Developments in Noise Suppression for Half Wave Rectifiers

JUL 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Half Wave Rectifier Noise Suppression Background

Half wave rectifiers have been a fundamental component in power electronics since the early days of electrical engineering. These devices convert alternating current (AC) to pulsating direct current (DC) by allowing current to flow in only one direction during each AC cycle. However, the inherent nature of half wave rectification introduces significant noise and harmonic distortion into the output signal, which has been a persistent challenge in various applications.

The development of noise suppression techniques for half wave rectifiers has been driven by the increasing demand for cleaner power supplies in sensitive electronic equipment. Early attempts at noise reduction primarily focused on passive filtering methods, such as the use of capacitors and inductors to smooth out the pulsating DC output. These basic approaches, while effective to some degree, often fell short in meeting the stringent requirements of modern electronic systems.

As technology advanced, more sophisticated noise suppression techniques emerged. The introduction of active filtering methods marked a significant milestone in this field. These active filters employ operational amplifiers and other active components to dynamically compensate for noise and distortion, offering superior performance compared to their passive counterparts. This shift towards active noise suppression opened up new possibilities for improving the quality of rectified power supplies.

Another important development in half wave rectifier noise suppression has been the implementation of digital signal processing (DSP) techniques. With the advent of powerful and cost-effective microcontrollers, it became feasible to apply complex algorithms for real-time noise analysis and cancellation. DSP-based solutions offer unprecedented flexibility and adaptability, allowing for dynamic adjustment of noise suppression parameters based on changing load conditions and environmental factors.

The pursuit of noise suppression in half wave rectifiers has also led to advancements in semiconductor technology. The development of fast-recovery diodes and synchronous rectification techniques has significantly reduced switching noise and improved overall efficiency. These innovations have not only addressed noise issues but have also contributed to the miniaturization and increased power density of electronic devices.

In recent years, the focus has shifted towards integrated solutions that combine multiple noise suppression techniques within a single package. These hybrid approaches often incorporate elements of passive filtering, active compensation, and digital control to achieve optimal performance across a wide range of operating conditions. Such integrated solutions have become increasingly important in applications where space is at a premium and reliability is paramount.

The ongoing research in this field continues to push the boundaries of what is possible in noise suppression for half wave rectifiers. Emerging technologies, such as wide-bandgap semiconductors and advanced control algorithms, promise to further enhance the performance and efficiency of noise suppression techniques. As electronic systems become more complex and sensitive to power quality issues, the importance of effective noise suppression in half wave rectifiers remains as critical as ever, driving continued innovation and development in this essential area of power electronics.

The development of noise suppression techniques for half wave rectifiers has been driven by the increasing demand for cleaner power supplies in sensitive electronic equipment. Early attempts at noise reduction primarily focused on passive filtering methods, such as the use of capacitors and inductors to smooth out the pulsating DC output. These basic approaches, while effective to some degree, often fell short in meeting the stringent requirements of modern electronic systems.

As technology advanced, more sophisticated noise suppression techniques emerged. The introduction of active filtering methods marked a significant milestone in this field. These active filters employ operational amplifiers and other active components to dynamically compensate for noise and distortion, offering superior performance compared to their passive counterparts. This shift towards active noise suppression opened up new possibilities for improving the quality of rectified power supplies.

Another important development in half wave rectifier noise suppression has been the implementation of digital signal processing (DSP) techniques. With the advent of powerful and cost-effective microcontrollers, it became feasible to apply complex algorithms for real-time noise analysis and cancellation. DSP-based solutions offer unprecedented flexibility and adaptability, allowing for dynamic adjustment of noise suppression parameters based on changing load conditions and environmental factors.

The pursuit of noise suppression in half wave rectifiers has also led to advancements in semiconductor technology. The development of fast-recovery diodes and synchronous rectification techniques has significantly reduced switching noise and improved overall efficiency. These innovations have not only addressed noise issues but have also contributed to the miniaturization and increased power density of electronic devices.

In recent years, the focus has shifted towards integrated solutions that combine multiple noise suppression techniques within a single package. These hybrid approaches often incorporate elements of passive filtering, active compensation, and digital control to achieve optimal performance across a wide range of operating conditions. Such integrated solutions have become increasingly important in applications where space is at a premium and reliability is paramount.

