Development of mild hybrid architectural frameworks in multi-vehicle platforms

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid Evolution and Objectives

Mild hybrid technology has evolved significantly over the past two decades, driven by the automotive industry's need to improve fuel efficiency and reduce emissions. The journey began with simple start-stop systems and has progressed to more sophisticated architectures that integrate electric motors with conventional powertrains. This evolution has been marked by incremental improvements in energy recovery, electric assist capabilities, and overall system integration.

The primary objective of mild hybrid systems is to enhance the efficiency of internal combustion engines without the complexity and cost associated with full hybrid or electric vehicles. By providing electric assist during acceleration, enabling engine-off coasting, and recovering energy during deceleration, mild hybrids aim to achieve a balance between performance improvement and cost-effectiveness.

In the context of multi-vehicle platforms, the development of mild hybrid architectural frameworks presents both opportunities and challenges. The goal is to create flexible and scalable solutions that can be adapted across various vehicle models and segments. This approach allows automakers to leverage economies of scale while tailoring the hybrid system to specific vehicle requirements.

Key objectives in the development of mild hybrid frameworks for multi-vehicle platforms include standardization of components, modular design principles, and seamless integration with existing powertrain architectures. Standardization enables cost reduction through volume production, while modularity allows for easy customization to meet diverse vehicle specifications. The integration challenge lies in developing systems that can be easily adapted to different engine types, transmission configurations, and vehicle sizes without extensive redesign.

Another critical objective is the optimization of power management strategies. As mild hybrid systems become more advanced, the complexity of controlling the interaction between the electric motor and the internal combustion engine increases. Developing sophisticated control algorithms that can be fine-tuned for different vehicle applications is essential for maximizing efficiency gains across the platform.

Furthermore, the evolution of mild hybrid frameworks aims to progressively increase the voltage levels of electrical systems. Moving from 12V to 48V and potentially higher voltages in the future allows for more powerful electric motors, enhanced energy recovery, and expanded electric-only operation capabilities. This progression is crucial for meeting increasingly stringent emissions regulations and improving fuel economy across diverse vehicle lineups.

As the technology continues to mature, the objectives extend beyond mere efficiency improvements. Future mild hybrid frameworks seek to enhance vehicle dynamics, provide smoother driving experiences, and serve as a stepping stone towards more extensive electrification. The ultimate goal is to create a versatile hybrid architecture that can be seamlessly scaled and adapted, paving the way for a gradual transition to electrified powertrains across multiple vehicle platforms.

The primary objective of mild hybrid systems is to enhance the efficiency of internal combustion engines without the complexity and cost associated with full hybrid or electric vehicles. By providing electric assist during acceleration, enabling engine-off coasting, and recovering energy during deceleration, mild hybrids aim to achieve a balance between performance improvement and cost-effectiveness.

In the context of multi-vehicle platforms, the development of mild hybrid architectural frameworks presents both opportunities and challenges. The goal is to create flexible and scalable solutions that can be adapted across various vehicle models and segments. This approach allows automakers to leverage economies of scale while tailoring the hybrid system to specific vehicle requirements.

Key objectives in the development of mild hybrid frameworks for multi-vehicle platforms include standardization of components, modular design principles, and seamless integration with existing powertrain architectures. Standardization enables cost reduction through volume production, while modularity allows for easy customization to meet diverse vehicle specifications. The integration challenge lies in developing systems that can be easily adapted to different engine types, transmission configurations, and vehicle sizes without extensive redesign.

Another critical objective is the optimization of power management strategies. As mild hybrid systems become more advanced, the complexity of controlling the interaction between the electric motor and the internal combustion engine increases. Developing sophisticated control algorithms that can be fine-tuned for different vehicle applications is essential for maximizing efficiency gains across the platform.

Furthermore, the evolution of mild hybrid frameworks aims to progressively increase the voltage levels of electrical systems. Moving from 12V to 48V and potentially higher voltages in the future allows for more powerful electric motors, enhanced energy recovery, and expanded electric-only operation capabilities. This progression is crucial for meeting increasingly stringent emissions regulations and improving fuel economy across diverse vehicle lineups.

