High-Temperature Alloys and Their Effect on Spacecraft Design

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Alloy Evolution and Spacecraft Design Goals

The evolution of high-temperature alloys represents one of the most significant technological advancements in materials science over the past century. Initially developed for gas turbine engines in the 1940s, these specialized metal compositions have undergone remarkable transformation to meet increasingly demanding thermal environments. The progression from simple nickel-chromium alloys to sophisticated superalloys incorporating elements such as cobalt, rhenium, and ruthenium demonstrates the field's continuous innovation trajectory.

Early spacecraft design relied on relatively simple heat-resistant materials that could withstand the extreme temperatures of atmospheric re-entry, typically reaching 1,500°C. However, as space missions became more ambitious, particularly with deep space exploration and longer-duration missions, the thermal performance requirements expanded dramatically. Modern spacecraft must now contend with thermal cycling between extreme cold (-150°C in shadow) and intense heat (+150°C in direct solar exposure) while maintaining structural integrity.

The technical evolution pathway shows clear generational improvements. First-generation high-temperature alloys focused primarily on solid-solution strengthening mechanisms. Second-generation alloys introduced precipitation hardening through carefully controlled microstructures. Current third-generation alloys employ complex multi-element systems with nanoscale precipitate engineering to achieve unprecedented thermal stability and mechanical properties at temperatures exceeding 1,100°C.

A critical inflection point occurred in the 1990s with the introduction of single-crystal manufacturing techniques, eliminating grain boundaries that traditionally served as failure initiation sites. This breakthrough enabled a step-change in temperature capability, allowing engine and spacecraft components to operate closer to their theoretical melting points.

The primary technical goals driving current high-temperature alloy development for spacecraft applications include: increasing the temperature-to-weight performance ratio; enhancing oxidation and corrosion resistance in space environments; improving thermal fatigue resistance for components experiencing repeated heating-cooling cycles; and developing manufacturing processes compatible with complex geometries required for optimized spacecraft design.

Emerging trends indicate a shift toward ceramic matrix composites and refractory metal alloys for ultra-high temperature applications exceeding 1,600°C. Additionally, computational materials science is accelerating development cycles through predictive modeling of alloy performance, reducing the traditional trial-and-error approach that dominated earlier development efforts.

The convergence of these technological trajectories points toward a future where spacecraft thermal protection systems and propulsion components will leverage increasingly sophisticated material solutions, enabling missions previously considered technically infeasible due to thermal constraints.

Early spacecraft design relied on relatively simple heat-resistant materials that could withstand the extreme temperatures of atmospheric re-entry, typically reaching 1,500°C. However, as space missions became more ambitious, particularly with deep space exploration and longer-duration missions, the thermal performance requirements expanded dramatically. Modern spacecraft must now contend with thermal cycling between extreme cold (-150°C in shadow) and intense heat (+150°C in direct solar exposure) while maintaining structural integrity.

The technical evolution pathway shows clear generational improvements. First-generation high-temperature alloys focused primarily on solid-solution strengthening mechanisms. Second-generation alloys introduced precipitation hardening through carefully controlled microstructures. Current third-generation alloys employ complex multi-element systems with nanoscale precipitate engineering to achieve unprecedented thermal stability and mechanical properties at temperatures exceeding 1,100°C.

A critical inflection point occurred in the 1990s with the introduction of single-crystal manufacturing techniques, eliminating grain boundaries that traditionally served as failure initiation sites. This breakthrough enabled a step-change in temperature capability, allowing engine and spacecraft components to operate closer to their theoretical melting points.

The primary technical goals driving current high-temperature alloy development for spacecraft applications include: increasing the temperature-to-weight performance ratio; enhancing oxidation and corrosion resistance in space environments; improving thermal fatigue resistance for components experiencing repeated heating-cooling cycles; and developing manufacturing processes compatible with complex geometries required for optimized spacecraft design.

Emerging trends indicate a shift toward ceramic matrix composites and refractory metal alloys for ultra-high temperature applications exceeding 1,600°C. Additionally, computational materials science is accelerating development cycles through predictive modeling of alloy performance, reducing the traditional trial-and-error approach that dominated earlier development efforts.