The ongoing research in this field continues to push the boundaries of what is possible in noise suppression for half wave rectifiers. Emerging technologies, such as wide-bandgap semiconductors and advanced control algorithms, promise to further enhance the performance and efficiency of noise suppression techniques. As electronic systems become more complex and sensitive to power quality issues, the importance of effective noise suppression in half wave rectifiers remains as critical as ever, driving continued innovation and development in this essential area of power electronics.

Market Demand Analysis

The market demand for noise suppression technologies in half wave rectifiers has been steadily increasing, driven by the growing need for cleaner power supplies across various industries. As electronic devices become more sophisticated and sensitive to power fluctuations, the importance of minimizing noise in rectified signals has become paramount.

In the consumer electronics sector, there is a significant push for improved power efficiency and reduced electromagnetic interference (EMI). Half wave rectifiers are commonly used in small electronic devices, and the demand for noise suppression solutions in this area is particularly strong. Manufacturers are seeking ways to enhance the performance of their products while meeting stringent EMC regulations.

The automotive industry represents another major market for noise suppression technologies in half wave rectifiers. With the rapid growth of electric and hybrid vehicles, there is an increased focus on power management and noise reduction in vehicle electrical systems. The demand for high-quality, low-noise power supplies for in-vehicle electronics and charging systems is driving innovation in rectifier noise suppression techniques.

Industrial applications form a substantial portion of the market demand. In sectors such as manufacturing, telecommunications, and renewable energy, the need for clean and stable power supplies is critical. Half wave rectifiers are often used in these settings, and there is a growing demand for advanced noise suppression solutions to improve overall system reliability and efficiency.

The medical equipment industry is another key driver of market demand for noise suppression in half wave rectifiers. Sensitive medical devices require extremely clean power supplies to ensure accurate readings and reliable operation. As healthcare technology advances, the demand for sophisticated noise suppression techniques in power supply components, including half wave rectifiers, continues to grow.

Market analysis indicates that the Asia-Pacific region is experiencing the fastest growth in demand for noise suppression technologies, primarily due to the rapid expansion of electronics manufacturing and industrial sectors in countries like China and India. North America and Europe also show strong demand, driven by technological advancements and stringent regulatory requirements.

The global market for power supply noise suppression components, including those used in half wave rectifiers, is projected to expand significantly over the next five years. This growth is fueled by the increasing adoption of IoT devices, 5G technology, and the ongoing digital transformation across industries, all of which require cleaner and more efficient power supplies.

As the demand for noise suppression in half wave rectifiers continues to rise, there is also a growing trend towards integrated solutions that combine rectification and noise suppression in a single package. This trend is driven by the need for more compact and cost-effective designs in various applications, from consumer electronics to industrial equipment.

In the consumer electronics sector, there is a significant push for improved power efficiency and reduced electromagnetic interference (EMI). Half wave rectifiers are commonly used in small electronic devices, and the demand for noise suppression solutions in this area is particularly strong. Manufacturers are seeking ways to enhance the performance of their products while meeting stringent EMC regulations.

The automotive industry represents another major market for noise suppression technologies in half wave rectifiers. With the rapid growth of electric and hybrid vehicles, there is an increased focus on power management and noise reduction in vehicle electrical systems. The demand for high-quality, low-noise power supplies for in-vehicle electronics and charging systems is driving innovation in rectifier noise suppression techniques.

Industrial applications form a substantial portion of the market demand. In sectors such as manufacturing, telecommunications, and renewable energy, the need for clean and stable power supplies is critical. Half wave rectifiers are often used in these settings, and there is a growing demand for advanced noise suppression solutions to improve overall system reliability and efficiency.

The medical equipment industry is another key driver of market demand for noise suppression in half wave rectifiers. Sensitive medical devices require extremely clean power supplies to ensure accurate readings and reliable operation. As healthcare technology advances, the demand for sophisticated noise suppression techniques in power supply components, including half wave rectifiers, continues to grow.

