Energy density enhancements in mild hybrid battery designs

AUG 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mild Hybrid Battery Evolution and Objectives

Mild hybrid battery technology has undergone significant evolution since its inception in the early 2000s. Initially, these systems were designed to provide minimal electrical assistance to conventional internal combustion engines, primarily focusing on start-stop functionality and regenerative braking. The primary objective was to improve fuel efficiency and reduce emissions without drastically altering the vehicle's powertrain architecture.

As environmental regulations tightened and consumer demand for more efficient vehicles increased, the objectives for mild hybrid battery designs shifted towards enhancing energy density. This evolution aimed to strike a balance between performance improvements and cost-effectiveness, making mild hybrid technology a viable option for a broader range of vehicles.

The development of lithium-ion batteries in the mid-2000s marked a crucial turning point in mild hybrid battery evolution. These batteries offered higher energy density compared to their nickel-metal hydride predecessors, allowing for more compact and lightweight designs. This advancement enabled automakers to integrate mild hybrid systems into smaller vehicle segments without significant compromises in space or performance.

Recent years have seen a focus on pushing the boundaries of energy density in mild hybrid battery designs. The objective has been to maximize the electrical assistance provided to the internal combustion engine, enabling extended electric-only operation and more substantial fuel savings. This has led to the exploration of advanced battery chemistries, such as lithium-titanate and silicon-based anodes, which promise higher energy densities and faster charging capabilities.

Another key objective in the evolution of mild hybrid battery designs has been to improve thermal management and overall system efficiency. As energy density increases, so does the need for effective cooling solutions to maintain battery performance and longevity. Manufacturers have invested in developing sophisticated thermal management systems and battery management algorithms to optimize energy flow and extend battery life.

The current landscape of mild hybrid battery technology is characterized by a drive towards 48-volt systems, which offer a sweet spot between performance enhancement and cost-effectiveness. These systems aim to provide substantial electrical assistance while remaining relatively simple to integrate into existing vehicle architectures. The objective is to achieve a 10-15% improvement in fuel efficiency while keeping the additional cost to consumers at a minimum.

Looking ahead, the evolution of mild hybrid battery designs is expected to continue focusing on further energy density enhancements. Objectives include developing batteries that can deliver higher power outputs for improved vehicle performance, while also supporting longer electric-only driving ranges. Additionally, there is a growing emphasis on sustainability, with research directed towards more environmentally friendly battery materials and manufacturing processes.

As environmental regulations tightened and consumer demand for more efficient vehicles increased, the objectives for mild hybrid battery designs shifted towards enhancing energy density. This evolution aimed to strike a balance between performance improvements and cost-effectiveness, making mild hybrid technology a viable option for a broader range of vehicles.

The development of lithium-ion batteries in the mid-2000s marked a crucial turning point in mild hybrid battery evolution. These batteries offered higher energy density compared to their nickel-metal hydride predecessors, allowing for more compact and lightweight designs. This advancement enabled automakers to integrate mild hybrid systems into smaller vehicle segments without significant compromises in space or performance.

Recent years have seen a focus on pushing the boundaries of energy density in mild hybrid battery designs. The objective has been to maximize the electrical assistance provided to the internal combustion engine, enabling extended electric-only operation and more substantial fuel savings. This has led to the exploration of advanced battery chemistries, such as lithium-titanate and silicon-based anodes, which promise higher energy densities and faster charging capabilities.

Another key objective in the evolution of mild hybrid battery designs has been to improve thermal management and overall system efficiency. As energy density increases, so does the need for effective cooling solutions to maintain battery performance and longevity. Manufacturers have invested in developing sophisticated thermal management systems and battery management algorithms to optimize energy flow and extend battery life.

The current landscape of mild hybrid battery technology is characterized by a drive towards 48-volt systems, which offer a sweet spot between performance enhancement and cost-effectiveness. These systems aim to provide substantial electrical assistance while remaining relatively simple to integrate into existing vehicle architectures. The objective is to achieve a 10-15% improvement in fuel efficiency while keeping the additional cost to consumers at a minimum.

Looking ahead, the evolution of mild hybrid battery designs is expected to continue focusing on further energy density enhancements. Objectives include developing batteries that can deliver higher power outputs for improved vehicle performance, while also supporting longer electric-only driving ranges. Additionally, there is a growing emphasis on sustainability, with research directed towards more environmentally friendly battery materials and manufacturing processes.