The convergence of these technological trajectories points toward a future where spacecraft thermal protection systems and propulsion components will leverage increasingly sophisticated material solutions, enabling missions previously considered technically infeasible due to thermal constraints.

Aerospace Market Demands for Advanced Thermal Materials

The aerospace industry is experiencing a significant shift towards more advanced thermal management solutions, driven by the increasing complexity and demands of modern spacecraft missions. The market for high-temperature materials, particularly specialized alloys, has seen substantial growth as spacecraft designs push the boundaries of thermal resistance and structural integrity. This growth is particularly evident in the commercial space sector, where private companies are developing reusable launch vehicles that must withstand multiple re-entry cycles.

Current market analysis indicates that the demand for high-temperature alloys in aerospace applications is primarily driven by three factors: extended mission durations, extreme operating environments, and the need for reduced maintenance cycles. Satellites designed for long-term deployment in geosynchronous orbits require materials that can withstand thermal cycling for periods exceeding 15 years, creating a premium segment for ultra-durable alloys.

The hypersonic vehicle market represents another significant growth area, with both defense and commercial sectors investing heavily in vehicles capable of sustained flight at Mach 5+. These applications demand materials that can perform reliably at temperatures exceeding 1000°C while maintaining structural properties. Market forecasts suggest this segment will expand at double-digit rates over the next decade as hypersonic technology matures from experimental to operational status.

Reusable launch systems have created a new paradigm in material requirements, where components must withstand not only single extreme thermal events but repeated cycles of heating and cooling. This has shifted procurement strategies toward higher-cost but more durable nickel-based superalloys and ceramic matrix composites, despite their higher initial investment costs.

Regional market distribution shows North America maintaining leadership in aerospace thermal material consumption, followed by Europe and increasingly Asia, where space programs in China, India, and Japan are expanding rapidly. The defense sector remains the largest consumer of advanced thermal materials, though commercial space applications are growing at a faster rate.

Supply chain considerations have become increasingly important in the market landscape, with aerospace manufacturers seeking materials that not only meet performance specifications but also offer manufacturing scalability and supply security. This has led to increased interest in developing domestic production capabilities for critical high-temperature alloys, particularly those containing strategic elements like rhenium, hafnium, and rare earth metals.

Customer requirements are evolving toward integrated material solutions that combine thermal performance with other functionalities such as radiation resistance, reduced weight, and compatibility with advanced manufacturing techniques like additive manufacturing. This trend is creating new market opportunities for material suppliers who can deliver multi-functional high-temperature alloy systems rather than single-property solutions.

Current market analysis indicates that the demand for high-temperature alloys in aerospace applications is primarily driven by three factors: extended mission durations, extreme operating environments, and the need for reduced maintenance cycles. Satellites designed for long-term deployment in geosynchronous orbits require materials that can withstand thermal cycling for periods exceeding 15 years, creating a premium segment for ultra-durable alloys.

The hypersonic vehicle market represents another significant growth area, with both defense and commercial sectors investing heavily in vehicles capable of sustained flight at Mach 5+. These applications demand materials that can perform reliably at temperatures exceeding 1000°C while maintaining structural properties. Market forecasts suggest this segment will expand at double-digit rates over the next decade as hypersonic technology matures from experimental to operational status.

Reusable launch systems have created a new paradigm in material requirements, where components must withstand not only single extreme thermal events but repeated cycles of heating and cooling. This has shifted procurement strategies toward higher-cost but more durable nickel-based superalloys and ceramic matrix composites, despite their higher initial investment costs.

Regional market distribution shows North America maintaining leadership in aerospace thermal material consumption, followed by Europe and increasingly Asia, where space programs in China, India, and Japan are expanding rapidly. The defense sector remains the largest consumer of advanced thermal materials, though commercial space applications are growing at a faster rate.

Supply chain considerations have become increasingly important in the market landscape, with aerospace manufacturers seeking materials that not only meet performance specifications but also offer manufacturing scalability and supply security. This has led to increased interest in developing domestic production capabilities for critical high-temperature alloys, particularly those containing strategic elements like rhenium, hafnium, and rare earth metals.