As the technology continues to mature, the objectives extend beyond mere efficiency improvements. Future mild hybrid frameworks seek to enhance vehicle dynamics, provide smoother driving experiences, and serve as a stepping stone towards more extensive electrification. The ultimate goal is to create a versatile hybrid architecture that can be seamlessly scaled and adapted, paving the way for a gradual transition to electrified powertrains across multiple vehicle platforms.

Market Demand Analysis

The market demand for mild hybrid architectural frameworks in multi-vehicle platforms has been steadily increasing in recent years, driven by stringent emission regulations, growing environmental concerns, and the automotive industry's push towards electrification. This technology offers a cost-effective solution for automakers to improve fuel efficiency and reduce emissions without the complexity and expense of full hybrid or electric powertrains.

The global mild hybrid vehicle market is experiencing significant growth, with a projected compound annual growth rate (CAGR) of over 10% from 2021 to 2026. This growth is primarily fueled by the increasing adoption of 48V mild hybrid systems across various vehicle segments, from compact cars to luxury SUVs. The market size for mild hybrid systems is expected to reach several billion dollars by 2025, reflecting the strong demand for this technology.

Consumer preferences are shifting towards more fuel-efficient vehicles, and mild hybrid systems offer an attractive compromise between conventional internal combustion engines and full hybrid powertrains. These systems provide improved fuel economy, enhanced performance, and reduced emissions without significantly increasing vehicle costs or requiring extensive changes to existing vehicle architectures.

The automotive industry's focus on developing scalable and flexible platforms has further boosted the demand for mild hybrid architectural frameworks. Automakers are seeking solutions that can be easily integrated into multiple vehicle models across different segments, allowing for economies of scale and reduced development costs. This trend has led to increased interest in modular mild hybrid systems that can be adapted to various vehicle types and powertrain configurations.

Regional market analysis reveals that Europe and Asia-Pacific are leading the adoption of mild hybrid technologies, driven by stringent emission norms and government incentives. North America is also showing growing interest, particularly in the light truck and SUV segments. Emerging markets are expected to contribute significantly to future growth as they implement stricter emission standards and consumers become more environmentally conscious.

The demand for mild hybrid systems is not limited to passenger vehicles. Commercial vehicle manufacturers are also exploring mild hybrid technologies to meet increasingly stringent emission regulations for trucks and buses. This expansion into the commercial sector is opening up new market opportunities and driving further innovation in mild hybrid architectural frameworks.

As the automotive industry continues its transition towards electrification, mild hybrid systems are positioned as a crucial stepping stone. They offer a balance between improved efficiency and cost-effectiveness, making them an attractive option for both manufacturers and consumers. The ongoing development of more advanced and integrated mild hybrid architectural frameworks for multi-vehicle platforms is expected to sustain market growth and drive technological advancements in the coming years.

The global mild hybrid vehicle market is experiencing significant growth, with a projected compound annual growth rate (CAGR) of over 10% from 2021 to 2026. This growth is primarily fueled by the increasing adoption of 48V mild hybrid systems across various vehicle segments, from compact cars to luxury SUVs. The market size for mild hybrid systems is expected to reach several billion dollars by 2025, reflecting the strong demand for this technology.

Consumer preferences are shifting towards more fuel-efficient vehicles, and mild hybrid systems offer an attractive compromise between conventional internal combustion engines and full hybrid powertrains. These systems provide improved fuel economy, enhanced performance, and reduced emissions without significantly increasing vehicle costs or requiring extensive changes to existing vehicle architectures.

The automotive industry's focus on developing scalable and flexible platforms has further boosted the demand for mild hybrid architectural frameworks. Automakers are seeking solutions that can be easily integrated into multiple vehicle models across different segments, allowing for economies of scale and reduced development costs. This trend has led to increased interest in modular mild hybrid systems that can be adapted to various vehicle types and powertrain configurations.

Regional market analysis reveals that Europe and Asia-Pacific are leading the adoption of mild hybrid technologies, driven by stringent emission norms and government incentives. North America is also showing growing interest, particularly in the light truck and SUV segments. Emerging markets are expected to contribute significantly to future growth as they implement stricter emission standards and consumers become more environmentally conscious.