Market Analysis for Enhanced Energy Density Batteries

The market for enhanced energy density batteries in mild hybrid vehicles is experiencing significant growth, driven by the increasing demand for more efficient and environmentally friendly transportation solutions. As automotive manufacturers strive to meet stringent emissions regulations and consumer expectations for improved fuel economy, the adoption of mild hybrid systems has accelerated. This trend has created a substantial market opportunity for battery manufacturers specializing in high-energy-density solutions.

The global mild hybrid vehicle market is projected to expand at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is primarily fueled by the automotive industry's shift towards electrification and the need for cost-effective solutions that bridge the gap between conventional internal combustion engines and fully electric vehicles. Enhanced energy density batteries play a crucial role in this transition, as they enable manufacturers to optimize the performance and efficiency of mild hybrid systems without significantly increasing vehicle weight or compromising interior space.

Key market drivers for enhanced energy density batteries include government regulations promoting lower emissions, consumer demand for improved fuel efficiency, and the automotive industry's push for more sustainable transportation options. Additionally, the increasing focus on reducing the total cost of ownership for vehicles has created a strong incentive for manufacturers to invest in advanced battery technologies that can deliver superior performance and longevity.

The market for enhanced energy density batteries in mild hybrid applications is characterized by intense competition among established battery manufacturers and emerging technology companies. Major players in this space are investing heavily in research and development to improve energy density, reduce costs, and enhance overall battery performance. This competitive landscape is driving rapid innovation and technological advancements in battery chemistry, cell design, and manufacturing processes.

Geographically, the market for enhanced energy density batteries in mild hybrid vehicles is most developed in regions with stringent emissions regulations and strong government support for electrification. Europe and Asia-Pacific, particularly China, are leading the adoption of mild hybrid technologies and, consequently, the demand for high-energy-density batteries. North America is also showing increasing interest in mild hybrid systems, driven by tightening fuel economy standards and growing consumer awareness of environmental issues.

The market potential for enhanced energy density batteries extends beyond the automotive sector. As the technology matures and costs decrease, these advanced batteries are likely to find applications in other industries, such as renewable energy storage, consumer electronics, and industrial equipment. This cross-sector potential further enhances the attractiveness of the market for battery manufacturers and investors.

The global mild hybrid vehicle market is projected to expand at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is primarily fueled by the automotive industry's shift towards electrification and the need for cost-effective solutions that bridge the gap between conventional internal combustion engines and fully electric vehicles. Enhanced energy density batteries play a crucial role in this transition, as they enable manufacturers to optimize the performance and efficiency of mild hybrid systems without significantly increasing vehicle weight or compromising interior space.

Key market drivers for enhanced energy density batteries include government regulations promoting lower emissions, consumer demand for improved fuel efficiency, and the automotive industry's push for more sustainable transportation options. Additionally, the increasing focus on reducing the total cost of ownership for vehicles has created a strong incentive for manufacturers to invest in advanced battery technologies that can deliver superior performance and longevity.

The market for enhanced energy density batteries in mild hybrid applications is characterized by intense competition among established battery manufacturers and emerging technology companies. Major players in this space are investing heavily in research and development to improve energy density, reduce costs, and enhance overall battery performance. This competitive landscape is driving rapid innovation and technological advancements in battery chemistry, cell design, and manufacturing processes.

Geographically, the market for enhanced energy density batteries in mild hybrid vehicles is most developed in regions with stringent emissions regulations and strong government support for electrification. Europe and Asia-Pacific, particularly China, are leading the adoption of mild hybrid technologies and, consequently, the demand for high-energy-density batteries. North America is also showing increasing interest in mild hybrid systems, driven by tightening fuel economy standards and growing consumer awareness of environmental issues.

The market potential for enhanced energy density batteries extends beyond the automotive sector. As the technology matures and costs decrease, these advanced batteries are likely to find applications in other industries, such as renewable energy storage, consumer electronics, and industrial equipment. This cross-sector potential further enhances the attractiveness of the market for battery manufacturers and investors.