Customer requirements are evolving toward integrated material solutions that combine thermal performance with other functionalities such as radiation resistance, reduced weight, and compatibility with advanced manufacturing techniques like additive manufacturing. This trend is creating new market opportunities for material suppliers who can deliver multi-functional high-temperature alloy systems rather than single-property solutions.

Current State and Challenges in High-Temperature Metallurgy

The global landscape of high-temperature metallurgy has witnessed significant advancements in recent years, with the United States, Europe, Japan, and China emerging as key players. Current high-temperature alloys primarily include nickel-based superalloys, cobalt-based alloys, and refractory metal alloys, each offering distinct advantages for spacecraft applications. However, despite these advancements, several critical challenges persist in this field.

Material performance limitations represent a primary obstacle, particularly in achieving optimal combinations of high-temperature strength, oxidation resistance, and thermal stability. Most existing alloys experience significant degradation in mechanical properties at temperatures exceeding 1100°C, creating a substantial barrier for next-generation spacecraft designs that require materials capable of withstanding 1300°C or higher.

Manufacturing complexities further compound these challenges. Advanced high-temperature alloys often require sophisticated processing techniques such as vacuum induction melting, directional solidification, or powder metallurgy. These processes are not only technically demanding but also economically intensive, limiting widespread adoption and scalability.

Weight considerations remain paramount in spacecraft design, where every gram impacts mission capabilities. Current high-temperature alloys typically exhibit high density, creating an inherent trade-off between thermal performance and weight efficiency. This balance becomes increasingly critical as missions demand both higher temperature resistance and improved payload capacity.

Environmental degradation mechanisms, including oxidation, hot corrosion, and thermal fatigue, continue to undermine long-term material performance. The harsh space environment, characterized by extreme temperature fluctuations, vacuum conditions, and radiation exposure, accelerates these degradation processes beyond what is typically observed in terrestrial applications.

Cost factors present significant barriers to innovation in this field. The rare elements commonly used in high-performance alloys, such as rhenium, ruthenium, and hafnium, face supply constraints and price volatility. These economic considerations often restrict material selection and limit the commercial viability of advanced alloy systems.

Emerging research directions focus on addressing these challenges through computational materials science, additive manufacturing techniques, and novel material architectures. Multi-component high-entropy alloys and ceramic-metal composites show particular promise for pushing temperature capabilities beyond current limitations. Additionally, surface engineering approaches, including advanced coating systems and surface treatments, are being explored to enhance oxidation resistance while maintaining bulk mechanical properties.

Material performance limitations represent a primary obstacle, particularly in achieving optimal combinations of high-temperature strength, oxidation resistance, and thermal stability. Most existing alloys experience significant degradation in mechanical properties at temperatures exceeding 1100°C, creating a substantial barrier for next-generation spacecraft designs that require materials capable of withstanding 1300°C or higher.

Manufacturing complexities further compound these challenges. Advanced high-temperature alloys often require sophisticated processing techniques such as vacuum induction melting, directional solidification, or powder metallurgy. These processes are not only technically demanding but also economically intensive, limiting widespread adoption and scalability.

Weight considerations remain paramount in spacecraft design, where every gram impacts mission capabilities. Current high-temperature alloys typically exhibit high density, creating an inherent trade-off between thermal performance and weight efficiency. This balance becomes increasingly critical as missions demand both higher temperature resistance and improved payload capacity.

Environmental degradation mechanisms, including oxidation, hot corrosion, and thermal fatigue, continue to undermine long-term material performance. The harsh space environment, characterized by extreme temperature fluctuations, vacuum conditions, and radiation exposure, accelerates these degradation processes beyond what is typically observed in terrestrial applications.

Cost factors present significant barriers to innovation in this field. The rare elements commonly used in high-performance alloys, such as rhenium, ruthenium, and hafnium, face supply constraints and price volatility. These economic considerations often restrict material selection and limit the commercial viability of advanced alloy systems.

Emerging research directions focus on addressing these challenges through computational materials science, additive manufacturing techniques, and novel material architectures. Multi-component high-entropy alloys and ceramic-metal composites show particular promise for pushing temperature capabilities beyond current limitations. Additionally, surface engineering approaches, including advanced coating systems and surface treatments, are being explored to enhance oxidation resistance while maintaining bulk mechanical properties.

