Research on High-Temperature Alloys for Heat Exchanger Efficiency

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Alloy Development Background and Objectives

High-temperature alloys have evolved significantly since their inception in the early 20th century, initially developed for aircraft engines and later expanding to various industrial applications including heat exchangers. The progression from simple nickel-based alloys to sophisticated superalloys represents a remarkable journey of metallurgical innovation driven by increasing demands for thermal efficiency in energy systems.

The development of these alloys has been characterized by continuous improvements in creep resistance, oxidation resistance, and mechanical stability at elevated temperatures. Early generations focused primarily on basic compositional adjustments, while modern iterations incorporate complex microstructural engineering and precise control of trace elements to achieve superior performance characteristics.

Current global energy challenges, particularly the push for greater efficiency in power generation and industrial processes, have intensified research efforts in high-temperature alloy development. Heat exchangers, as critical components in these systems, directly impact overall efficiency, with even marginal improvements translating to significant energy savings and reduced carbon emissions at scale.

The primary technical objective in this field is to develop alloys capable of reliable operation at temperatures exceeding 1000°C while maintaining structural integrity and resistance to environmental degradation. This represents a significant advancement beyond current commercial alloys that typically operate reliably up to 800-900°C. Secondary objectives include cost reduction through optimized manufacturing processes and the incorporation of less expensive alloying elements without compromising performance.

Recent technological breakthroughs in computational materials science, particularly in CALPHAD (CALculation of PHAse Diagrams) modeling and machine learning approaches, have accelerated alloy development cycles. These tools enable more efficient exploration of complex compositional spaces and prediction of microstructural evolution under service conditions, reducing the traditional reliance on extensive experimental testing.

The convergence of advanced manufacturing techniques, particularly additive manufacturing, with high-temperature alloy development presents unprecedented opportunities for creating geometrically optimized heat exchanger designs with tailored microstructures. This synergy potentially addresses both material and design limitations simultaneously.

Looking forward, the trajectory of high-temperature alloy development aims to push operational temperature boundaries while simultaneously addressing sustainability concerns through reduced reliance on critical raw materials and improved recyclability. The ultimate goal remains creating materials that enable next-generation energy systems with significantly higher thermal efficiency than current technologies, directly contributing to global decarbonization efforts.

The development of these alloys has been characterized by continuous improvements in creep resistance, oxidation resistance, and mechanical stability at elevated temperatures. Early generations focused primarily on basic compositional adjustments, while modern iterations incorporate complex microstructural engineering and precise control of trace elements to achieve superior performance characteristics.

Current global energy challenges, particularly the push for greater efficiency in power generation and industrial processes, have intensified research efforts in high-temperature alloy development. Heat exchangers, as critical components in these systems, directly impact overall efficiency, with even marginal improvements translating to significant energy savings and reduced carbon emissions at scale.

The primary technical objective in this field is to develop alloys capable of reliable operation at temperatures exceeding 1000°C while maintaining structural integrity and resistance to environmental degradation. This represents a significant advancement beyond current commercial alloys that typically operate reliably up to 800-900°C. Secondary objectives include cost reduction through optimized manufacturing processes and the incorporation of less expensive alloying elements without compromising performance.

Recent technological breakthroughs in computational materials science, particularly in CALPHAD (CALculation of PHAse Diagrams) modeling and machine learning approaches, have accelerated alloy development cycles. These tools enable more efficient exploration of complex compositional spaces and prediction of microstructural evolution under service conditions, reducing the traditional reliance on extensive experimental testing.

The convergence of advanced manufacturing techniques, particularly additive manufacturing, with high-temperature alloy development presents unprecedented opportunities for creating geometrically optimized heat exchanger designs with tailored microstructures. This synergy potentially addresses both material and design limitations simultaneously.

