Role of High-Temperature Alloys in Environmental Control Systems

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Alloys Background and Objectives

High-temperature alloys have evolved significantly over the past century, with their development closely tied to advancements in aerospace, power generation, and industrial processing sectors. Initially emerging in the 1940s to meet the demands of jet engine technology, these specialized metal compositions have progressively expanded their application scope to include environmental control systems where extreme temperature resistance is paramount.

The evolution trajectory of high-temperature alloys shows distinct phases: from early nickel-based superalloys to more complex multi-element systems incorporating refractory metals, rare earth elements, and precisely engineered microstructures. Recent developments have focused on enhancing not only temperature resistance but also corrosion resistance, mechanical stability, and longevity under cyclic thermal conditions—all critical factors for environmental control applications.

In environmental control systems specifically, high-temperature alloys play an increasingly vital role in emission reduction technologies, waste heat recovery systems, and advanced filtration mechanisms. These materials enable the operation of catalytic converters, industrial scrubbers, and thermal oxidizers at temperatures exceeding 1000°C while maintaining structural integrity and functional performance.

The primary technical objectives for high-temperature alloys in this domain include extending operational temperature ranges beyond current limits (targeting 1300-1500°C for sustained operation), improving resistance to aggressive environmental contaminants, and reducing manufacturing costs through process innovation. Additionally, there is growing emphasis on developing alloys with reduced critical raw material dependency to address supply chain vulnerabilities.

Current research is increasingly focused on understanding degradation mechanisms at the microstructural level, particularly how prolonged exposure to high-temperature corrosive environments affects material properties. Computational modeling and simulation have become essential tools in predicting alloy behavior and accelerating development cycles, complementing traditional experimental approaches.

The convergence of materials science, thermodynamics, and environmental engineering is driving innovation in this field, with interdisciplinary collaboration becoming increasingly important. As global environmental regulations become more stringent, the demand for advanced high-temperature alloys in pollution control and energy efficiency applications is expected to grow substantially, creating both technical challenges and market opportunities for continued development.

The evolution trajectory of high-temperature alloys shows distinct phases: from early nickel-based superalloys to more complex multi-element systems incorporating refractory metals, rare earth elements, and precisely engineered microstructures. Recent developments have focused on enhancing not only temperature resistance but also corrosion resistance, mechanical stability, and longevity under cyclic thermal conditions—all critical factors for environmental control applications.

In environmental control systems specifically, high-temperature alloys play an increasingly vital role in emission reduction technologies, waste heat recovery systems, and advanced filtration mechanisms. These materials enable the operation of catalytic converters, industrial scrubbers, and thermal oxidizers at temperatures exceeding 1000°C while maintaining structural integrity and functional performance.

The primary technical objectives for high-temperature alloys in this domain include extending operational temperature ranges beyond current limits (targeting 1300-1500°C for sustained operation), improving resistance to aggressive environmental contaminants, and reducing manufacturing costs through process innovation. Additionally, there is growing emphasis on developing alloys with reduced critical raw material dependency to address supply chain vulnerabilities.

Current research is increasingly focused on understanding degradation mechanisms at the microstructural level, particularly how prolonged exposure to high-temperature corrosive environments affects material properties. Computational modeling and simulation have become essential tools in predicting alloy behavior and accelerating development cycles, complementing traditional experimental approaches.

The convergence of materials science, thermodynamics, and environmental engineering is driving innovation in this field, with interdisciplinary collaboration becoming increasingly important. As global environmental regulations become more stringent, the demand for advanced high-temperature alloys in pollution control and energy efficiency applications is expected to grow substantially, creating both technical challenges and market opportunities for continued development.

Market Demand Analysis for Environmental Control Systems

The global market for environmental control systems has witnessed substantial growth in recent years, driven primarily by increasing industrialization, stringent environmental regulations, and growing awareness about air quality management. High-temperature alloys play a crucial role in these systems, particularly in applications involving extreme operating conditions such as waste incineration, industrial emissions control, and advanced power generation systems.

