Exploration of High-Temperature Alloys in High-Pressure Valves

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Alloy Evolution and Objectives

High-temperature alloys have undergone significant evolution since their inception in the early 20th century, initially developed for aircraft engines and later expanding into various industrial applications including high-pressure valve systems. The progression from simple nickel-chromium compositions to complex superalloys represents a remarkable journey of metallurgical innovation driven by increasingly demanding operational environments.

The 1940s marked the beginning of systematic development of superalloys, with the introduction of precipitation-hardening mechanisms. By the 1960s, vacuum melting techniques revolutionized alloy production, enabling precise control over composition and significantly reducing impurities that compromised high-temperature performance. The subsequent decades witnessed the refinement of directional solidification and single-crystal manufacturing processes, dramatically enhancing creep resistance and thermal stability.

In the context of high-pressure valves, the evolution trajectory has been particularly focused on addressing the combined challenges of thermal cycling, corrosive media exposure, and mechanical stress. Traditional valve materials like stainless steel proved inadequate in extreme environments, necessitating the development of specialized nickel and cobalt-based superalloys capable of maintaining structural integrity at temperatures exceeding 650°C while under substantial pressure loads.

Recent advancements have concentrated on optimizing microstructural stability through controlled precipitation of secondary phases and the strategic incorporation of refractory elements such as tungsten, molybdenum, and rhenium. These innovations have extended service life and reliability in critical valve applications within petrochemical processing, power generation, and aerospace systems.

The primary technical objectives for high-temperature alloys in pressure valve applications center on several key performance parameters. First, achieving enhanced creep resistance at operating temperatures between 650-1100°C remains paramount for maintaining dimensional stability and sealing integrity. Second, improving oxidation and corrosion resistance, particularly in the presence of sulfur compounds and steam environments, continues to drive compositional refinements.

Additional objectives include reducing manufacturing complexity and cost through advanced processing techniques, enhancing weldability for repair operations, and developing predictive models for long-term material behavior under combined thermal and mechanical cycling. The integration of computational materials science with experimental validation has accelerated progress toward these goals, enabling more rapid iteration and optimization of alloy compositions.

Looking forward, the field aims to develop alloys capable of reliable operation at even higher temperatures (>1200°C) while maintaining mechanical properties, potentially through novel strengthening mechanisms and the incorporation of ceramic phases or intermetallic compounds. These advances would enable significant efficiency improvements in next-generation energy systems and industrial processes requiring extreme-condition valve technologies.

The 1940s marked the beginning of systematic development of superalloys, with the introduction of precipitation-hardening mechanisms. By the 1960s, vacuum melting techniques revolutionized alloy production, enabling precise control over composition and significantly reducing impurities that compromised high-temperature performance. The subsequent decades witnessed the refinement of directional solidification and single-crystal manufacturing processes, dramatically enhancing creep resistance and thermal stability.

In the context of high-pressure valves, the evolution trajectory has been particularly focused on addressing the combined challenges of thermal cycling, corrosive media exposure, and mechanical stress. Traditional valve materials like stainless steel proved inadequate in extreme environments, necessitating the development of specialized nickel and cobalt-based superalloys capable of maintaining structural integrity at temperatures exceeding 650°C while under substantial pressure loads.

Recent advancements have concentrated on optimizing microstructural stability through controlled precipitation of secondary phases and the strategic incorporation of refractory elements such as tungsten, molybdenum, and rhenium. These innovations have extended service life and reliability in critical valve applications within petrochemical processing, power generation, and aerospace systems.

The primary technical objectives for high-temperature alloys in pressure valve applications center on several key performance parameters. First, achieving enhanced creep resistance at operating temperatures between 650-1100°C remains paramount for maintaining dimensional stability and sealing integrity. Second, improving oxidation and corrosion resistance, particularly in the presence of sulfur compounds and steam environments, continues to drive compositional refinements.