Current Challenges in Mild Hybrid Battery Technology

Mild hybrid battery technology faces several significant challenges that hinder its widespread adoption and performance optimization. One of the primary issues is the limited energy density of current battery designs. As mild hybrid systems require compact and lightweight energy storage solutions, the inability to pack sufficient energy into a small form factor restricts the electric-only driving range and overall system efficiency.

Another critical challenge is the thermal management of mild hybrid batteries. The frequent charge-discharge cycles and high power demands during acceleration and regenerative braking generate substantial heat. Ineffective thermal management can lead to reduced battery life, decreased performance, and potential safety risks. Developing advanced cooling systems that can maintain optimal operating temperatures without adding significant weight or complexity to the vehicle remains a pressing concern.

The durability and longevity of mild hybrid batteries also present ongoing challenges. The stop-start functionality and frequent power cycling in mild hybrid systems subject batteries to more stress than traditional automotive batteries. This accelerated wear can lead to reduced capacity and performance over time, necessitating more frequent replacements and increasing the total cost of ownership for consumers.

Cost-effectiveness is another major hurdle in mild hybrid battery technology. While mild hybrid systems offer improved fuel efficiency, the additional expense of advanced battery systems can offset potential savings for consumers. Striking a balance between performance, durability, and affordability is crucial for widespread market acceptance.

Furthermore, the integration of mild hybrid batteries with existing vehicle architectures poses significant engineering challenges. Retrofitting conventional vehicles with mild hybrid systems requires careful consideration of space constraints, weight distribution, and electrical system compatibility. Seamless integration that doesn't compromise vehicle dynamics or passenger comfort remains a complex task for automotive engineers.

Lastly, the environmental impact of mild hybrid battery production and disposal is an growing concern. As the automotive industry shifts towards electrification, the sustainable sourcing of battery materials and the development of efficient recycling processes become increasingly important. Addressing these environmental challenges is crucial for the long-term viability and public acceptance of mild hybrid technology.

Another critical challenge is the thermal management of mild hybrid batteries. The frequent charge-discharge cycles and high power demands during acceleration and regenerative braking generate substantial heat. Ineffective thermal management can lead to reduced battery life, decreased performance, and potential safety risks. Developing advanced cooling systems that can maintain optimal operating temperatures without adding significant weight or complexity to the vehicle remains a pressing concern.

The durability and longevity of mild hybrid batteries also present ongoing challenges. The stop-start functionality and frequent power cycling in mild hybrid systems subject batteries to more stress than traditional automotive batteries. This accelerated wear can lead to reduced capacity and performance over time, necessitating more frequent replacements and increasing the total cost of ownership for consumers.

Cost-effectiveness is another major hurdle in mild hybrid battery technology. While mild hybrid systems offer improved fuel efficiency, the additional expense of advanced battery systems can offset potential savings for consumers. Striking a balance between performance, durability, and affordability is crucial for widespread market acceptance.

Furthermore, the integration of mild hybrid batteries with existing vehicle architectures poses significant engineering challenges. Retrofitting conventional vehicles with mild hybrid systems requires careful consideration of space constraints, weight distribution, and electrical system compatibility. Seamless integration that doesn't compromise vehicle dynamics or passenger comfort remains a complex task for automotive engineers.

Lastly, the environmental impact of mild hybrid battery production and disposal is an growing concern. As the automotive industry shifts towards electrification, the sustainable sourcing of battery materials and the development of efficient recycling processes become increasingly important. Addressing these environmental challenges is crucial for the long-term viability and public acceptance of mild hybrid technology.

Existing Energy Density Enhancement Solutions

01 High energy density battery systems for mild hybrids

Advanced battery systems with high energy density are being developed for mild hybrid vehicles. These systems aim to provide improved power output and storage capacity while maintaining a compact size suitable for mild hybrid applications. The focus is on enhancing the energy-to-weight ratio to optimize vehicle performance and efficiency.- High energy density battery systems for mild hybrid vehicles: Advanced battery systems with high energy density are being developed for mild hybrid vehicles. These systems aim to provide improved power output and storage capacity while maintaining a compact size suitable for integration into mild hybrid powertrains. The focus is on enhancing the overall energy efficiency of the vehicle while minimizing the space required for the battery pack.