The demand for mild hybrid systems is not limited to passenger vehicles. Commercial vehicle manufacturers are also exploring mild hybrid technologies to meet increasingly stringent emission regulations for trucks and buses. This expansion into the commercial sector is opening up new market opportunities and driving further innovation in mild hybrid architectural frameworks.

As the automotive industry continues its transition towards electrification, mild hybrid systems are positioned as a crucial stepping stone. They offer a balance between improved efficiency and cost-effectiveness, making them an attractive option for both manufacturers and consumers. The ongoing development of more advanced and integrated mild hybrid architectural frameworks for multi-vehicle platforms is expected to sustain market growth and drive technological advancements in the coming years.

Technical Challenges

The development of mild hybrid architectural frameworks for multi-vehicle platforms faces several significant technical challenges. One of the primary obstacles is the integration of hybrid systems across diverse vehicle types and sizes. This requires a flexible and scalable architecture that can accommodate varying power requirements, space constraints, and performance expectations.

Optimizing energy management strategies poses another major challenge. The mild hybrid system must efficiently distribute power between the internal combustion engine and the electric motor, considering factors such as driving conditions, battery state of charge, and vehicle load. Developing sophisticated control algorithms that can adapt to different vehicle configurations and driving scenarios is crucial for maximizing fuel efficiency and performance.

Thermal management presents a complex challenge in mild hybrid systems. The addition of electric components introduces new heat sources that must be effectively managed to ensure optimal performance and longevity of both the hybrid system and the vehicle as a whole. Designing an integrated cooling system that can handle the thermal loads from both the conventional powertrain and the electric components requires innovative solutions.

Weight reduction and packaging constraints are significant hurdles in developing mild hybrid frameworks. The addition of electric motors, batteries, and associated electronics increases the overall vehicle weight, which can negatively impact fuel efficiency and performance. Engineers must find creative ways to integrate these components within existing vehicle architectures while minimizing weight gain and maintaining optimal weight distribution.

Cost optimization remains a critical challenge in the widespread adoption of mild hybrid technologies. Developing a cost-effective solution that can be implemented across multiple vehicle platforms requires careful consideration of component selection, manufacturing processes, and supply chain management. Balancing the additional costs of hybrid components against the potential fuel savings and performance benefits is essential for market viability.

Ensuring compatibility with existing manufacturing processes and supply chains presents another technical challenge. The mild hybrid framework must be designed in a way that allows for seamless integration into current production lines, minimizing disruption and additional tooling costs. This requires close collaboration between hybrid system developers and vehicle manufacturers to create standardized interfaces and modular components.

Lastly, meeting increasingly stringent emissions regulations across different markets adds complexity to the development process. The mild hybrid system must be capable of reducing emissions effectively in various driving conditions and regulatory environments. This necessitates advanced emission control strategies and the ability to adapt the hybrid system's operation to meet specific regional requirements.

Optimizing energy management strategies poses another major challenge. The mild hybrid system must efficiently distribute power between the internal combustion engine and the electric motor, considering factors such as driving conditions, battery state of charge, and vehicle load. Developing sophisticated control algorithms that can adapt to different vehicle configurations and driving scenarios is crucial for maximizing fuel efficiency and performance.

Thermal management presents a complex challenge in mild hybrid systems. The addition of electric components introduces new heat sources that must be effectively managed to ensure optimal performance and longevity of both the hybrid system and the vehicle as a whole. Designing an integrated cooling system that can handle the thermal loads from both the conventional powertrain and the electric components requires innovative solutions.

Weight reduction and packaging constraints are significant hurdles in developing mild hybrid frameworks. The addition of electric motors, batteries, and associated electronics increases the overall vehicle weight, which can negatively impact fuel efficiency and performance. Engineers must find creative ways to integrate these components within existing vehicle architectures while minimizing weight gain and maintaining optimal weight distribution.