Additional objectives include reducing manufacturing complexity and cost through advanced processing techniques, enhancing weldability for repair operations, and developing predictive models for long-term material behavior under combined thermal and mechanical cycling. The integration of computational materials science with experimental validation has accelerated progress toward these goals, enabling more rapid iteration and optimization of alloy compositions.

Looking forward, the field aims to develop alloys capable of reliable operation at even higher temperatures (>1200°C) while maintaining mechanical properties, potentially through novel strengthening mechanisms and the incorporation of ceramic phases or intermetallic compounds. These advances would enable significant efficiency improvements in next-generation energy systems and industrial processes requiring extreme-condition valve technologies.

Market Demand Analysis for High-Pressure Valve Materials

The global market for high-pressure valve materials, particularly high-temperature alloys, has been experiencing significant growth driven by expanding applications in critical industries. The oil and gas sector remains the largest consumer of high-pressure valves, accounting for approximately 35% of the global market share. This demand is fueled by increasing deep-sea exploration activities and the development of unconventional oil and gas resources, which require valves capable of withstanding extreme pressure and temperature conditions.

The power generation industry represents another substantial market segment, with nuclear and thermal power plants requiring specialized high-temperature alloy valves for steam management systems. The transition toward cleaner energy sources has not diminished this demand, as advanced ultra-supercritical power plants operate at even higher temperatures and pressures to improve efficiency, thereby necessitating more sophisticated valve materials.

Chemical processing industries contribute significantly to market growth, with projected increases of 6-7% annually through 2028. These industries require valves that can withstand not only high pressures and temperatures but also corrosive environments, driving innovation in alloy compositions that offer superior corrosion resistance alongside mechanical strength.

Geographically, Asia-Pacific dominates the market consumption, led by China and India's rapid industrialization and energy infrastructure development. North America follows closely, with its established oil and gas sector and ongoing investments in refinery upgrades. Europe's market is characterized by demand for high-specification valves meeting stringent safety standards, particularly in the chemical and petrochemical sectors.

Market analysis indicates a growing preference for nickel-based superalloys and advanced stainless steel variants, with cobalt-based alloys gaining traction in specialized applications. End-users increasingly prioritize total lifecycle cost over initial investment, recognizing that higher-quality alloys, despite premium pricing, offer superior longevity and reduced maintenance requirements in high-stress environments.

Industry surveys reveal that procurement decisions are increasingly influenced by performance metrics such as creep resistance at elevated temperatures, thermal fatigue resistance, and long-term stability under cyclic loading conditions. This represents a shift from traditional purchasing patterns that emphasized initial cost considerations.

Emerging market trends include growing demand for customized alloy solutions tailored to specific operational environments, increased interest in additive manufacturing techniques for complex valve components, and rising requirements for materials certification and traceability throughout the supply chain. These trends reflect the industry's movement toward more sophisticated, application-specific material solutions rather than generic offerings.

The power generation industry represents another substantial market segment, with nuclear and thermal power plants requiring specialized high-temperature alloy valves for steam management systems. The transition toward cleaner energy sources has not diminished this demand, as advanced ultra-supercritical power plants operate at even higher temperatures and pressures to improve efficiency, thereby necessitating more sophisticated valve materials.

Chemical processing industries contribute significantly to market growth, with projected increases of 6-7% annually through 2028. These industries require valves that can withstand not only high pressures and temperatures but also corrosive environments, driving innovation in alloy compositions that offer superior corrosion resistance alongside mechanical strength.

Geographically, Asia-Pacific dominates the market consumption, led by China and India's rapid industrialization and energy infrastructure development. North America follows closely, with its established oil and gas sector and ongoing investments in refinery upgrades. Europe's market is characterized by demand for high-specification valves meeting stringent safety standards, particularly in the chemical and petrochemical sectors.

Market analysis indicates a growing preference for nickel-based superalloys and advanced stainless steel variants, with cobalt-based alloys gaining traction in specialized applications. End-users increasingly prioritize total lifecycle cost over initial investment, recognizing that higher-quality alloys, despite premium pricing, offer superior longevity and reduced maintenance requirements in high-stress environments.