- Lithium-ion battery technology for mild hybrid applications: Lithium-ion batteries are being optimized for use in mild hybrid vehicles due to their high energy density and power capabilities. Researchers are working on improving the electrode materials, electrolyte compositions, and cell designs to enhance the performance and longevity of these batteries in mild hybrid systems. The goal is to achieve a balance between power output, energy storage, and fast charging capabilities.

- Battery management systems for optimizing energy density: Advanced battery management systems are being developed to maximize the energy density and overall performance of mild hybrid batteries. These systems employ sophisticated algorithms and sensors to monitor battery health, optimize charging and discharging cycles, and ensure efficient energy utilization. The focus is on extending battery life and maintaining high energy density throughout the battery's operational lifespan.

- Thermal management for high energy density batteries: Effective thermal management solutions are being implemented to maintain optimal operating temperatures for high energy density batteries in mild hybrid vehicles. These systems help prevent overheating, extend battery life, and ensure consistent performance across various driving conditions. Advanced cooling techniques and materials are being explored to enhance the energy density and safety of mild hybrid battery packs.

- Integration of supercapacitors with high energy density batteries: Hybrid energy storage systems combining high energy density batteries with supercapacitors are being developed for mild hybrid vehicles. This approach aims to leverage the high power density of supercapacitors for quick energy bursts while utilizing the high energy density of batteries for sustained power delivery. The integration of these technologies seeks to optimize overall system performance and efficiency in mild hybrid applications.

02 Lithium-ion battery technology for mild hybrids

Lithium-ion batteries are increasingly being utilized in mild hybrid vehicles due to their high energy density and power capabilities. These batteries offer improved performance, longer lifespan, and faster charging compared to traditional battery technologies. Advancements in lithium-ion chemistry and cell design are focused on meeting the specific requirements of mild hybrid systems.Expand Specific Solutions03 Battery management systems for optimizing energy density

Sophisticated battery management systems are being developed to maximize the energy density and overall performance of mild hybrid batteries. These systems monitor and control various parameters such as temperature, state of charge, and power distribution to ensure optimal battery operation and longevity. Advanced algorithms and sensors are employed to enhance energy efficiency and battery life.Expand Specific Solutions04 Integration of supercapacitors with batteries for improved energy density

Hybrid energy storage systems combining batteries with supercapacitors are being explored to enhance the overall energy density and power capabilities of mild hybrid vehicles. This integration allows for rapid energy storage and release, complementing the high energy density of batteries with the high power density of supercapacitors. The combined system aims to improve vehicle performance and fuel efficiency.Expand Specific Solutions05 Thermal management for enhancing battery energy density

Advanced thermal management systems are being developed to maintain optimal operating temperatures for mild hybrid batteries, thereby maximizing their energy density and performance. These systems employ various cooling and heating techniques to prevent temperature-related degradation and ensure consistent battery output across different operating conditions. Effective thermal management contributes to increased battery lifespan and improved overall system efficiency.Expand Specific Solutions

Key Players in Mild Hybrid Battery Industry

The energy density enhancement in mild hybrid battery designs is currently in a growth phase, with increasing market demand driven by automotive electrification trends. The market size is expanding rapidly as more automakers adopt mild hybrid systems. Technologically, the field is advancing but still evolving, with key players like Contemporary Amperex Technology, LG Energy Solution, and Samsung SDI leading innovation. These companies are developing higher energy density cathode materials, silicon-based anodes, and advanced cell designs to improve performance. Other major automotive and battery manufacturers like Toyota, Subaru, and SK On are also actively researching and commercializing enhanced mild hybrid battery technologies to meet growing market needs.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a novel Cell-to-Pack (CTP) technology for mild hybrid battery designs, which significantly enhances energy density. This approach eliminates the need for module housings, reducing the number of parts and simplifying the manufacturing process. The CTP technology integrates cells directly into the battery pack, increasing the volume utilization rate by 15-20% compared to conventional designs[1]. CATL has also introduced a new lithium-ion phosphate (LFP) battery chemistry optimized for mild hybrid applications, offering improved energy density without compromising on safety or cost-effectiveness[2]. Additionally, they have implemented advanced thermal management systems that allow for more compact battery designs while maintaining optimal operating temperatures, further contributing to overall energy density improvements[3].