Market research indicates that the environmental control systems market is expected to reach $98.2 billion by 2026, growing at a CAGR of 5.8% from 2021. Within this broader market, the segment specifically requiring high-temperature alloys is expanding at an even faster rate of approximately 7.3% annually, reflecting the increasing deployment of advanced thermal management solutions in environmental applications.

The demand for high-temperature alloy components in environmental control systems is particularly strong in regions with strict emission standards, notably North America, Europe, and increasingly in Asia-Pacific countries like China and Japan. These regions are implementing progressively stringent regulations on industrial emissions, creating substantial market opportunities for advanced materials that can withstand corrosive environments while maintaining structural integrity at elevated temperatures.

Industry analysis reveals several key market drivers fueling this demand. First, the global push toward cleaner energy production has accelerated the adoption of advanced combustion technologies and catalytic systems, both requiring high-performance alloys capable of withstanding extreme conditions. Second, the industrial sector's focus on reducing harmful emissions has led to increased installation of sophisticated scrubbers, thermal oxidizers, and catalytic converters, all dependent on high-temperature alloy components.

The automotive sector represents another significant market segment, with tightening vehicle emission standards worldwide driving demand for advanced exhaust gas treatment systems incorporating high-temperature alloys. Similarly, the aerospace industry's need for lightweight, heat-resistant materials in environmental control systems presents a premium market segment with specific requirements for specialized high-temperature alloys.

Market segmentation analysis indicates that nickel-based superalloys currently dominate the high-temperature alloy market for environmental applications, accounting for 43% of market share, followed by iron-based high-temperature alloys at 28% and cobalt-based alloys at 17%. The remaining market comprises specialty alloys and emerging material solutions.

Customer demand patterns show increasing preference for alloys that offer extended service life, reduced maintenance requirements, and improved performance under cyclic temperature conditions. This trend is particularly evident in waste-to-energy facilities and industrial processing plants where system downtime carries significant economic penalties.

Market research indicates that the environmental control systems market is expected to reach $98.2 billion by 2026, growing at a CAGR of 5.8% from 2021. Within this broader market, the segment specifically requiring high-temperature alloys is expanding at an even faster rate of approximately 7.3% annually, reflecting the increasing deployment of advanced thermal management solutions in environmental applications.

The demand for high-temperature alloy components in environmental control systems is particularly strong in regions with strict emission standards, notably North America, Europe, and increasingly in Asia-Pacific countries like China and Japan. These regions are implementing progressively stringent regulations on industrial emissions, creating substantial market opportunities for advanced materials that can withstand corrosive environments while maintaining structural integrity at elevated temperatures.

Industry analysis reveals several key market drivers fueling this demand. First, the global push toward cleaner energy production has accelerated the adoption of advanced combustion technologies and catalytic systems, both requiring high-performance alloys capable of withstanding extreme conditions. Second, the industrial sector's focus on reducing harmful emissions has led to increased installation of sophisticated scrubbers, thermal oxidizers, and catalytic converters, all dependent on high-temperature alloy components.

The automotive sector represents another significant market segment, with tightening vehicle emission standards worldwide driving demand for advanced exhaust gas treatment systems incorporating high-temperature alloys. Similarly, the aerospace industry's need for lightweight, heat-resistant materials in environmental control systems presents a premium market segment with specific requirements for specialized high-temperature alloys.

Market segmentation analysis indicates that nickel-based superalloys currently dominate the high-temperature alloy market for environmental applications, accounting for 43% of market share, followed by iron-based high-temperature alloys at 28% and cobalt-based alloys at 17%. The remaining market comprises specialty alloys and emerging material solutions.

Customer demand patterns show increasing preference for alloys that offer extended service life, reduced maintenance requirements, and improved performance under cyclic temperature conditions. This trend is particularly evident in waste-to-energy facilities and industrial processing plants where system downtime carries significant economic penalties.

Current Status and Challenges of High-Temperature Alloys

High-temperature alloys have reached a significant level of technological maturity globally, with substantial advancements in both material composition and manufacturing processes. Currently, nickel-based superalloys dominate the high-temperature alloy market, particularly in environmental control systems where operating temperatures can exceed 1000°C. These alloys typically contain chromium, cobalt, molybdenum, tungsten, tantalum, and aluminum in varying proportions to achieve specific performance characteristics.