Industry surveys reveal that procurement decisions are increasingly influenced by performance metrics such as creep resistance at elevated temperatures, thermal fatigue resistance, and long-term stability under cyclic loading conditions. This represents a shift from traditional purchasing patterns that emphasized initial cost considerations.

Emerging market trends include growing demand for customized alloy solutions tailored to specific operational environments, increased interest in additive manufacturing techniques for complex valve components, and rising requirements for materials certification and traceability throughout the supply chain. These trends reflect the industry's movement toward more sophisticated, application-specific material solutions rather than generic offerings.

Current Status and Challenges in High-Temperature Alloy Development

The global landscape of high-temperature alloy development for high-pressure valve applications presents a complex picture of significant advancements alongside persistent technical challenges. Currently, nickel-based superalloys dominate the market, with materials such as Inconel 718, Hastelloy X, and Waspaloy being widely implemented in critical valve components operating in extreme environments. These alloys demonstrate remarkable strength retention at temperatures exceeding 650°C while maintaining acceptable corrosion resistance in aggressive media.

Recent developments in powder metallurgy and additive manufacturing have enabled the production of high-temperature alloys with more precise microstructural control, resulting in enhanced mechanical properties. However, these manufacturing advances have not fully addressed the fundamental materials challenges that persist in high-pressure valve applications, particularly in ultra-high temperature regimes above 1000°C where even the most advanced superalloys begin to exhibit significant degradation.

A major technical hurdle remains the trade-off between creep resistance and ductility in these alloys. The precipitation-strengthened microstructures that provide excellent high-temperature strength often compromise the material's ability to withstand thermal cycling and mechanical shock—both critical requirements for valve applications. This dichotomy has led to compromised designs that sacrifice optimal performance in one area to maintain acceptable performance in another.

Oxidation and hot corrosion resistance represent another significant challenge, particularly in valves exposed to sulfur-containing process fluids or combustion environments. While protective oxide scales form on most high-temperature alloys, the cyclic thermal conditions and high-pressure differentials in valve applications can cause these protective layers to crack or spall, accelerating material degradation. Current coating technologies provide only partial solutions and often introduce new complications related to thermal expansion mismatches and interfacial stability.

Geographically, the development landscape shows concentration in specific regions. The United States, Japan, and Germany lead in traditional superalloy development, while China has made substantial investments in recent years, particularly in oxide dispersion strengthened (ODS) alloys. European research consortia have focused on intermetallic compounds, especially titanium aluminides, as potential alternatives for intermediate temperature applications.

The economic constraints of rare element availability present another challenge, as many high-performance alloys rely heavily on elements like rhenium, hafnium, and tantalum, which face supply chain vulnerabilities. This has spurred research into resource-efficient alloy designs that maintain performance while reducing dependency on these critical elements.

Despite these challenges, incremental progress continues through collaborative efforts between industry and academic institutions, with computational alloy design and high-throughput experimental methodologies accelerating the development cycle for next-generation high-temperature valve materials.

Recent developments in powder metallurgy and additive manufacturing have enabled the production of high-temperature alloys with more precise microstructural control, resulting in enhanced mechanical properties. However, these manufacturing advances have not fully addressed the fundamental materials challenges that persist in high-pressure valve applications, particularly in ultra-high temperature regimes above 1000°C where even the most advanced superalloys begin to exhibit significant degradation.

A major technical hurdle remains the trade-off between creep resistance and ductility in these alloys. The precipitation-strengthened microstructures that provide excellent high-temperature strength often compromise the material's ability to withstand thermal cycling and mechanical shock—both critical requirements for valve applications. This dichotomy has led to compromised designs that sacrifice optimal performance in one area to maintain acceptable performance in another.