Current High-Temperature Alloy Solutions for Spacecraft

01 Nickel-based superalloys for high-temperature applications

Nickel-based superalloys are widely used in high-temperature applications due to their excellent mechanical properties and oxidation resistance at elevated temperatures. These alloys typically contain chromium, cobalt, aluminum, titanium, and other elements to enhance their strength, creep resistance, and thermal stability. They are commonly employed in gas turbines, aerospace engines, and other components that operate under extreme temperature conditions.- Nickel-based superalloys for high-temperature applications: Nickel-based superalloys are widely used in high-temperature applications due to their excellent mechanical properties and oxidation resistance at elevated temperatures. These alloys typically contain chromium, cobalt, aluminum, titanium, and other elements to enhance their strength, creep resistance, and thermal stability. They are commonly employed in gas turbines, aerospace engines, and other components that operate under extreme temperature conditions.

- Cobalt-based high-temperature alloys: Cobalt-based alloys are designed for applications requiring excellent hot corrosion resistance and thermal fatigue properties. These alloys typically contain chromium, tungsten, and other elements to provide strength at high temperatures while maintaining good wear resistance. They are particularly suitable for components exposed to severe thermal cycling and corrosive environments, such as turbine vanes, combustion chambers, and industrial furnace parts.

- Refractory metal alloys for extreme temperature applications: Refractory metal alloys based on tungsten, molybdenum, niobium, and tantalum are designed for ultra-high temperature applications exceeding 1200°C. These alloys offer exceptional melting points and strength retention at extreme temperatures. They are used in specialized applications such as rocket nozzles, furnace components, and nuclear reactors where conventional superalloys would fail. Various alloying elements and processing techniques are employed to improve their oxidation resistance and workability.

- Advanced manufacturing techniques for high-temperature alloys: Novel manufacturing processes have been developed to enhance the properties and performance of high-temperature alloys. These include powder metallurgy, directional solidification, single crystal growth, additive manufacturing, and various heat treatment protocols. These techniques allow for precise control of microstructure, grain orientation, and precipitate formation, resulting in alloys with superior creep resistance, thermal stability, and extended service life at elevated temperatures.

- Surface treatments and coatings for high-temperature alloys: Various surface treatments and coating systems have been developed to protect high-temperature alloys from oxidation, corrosion, and thermal degradation. These include thermal barrier coatings, diffusion coatings, overlay coatings, and surface modification techniques. Such protective systems typically consist of multiple layers designed to provide oxidation resistance, reduce thermal conductivity, and extend component life in extreme environments. They are crucial for applications in power generation, aerospace, and chemical processing industries.

02 Refractory metal alloys for ultra-high temperature environments

Refractory metal alloys based on tungsten, molybdenum, niobium, and tantalum are designed for ultra-high temperature applications exceeding 1200°C. These alloys exhibit exceptional melting points, strength retention at extreme temperatures, and resistance to thermal shock. They are particularly valuable in aerospace, nuclear reactors, and industrial furnace components where conventional superalloys would fail.Expand Specific Solutions03 Heat treatment processes for high-temperature alloys

Specialized heat treatment processes are crucial for optimizing the microstructure and properties of high-temperature alloys. These processes include solution treatment, aging, annealing, and quenching, which control precipitation hardening, grain size, and phase stability. Proper heat treatment significantly enhances creep resistance, thermal fatigue properties, and overall service life of components operating in high-temperature environments.Expand Specific Solutions04 Coating systems for high-temperature alloy protection

Advanced coating systems are developed to protect high-temperature alloys from oxidation, corrosion, and thermal degradation. These include thermal barrier coatings, diffusion coatings, overlay coatings, and multi-layer protective systems. The coatings create protective oxide layers, reduce thermal conductivity, and extend component life by preventing direct exposure of the base alloy to extreme environments.Expand Specific Solutions05 Novel manufacturing techniques for high-temperature alloys

Innovative manufacturing techniques are being developed for producing complex high-temperature alloy components. These include powder metallurgy, additive manufacturing, directional solidification, and single crystal growth processes. These advanced manufacturing methods enable the production of components with superior high-temperature properties, complex geometries, and optimized microstructures that cannot be achieved through conventional casting or forging techniques.Expand Specific Solutions