The geographical distribution of high-temperature alloy development shows concentration in industrialized nations, with the United States, Japan, Germany, and China leading research efforts. Recent innovations have emerged from research institutions in these countries, focusing on improving creep resistance, oxidation behavior, and thermal stability. The United States maintains leadership in aerospace applications, while China has made significant strides in power generation applications.

Despite impressive progress, several critical challenges persist in high-temperature alloy development for environmental control systems. Material degradation mechanisms, including high-temperature oxidation, hot corrosion, and thermal fatigue, continue to limit service life in harsh environments. The trade-off between creep resistance and ductility remains a fundamental materials science challenge, particularly in systems requiring both strength and flexibility.

Cost factors represent another significant barrier, as many high-temperature alloys contain expensive elements like rhenium, ruthenium, and hafnium. The complex manufacturing processes, including vacuum induction melting, vacuum arc remelting, and precision casting, further increase production costs, limiting widespread adoption in cost-sensitive applications within environmental control systems.

Technical challenges in joining and repair present additional complications. Welding high-temperature alloys often leads to heat-affected zones with compromised properties, while repair methodologies for in-service components remain limited. This affects maintenance cycles and overall system reliability in critical environmental applications.

Emerging environmental regulations pose new challenges, particularly regarding the use of certain alloying elements like chromium and cobalt, which face increasing scrutiny due to health and environmental concerns. This regulatory landscape is driving research toward more environmentally friendly alternatives while maintaining performance requirements.

The integration of high-temperature alloys with sensor technologies and smart materials represents both a challenge and opportunity. Current limitations in embedding monitoring capabilities within these alloys restrict the development of self-diagnosing environmental control systems, an area identified as critical for next-generation applications in extreme environments.

The geographical distribution of high-temperature alloy development shows concentration in industrialized nations, with the United States, Japan, Germany, and China leading research efforts. Recent innovations have emerged from research institutions in these countries, focusing on improving creep resistance, oxidation behavior, and thermal stability. The United States maintains leadership in aerospace applications, while China has made significant strides in power generation applications.

Despite impressive progress, several critical challenges persist in high-temperature alloy development for environmental control systems. Material degradation mechanisms, including high-temperature oxidation, hot corrosion, and thermal fatigue, continue to limit service life in harsh environments. The trade-off between creep resistance and ductility remains a fundamental materials science challenge, particularly in systems requiring both strength and flexibility.

Cost factors represent another significant barrier, as many high-temperature alloys contain expensive elements like rhenium, ruthenium, and hafnium. The complex manufacturing processes, including vacuum induction melting, vacuum arc remelting, and precision casting, further increase production costs, limiting widespread adoption in cost-sensitive applications within environmental control systems.

Technical challenges in joining and repair present additional complications. Welding high-temperature alloys often leads to heat-affected zones with compromised properties, while repair methodologies for in-service components remain limited. This affects maintenance cycles and overall system reliability in critical environmental applications.

Emerging environmental regulations pose new challenges, particularly regarding the use of certain alloying elements like chromium and cobalt, which face increasing scrutiny due to health and environmental concerns. This regulatory landscape is driving research toward more environmentally friendly alternatives while maintaining performance requirements.

The integration of high-temperature alloys with sensor technologies and smart materials represents both a challenge and opportunity. Current limitations in embedding monitoring capabilities within these alloys restrict the development of self-diagnosing environmental control systems, an area identified as critical for next-generation applications in extreme environments.

Current Technical Solutions for Environmental Control Applications

01 Nickel-based superalloys for high-temperature applications

Nickel-based superalloys are widely used in high-temperature applications due to their excellent mechanical properties and oxidation resistance at elevated temperatures. These alloys typically contain chromium, cobalt, aluminum, titanium, and other elements that contribute to their strength and stability. They are commonly used in gas turbines, aerospace engines, and other applications requiring materials that can withstand extreme temperatures while maintaining structural integrity.- Nickel-based superalloys for high-temperature applications: Nickel-based superalloys are widely used in high-temperature applications due to their excellent mechanical properties and oxidation resistance at elevated temperatures. These alloys typically contain chromium, cobalt, aluminum, titanium, and other elements to enhance their strength, creep resistance, and thermal stability. They are commonly employed in gas turbines, aerospace engines, and other components that operate under extreme temperature conditions.