Oxidation and hot corrosion resistance represent another significant challenge, particularly in valves exposed to sulfur-containing process fluids or combustion environments. While protective oxide scales form on most high-temperature alloys, the cyclic thermal conditions and high-pressure differentials in valve applications can cause these protective layers to crack or spall, accelerating material degradation. Current coating technologies provide only partial solutions and often introduce new complications related to thermal expansion mismatches and interfacial stability.

Geographically, the development landscape shows concentration in specific regions. The United States, Japan, and Germany lead in traditional superalloy development, while China has made substantial investments in recent years, particularly in oxide dispersion strengthened (ODS) alloys. European research consortia have focused on intermetallic compounds, especially titanium aluminides, as potential alternatives for intermediate temperature applications.

The economic constraints of rare element availability present another challenge, as many high-performance alloys rely heavily on elements like rhenium, hafnium, and tantalum, which face supply chain vulnerabilities. This has spurred research into resource-efficient alloy designs that maintain performance while reducing dependency on these critical elements.

Despite these challenges, incremental progress continues through collaborative efforts between industry and academic institutions, with computational alloy design and high-throughput experimental methodologies accelerating the development cycle for next-generation high-temperature valve materials.

Current Technical Solutions for High-Pressure Valve Applications

01 Nickel-based superalloys for high-temperature applications

Nickel-based superalloys are widely used in high-temperature applications due to their excellent mechanical properties and oxidation resistance at elevated temperatures. These alloys typically contain chromium, cobalt, aluminum, titanium, and other elements to enhance their strength, creep resistance, and thermal stability. They are commonly employed in gas turbines, aerospace engines, and power generation equipment where materials must withstand extreme temperatures while maintaining structural integrity.- Nickel-based superalloys for high-temperature applications: Nickel-based superalloys are widely used in high-temperature applications due to their excellent mechanical properties and oxidation resistance at elevated temperatures. These alloys typically contain chromium, cobalt, aluminum, titanium, and other elements to enhance their strength, creep resistance, and corrosion resistance. They are commonly used in gas turbines, aerospace engines, and other components that operate under extreme temperature conditions.

- Cobalt-based high-temperature alloys: Cobalt-based alloys are designed for applications requiring high-temperature strength, wear resistance, and corrosion resistance. These alloys typically contain chromium, tungsten, and other elements to improve their performance in extreme environments. They maintain their mechanical properties at elevated temperatures and are often used in gas turbine hot sections, industrial furnace components, and other high-temperature applications where both strength and wear resistance are required.

- Refractory metal alloys for ultra-high temperature applications: Refractory metal alloys based on tungsten, molybdenum, niobium, and tantalum are designed for ultra-high temperature applications exceeding 1200°C. These alloys offer exceptional high-temperature strength, low thermal expansion, and good thermal conductivity. They are used in aerospace components, nuclear reactors, and industrial furnaces where extreme temperature resistance is required. Various alloying elements are added to improve oxidation resistance and workability while maintaining their high-temperature capabilities.

- Heat treatment processes for high-temperature alloys: Specialized heat treatment processes are crucial for optimizing the microstructure and properties of high-temperature alloys. These processes include solution treatment, aging, and precipitation hardening, which control the formation and distribution of strengthening phases. Proper heat treatment can significantly enhance creep resistance, thermal stability, and mechanical properties at elevated temperatures. The parameters of these treatments are carefully controlled to achieve the desired microstructure for specific high-temperature applications.

- Advanced manufacturing techniques for high-temperature alloys: Advanced manufacturing techniques such as powder metallurgy, additive manufacturing, and directional solidification are employed to produce high-temperature alloys with enhanced properties. These techniques allow for better control of microstructure, reduced segregation, and improved homogeneity. They enable the production of complex geometries with superior high-temperature performance compared to conventional casting methods. These manufacturing approaches are particularly important for aerospace and energy applications where component performance at extreme temperatures is critical.