Strengths: Innovative CTP technology significantly increases energy density; Advanced thermal management allows for more compact designs. Weaknesses: LFP chemistry may still have lower energy density compared to some other lithium-ion variants; Potential increased complexity in battery pack replacement or maintenance.

LG Chem Ltd.

Technical Solution: LG Chem has developed a high-nickel cathode material specifically for mild hybrid battery systems, which offers increased energy density without compromising on safety or cycle life. Their proprietary NCM (Nickel Cobalt Manganese) cathode composition achieves up to 25% higher energy density compared to conventional mild hybrid batteries[1]. LG Chem has also introduced a silicon-graphite composite anode material that significantly enhances the battery's capacity and energy density. This innovative anode technology allows for up to 30% more energy storage in the same volume[2]. Furthermore, LG Chem has implemented advanced electrolyte formulations that improve ionic conductivity and stability, contributing to both higher energy density and improved battery longevity in mild hybrid applications[3].

Strengths: High-nickel cathode material offers significant energy density improvements; Silicon-graphite composite anode technology further enhances capacity. Weaknesses: Potential higher costs associated with advanced materials; Possible thermal management challenges with high-nickel cathodes.

Innovative Approaches to Battery Energy Density

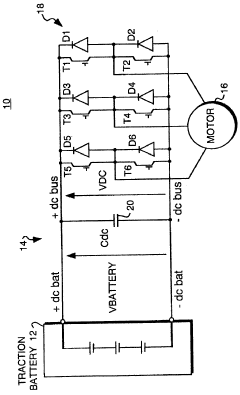

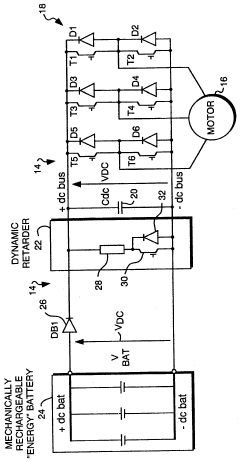

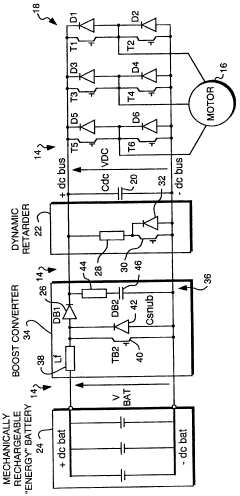

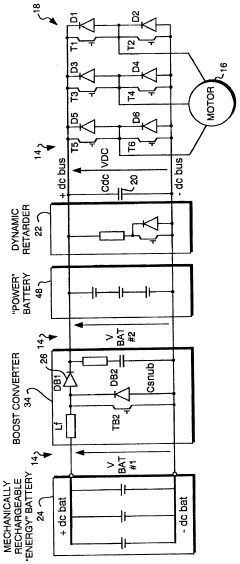

Method and apparatus for a hybrid battery configuration for use in an electric or hybrid electric motive power system

PatentInactiveCA2591696C

Innovation

- A hybrid battery system combining a high energy density mechanically rechargeable battery with a high power density battery, using a dynamic retarder and boost converter to capture regenerative energy and prevent electrical recharge of the high energy density battery, while allowing recharge of the high power density battery, thus optimizing energy use and extending vehicle range.

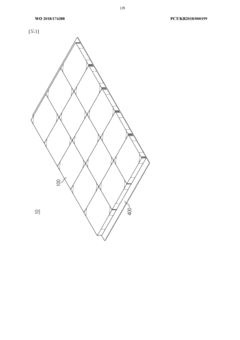

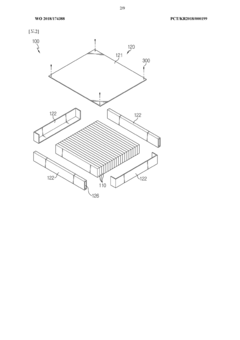

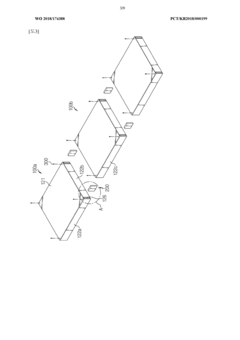

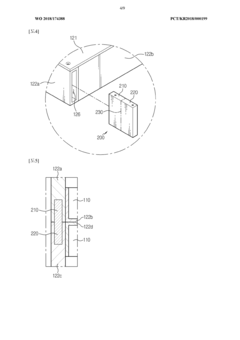

Battery pack

PatentWO2018174388A1

Innovation

- A battery pack design featuring a plurality of stacked battery cells surrounded by a casing member, connected by a connecting member that allows modules to be arranged in a single layer, eliminating the need for a frame and optimizing space usage, with features like stoppers for precise insertion and screw or hook coupling for secure attachment.