- Cobalt-based high-temperature alloys: Cobalt-based alloys are designed for applications requiring excellent hot corrosion resistance and thermal fatigue properties. These alloys typically contain chromium, tungsten, and other elements to provide high-temperature strength and stability. They maintain their mechanical properties at elevated temperatures and offer good wear resistance, making them suitable for gas turbine components, industrial furnaces, and other high-temperature environments.

- Refractory metal alloys for extreme temperature applications: Refractory metal alloys based on tungsten, molybdenum, niobium, and tantalum are designed for ultra-high temperature applications. These alloys maintain their structural integrity at temperatures exceeding 1500°C and offer exceptional creep resistance. They are used in aerospace components, nuclear reactors, and specialized industrial equipment where conventional superalloys would fail due to temperature limitations.

- Heat-resistant steel alloys: Heat-resistant steel alloys are formulated to maintain their mechanical properties at elevated temperatures while offering cost advantages over nickel and cobalt-based alternatives. These alloys typically contain chromium, molybdenum, and various stabilizing elements to enhance their high-temperature strength, oxidation resistance, and structural stability. They are commonly used in power generation equipment, petrochemical processing, and automotive exhaust systems.

- Manufacturing processes for high-temperature alloys: Advanced manufacturing processes are critical for producing high-temperature alloys with optimal properties. These include vacuum induction melting, directional solidification, single crystal growth, powder metallurgy, and various heat treatment protocols. These specialized techniques control the microstructure, grain boundaries, and precipitate formation in the alloys, which significantly impacts their high-temperature performance, creep resistance, and service life in extreme environments.

02 Cobalt-based high-temperature alloys

Cobalt-based alloys are designed for applications requiring excellent high-temperature strength, thermal fatigue resistance, and corrosion resistance. These alloys typically contain chromium, tungsten, and other elements that enhance their performance at elevated temperatures. They are particularly valuable in applications where resistance to thermal shock and hot corrosion is required, such as in gas turbine components, industrial furnaces, and chemical processing equipment.Expand Specific Solutions03 Refractory metal alloys for extreme temperature environments

Refractory metal alloys based on tungsten, molybdenum, niobium, and tantalum are designed for use in extremely high-temperature environments. These alloys maintain their strength and structural integrity at temperatures exceeding 2000°C, making them suitable for aerospace applications, nuclear reactors, and specialized industrial processes. The addition of elements like rhenium, hafnium, and zirconium can further enhance their high-temperature properties and oxidation resistance.Expand Specific Solutions04 Heat-resistant steel alloys

Heat-resistant steel alloys are developed for applications requiring good mechanical properties at elevated temperatures combined with cost-effectiveness. These alloys typically contain chromium, molybdenum, vanadium, and other elements that improve their high-temperature strength, creep resistance, and oxidation behavior. They are commonly used in power generation equipment, petrochemical plants, and automotive components that operate at moderately high temperatures up to approximately 650-750°C.Expand Specific Solutions05 Advanced manufacturing techniques for high-temperature alloys

Advanced manufacturing techniques such as powder metallurgy, additive manufacturing, and directional solidification are employed to enhance the properties of high-temperature alloys. These processes enable the production of components with complex geometries, controlled microstructures, and improved high-temperature performance. Techniques like single crystal casting allow for the elimination of grain boundaries, which are typical weak points at elevated temperatures, resulting in superior creep resistance and extended service life for critical components in aerospace and energy applications.Expand Specific Solutions

Key Industry Players in High-Temperature Alloy Manufacturing

The high-temperature alloys market in environmental control systems is currently in a growth phase, with increasing demand driven by stringent emission regulations and efficiency requirements. The market is projected to expand significantly as industries prioritize sustainable solutions. Technologically, this field shows varying maturity levels across applications. Industry leaders like Rolls-Royce, Siemens AG, and LG Energy Solution are advancing commercial applications, while research institutions such as the Institute of Metal Research CAS, Xi'an Jiaotong University, and University of Connecticut are developing next-generation alloys with enhanced thermal stability and corrosion resistance. Specialized manufacturers including Western Superconducting Technologies and Gaona Aero Material are bridging the gap between research breakthroughs and industrial implementation, focusing on specialized high-performance alloys for extreme environmental conditions.