02 Refractory metal alloys for ultra-high temperature environments

Refractory metal alloys based on tungsten, molybdenum, niobium, and tantalum are designed for ultra-high temperature environments exceeding 1200°C. These alloys exhibit exceptional melting points, hardness, and strength retention at extreme temperatures. They are typically alloyed with elements like rhenium, hafnium, and zirconium to improve ductility and oxidation resistance. Applications include rocket nozzles, furnace components, and specialized industrial equipment operating in severe thermal conditions.Expand Specific Solutions03 Advanced coating systems for high-temperature alloy protection

Protective coating systems are essential for extending the service life of high-temperature alloys by providing thermal barrier and oxidation resistance. These coatings typically consist of multiple layers including bond coats, thermal barrier coatings (TBCs), and environmental barrier coatings (EBCs). Ceramic materials like yttria-stabilized zirconia are commonly used for their low thermal conductivity, while aluminide and MCrAlY (where M is nickel, cobalt, or iron) coatings provide oxidation protection by forming stable oxide scales.Expand Specific Solutions04 Intermetallic compounds for structural high-temperature applications

Intermetallic compounds such as titanium aluminides, nickel aluminides, and iron aluminides offer unique combinations of properties for high-temperature structural applications. These ordered compounds maintain their strength and stiffness at elevated temperatures while providing good oxidation resistance due to the formation of protective alumina scales. Recent developments focus on improving room temperature ductility and processing techniques to enable wider industrial adoption in aerospace, automotive, and energy sectors.Expand Specific Solutions05 Novel manufacturing techniques for high-temperature alloys

Advanced manufacturing techniques are being developed to enhance the properties and production efficiency of high-temperature alloys. These include powder metallurgy, additive manufacturing, directional solidification, and single crystal growth processes. These techniques enable precise control over microstructure, grain orientation, and composition distribution, resulting in superior mechanical properties and temperature capabilities. They also allow for complex geometries and integrated cooling features that were previously impossible with conventional manufacturing methods.Expand Specific Solutions

Key Industry Players in High-Temperature Alloy Manufacturing

The high-temperature alloy market for high-pressure valves is currently in a growth phase, with increasing demand across energy, aerospace, and industrial sectors. The global market is estimated at $3.5-4 billion annually with projected 6-8% CAGR through 2028. Technologically, established players like Hitachi Ltd., Eaton Corp., and Honeywell International lead with mature solutions, while specialized manufacturers such as Daido Steel, voestalpine BÖHLER Edelstahl, and BLEISTAHL are advancing material innovations. Japanese firms (Proterial, Motoyama Eng. Works) dominate in automotive and industrial applications, while Western companies (Hans Sasserath, Bucher Hydraulics) focus on specialized valve technologies. Research partnerships between corporations and institutions like University of Science & Technology Beijing are accelerating material development for extreme operating conditions.

Daido Steel Co., Ltd.

Technical Solution: Daido Steel has established itself as a pioneer in high-temperature alloy development for high-pressure valve applications, particularly in power generation and petrochemical industries. Their DEH (Daido Extreme Heat) series features advanced austenitic stainless steels and nickel-based superalloys with carefully controlled additions of nitrogen, niobium, and rare earth elements to enhance grain boundary stability at elevated temperatures. Daido employs proprietary electroslag remelting (ESR) technology combined with precision forging processes to achieve exceptional microstructural control and minimize inclusion content. Their alloys demonstrate superior resistance to both high-temperature oxidation and sulfidation, with documented performance in environments containing up to 2% hydrogen sulfide at temperatures exceeding 650°C. Daido's research team has developed innovative precipitation strengthening mechanisms that maintain mechanical properties after extended exposure to temperatures up to 760°C while preserving the machinability required for precision valve components. Recent advancements include their nano-carbide dispersion technology that creates uniformly distributed carbide particles averaging 20-50nm in size, significantly enhancing creep resistance while maintaining essential ductility for valve manufacturing processes.