Environmental Impact of Battery Technologies

The environmental impact of battery technologies is a critical consideration in the development of mild hybrid battery designs, particularly as energy density enhancements are pursued. These advancements in battery technology have significant implications for both the production and end-of-life phases of batteries used in mild hybrid vehicles.

In the production phase, the pursuit of higher energy density often involves the use of more energy-intensive manufacturing processes and potentially more environmentally sensitive materials. For instance, the incorporation of advanced cathode materials like nickel-rich NMC (Nickel Manganese Cobalt) or NCA (Nickel Cobalt Aluminum) can lead to increased energy consumption during production and potentially greater environmental risks associated with material extraction.

However, these energy density improvements also offer environmental benefits. Higher energy density batteries in mild hybrid systems allow for more efficient energy storage and utilization, potentially reducing the overall fuel consumption and emissions of the vehicle during its operational life. This can lead to a net positive environmental impact over the vehicle's lifecycle, despite the potentially higher environmental costs during production.

The end-of-life phase of these advanced batteries presents both challenges and opportunities. The complex chemistry of high-energy-density batteries can make recycling more difficult, potentially increasing the environmental burden if not properly managed. However, the higher value of materials used in these batteries also provides a stronger economic incentive for recycling and material recovery.

Advancements in battery technology for mild hybrids are also driving innovations in recycling processes. New techniques are being developed to more efficiently recover valuable materials like nickel, cobalt, and lithium from spent batteries, reducing the need for primary resource extraction and minimizing waste.

It's important to note that the environmental impact of these battery technologies extends beyond just the batteries themselves. The improved performance of mild hybrid systems enabled by higher energy density batteries can lead to broader adoption of hybrid technology, potentially accelerating the transition away from conventional internal combustion engines and towards more environmentally friendly transportation solutions.

In conclusion, while the pursuit of energy density enhancements in mild hybrid battery designs does present some environmental challenges, particularly in production and end-of-life management, the overall impact is likely to be positive when considering the full lifecycle of the vehicle and the broader implications for transportation electrification.

In the production phase, the pursuit of higher energy density often involves the use of more energy-intensive manufacturing processes and potentially more environmentally sensitive materials. For instance, the incorporation of advanced cathode materials like nickel-rich NMC (Nickel Manganese Cobalt) or NCA (Nickel Cobalt Aluminum) can lead to increased energy consumption during production and potentially greater environmental risks associated with material extraction.

However, these energy density improvements also offer environmental benefits. Higher energy density batteries in mild hybrid systems allow for more efficient energy storage and utilization, potentially reducing the overall fuel consumption and emissions of the vehicle during its operational life. This can lead to a net positive environmental impact over the vehicle's lifecycle, despite the potentially higher environmental costs during production.

The end-of-life phase of these advanced batteries presents both challenges and opportunities. The complex chemistry of high-energy-density batteries can make recycling more difficult, potentially increasing the environmental burden if not properly managed. However, the higher value of materials used in these batteries also provides a stronger economic incentive for recycling and material recovery.

Advancements in battery technology for mild hybrids are also driving innovations in recycling processes. New techniques are being developed to more efficiently recover valuable materials like nickel, cobalt, and lithium from spent batteries, reducing the need for primary resource extraction and minimizing waste.

It's important to note that the environmental impact of these battery technologies extends beyond just the batteries themselves. The improved performance of mild hybrid systems enabled by higher energy density batteries can lead to broader adoption of hybrid technology, potentially accelerating the transition away from conventional internal combustion engines and towards more environmentally friendly transportation solutions.

