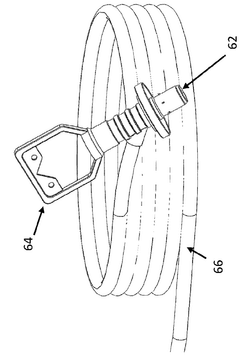

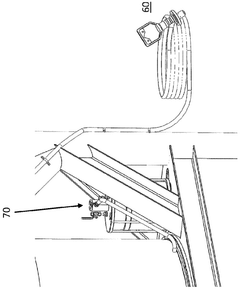

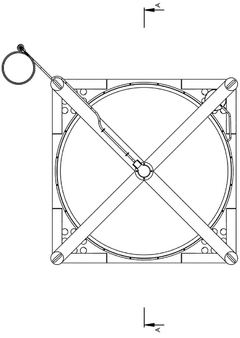

Core BMS Innovations for Flywheel Energy Storage

Developments to flywheel energy storage

PatentPendingAU2024210137A1

Innovation

- Utilize ambient high-pressure environments, such as underwater or caves, to compress flywheel rotors made of low tensile strength materials like concrete or ceramics, using the external pressure to increase energy storage capacity and reduce material costs by eliminating the need for high-pressure vessels.

Safety Standards for Flywheel Energy Storage

Safety standards for flywheel energy storage systems are critical to ensure the reliable and secure operation of these advanced energy storage technologies. The development of comprehensive safety guidelines is essential due to the high-speed rotation and significant kinetic energy involved in flywheel systems. These standards typically address various aspects, including mechanical integrity, containment systems, and operational procedures.

One of the primary safety concerns for flywheel energy storage is the risk of catastrophic failure, which could result in the release of high-energy fragments. To mitigate this risk, safety standards often require robust containment systems designed to withstand the maximum energy release in case of a rotor failure. These containment systems usually consist of multiple layers of high-strength materials, such as steel or composite materials, capable of absorbing and dissipating the energy from potential rotor fragments.

Vibration monitoring and control are also crucial components of flywheel safety standards. Excessive vibration can lead to imbalances and potential system failures. Safety guidelines typically mandate the implementation of advanced vibration sensors and control systems to detect and mitigate any abnormal vibrations during operation. These systems may include automatic shutdown procedures if vibration levels exceed predetermined thresholds.

Electrical safety is another key aspect addressed in flywheel energy storage safety standards. The high-speed rotation of the flywheel requires sophisticated power electronics for energy conversion and control. Safety guidelines often specify requirements for electrical insulation, grounding systems, and protection against electromagnetic interference to prevent electrical hazards and ensure system stability.

Environmental factors, such as temperature and humidity control, are also considered in safety standards. Flywheels generate heat during operation, and proper thermal management is essential to maintain system integrity and prevent material degradation. Standards may specify acceptable temperature ranges and cooling system requirements to ensure safe and efficient operation across various environmental conditions.

Operational safety procedures form a significant part of flywheel energy storage safety standards. These include guidelines for system startup, shutdown, and maintenance activities. Safety protocols often require trained personnel to perform these operations and may specify the use of personal protective equipment when working with or near flywheel systems.

Emergency response and failure mitigation strategies are integral components of safety standards. These may include automatic shutdown procedures, fire suppression systems, and containment breach detection mechanisms. Standards often require the development of comprehensive emergency response plans and regular safety drills to ensure preparedness in case of system failures or accidents.

As the technology continues to evolve, safety standards for flywheel energy storage systems are regularly updated to incorporate new insights and address emerging challenges. Collaboration between industry stakeholders, regulatory bodies, and research institutions is crucial in developing and refining these standards to ensure the safe and widespread adoption of flywheel energy storage technology.

One of the primary safety concerns for flywheel energy storage is the risk of catastrophic failure, which could result in the release of high-energy fragments. To mitigate this risk, safety standards often require robust containment systems designed to withstand the maximum energy release in case of a rotor failure. These containment systems usually consist of multiple layers of high-strength materials, such as steel or composite materials, capable of absorbing and dissipating the energy from potential rotor fragments.

Vibration monitoring and control are also crucial components of flywheel safety standards. Excessive vibration can lead to imbalances and potential system failures. Safety guidelines typically mandate the implementation of advanced vibration sensors and control systems to detect and mitigate any abnormal vibrations during operation. These systems may include automatic shutdown procedures if vibration levels exceed predetermined thresholds.

Electrical safety is another key aspect addressed in flywheel energy storage safety standards. The high-speed rotation of the flywheel requires sophisticated power electronics for energy conversion and control. Safety guidelines often specify requirements for electrical insulation, grounding systems, and protection against electromagnetic interference to prevent electrical hazards and ensure system stability.

Environmental factors, such as temperature and humidity control, are also considered in safety standards. Flywheels generate heat during operation, and proper thermal management is essential to maintain system integrity and prevent material degradation. Standards may specify acceptable temperature ranges and cooling system requirements to ensure safe and efficient operation across various environmental conditions.

Operational safety procedures form a significant part of flywheel energy storage safety standards. These include guidelines for system startup, shutdown, and maintenance activities. Safety protocols often require trained personnel to perform these operations and may specify the use of personal protective equipment when working with or near flywheel systems.