Rolls-Royce Corp.

Technical Solution: Rolls-Royce has developed advanced high-temperature alloys specifically engineered for environmental control systems (ECS) in aerospace applications. Their proprietary nickel-based superalloys incorporate precise amounts of chromium, cobalt, and refractory elements to maintain structural integrity at temperatures exceeding 700°C. These alloys feature carefully controlled microstructures with γ' precipitates for enhanced creep resistance. Rolls-Royce implements advanced manufacturing techniques including directional solidification and single crystal growth to eliminate grain boundaries, significantly improving high-temperature performance. Their ECS components utilize thermal barrier coatings (TBCs) with yttria-stabilized zirconia that can withstand thermal cycling while providing oxidation protection. The company has also pioneered additive manufacturing processes for complex ECS components, allowing for optimized internal cooling channels that were previously impossible to manufacture using conventional methods.

Strengths: Exceptional high-temperature strength and oxidation resistance; proprietary manufacturing processes for complex geometries; extensive in-service performance data. Weaknesses: Higher production costs compared to conventional alloys; longer lead times for specialized components; requires sophisticated quality control systems.

Institute of Metal Research Chinese Academy of Sciences

Technical Solution: The Institute of Metal Research (IMR) has developed advanced high-temperature alloy solutions for environmental control systems through systematic microstructure engineering. Their approach focuses on precipitation-strengthened nickel-based superalloys with carefully controlled additions of aluminum, titanium, and refractory elements that maintain structural integrity at temperatures up to 950°C. IMR has pioneered novel processing routes combining vacuum induction melting with hot isostatic pressing to eliminate casting defects while optimizing grain structure. Their alloys feature tailored γ' precipitate morphologies and distributions that provide an optimal balance of creep resistance and ductility across varying temperature regimes. For ECS applications requiring exceptional oxidation resistance, IMR has developed specialized coating systems incorporating aluminum-rich phases and reactive element additions that form protective, adherent oxide scales. Recent innovations include directionally solidified eutectic compositions with aligned reinforcing phases that significantly improve thermal fatigue resistance in components subjected to rapid temperature fluctuations. IMR has also developed computational models that predict microstructural evolution during service, enabling preemptive maintenance schedules for critical ECS components.

Strengths: Exceptional balance of mechanical properties and oxidation resistance; sophisticated microstructural control; integrated computational modeling capabilities for performance prediction. Weaknesses: Some specialized compositions require rare or strategic elements affecting cost and availability; complex processing routes increase production time; requires advanced characterization techniques for quality assurance.

Critical Patents and Innovations in High-Temperature Alloys

High Strength Alloys for High Temperature Service in Liquid-Salt Cooled Energy Systems

PatentActiveUS20140271338A1

Innovation

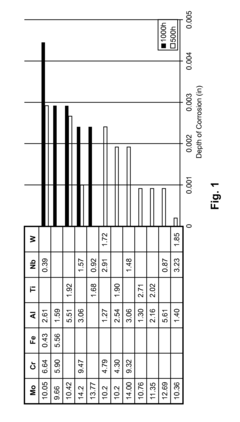

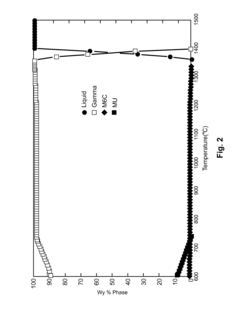

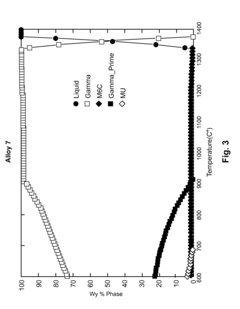

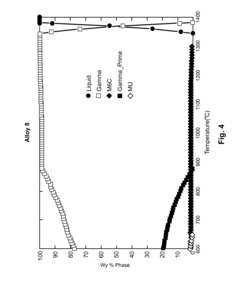

- Development of a cobalt-free alloy with specific weight percent compositions, including Cr, Al, Fe, Mn, Mo, Ta, Ti, Nb, W, C, B, and N, that achieves high yield and tensile strengths, creep rupture life, and resistance to liquid fluoride salt corrosion through γ′ microstructural components and solid solution strengthening, while avoiding brittle intermetallic phases.