In conclusion, while the pursuit of energy density enhancements in mild hybrid battery designs does present some environmental challenges, particularly in production and end-of-life management, the overall impact is likely to be positive when considering the full lifecycle of the vehicle and the broader implications for transportation electrification.

Cost-Benefit Analysis of Energy Density Improvements

The cost-benefit analysis of energy density improvements in mild hybrid battery designs is a critical consideration for automotive manufacturers and suppliers. As energy density increases, the potential benefits include extended electric-only driving range, improved fuel efficiency, and enhanced overall vehicle performance. However, these improvements come with associated costs that must be carefully evaluated.

One of the primary benefits of increased energy density is the ability to store more energy in the same or smaller battery volume. This can lead to weight reduction in the vehicle, which in turn contributes to improved fuel economy and performance. For mild hybrid systems, even modest increases in energy density can translate to significant gains in efficiency, particularly in stop-start urban driving conditions.

The cost implications of energy density enhancements are multifaceted. Research and development expenses for advanced battery chemistries and materials can be substantial. Additionally, the manufacturing processes for higher energy density batteries may require new equipment or techniques, leading to increased production costs. However, these initial investments may be offset by long-term savings in raw materials and improved production efficiency as technologies mature.

When considering the economic impact, it's essential to factor in the potential for economies of scale. As production volumes increase, the per-unit cost of high-energy-density batteries is likely to decrease, making them more cost-effective for widespread adoption in mild hybrid vehicles. This trend has been observed in the broader electric vehicle market and is expected to apply to mild hybrid systems as well.

From a consumer perspective, the cost-benefit analysis must also consider the total cost of ownership. While vehicles with enhanced energy density batteries may have a higher initial purchase price, the long-term savings in fuel costs and potential increases in vehicle resale value could provide a net benefit to the end-user. This balance is crucial for market acceptance and the widespread adoption of mild hybrid technologies.

Environmental benefits, while not directly monetary, play a significant role in the overall cost-benefit analysis. Improved energy density can lead to reduced emissions and lower environmental impact, which may translate to regulatory compliance benefits for manufacturers and potential incentives or tax breaks in certain markets.

In conclusion, while the upfront costs of improving energy density in mild hybrid battery designs can be significant, the long-term benefits in terms of vehicle performance, efficiency, and environmental impact present a compelling case for investment. As technology advances and production scales up, the cost-benefit ratio is expected to improve further, making high-energy-density batteries an increasingly attractive option for mild hybrid vehicle manufacturers.

One of the primary benefits of increased energy density is the ability to store more energy in the same or smaller battery volume. This can lead to weight reduction in the vehicle, which in turn contributes to improved fuel economy and performance. For mild hybrid systems, even modest increases in energy density can translate to significant gains in efficiency, particularly in stop-start urban driving conditions.

The cost implications of energy density enhancements are multifaceted. Research and development expenses for advanced battery chemistries and materials can be substantial. Additionally, the manufacturing processes for higher energy density batteries may require new equipment or techniques, leading to increased production costs. However, these initial investments may be offset by long-term savings in raw materials and improved production efficiency as technologies mature.

When considering the economic impact, it's essential to factor in the potential for economies of scale. As production volumes increase, the per-unit cost of high-energy-density batteries is likely to decrease, making them more cost-effective for widespread adoption in mild hybrid vehicles. This trend has been observed in the broader electric vehicle market and is expected to apply to mild hybrid systems as well.

From a consumer perspective, the cost-benefit analysis must also consider the total cost of ownership. While vehicles with enhanced energy density batteries may have a higher initial purchase price, the long-term savings in fuel costs and potential increases in vehicle resale value could provide a net benefit to the end-user. This balance is crucial for market acceptance and the widespread adoption of mild hybrid technologies.

Environmental benefits, while not directly monetary, play a significant role in the overall cost-benefit analysis. Improved energy density can lead to reduced emissions and lower environmental impact, which may translate to regulatory compliance benefits for manufacturers and potential incentives or tax breaks in certain markets.

In conclusion, while the upfront costs of improving energy density in mild hybrid battery designs can be significant, the long-term benefits in terms of vehicle performance, efficiency, and environmental impact present a compelling case for investment. As technology advances and production scales up, the cost-benefit ratio is expected to improve further, making high-energy-density batteries an increasingly attractive option for mild hybrid vehicle manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!