Emergency response and failure mitigation strategies are integral components of safety standards. These may include automatic shutdown procedures, fire suppression systems, and containment breach detection mechanisms. Standards often require the development of comprehensive emergency response plans and regular safety drills to ensure preparedness in case of system failures or accidents.

As the technology continues to evolve, safety standards for flywheel energy storage systems are regularly updated to incorporate new insights and address emerging challenges. Collaboration between industry stakeholders, regulatory bodies, and research institutions is crucial in developing and refining these standards to ensure the safe and widespread adoption of flywheel energy storage technology.

Environmental Impact of Flywheel BMS

The environmental impact of Battery Management Systems (BMS) for Flywheel Energy Storage is a crucial consideration in the development and implementation of this technology. Flywheel energy storage systems, when coupled with efficient BMS, offer several environmental benefits compared to traditional energy storage methods.

One of the primary advantages of flywheel BMS is their contribution to reducing greenhouse gas emissions. By enabling more efficient energy storage and distribution, these systems can help optimize the use of renewable energy sources, such as wind and solar power. This optimization leads to a decreased reliance on fossil fuel-based energy generation, resulting in lower carbon dioxide emissions and other pollutants associated with conventional power plants.

The materials used in flywheel BMS also play a significant role in their environmental impact. Unlike many battery technologies that rely on rare earth elements or toxic materials, flywheels typically use more environmentally friendly components. The use of composite materials in modern flywheels further reduces their environmental footprint, as these materials are often lighter and more durable than traditional metal alternatives.

Flywheel BMS systems also demonstrate superior longevity compared to chemical batteries. With proper maintenance, flywheels can operate for decades without significant degradation in performance. This extended lifespan reduces the need for frequent replacements, minimizing waste generation and the environmental impact associated with manufacturing and disposing of energy storage components.

The operational efficiency of flywheel BMS contributes to their positive environmental profile. These systems have minimal energy losses during charge and discharge cycles, leading to better overall energy utilization. This efficiency translates to reduced energy consumption and, consequently, lower environmental impact throughout the system's lifecycle.

However, it is important to consider the potential negative environmental aspects of flywheel BMS. The manufacturing process of high-precision components used in flywheels and their management systems can be energy-intensive. Additionally, the rare earth magnets sometimes used in flywheel designs may have environmental implications related to their extraction and processing.

Noise pollution is another factor to consider, as some flywheel systems can generate significant noise during operation. This issue is particularly relevant in urban or residential settings where noise regulations may be stringent. However, advancements in design and insulation techniques are continuously addressing this concern.

In conclusion, while flywheel BMS technology presents some environmental challenges, its overall impact is generally positive when compared to many alternative energy storage solutions. The technology's ability to enhance renewable energy integration, coupled with its long lifespan and efficient operation, positions it as an environmentally favorable option for energy storage applications. As research and development in this field continue, further improvements in materials and design are likely to enhance the environmental benefits of flywheel BMS systems.

One of the primary advantages of flywheel BMS is their contribution to reducing greenhouse gas emissions. By enabling more efficient energy storage and distribution, these systems can help optimize the use of renewable energy sources, such as wind and solar power. This optimization leads to a decreased reliance on fossil fuel-based energy generation, resulting in lower carbon dioxide emissions and other pollutants associated with conventional power plants.

The materials used in flywheel BMS also play a significant role in their environmental impact. Unlike many battery technologies that rely on rare earth elements or toxic materials, flywheels typically use more environmentally friendly components. The use of composite materials in modern flywheels further reduces their environmental footprint, as these materials are often lighter and more durable than traditional metal alternatives.

Flywheel BMS systems also demonstrate superior longevity compared to chemical batteries. With proper maintenance, flywheels can operate for decades without significant degradation in performance. This extended lifespan reduces the need for frequent replacements, minimizing waste generation and the environmental impact associated with manufacturing and disposing of energy storage components.

The operational efficiency of flywheel BMS contributes to their positive environmental profile. These systems have minimal energy losses during charge and discharge cycles, leading to better overall energy utilization. This efficiency translates to reduced energy consumption and, consequently, lower environmental impact throughout the system's lifecycle.

However, it is important to consider the potential negative environmental aspects of flywheel BMS. The manufacturing process of high-precision components used in flywheels and their management systems can be energy-intensive. Additionally, the rare earth magnets sometimes used in flywheel designs may have environmental implications related to their extraction and processing.

Noise pollution is another factor to consider, as some flywheel systems can generate significant noise during operation. This issue is particularly relevant in urban or residential settings where noise regulations may be stringent. However, advancements in design and insulation techniques are continuously addressing this concern.

In conclusion, while flywheel BMS technology presents some environmental challenges, its overall impact is generally positive when compared to many alternative energy storage solutions. The technology's ability to enhance renewable energy integration, coupled with its long lifespan and efficient operation, positions it as an environmentally favorable option for energy storage applications. As research and development in this field continue, further improvements in materials and design are likely to enhance the environmental benefits of flywheel BMS systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!