Market analysis indicates that the Asia-Pacific region is experiencing the fastest growth in demand for noise suppression technologies, primarily due to the rapid expansion of electronics manufacturing and industrial sectors in countries like China and India. North America and Europe also show strong demand, driven by technological advancements and stringent regulatory requirements.

The global market for power supply noise suppression components, including those used in half wave rectifiers, is projected to expand significantly over the next five years. This growth is fueled by the increasing adoption of IoT devices, 5G technology, and the ongoing digital transformation across industries, all of which require cleaner and more efficient power supplies.

As the demand for noise suppression in half wave rectifiers continues to rise, there is also a growing trend towards integrated solutions that combine rectification and noise suppression in a single package. This trend is driven by the need for more compact and cost-effective designs in various applications, from consumer electronics to industrial equipment.

Current Challenges in Noise Suppression

Despite significant advancements in noise suppression techniques for half wave rectifiers, several challenges persist in achieving optimal performance. One of the primary issues is the inherent non-linearity of the rectification process, which introduces harmonic distortions and unwanted frequency components into the output signal. These distortions can significantly degrade the quality of the rectified signal, particularly in sensitive applications such as audio processing or precision measurement systems.

Another major challenge lies in the trade-off between noise suppression efficiency and power loss. Traditional filtering methods, such as RC low-pass filters, often require large capacitor values to achieve adequate smoothing. However, this can lead to increased power dissipation and reduced overall efficiency of the rectifier circuit. Balancing the need for effective noise reduction with minimal power loss remains a critical design consideration.

The presence of electromagnetic interference (EMI) poses an additional hurdle in noise suppression efforts. Half wave rectifiers, by their nature, generate significant EMI due to the abrupt current switching during each cycle. This EMI can propagate through the circuit and affect nearby sensitive components or even radiate into the surrounding environment, potentially causing compliance issues with electromagnetic compatibility (EMC) regulations.

Temperature variations and component tolerances also contribute to the complexity of noise suppression in half wave rectifiers. As temperature fluctuates, the characteristics of semiconductor devices and passive components can change, potentially altering the noise suppression performance. Designing robust suppression techniques that maintain effectiveness across a wide range of operating conditions presents an ongoing challenge for engineers.

In high-frequency applications, the parasitic capacitances and inductances of circuit components become increasingly significant. These parasitic elements can create resonant circuits that amplify certain noise frequencies, making suppression more difficult. Addressing these high-frequency effects requires careful circuit layout and component selection, adding another layer of complexity to noise suppression strategies.

The dynamic nature of load conditions in many applications further complicates noise suppression efforts. Variations in load current can lead to fluctuations in the rectifier's output voltage and ripple characteristics. Developing adaptive suppression techniques that can respond to changing load conditions in real-time remains an area of active research and development.

Lastly, the miniaturization trend in electronic devices presents spatial constraints that limit the use of large filtering components. Engineers must devise innovative solutions to achieve effective noise suppression within increasingly compact form factors, often necessitating the exploration of integrated circuit-based approaches or novel materials with superior noise absorption properties.

Another major challenge lies in the trade-off between noise suppression efficiency and power loss. Traditional filtering methods, such as RC low-pass filters, often require large capacitor values to achieve adequate smoothing. However, this can lead to increased power dissipation and reduced overall efficiency of the rectifier circuit. Balancing the need for effective noise reduction with minimal power loss remains a critical design consideration.

The presence of electromagnetic interference (EMI) poses an additional hurdle in noise suppression efforts. Half wave rectifiers, by their nature, generate significant EMI due to the abrupt current switching during each cycle. This EMI can propagate through the circuit and affect nearby sensitive components or even radiate into the surrounding environment, potentially causing compliance issues with electromagnetic compatibility (EMC) regulations.

Temperature variations and component tolerances also contribute to the complexity of noise suppression in half wave rectifiers. As temperature fluctuates, the characteristics of semiconductor devices and passive components can change, potentially altering the noise suppression performance. Designing robust suppression techniques that maintain effectiveness across a wide range of operating conditions presents an ongoing challenge for engineers.