Cost optimization remains a critical challenge in the widespread adoption of mild hybrid technologies. Developing a cost-effective solution that can be implemented across multiple vehicle platforms requires careful consideration of component selection, manufacturing processes, and supply chain management. Balancing the additional costs of hybrid components against the potential fuel savings and performance benefits is essential for market viability.

Ensuring compatibility with existing manufacturing processes and supply chains presents another technical challenge. The mild hybrid framework must be designed in a way that allows for seamless integration into current production lines, minimizing disruption and additional tooling costs. This requires close collaboration between hybrid system developers and vehicle manufacturers to create standardized interfaces and modular components.

Lastly, meeting increasingly stringent emissions regulations across different markets adds complexity to the development process. The mild hybrid system must be capable of reducing emissions effectively in various driving conditions and regulatory environments. This necessitates advanced emission control strategies and the ability to adapt the hybrid system's operation to meet specific regional requirements.

Current Architectural Solutions

01 Powertrain configurations for mild hybrid vehicles

Various powertrain configurations are designed for mild hybrid vehicles, integrating electric motors with conventional internal combustion engines. These architectures aim to improve fuel efficiency and reduce emissions while maintaining performance. The configurations may include different placements of the electric motor, such as between the engine and transmission or integrated into the transmission itself.- Powertrain configurations for mild hybrid vehicles: Various powertrain configurations are designed for mild hybrid vehicles, integrating electric motors with conventional internal combustion engines. These architectures aim to improve fuel efficiency and reduce emissions while maintaining performance. The configurations may include different placements of electric motors, such as between the engine and transmission or integrated into the transmission itself.

- Energy management systems for mild hybrids: Advanced energy management systems are developed to optimize the operation of mild hybrid vehicles. These systems control the distribution of power between the internal combustion engine and electric motor, manage battery charging and discharging, and implement regenerative braking strategies. The goal is to maximize overall system efficiency and reduce fuel consumption.

- Transmission designs for mild hybrid systems: Specialized transmission designs are created to accommodate the unique requirements of mild hybrid powertrains. These may include integrated motor-generator units, advanced clutch systems, and innovative gear arrangements. The transmissions are designed to seamlessly blend power from both the electric motor and internal combustion engine while enabling various operating modes.

- Control strategies for mild hybrid operations: Sophisticated control strategies are developed to manage the complex interactions between the internal combustion engine, electric motor, and other vehicle systems in mild hybrids. These strategies may include predictive algorithms, adaptive learning, and real-time optimization to enhance vehicle performance, efficiency, and drivability across various driving conditions.

- Integration of mild hybrid systems with vehicle architecture: Architectural frameworks are designed to seamlessly integrate mild hybrid components into the overall vehicle structure. This includes considerations for packaging, thermal management, electrical systems, and weight distribution. The goal is to minimize the impact on vehicle design while maximizing the benefits of the mild hybrid system.

02 Energy management systems for mild hybrids

Advanced energy management systems are developed to optimize the operation of mild hybrid vehicles. These systems control the distribution of power between the internal combustion engine and the electric motor, manage battery charging and discharging, and implement regenerative braking strategies. The goal is to maximize overall system efficiency and reduce fuel consumption.Expand Specific Solutions03 Integration of mild hybrid systems in existing vehicle platforms

Architectural frameworks are designed to facilitate the integration of mild hybrid systems into existing vehicle platforms. These frameworks focus on minimizing modifications to the base vehicle architecture while incorporating hybrid components such as electric motors, batteries, and power electronics. The aim is to reduce development costs and time-to-market for mild hybrid vehicles.Expand Specific Solutions04 Control strategies for mild hybrid drivetrains

Sophisticated control strategies are developed for mild hybrid drivetrains to optimize vehicle performance, fuel efficiency, and emissions. These strategies include torque blending between the electric motor and internal combustion engine, start-stop functionality, and adaptive control based on driving conditions and driver behavior. The control systems aim to provide seamless operation and improved driving experience.Expand Specific Solutions05 Thermal management in mild hybrid systems

Thermal management solutions are developed for mild hybrid systems to ensure optimal performance and longevity of components. These solutions address the cooling needs of electric motors, power electronics, and batteries, as well as the integration with the existing cooling system of the internal combustion engine. Efficient thermal management contributes to improved overall system efficiency and reliability.Expand Specific Solutions