Leading Aerospace and Metallurgical Industry Players

High-temperature alloys for spacecraft design are in a mature development phase, with a global market exceeding $5 billion annually and growing steadily at 6-8%. The competitive landscape features established aerospace giants like RTX Corp., United Technologies, and Airbus Defence & Space, alongside specialized materials innovators such as QuesTek Innovations, NanoAL, and Kobe Steel. Academic institutions including Beihang University, Shanghai Jiao Tong University, and Harbin Institute of Technology contribute significant research advancements. The technology has reached high maturity (TRL 7-9) for conventional applications, while next-generation alloys incorporating nanomaterials and advanced manufacturing techniques are emerging through collaborative industry-academia partnerships, driving continued innovation in spacecraft thermal protection systems and propulsion components.

Airbus Defence & Space GmbH

Technical Solution: Airbus Defence & Space has developed proprietary high-temperature alloy solutions specifically engineered for spacecraft thermal protection systems and propulsion components. Their advanced nickel-based superalloys incorporate precise amounts of refractory elements and are manufactured using vacuum melting and directional solidification techniques to ensure optimal grain structure. Airbus employs a unique combination of gamma/gamma-prime microstructure optimization that enables their alloys to maintain mechanical properties at temperatures exceeding 1000°C. Their manufacturing process includes specialized heat treatments that precisely control precipitate size and distribution, critical for long-duration space missions. Airbus has pioneered the integration of ceramic matrix composites with high-temperature alloys to create hybrid structures that maximize thermal protection while minimizing mass[4]. Their alloys feature carefully engineered additions of hafnium and zirconium to improve grain boundary strength and creep resistance. Recent developments include advanced thermal barrier coating systems that can extend component life by up to 30% in extreme reentry conditions[5].

Strengths: Exceptional thermal stability in vacuum environments; proven reliability in European space programs; comprehensive testing facilities for space environment simulation; integrated systems approach to thermal management. Weaknesses: Higher production costs compared to conventional aerospace alloys; complex manufacturing processes requiring specialized equipment; longer development cycles; challenges in scaling production for larger spacecraft components.

RTX Corp.

Technical Solution: RTX Corporation (formerly Raytheon Technologies) has pioneered advanced high-temperature alloy solutions specifically designed for spacecraft thermal protection systems and propulsion components. Their proprietary nickel and cobalt-based superalloys incorporate precise amounts of refractory elements like tungsten, molybdenum, and tantalum to achieve exceptional high-temperature strength. RTX employs vacuum induction melting followed by vacuum arc remelting to ensure ultra-high purity levels critical for aerospace applications. Their alloys feature carefully engineered microstructures with gamma prime and gamma double prime precipitates that maintain stability at temperatures up to 1200°C. RTX has developed specialized coating systems that provide oxidation protection while minimizing weight penalties, extending component life by up to 40% in extreme environments[2]. Their manufacturing processes include hot isostatic pressing and precision machining techniques that maintain tight tolerances even for complex geometrical components used in spacecraft thermal management systems.

Strengths: Exceptional high-temperature mechanical properties; superior oxidation and corrosion resistance in space environments; extensive flight heritage data; integrated design and testing capabilities. Weaknesses: Higher production costs compared to conventional alloys; complex processing requirements; limited suppliers for specialized raw materials; challenges in joining and repair processes.

Key Innovations in Heat-Resistant Material Science

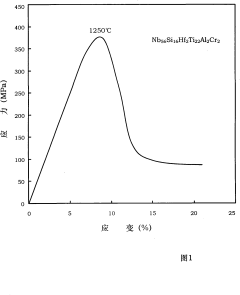

Niobium-silicon-hafnium-titanium-aluminum-chromium ultra-high temperature alloy and preparation method thereof

PatentInactiveCN101235460A

Innovation

- Hf and Ti elements are added to the niobium Nb matrix for toughening, forming silicide Nb5Si3 for strengthening, and Cr elements are added to form the high-temperature oxidation resistant phase Cr2Nb, and the phase composition is adjusted to achieve a balance between high-temperature strength, room-temperature toughness and high-temperature oxidation resistance. .