In high-frequency applications, the parasitic capacitances and inductances of circuit components become increasingly significant. These parasitic elements can create resonant circuits that amplify certain noise frequencies, making suppression more difficult. Addressing these high-frequency effects requires careful circuit layout and component selection, adding another layer of complexity to noise suppression strategies.

The dynamic nature of load conditions in many applications further complicates noise suppression efforts. Variations in load current can lead to fluctuations in the rectifier's output voltage and ripple characteristics. Developing adaptive suppression techniques that can respond to changing load conditions in real-time remains an area of active research and development.

Lastly, the miniaturization trend in electronic devices presents spatial constraints that limit the use of large filtering components. Engineers must devise innovative solutions to achieve effective noise suppression within increasingly compact form factors, often necessitating the exploration of integrated circuit-based approaches or novel materials with superior noise absorption properties.

Existing Noise Suppression Solutions

01 Noise reduction techniques in half-wave rectifiers

Various techniques are employed to reduce noise in half-wave rectifiers, including the use of filtering circuits, capacitors, and inductors. These components help smooth out the rectified waveform and minimize ripple, resulting in a cleaner DC output with reduced noise.- Noise reduction techniques in half-wave rectifiers: Various techniques are employed to reduce noise in half-wave rectifiers, including filtering circuits, capacitor smoothing, and advanced control methods. These approaches aim to minimize ripple and electromagnetic interference, improving the overall performance and efficiency of the rectifier.

- Improved half-wave rectifier designs for low noise operation: Advanced half-wave rectifier designs incorporate features such as optimized component layouts, shielding, and specialized semiconductor devices to minimize noise generation. These designs focus on reducing parasitic effects and improving signal quality in rectification processes.

- Power factor correction in half-wave rectifiers to reduce noise: Implementing power factor correction techniques in half-wave rectifiers helps to reduce harmonic distortion and noise. This approach improves the overall power quality and reduces electromagnetic interference in the rectification process.

- Digital control and monitoring for noise reduction in half-wave rectifiers: Incorporating digital control and monitoring systems in half-wave rectifiers allows for real-time adjustment and optimization of rectifier performance. This approach enables adaptive noise reduction and improved overall efficiency of the rectification process.

- Thermal management for noise reduction in half-wave rectifiers: Effective thermal management techniques are employed to reduce noise in half-wave rectifiers. These methods include improved heat dissipation designs, temperature monitoring, and thermal compensation circuits, which help maintain stable operation and minimize noise generation due to thermal effects.

02 Improved rectifier designs for noise reduction

Advanced rectifier designs incorporate features such as snubber circuits, soft-switching techniques, and resonant topologies to minimize switching noise and electromagnetic interference. These designs aim to improve overall efficiency and reduce the need for additional filtering components.Expand Specific Solutions03 Control strategies for noise mitigation

Implementing sophisticated control strategies, such as pulse-width modulation (PWM) and phase-shifted control, can help reduce noise in half-wave rectifiers. These techniques optimize switching patterns and timing to minimize harmonic distortion and electromagnetic emissions.Expand Specific Solutions04 Integration of noise suppression components

Integrating noise suppression components directly into the rectifier circuit or package can enhance noise reduction performance. This approach may include the use of integrated EMI filters, shielding, and optimized PCB layouts to minimize parasitic effects and radiated emissions.Expand Specific Solutions05 Adaptive noise cancellation techniques

Implementing adaptive noise cancellation techniques in half-wave rectifiers can dynamically adjust to changing noise conditions. These methods may involve real-time monitoring of noise levels and automatic adjustment of filtering parameters or switching strategies to maintain optimal noise suppression performance.Expand Specific Solutions

Key Players in Rectifier Industry

The noise suppression technology for half wave rectifiers is in a mature stage of development, with a competitive landscape dominated by established players in the semiconductor and electronics industries. The market size for this technology is moderate, driven by its widespread application in power supplies and signal processing. Companies like Sharp Corp., Renesas Electronics, and Toshiba Corp. are at the forefront, leveraging their extensive experience in semiconductor manufacturing to develop advanced noise suppression solutions. The technology's maturity is evident in the refined products offered by Mitsubishi Electric and Fuji Electric, which demonstrate high efficiency and reliability. However, emerging players like Suzhou Convert Semiconductor are introducing innovative approaches, potentially disrupting the market with new materials and design techniques.