Key Industry Players

The development of mild hybrid architectural frameworks in multi-vehicle platforms is currently in a transitional phase, with the market showing significant growth potential. The global mild hybrid market is expanding rapidly, driven by increasing demand for fuel-efficient vehicles and stricter emissions regulations. Technologically, the field is advancing, with major players like Mercedes-Benz, BMW, and Hyundai-Kia leading innovation. Companies such as Schaeffler, Bosch, and Johnson Controls are contributing crucial components and systems. While the technology is maturing, there's still room for improvement in areas like cost-effectiveness and integration across diverse vehicle platforms. Collaboration between automakers and suppliers is accelerating progress, with companies like Volkswagen and SAIC GM Wuling exploring new applications.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has implemented a sophisticated mild hybrid architecture across its vehicle lineup, branded as EQ Boost. The system utilizes a 48V electrical system with an Integrated Starter Generator (ISG) positioned between the engine and transmission. This configuration allows for seamless integration into various vehicle platforms, from compact cars to luxury sedans and SUVs. The ISG can provide up to 20 kW of power and 250 Nm of torque, enabling functions such as energy recuperation, electric boost, and gliding mode [4]. Mercedes-Benz has also developed an advanced power management system that optimizes the interaction between the combustion engine and electric components, resulting in improved fuel efficiency and performance. The EQ Boost system has been reported to reduce fuel consumption by up to 20% in certain driving scenarios [5].

Strengths: Seamless integration across diverse vehicle platforms; High power output from ISG; Advanced power management system. Weaknesses: Higher cost compared to simpler mild hybrid systems; Potential complexity in maintenance and repairs.

Bayerische Motoren Werke AG

Technical Solution: BMW has developed a versatile mild hybrid architecture that can be adapted to various vehicle platforms, from compact cars to luxury SUVs. Their system, often referred to as BMW eDrive, incorporates a 48V electrical system with an Integrated Starter Generator (ISG) that can provide up to 8 kW of electrical power. The ISG is positioned between the engine and transmission, allowing for efficient energy recuperation and power assistance [6]. BMW's mild hybrid system includes advanced power electronics and a 48V lithium-ion battery, typically with a capacity of 0.5 kWh. The system enables features such as electric boost, coasting with the engine off, and an enhanced start-stop function. BMW has reported fuel efficiency improvements of up to 10% in real-world driving conditions with their mild hybrid technology [7]. The company has also focused on optimizing the integration of the mild hybrid system with their existing powertrain architectures to ensure seamless operation and minimal impact on vehicle packaging.

Strengths: Wide range of vehicle applications; Seamless integration with existing powertrains; Focus on driving dynamics. Weaknesses: Lower power output compared to some competitors; Potential for increased vehicle weight.

Core Innovations

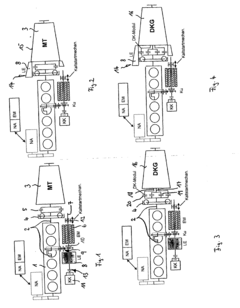

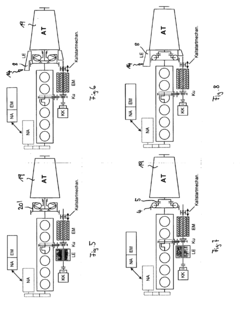

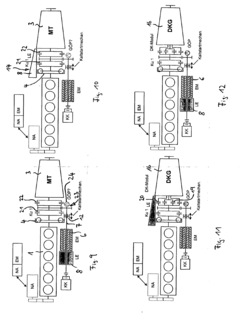

Hybrid transmission with offset electric machine and method for controlling gear changes

PatentWO2015197927A1

Innovation

- A compact hybrid transmission design with the electric machine positioned at the opposite end of the primary line from the heat engine, featuring a single differential drive pinion on the secondary shaft and a second electric machine coupled to the transfer shaft, along with three-position coupling devices controlled by a three-position electrical passage group and a five-position thermal passage functional group.