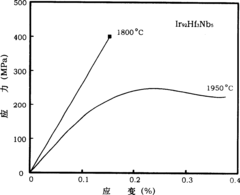

Iridium hafnium niobium high temperature alloy materials and method for preparing same

PatentInactiveCN1294286C

Innovation

- Hafnium and niobium elements are added to the iridium matrix through saturated solid solution strengthening to prepare IrHfNb high-temperature alloy materials to improve their high-temperature mechanical properties.

Space Environment Testing Standards for Advanced Alloys

Space environment testing standards for advanced alloys have evolved significantly over the past decades to address the unique challenges faced by spacecraft materials. These standards encompass rigorous protocols designed to simulate the extreme conditions encountered in space, including vacuum, radiation, atomic oxygen exposure, and rapid temperature fluctuations that can range from -150°C to +150°C.

The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have established comprehensive frameworks specifically for high-temperature alloys used in spacecraft. ASTM E595 standard, for instance, evaluates outgassing properties of materials in vacuum environments, critical for preventing contamination of sensitive optical equipment. Similarly, ISO 11221 addresses atomic oxygen resistance testing, particularly relevant for materials used in low Earth orbit.

Thermal cycling tests represent a cornerstone of space environment testing, with standards requiring materials to withstand thousands of cycles between extreme temperatures. For high-temperature nickel-based and cobalt-based superalloys, ASTM E21 provides guidelines for elevated temperature tension tests, while ASTM E139 covers creep and stress-rupture testing methodologies.

Radiation resistance testing has become increasingly standardized, with protocols such as ASTM E1027 for evaluating the effects of high-energy radiation on materials. These tests typically expose alloys to simulated space radiation environments, including proton, electron, and heavy ion bombardment, measuring changes in mechanical properties and microstructural stability.

The European Space Agency (ESA) and NASA have developed complementary standards, including ESA ECSS-Q-ST-70-04C for thermal vacuum outgassing and NASA-STD-6016 for materials requirements. These standards are regularly updated to incorporate new understanding of space environment effects and advances in alloy development.

Qualification testing for advanced alloys now increasingly includes combined environment testing, where materials are simultaneously exposed to multiple space stressors. This approach, though not fully standardized, better represents actual service conditions and reveals synergistic degradation mechanisms that might be missed in single-factor tests.

Recent developments in testing standards have begun to address the unique requirements of additive manufactured high-temperature alloys, with specialized protocols for evaluating build orientation effects, residual stress, and microstructural homogeneity. These emerging standards recognize that manufacturing processes significantly influence how advanced alloys perform in the extreme conditions of space.

The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have established comprehensive frameworks specifically for high-temperature alloys used in spacecraft. ASTM E595 standard, for instance, evaluates outgassing properties of materials in vacuum environments, critical for preventing contamination of sensitive optical equipment. Similarly, ISO 11221 addresses atomic oxygen resistance testing, particularly relevant for materials used in low Earth orbit.

Thermal cycling tests represent a cornerstone of space environment testing, with standards requiring materials to withstand thousands of cycles between extreme temperatures. For high-temperature nickel-based and cobalt-based superalloys, ASTM E21 provides guidelines for elevated temperature tension tests, while ASTM E139 covers creep and stress-rupture testing methodologies.

Radiation resistance testing has become increasingly standardized, with protocols such as ASTM E1027 for evaluating the effects of high-energy radiation on materials. These tests typically expose alloys to simulated space radiation environments, including proton, electron, and heavy ion bombardment, measuring changes in mechanical properties and microstructural stability.

The European Space Agency (ESA) and NASA have developed complementary standards, including ESA ECSS-Q-ST-70-04C for thermal vacuum outgassing and NASA-STD-6016 for materials requirements. These standards are regularly updated to incorporate new understanding of space environment effects and advances in alloy development.

Qualification testing for advanced alloys now increasingly includes combined environment testing, where materials are simultaneously exposed to multiple space stressors. This approach, though not fully standardized, better represents actual service conditions and reveals synergistic degradation mechanisms that might be missed in single-factor tests.