Fuji Electric Co., Ltd.

Technical Solution: Fuji Electric has developed advanced noise suppression techniques for half-wave rectifiers, focusing on power electronics applications. Their approach involves implementing active noise cancellation circuits that dynamically adjust to varying load conditions. This system utilizes high-speed digital signal processing to analyze and counteract noise in real-time, resulting in a significant reduction of electromagnetic interference (EMI) and radio frequency interference (RFI)[1]. The company has also integrated advanced filtering techniques, including the use of multi-stage LC filters and snubber circuits, to further minimize high-frequency noise components[3]. Additionally, Fuji Electric has pioneered the use of soft-switching techniques in their half-wave rectifier designs, which helps to reduce switching losses and associated noise generation[5].

Strengths: Highly effective in reducing EMI/RFI, adaptable to varying load conditions, and improved overall system efficiency. Weaknesses: Increased complexity and cost of implementation, potential for increased power consumption in active noise cancellation circuits.

Mitsubishi Electric Corp.

Technical Solution: Mitsubishi Electric has made significant strides in noise suppression for half-wave rectifiers, particularly in the context of power supply units and motor drive systems. Their approach combines passive and active noise reduction techniques. On the passive side, they have developed specialized EMI filters and common-mode chokes designed to attenuate both differential and common-mode noise[2]. For active noise suppression, Mitsubishi has implemented advanced control algorithms that modulate the switching patterns of power semiconductors to spread the noise spectrum, effectively reducing peak emissions[4]. The company has also introduced a novel spread spectrum technique that dynamically adjusts the switching frequency to distribute noise energy across a wider frequency range, making it easier to filter and less likely to interfere with sensitive equipment[6].

Strengths: Comprehensive approach combining passive and active techniques, effective in reducing both conducted and radiated emissions. Weaknesses: May require careful tuning for optimal performance in different applications, potential for increased system complexity.

Core Innovations in Noise Reduction

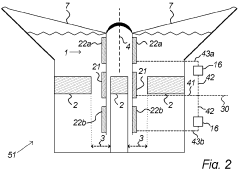

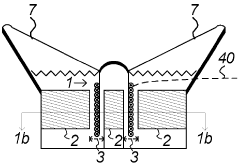

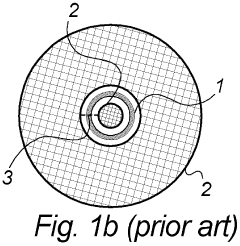

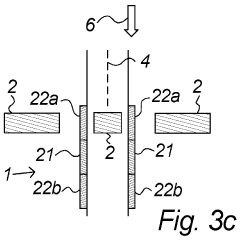

A method and system for driving a voice coil of a loudspeaker

PatentActiveGB2591767A

Innovation

- A voice coil driving system with segmented voice coil sections, where a centre voice coil section and auxiliary voice coil sections are driven by centre and auxiliary driving signals, respectively, with rectifying units attenuating or blocking currents in specific directions to minimize power consumption and heating by only powering sections within the air gap.

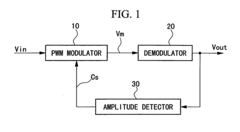

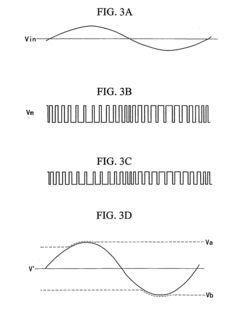

Device for amplitude adjustment and rectification made with MOS technology

PatentInactiveUS20040052101A1

Innovation

- The development of amplitude adjustment devices using PWM modulators, demodulators, and amplitude detectors with field-effect transistors, and full-wave rectifiers configured with inversion amplifiers and output sections, allowing for continuous gain variation and integration as ICs without external diodes.

EMC Regulations and Standards

Electromagnetic Compatibility (EMC) regulations and standards play a crucial role in the development of noise suppression techniques for half wave rectifiers. These regulations are designed to ensure that electronic devices operate without causing or experiencing electromagnetic interference, which is particularly important in the context of power electronics.