Looking forward, the trajectory of high-temperature alloy development aims to push operational temperature boundaries while simultaneously addressing sustainability concerns through reduced reliance on critical raw materials and improved recyclability. The ultimate goal remains creating materials that enable next-generation energy systems with significantly higher thermal efficiency than current technologies, directly contributing to global decarbonization efforts.

Market Demand Analysis for Efficient Heat Exchangers

The global heat exchanger market is experiencing significant growth driven by increasing energy efficiency requirements across multiple industries. Current market analysis indicates that the heat exchanger market is projected to reach $28.3 billion by 2025, with a compound annual growth rate of approximately 6.8%. This growth is primarily fueled by stringent environmental regulations, rising energy costs, and the industrial push toward sustainable operations.

Energy-intensive industries such as power generation, chemical processing, oil and gas, and metallurgy represent the largest demand segments for high-efficiency heat exchangers. These sectors are increasingly seeking solutions that can withstand extreme operating conditions while maximizing thermal transfer efficiency. The ability to operate reliably at higher temperatures directly translates to improved process efficiency, reduced energy consumption, and lower operational costs.

Particularly notable is the growing demand from emerging economies, where rapid industrialization and infrastructure development are creating substantial market opportunities. China, India, and Southeast Asian countries are investing heavily in power generation and industrial capacity, necessitating advanced heat exchange technologies that can deliver superior performance under demanding conditions.

The renewable energy sector presents another significant growth vector for high-temperature heat exchanger applications. Concentrated solar power systems, geothermal energy plants, and next-generation nuclear facilities all require heat exchangers capable of handling elevated temperatures with minimal degradation. Market research indicates that renewable energy applications for advanced heat exchangers are expected to grow at nearly twice the rate of traditional applications over the next decade.

End-users are increasingly prioritizing total lifecycle cost over initial acquisition expenses. This shift has created market demand for premium heat exchangers constructed from high-temperature alloys that offer extended service life, reduced maintenance requirements, and improved reliability. Industry surveys reveal that customers are willing to pay 15-30% premium for heat exchangers that demonstrate superior high-temperature performance and corrosion resistance.

The aerospace and defense sectors represent specialized but lucrative market segments for high-temperature heat exchanger technologies. These applications demand exceptional performance under extreme conditions and can support the development of cutting-edge alloy solutions that may eventually find broader commercial applications.

Market feedback indicates growing customer interest in modular, compact heat exchanger designs that maximize efficiency while minimizing space requirements. This trend is particularly evident in applications where installation space is limited, such as offshore platforms, marine vessels, and compact industrial facilities.

Energy-intensive industries such as power generation, chemical processing, oil and gas, and metallurgy represent the largest demand segments for high-efficiency heat exchangers. These sectors are increasingly seeking solutions that can withstand extreme operating conditions while maximizing thermal transfer efficiency. The ability to operate reliably at higher temperatures directly translates to improved process efficiency, reduced energy consumption, and lower operational costs.

Particularly notable is the growing demand from emerging economies, where rapid industrialization and infrastructure development are creating substantial market opportunities. China, India, and Southeast Asian countries are investing heavily in power generation and industrial capacity, necessitating advanced heat exchange technologies that can deliver superior performance under demanding conditions.

The renewable energy sector presents another significant growth vector for high-temperature heat exchanger applications. Concentrated solar power systems, geothermal energy plants, and next-generation nuclear facilities all require heat exchangers capable of handling elevated temperatures with minimal degradation. Market research indicates that renewable energy applications for advanced heat exchangers are expected to grow at nearly twice the rate of traditional applications over the next decade.

End-users are increasingly prioritizing total lifecycle cost over initial acquisition expenses. This shift has created market demand for premium heat exchangers constructed from high-temperature alloys that offer extended service life, reduced maintenance requirements, and improved reliability. Industry surveys reveal that customers are willing to pay 15-30% premium for heat exchangers that demonstrate superior high-temperature performance and corrosion resistance.