Hybrid vehicle

PatentActiveEP1870273A2

Innovation

- A hybrid vehicle design featuring a laterally offset electric machine with a large overall length and small diameter, allowing for a transmission device between the primary and secondary drives, enabling efficient energy recovery and ancillary unit operation, and providing multiple starting options including a starter pinion and separate cold start device.

Regulatory Landscape

The regulatory landscape for mild hybrid architectural frameworks in multi-vehicle platforms is rapidly evolving to address the growing demand for more fuel-efficient and environmentally friendly transportation solutions. Governments worldwide are implementing increasingly stringent emissions standards and fuel economy regulations, driving automotive manufacturers to adopt hybrid technologies across their vehicle lineups.

In the European Union, the implementation of Euro 7 emissions standards is expected to further accelerate the adoption of mild hybrid systems. These regulations aim to reduce nitrogen oxide (NOx) and particulate matter emissions from vehicles, pushing manufacturers to integrate electrification technologies into their powertrains. Similarly, the Corporate Average Fuel Economy (CAFE) standards in the United States continue to tighten, incentivizing automakers to incorporate mild hybrid architectures to meet fleet-wide fuel efficiency targets.

China, the world's largest automotive market, has also introduced policies to promote the development and adoption of new energy vehicles, including mild hybrids. The country's dual-credit policy system rewards manufacturers for producing vehicles with lower fuel consumption and higher electrification levels, creating a favorable regulatory environment for mild hybrid technologies.

The global trend towards carbon neutrality has led many countries to announce plans for phasing out internal combustion engine vehicles. This transition period presents a significant opportunity for mild hybrid architectures, as they offer a cost-effective stepping stone towards full electrification. Regulatory bodies are increasingly recognizing the role of mild hybrids in achieving short-term emissions reduction goals while the infrastructure for full electric vehicles continues to develop.

However, the regulatory landscape also presents challenges for multi-vehicle platform development. Varying emissions standards and incentive structures across different regions require manufacturers to design flexible mild hybrid architectures that can be easily adapted to meet diverse regulatory requirements. This necessitates a modular approach to hybrid system integration, allowing for scalability across different vehicle segments and markets.

Furthermore, regulations surrounding the recycling and disposal of hybrid components, particularly batteries, are becoming more stringent. Manufacturers must consider the entire lifecycle of their mild hybrid systems, from production to end-of-life management, to ensure compliance with emerging environmental regulations.

As the automotive industry continues to navigate this complex regulatory landscape, collaboration between manufacturers, suppliers, and regulatory bodies will be crucial in developing mild hybrid architectural frameworks that are both technologically advanced and compliant with global standards.

In the European Union, the implementation of Euro 7 emissions standards is expected to further accelerate the adoption of mild hybrid systems. These regulations aim to reduce nitrogen oxide (NOx) and particulate matter emissions from vehicles, pushing manufacturers to integrate electrification technologies into their powertrains. Similarly, the Corporate Average Fuel Economy (CAFE) standards in the United States continue to tighten, incentivizing automakers to incorporate mild hybrid architectures to meet fleet-wide fuel efficiency targets.

China, the world's largest automotive market, has also introduced policies to promote the development and adoption of new energy vehicles, including mild hybrids. The country's dual-credit policy system rewards manufacturers for producing vehicles with lower fuel consumption and higher electrification levels, creating a favorable regulatory environment for mild hybrid technologies.

The global trend towards carbon neutrality has led many countries to announce plans for phasing out internal combustion engine vehicles. This transition period presents a significant opportunity for mild hybrid architectures, as they offer a cost-effective stepping stone towards full electrification. Regulatory bodies are increasingly recognizing the role of mild hybrids in achieving short-term emissions reduction goals while the infrastructure for full electric vehicles continues to develop.

However, the regulatory landscape also presents challenges for multi-vehicle platform development. Varying emissions standards and incentive structures across different regions require manufacturers to design flexible mild hybrid architectures that can be easily adapted to meet diverse regulatory requirements. This necessitates a modular approach to hybrid system integration, allowing for scalability across different vehicle segments and markets.