The International Electrotechnical Commission (IEC) has established several standards that directly impact the design and implementation of noise suppression techniques in half wave rectifiers. IEC 61000-3-2, for instance, sets limits on harmonic current emissions for equipment with input current up to and including 16A per phase. This standard is particularly relevant to half wave rectifiers, as they are known to generate significant harmonic distortion.

In the United States, the Federal Communications Commission (FCC) has implemented regulations that address electromagnetic interference. Part 15 of the FCC rules specifically deals with unintentional radiators, which includes power supplies and rectifiers. These regulations set limits on conducted and radiated emissions, necessitating the implementation of effective noise suppression techniques in half wave rectifiers.

The European Union's EMC Directive (2014/30/EU) mandates that all electronic equipment sold within the EU must comply with specific EMC standards. This directive has led to the development of harmonized standards, such as EN 55011 for industrial, scientific, and medical equipment, which includes requirements for conducted and radiated emissions that are applicable to half wave rectifiers.

In the automotive industry, the ISO 7637 series of standards addresses the electrical disturbances from conduction and coupling in vehicles. These standards are particularly relevant for half wave rectifiers used in automotive applications, as they set stringent requirements for noise suppression to ensure the reliable operation of vehicle electronics.

The development of noise suppression techniques for half wave rectifiers is also influenced by industry-specific standards. For example, in the aerospace sector, DO-160 provides environmental conditions and test procedures for airborne equipment, including stringent EMC requirements that impact the design of power electronics systems.

As technology advances, EMC regulations and standards continue to evolve. The increasing prevalence of high-frequency switching in power electronics has led to updates in existing standards and the development of new ones. For instance, CISPR 32 now includes requirements for emissions at frequencies up to 6 GHz, reflecting the growing concern over high-frequency noise in modern electronic systems.

Compliance with these regulations and standards often necessitates the use of advanced noise suppression techniques in half wave rectifiers. This has driven innovation in areas such as passive and active filtering, spread spectrum techniques, and advanced control algorithms designed to minimize electromagnetic emissions while maintaining efficient power conversion.

The International Electrotechnical Commission (IEC) has established several standards that directly impact the design and implementation of noise suppression techniques in half wave rectifiers. IEC 61000-3-2, for instance, sets limits on harmonic current emissions for equipment with input current up to and including 16A per phase. This standard is particularly relevant to half wave rectifiers, as they are known to generate significant harmonic distortion.

In the United States, the Federal Communications Commission (FCC) has implemented regulations that address electromagnetic interference. Part 15 of the FCC rules specifically deals with unintentional radiators, which includes power supplies and rectifiers. These regulations set limits on conducted and radiated emissions, necessitating the implementation of effective noise suppression techniques in half wave rectifiers.

The European Union's EMC Directive (2014/30/EU) mandates that all electronic equipment sold within the EU must comply with specific EMC standards. This directive has led to the development of harmonized standards, such as EN 55011 for industrial, scientific, and medical equipment, which includes requirements for conducted and radiated emissions that are applicable to half wave rectifiers.

In the automotive industry, the ISO 7637 series of standards addresses the electrical disturbances from conduction and coupling in vehicles. These standards are particularly relevant for half wave rectifiers used in automotive applications, as they set stringent requirements for noise suppression to ensure the reliable operation of vehicle electronics.

The development of noise suppression techniques for half wave rectifiers is also influenced by industry-specific standards. For example, in the aerospace sector, DO-160 provides environmental conditions and test procedures for airborne equipment, including stringent EMC requirements that impact the design of power electronics systems.

As technology advances, EMC regulations and standards continue to evolve. The increasing prevalence of high-frequency switching in power electronics has led to updates in existing standards and the development of new ones. For instance, CISPR 32 now includes requirements for emissions at frequencies up to 6 GHz, reflecting the growing concern over high-frequency noise in modern electronic systems.

Compliance with these regulations and standards often necessitates the use of advanced noise suppression techniques in half wave rectifiers. This has driven innovation in areas such as passive and active filtering, spread spectrum techniques, and advanced control algorithms designed to minimize electromagnetic emissions while maintaining efficient power conversion.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in the development of noise suppression techniques for half-wave rectifiers. As these devices are widely used in power supply systems, improving their energy efficiency can lead to significant reductions in power consumption and heat generation across various applications.