Strengths: Exceptional balance of high-temperature strength and fabricability; superior resistance to sulfidation in petrochemical environments; extensive experience in power generation applications; comprehensive material characterization database spanning decades of field performance. Weaknesses: Limited global manufacturing footprint potentially affecting supply chain resilience; higher cost compared to conventional alloys; specialized welding procedures required for field repairs; potential challenges with very large component sizes due to manufacturing constraints.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell International Technologies has developed a comprehensive suite of high-temperature alloy solutions specifically engineered for high-pressure valve applications in extreme environments. Their SmartAlloy™ technology platform incorporates nickel-chromium-cobalt base materials with precisely controlled additions of refractory elements including tungsten, molybdenum, and rhenium to achieve exceptional creep resistance at temperatures up to 870°C. Honeywell employs advanced powder metallurgy techniques, including hot isostatic pressing (HIP), to create near-net-shape valve components with superior microstructural homogeneity compared to conventional casting methods. Their proprietary heat treatment protocols optimize precipitate distribution and grain boundary characteristics, resulting in documented service life improvements of 30-40% compared to traditional forged components in similar applications. Honeywell's materials science team has pioneered the integration of ceramic reinforcement phases within metallic matrices, creating metal matrix composites (MMCs) that demonstrate exceptional wear resistance while maintaining the necessary ductility for valve applications. Recent innovations include their adaptive microstructure technology that responds to operating conditions by forming protective oxide scales that self-heal under thermal cycling.

Strengths: Industry-leading temperature capability (up to 870°C); advanced manufacturing techniques enabling complex geometries with optimized material properties; comprehensive in-house testing facilities validating long-term performance; integrated sensors for real-time material condition monitoring. Weaknesses: Significantly higher initial cost compared to conventional alloys; limited supplier network for specialized raw materials; complex qualification process for new applications; potential intellectual property constraints limiting customization for specific customer requirements.

Critical Patents and Innovations in High-Temperature Alloy Design

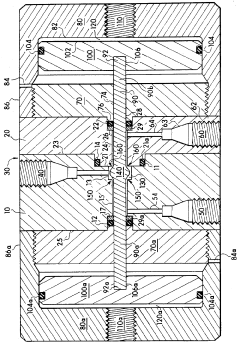

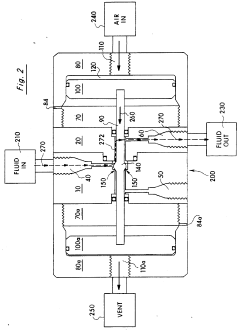

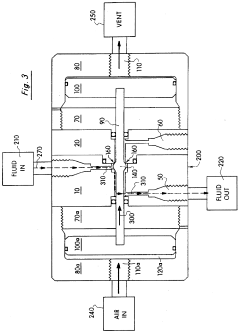

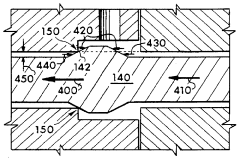

High speed, high temperature three-way valve for switching high pressure fluids under low pressure control

PatentInactiveUSRE33246E1

Innovation

- A low internal volume, three-way sliding poppet valve with a metal body and spool, utilizing metallic sealing surfaces and low-pressure actuation to switch fluids rapidly without volume change, designed for high temperature and pressure environments, featuring a central raised spool with conical seats for precise sealing and minimal actuation travel.

High temperature resistant alloys

PatentInactiveGB848043A

Innovation

- A new alloy composition with a range of elements including carbon, chromium, nickel, molybdenum, silicon, manganese, aluminum, nitrogen, and boron, which cooperate to provide superior properties without excessive nickel, such as enhanced strength, creep resistance, and oxidation resistance at high temperatures.

Corrosion Resistance Performance Analysis

Corrosion resistance represents a critical performance parameter for high-temperature alloys used in high-pressure valve applications. These components operate in extreme environments where chemical attack can significantly compromise structural integrity and operational reliability. The corrosion mechanisms affecting these alloys are diverse, including oxidation, sulfidation, carburization, and various forms of aqueous corrosion depending on the specific operating environment.