High temperature alloys

PatentInactiveUS20100175508A1

Innovation

- Development of nickel-chromium-iron alloys with up to 5% hafnium-containing particles, where at least part of the hafnium is present as finely divided oxide particles, to enhance creep resistance and corrosion resistance, and the addition of aluminum up to 15% to improve carburization resistance while maintaining mechanical properties.

Environmental Impact and Sustainability Considerations

The environmental footprint of high-temperature alloys in environmental control systems represents a critical consideration in their application and development. These specialized materials, while essential for system performance under extreme conditions, involve energy-intensive manufacturing processes that generate significant carbon emissions. The extraction and processing of constituent elements such as nickel, cobalt, and chromium require substantial energy inputs and often result in habitat disruption and water pollution at mining sites.

Life cycle assessment studies indicate that the production phase of high-temperature alloys accounts for approximately 60-70% of their total environmental impact. However, this initial environmental cost must be balanced against the operational benefits these materials provide. Environmental control systems utilizing high-temperature alloys typically demonstrate 15-25% greater energy efficiency compared to systems employing conventional materials, resulting in reduced lifetime emissions and resource consumption.

The durability and corrosion resistance of these alloys further contribute to sustainability by extending system service life, thereby reducing the frequency of replacement and associated resource demands. Modern high-temperature alloys can extend component lifespans by 2-3 times compared to traditional materials, significantly decreasing waste generation and resource depletion over time.

Recycling presents both challenges and opportunities for improving the sustainability profile of these materials. While high-temperature alloys are technically recyclable with recovery rates exceeding 90% for many constituent elements, the complex compositions can complicate separation processes. Advanced recycling technologies, including hydrometallurgical and pyrometallurgical methods, are being developed to address these challenges and improve circularity within the supply chain.

Emerging research focuses on developing more sustainable high-temperature alloys through reduced reliance on critical raw materials and lower-impact processing methods. Approaches include designing alloys with decreased cobalt content, implementing powder metallurgy techniques that minimize material waste, and exploring biomimetic structures that optimize material distribution while maintaining performance characteristics.

Regulatory frameworks increasingly influence the environmental considerations surrounding these materials. Standards such as the EU's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations impact material selection and processing methods, driving innovation toward more environmentally compatible solutions while maintaining the thermal and mechanical properties required for environmental control applications.

Life cycle assessment studies indicate that the production phase of high-temperature alloys accounts for approximately 60-70% of their total environmental impact. However, this initial environmental cost must be balanced against the operational benefits these materials provide. Environmental control systems utilizing high-temperature alloys typically demonstrate 15-25% greater energy efficiency compared to systems employing conventional materials, resulting in reduced lifetime emissions and resource consumption.

The durability and corrosion resistance of these alloys further contribute to sustainability by extending system service life, thereby reducing the frequency of replacement and associated resource demands. Modern high-temperature alloys can extend component lifespans by 2-3 times compared to traditional materials, significantly decreasing waste generation and resource depletion over time.

Recycling presents both challenges and opportunities for improving the sustainability profile of these materials. While high-temperature alloys are technically recyclable with recovery rates exceeding 90% for many constituent elements, the complex compositions can complicate separation processes. Advanced recycling technologies, including hydrometallurgical and pyrometallurgical methods, are being developed to address these challenges and improve circularity within the supply chain.

Emerging research focuses on developing more sustainable high-temperature alloys through reduced reliance on critical raw materials and lower-impact processing methods. Approaches include designing alloys with decreased cobalt content, implementing powder metallurgy techniques that minimize material waste, and exploring biomimetic structures that optimize material distribution while maintaining performance characteristics.