One of the primary challenges in half-wave rectification is the inherent energy loss during the negative half-cycle of the AC input. Traditional noise suppression methods often exacerbate this issue by introducing additional components that consume power. Recent developments have focused on minimizing these losses while maintaining effective noise reduction.

Advanced semiconductor materials and designs have played a crucial role in enhancing energy efficiency. The use of low-loss diodes with faster switching speeds and lower forward voltage drops has significantly reduced conduction losses. Silicon carbide (SiC) and gallium nitride (GaN) diodes, for instance, offer superior performance compared to conventional silicon diodes, particularly in high-frequency applications.

Passive filtering techniques have also evolved to improve energy efficiency. The implementation of optimized LC filter designs with high-quality inductors and capacitors has led to reduced power dissipation in the filtering stage. These components are carefully selected to minimize series resistance and dielectric losses, thereby improving overall system efficiency.

Active noise suppression methods have gained traction due to their ability to adapt to varying load conditions. Techniques such as active power factor correction (PFC) not only reduce harmonic distortion but also improve the power factor, leading to more efficient power transfer. These active systems, while consuming some power themselves, often result in net energy savings by optimizing the overall power flow.

The integration of digital control systems has further enhanced energy efficiency in noise suppression circuits. Microcontrollers and digital signal processors (DSPs) enable real-time monitoring and adjustment of noise suppression parameters. This adaptive approach ensures optimal performance across different operating conditions, minimizing unnecessary power consumption.

Thermal management has also been a focus area for improving energy efficiency. By reducing noise-induced heat generation, cooling requirements are minimized, leading to lower overall system power consumption. Advanced thermal design techniques, such as the use of heat-spreading materials and optimized component layouts, contribute to this efficiency improvement.

As the demand for energy-efficient electronics continues to grow, research into novel materials and circuit topologies for noise suppression in half-wave rectifiers remains active. The development of nanomaterial-based filters and the exploration of quantum effects for noise cancellation represent promising avenues for future advancements in this field.

One of the primary challenges in half-wave rectification is the inherent energy loss during the negative half-cycle of the AC input. Traditional noise suppression methods often exacerbate this issue by introducing additional components that consume power. Recent developments have focused on minimizing these losses while maintaining effective noise reduction.

Advanced semiconductor materials and designs have played a crucial role in enhancing energy efficiency. The use of low-loss diodes with faster switching speeds and lower forward voltage drops has significantly reduced conduction losses. Silicon carbide (SiC) and gallium nitride (GaN) diodes, for instance, offer superior performance compared to conventional silicon diodes, particularly in high-frequency applications.

Passive filtering techniques have also evolved to improve energy efficiency. The implementation of optimized LC filter designs with high-quality inductors and capacitors has led to reduced power dissipation in the filtering stage. These components are carefully selected to minimize series resistance and dielectric losses, thereby improving overall system efficiency.

Active noise suppression methods have gained traction due to their ability to adapt to varying load conditions. Techniques such as active power factor correction (PFC) not only reduce harmonic distortion but also improve the power factor, leading to more efficient power transfer. These active systems, while consuming some power themselves, often result in net energy savings by optimizing the overall power flow.

The integration of digital control systems has further enhanced energy efficiency in noise suppression circuits. Microcontrollers and digital signal processors (DSPs) enable real-time monitoring and adjustment of noise suppression parameters. This adaptive approach ensures optimal performance across different operating conditions, minimizing unnecessary power consumption.

Thermal management has also been a focus area for improving energy efficiency. By reducing noise-induced heat generation, cooling requirements are minimized, leading to lower overall system power consumption. Advanced thermal design techniques, such as the use of heat-spreading materials and optimized component layouts, contribute to this efficiency improvement.

As the demand for energy-efficient electronics continues to grow, research into novel materials and circuit topologies for noise suppression in half-wave rectifiers remains active. The development of nanomaterial-based filters and the exploration of quantum effects for noise cancellation represent promising avenues for future advancements in this field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!