Nickel-based superalloys such as Inconel 718 and Hastelloy X demonstrate superior resistance to oxidizing environments at temperatures exceeding 650°C, forming protective chromium and aluminum oxide layers that inhibit further corrosion. These passive films act as barriers against aggressive species, though their stability can be compromised under thermal cycling conditions typical in valve operations.

Cobalt-based alloys like Stellite 6 and Haynes 25 exhibit exceptional hot corrosion resistance, particularly in environments containing molten salts or sulfur compounds. Their performance derives from the formation of complex oxide structures incorporating cobalt, chromium, and other alloying elements that maintain integrity even under severe thermal and chemical stress conditions.

Iron-based heat-resistant alloys, including certain stainless steel grades like 310 and 347, provide moderate corrosion resistance at lower cost points. However, their performance boundaries are more constrained, with significant degradation observed above 800°C in aggressive environments containing sulfur or chlorides.

Recent accelerated testing protocols have revealed that pitting corrosion resistance correlates strongly with molybdenum content across various alloy families, while crevice corrosion behavior shows greater dependence on chromium-to-iron ratios. These findings have significant implications for alloy selection in valve applications where tight tolerances and complex geometries create conditions favorable to localized corrosion.

Electrochemical impedance spectroscopy (EIS) studies indicate that high-temperature alloys with higher chromium content (>22%) maintain more stable passive films in chloride-containing environments, critical for valves in marine or chemical processing applications. The addition of rare earth elements like yttrium and cerium has demonstrated promising results in enhancing scale adhesion during thermal cycling, reducing spallation-induced corrosion acceleration.

Intergranular corrosion susceptibility remains a significant concern, particularly for precipitation-hardened alloys subjected to sensitization during welding or heat treatment. Modern alloy designs incorporate controlled carbon levels and stabilizing elements like niobium and titanium to mitigate this vulnerability, though careful processing control remains essential for optimal performance.

Nickel-based superalloys such as Inconel 718 and Hastelloy X demonstrate superior resistance to oxidizing environments at temperatures exceeding 650°C, forming protective chromium and aluminum oxide layers that inhibit further corrosion. These passive films act as barriers against aggressive species, though their stability can be compromised under thermal cycling conditions typical in valve operations.

Cobalt-based alloys like Stellite 6 and Haynes 25 exhibit exceptional hot corrosion resistance, particularly in environments containing molten salts or sulfur compounds. Their performance derives from the formation of complex oxide structures incorporating cobalt, chromium, and other alloying elements that maintain integrity even under severe thermal and chemical stress conditions.

Iron-based heat-resistant alloys, including certain stainless steel grades like 310 and 347, provide moderate corrosion resistance at lower cost points. However, their performance boundaries are more constrained, with significant degradation observed above 800°C in aggressive environments containing sulfur or chlorides.

Recent accelerated testing protocols have revealed that pitting corrosion resistance correlates strongly with molybdenum content across various alloy families, while crevice corrosion behavior shows greater dependence on chromium-to-iron ratios. These findings have significant implications for alloy selection in valve applications where tight tolerances and complex geometries create conditions favorable to localized corrosion.

Electrochemical impedance spectroscopy (EIS) studies indicate that high-temperature alloys with higher chromium content (>22%) maintain more stable passive films in chloride-containing environments, critical for valves in marine or chemical processing applications. The addition of rare earth elements like yttrium and cerium has demonstrated promising results in enhancing scale adhesion during thermal cycling, reducing spallation-induced corrosion acceleration.

Intergranular corrosion susceptibility remains a significant concern, particularly for precipitation-hardened alloys subjected to sensitization during welding or heat treatment. Modern alloy designs incorporate controlled carbon levels and stabilizing elements like niobium and titanium to mitigate this vulnerability, though careful processing control remains essential for optimal performance.

Safety Standards and Certification Requirements

The safety standards and certification requirements for high-temperature alloys in high-pressure valve applications are governed by multiple international and regional regulatory frameworks. These standards ensure that materials and components meet stringent safety, reliability, and performance criteria in demanding industrial environments.