Furthermore, regulations surrounding the recycling and disposal of hybrid components, particularly batteries, are becoming more stringent. Manufacturers must consider the entire lifecycle of their mild hybrid systems, from production to end-of-life management, to ensure compliance with emerging environmental regulations.

As the automotive industry continues to navigate this complex regulatory landscape, collaboration between manufacturers, suppliers, and regulatory bodies will be crucial in developing mild hybrid architectural frameworks that are both technologically advanced and compliant with global standards.

Cost-Benefit Analysis

The cost-benefit analysis of developing mild hybrid architectural frameworks for multi-vehicle platforms reveals a complex interplay of financial considerations and technological advantages. Initial investment costs for research, development, and implementation of mild hybrid systems across multiple vehicle platforms are substantial. These costs encompass engineering resources, prototype development, testing facilities, and potential retooling of production lines.

However, the long-term benefits of this investment are significant. Mild hybrid systems offer improved fuel efficiency and reduced emissions, aligning with increasingly stringent environmental regulations worldwide. This compliance can lead to avoided penalties and potential tax incentives, contributing to the overall cost-effectiveness of the technology.

From a manufacturing perspective, developing a unified mild hybrid framework for multiple vehicle platforms can lead to economies of scale. Standardized components and shared technology across different models reduce per-unit costs and simplify supply chain management. This approach also enhances production flexibility, allowing manufacturers to adapt quickly to market demands and regulatory changes.

Consumer benefits play a crucial role in the cost-benefit equation. While mild hybrid vehicles may have a higher initial price point, the improved fuel economy translates to lower operating costs for consumers over the vehicle's lifetime. This can enhance brand perception and potentially increase market share, offsetting development costs through increased sales volume.

The scalability of mild hybrid frameworks across multiple platforms also presents opportunities for faster return on investment. As the technology is implemented across a wider range of vehicles, development costs are spread over a larger production volume, accelerating the break-even point.

However, it's important to consider potential risks and hidden costs. These may include the need for specialized training for manufacturing and maintenance personnel, potential warranty issues related to new technology, and the cost of educating consumers about the benefits of mild hybrid systems.

In conclusion, while the upfront costs of developing mild hybrid architectural frameworks for multi-vehicle platforms are significant, the long-term benefits in terms of regulatory compliance, manufacturing efficiency, and market competitiveness present a compelling case for investment. The key to maximizing the cost-benefit ratio lies in effective planning, efficient implementation, and strategic deployment across the vehicle lineup.

However, the long-term benefits of this investment are significant. Mild hybrid systems offer improved fuel efficiency and reduced emissions, aligning with increasingly stringent environmental regulations worldwide. This compliance can lead to avoided penalties and potential tax incentives, contributing to the overall cost-effectiveness of the technology.

From a manufacturing perspective, developing a unified mild hybrid framework for multiple vehicle platforms can lead to economies of scale. Standardized components and shared technology across different models reduce per-unit costs and simplify supply chain management. This approach also enhances production flexibility, allowing manufacturers to adapt quickly to market demands and regulatory changes.

Consumer benefits play a crucial role in the cost-benefit equation. While mild hybrid vehicles may have a higher initial price point, the improved fuel economy translates to lower operating costs for consumers over the vehicle's lifetime. This can enhance brand perception and potentially increase market share, offsetting development costs through increased sales volume.

The scalability of mild hybrid frameworks across multiple platforms also presents opportunities for faster return on investment. As the technology is implemented across a wider range of vehicles, development costs are spread over a larger production volume, accelerating the break-even point.

However, it's important to consider potential risks and hidden costs. These may include the need for specialized training for manufacturing and maintenance personnel, potential warranty issues related to new technology, and the cost of educating consumers about the benefits of mild hybrid systems.

In conclusion, while the upfront costs of developing mild hybrid architectural frameworks for multi-vehicle platforms are significant, the long-term benefits in terms of regulatory compliance, manufacturing efficiency, and market competitiveness present a compelling case for investment. The key to maximizing the cost-benefit ratio lies in effective planning, efficient implementation, and strategic deployment across the vehicle lineup.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!