Recent developments in testing standards have begun to address the unique requirements of additive manufactured high-temperature alloys, with specialized protocols for evaluating build orientation effects, residual stress, and microstructural homogeneity. These emerging standards recognize that manufacturing processes significantly influence how advanced alloys perform in the extreme conditions of space.

Weight-to-Performance Optimization Strategies

Weight optimization in high-temperature alloy spacecraft components represents a critical engineering challenge that directly impacts mission capabilities and costs. The fundamental trade-off between structural integrity and mass reduction requires sophisticated approaches that consider both material properties and design methodologies. Current optimization strategies primarily focus on three interconnected areas: material selection, structural design innovation, and manufacturing process refinement.

Advanced material selection techniques now employ computational modeling to predict performance characteristics of various high-temperature alloy compositions under specific mission profiles. These models integrate thermal cycling effects, mechanical stress patterns, and environmental exposure factors to identify optimal alloy formulations that maintain strength while minimizing density. Nickel-based superalloys with carefully controlled precipitation hardening mechanisms have demonstrated up to 15% weight reduction compared to conventional alternatives while maintaining thermal stability above 1000°C.

Structural design optimization leverages topological analysis software that identifies non-critical material zones that can be removed without compromising structural integrity. This approach has evolved from simple lightweighting to complex biomimetic designs that distribute thermal and mechanical stresses more efficiently. Lattice structures and variable thickness components have proven particularly effective for high-temperature applications, offering weight reductions of 20-30% while maintaining or even improving thermal performance characteristics.

Manufacturing innovations have significantly expanded the feasible design space for weight optimization. Additive manufacturing techniques, particularly selective laser melting and electron beam melting, enable the production of previously impossible geometries with internal cooling channels, gradient structures, and optimized material distribution. These processes allow engineers to place material precisely where needed for structural and thermal requirements, eliminating unnecessary mass.

Integration of these optimization strategies requires sophisticated multiphysics simulation environments that simultaneously model thermal, structural, and fluid dynamics behaviors. Recent advances in digital twin technology enable real-time optimization throughout the development process, with continuous refinement based on simulated mission conditions and prototype testing data.

The economic implications of these weight optimization strategies extend beyond the immediate material cost savings. Each kilogram reduced from spacecraft mass can translate to approximately $20,000-$50,000 in launch cost savings, creating strong financial incentives for continued advancement in this field. Furthermore, optimized components often demonstrate improved thermal cycling resistance, potentially extending service life and reliability in the extreme temperature environments encountered during space missions.

Advanced material selection techniques now employ computational modeling to predict performance characteristics of various high-temperature alloy compositions under specific mission profiles. These models integrate thermal cycling effects, mechanical stress patterns, and environmental exposure factors to identify optimal alloy formulations that maintain strength while minimizing density. Nickel-based superalloys with carefully controlled precipitation hardening mechanisms have demonstrated up to 15% weight reduction compared to conventional alternatives while maintaining thermal stability above 1000°C.

Structural design optimization leverages topological analysis software that identifies non-critical material zones that can be removed without compromising structural integrity. This approach has evolved from simple lightweighting to complex biomimetic designs that distribute thermal and mechanical stresses more efficiently. Lattice structures and variable thickness components have proven particularly effective for high-temperature applications, offering weight reductions of 20-30% while maintaining or even improving thermal performance characteristics.

Manufacturing innovations have significantly expanded the feasible design space for weight optimization. Additive manufacturing techniques, particularly selective laser melting and electron beam melting, enable the production of previously impossible geometries with internal cooling channels, gradient structures, and optimized material distribution. These processes allow engineers to place material precisely where needed for structural and thermal requirements, eliminating unnecessary mass.

Integration of these optimization strategies requires sophisticated multiphysics simulation environments that simultaneously model thermal, structural, and fluid dynamics behaviors. Recent advances in digital twin technology enable real-time optimization throughout the development process, with continuous refinement based on simulated mission conditions and prototype testing data.

The economic implications of these weight optimization strategies extend beyond the immediate material cost savings. Each kilogram reduced from spacecraft mass can translate to approximately $20,000-$50,000 in launch cost savings, creating strong financial incentives for continued advancement in this field. Furthermore, optimized components often demonstrate improved thermal cycling resistance, potentially extending service life and reliability in the extreme temperature environments encountered during space missions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!