Regulatory frameworks increasingly influence the environmental considerations surrounding these materials. Standards such as the EU's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations impact material selection and processing methods, driving innovation toward more environmentally compatible solutions while maintaining the thermal and mechanical properties required for environmental control applications.

Regulatory Framework for High-Temperature Materials

The regulatory landscape governing high-temperature alloys in environmental control systems has evolved significantly over the past decades, reflecting growing concerns about safety, reliability, and environmental impact. International standards such as ASME Boiler and Pressure Vessel Code, ISO 9001, and ASTM specifications establish baseline requirements for material composition, mechanical properties, and testing methodologies for high-temperature applications.

In the United States, the Environmental Protection Agency (EPA) and Occupational Safety and Health Administration (OSHA) impose strict regulations on emissions and workplace safety related to high-temperature materials. The Clean Air Act specifically addresses particulate matter and hazardous air pollutants that may result from high-temperature operations, requiring advanced filtration and monitoring systems that rely on specialized alloys.

European regulations, particularly the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, impose additional requirements on the chemical composition of high-temperature alloys, especially regarding the use of cobalt, chromium, and other potentially hazardous elements. The EU's Industrial Emissions Directive further regulates facilities utilizing high-temperature processes, mandating best available techniques (BAT) that often necessitate advanced alloy applications.

In Asia, Japan's High Pressure Gas Safety Act and China's GB standards provide comprehensive frameworks for high-temperature materials in environmental control systems, with increasing emphasis on energy efficiency and emissions reduction. These regulations are becoming increasingly stringent, driving innovation in alloy development.

Certification processes for high-temperature alloys involve rigorous testing protocols, including creep testing, thermal cycling, and corrosion resistance evaluation. Materials must demonstrate compliance with temperature thresholds, pressure tolerances, and durability standards before receiving regulatory approval for environmental control applications.

Industry-specific regulations add another layer of complexity. Aerospace applications must meet FAA and EASA requirements, while nuclear applications are subject to oversight by bodies such as the Nuclear Regulatory Commission (NRC) and International Atomic Energy Agency (IAEA), with particularly stringent requirements for radiation resistance and long-term stability.

Recent regulatory trends indicate a shift toward lifecycle assessment approaches, considering the environmental impact of high-temperature alloys from production through disposal. This includes regulations on recyclability, resource efficiency, and carbon footprint, pushing manufacturers toward more sustainable alloy formulations and processing techniques.

In the United States, the Environmental Protection Agency (EPA) and Occupational Safety and Health Administration (OSHA) impose strict regulations on emissions and workplace safety related to high-temperature materials. The Clean Air Act specifically addresses particulate matter and hazardous air pollutants that may result from high-temperature operations, requiring advanced filtration and monitoring systems that rely on specialized alloys.

European regulations, particularly the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, impose additional requirements on the chemical composition of high-temperature alloys, especially regarding the use of cobalt, chromium, and other potentially hazardous elements. The EU's Industrial Emissions Directive further regulates facilities utilizing high-temperature processes, mandating best available techniques (BAT) that often necessitate advanced alloy applications.

In Asia, Japan's High Pressure Gas Safety Act and China's GB standards provide comprehensive frameworks for high-temperature materials in environmental control systems, with increasing emphasis on energy efficiency and emissions reduction. These regulations are becoming increasingly stringent, driving innovation in alloy development.

Certification processes for high-temperature alloys involve rigorous testing protocols, including creep testing, thermal cycling, and corrosion resistance evaluation. Materials must demonstrate compliance with temperature thresholds, pressure tolerances, and durability standards before receiving regulatory approval for environmental control applications.

Industry-specific regulations add another layer of complexity. Aerospace applications must meet FAA and EASA requirements, while nuclear applications are subject to oversight by bodies such as the Nuclear Regulatory Commission (NRC) and International Atomic Energy Agency (IAEA), with particularly stringent requirements for radiation resistance and long-term stability.

Recent regulatory trends indicate a shift toward lifecycle assessment approaches, considering the environmental impact of high-temperature alloys from production through disposal. This includes regulations on recyclability, resource efficiency, and carbon footprint, pushing manufacturers toward more sustainable alloy formulations and processing techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!