ASME Boiler and Pressure Vessel Code (BPVC) Section II and Section VIII provide comprehensive guidelines for material selection and design considerations for high-temperature alloy applications. These codes specifically address material properties at elevated temperatures and pressure conditions, establishing minimum requirements for tensile strength, creep resistance, and fatigue performance that high-temperature alloys must satisfy.

The European Pressure Equipment Directive (PED 2014/68/EU) mandates essential safety requirements for pressure equipment operating above 0.5 bar, with specific provisions for materials used in high-temperature environments. Manufacturers must obtain CE marking through conformity assessment procedures that verify material suitability for intended operating conditions.

API standards, particularly API 6A and API 600, outline specific requirements for valves used in oil and gas applications where high-temperature alloys are commonly deployed. These standards address material selection criteria, testing protocols, and performance requirements under extreme conditions.

Material certification processes such as EN 10204 Type 3.1 and 3.2 certificates are mandatory for high-temperature alloy components in critical applications. These certifications verify chemical composition, mechanical properties, and heat treatment conditions, ensuring traceability throughout the supply chain.

Testing requirements for high-temperature alloys in valve applications include elevated temperature tensile testing (ASTM E21), creep testing (ASTM E139), and stress-rupture testing (ASTM E292). Additionally, specialized tests for hydrogen embrittlement resistance (ASTM F1459) and sulfide stress cracking (NACE MR0175/ISO 15156) are required for specific service environments.

Emerging standards are addressing new challenges in high-temperature alloy applications, including the development of ISO 23936 for materials in hydrogen service and updates to NACE standards for increasingly aggressive environments. These evolving requirements reflect the industry's push toward more extreme operating conditions and the need for enhanced material performance.

Compliance with these standards requires comprehensive documentation, including material test reports, design calculations, risk assessments, and manufacturing process validations. This documentation forms the basis for third-party certification and regulatory approval, which is essential for market access in most jurisdictions.

ASME Boiler and Pressure Vessel Code (BPVC) Section II and Section VIII provide comprehensive guidelines for material selection and design considerations for high-temperature alloy applications. These codes specifically address material properties at elevated temperatures and pressure conditions, establishing minimum requirements for tensile strength, creep resistance, and fatigue performance that high-temperature alloys must satisfy.

The European Pressure Equipment Directive (PED 2014/68/EU) mandates essential safety requirements for pressure equipment operating above 0.5 bar, with specific provisions for materials used in high-temperature environments. Manufacturers must obtain CE marking through conformity assessment procedures that verify material suitability for intended operating conditions.

API standards, particularly API 6A and API 600, outline specific requirements for valves used in oil and gas applications where high-temperature alloys are commonly deployed. These standards address material selection criteria, testing protocols, and performance requirements under extreme conditions.

Material certification processes such as EN 10204 Type 3.1 and 3.2 certificates are mandatory for high-temperature alloy components in critical applications. These certifications verify chemical composition, mechanical properties, and heat treatment conditions, ensuring traceability throughout the supply chain.

Testing requirements for high-temperature alloys in valve applications include elevated temperature tensile testing (ASTM E21), creep testing (ASTM E139), and stress-rupture testing (ASTM E292). Additionally, specialized tests for hydrogen embrittlement resistance (ASTM F1459) and sulfide stress cracking (NACE MR0175/ISO 15156) are required for specific service environments.

Emerging standards are addressing new challenges in high-temperature alloy applications, including the development of ISO 23936 for materials in hydrogen service and updates to NACE standards for increasingly aggressive environments. These evolving requirements reflect the industry's push toward more extreme operating conditions and the need for enhanced material performance.

Compliance with these standards requires comprehensive documentation, including material test reports, design calculations, risk assessments, and manufacturing process validations. This documentation forms the basis for third-party certification and regulatory approval, which is essential for market access in most jurisdictions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!