The aerospace and defense sectors represent specialized but lucrative market segments for high-temperature heat exchanger technologies. These applications demand exceptional performance under extreme conditions and can support the development of cutting-edge alloy solutions that may eventually find broader commercial applications.

Market feedback indicates growing customer interest in modular, compact heat exchanger designs that maximize efficiency while minimizing space requirements. This trend is particularly evident in applications where installation space is limited, such as offshore platforms, marine vessels, and compact industrial facilities.

Current Status and Challenges in High-Temperature Alloy Technology

High-temperature alloys for heat exchangers have seen significant advancements globally, with current technologies primarily centered around nickel-based superalloys, oxide dispersion strengthened (ODS) alloys, and refractory metal alloys. These materials demonstrate exceptional performance at temperatures exceeding 800°C, which is crucial for next-generation heat exchange systems in aerospace, power generation, and industrial processing applications.

The global landscape shows uneven development, with the United States, Japan, and several European countries leading in advanced alloy research and commercialization. China has made substantial progress in recent years but still faces gaps in manufacturing precision and material performance consistency. Russia maintains strength in specialized refractory alloys, while emerging economies like India and South Korea are rapidly expanding their research capabilities.

Current technical challenges primarily revolve around four critical areas. First, oxidation and corrosion resistance remains problematic at ultra-high temperatures (>1000°C), particularly in aggressive environments containing sulfur, chlorine, or water vapor. Second, mechanical property degradation over extended service periods presents significant reliability concerns, with creep resistance and thermal fatigue being particularly challenging to maintain simultaneously.

Third, manufacturing complexities pose substantial barriers to widespread adoption. Advanced processing techniques such as powder metallurgy, directional solidification, and additive manufacturing show promise but face issues with scalability, reproducibility, and cost-effectiveness. The intricate microstructures required for optimal performance demand precise control during production.

Fourth, there exists a fundamental materials science challenge in balancing competing properties. Enhancing high-temperature strength often compromises ductility; improving oxidation resistance may reduce thermal conductivity; optimizing for one operating environment frequently diminishes performance in others. This creates a complex multi-parameter optimization problem that continues to challenge researchers.

Economic factors further complicate advancement, with many high-performance alloys requiring expensive elements like rhenium, hafnium, and rare earth metals. Supply chain vulnerabilities for these critical materials represent a significant constraint on industrial implementation, particularly as geopolitical tensions affect global trade in strategic materials.

Recent research has shown promising directions through computational alloy design, multi-component high-entropy alloys, and surface engineering approaches. However, the translation of laboratory successes to commercial-scale production remains a significant hurdle that requires coordinated efforts across the research-to-manufacturing pipeline.

The global landscape shows uneven development, with the United States, Japan, and several European countries leading in advanced alloy research and commercialization. China has made substantial progress in recent years but still faces gaps in manufacturing precision and material performance consistency. Russia maintains strength in specialized refractory alloys, while emerging economies like India and South Korea are rapidly expanding their research capabilities.

Current technical challenges primarily revolve around four critical areas. First, oxidation and corrosion resistance remains problematic at ultra-high temperatures (>1000°C), particularly in aggressive environments containing sulfur, chlorine, or water vapor. Second, mechanical property degradation over extended service periods presents significant reliability concerns, with creep resistance and thermal fatigue being particularly challenging to maintain simultaneously.

Third, manufacturing complexities pose substantial barriers to widespread adoption. Advanced processing techniques such as powder metallurgy, directional solidification, and additive manufacturing show promise but face issues with scalability, reproducibility, and cost-effectiveness. The intricate microstructures required for optimal performance demand precise control during production.

Fourth, there exists a fundamental materials science challenge in balancing competing properties. Enhancing high-temperature strength often compromises ductility; improving oxidation resistance may reduce thermal conductivity; optimizing for one operating environment frequently diminishes performance in others. This creates a complex multi-parameter optimization problem that continues to challenge researchers.

Economic factors further complicate advancement, with many high-performance alloys requiring expensive elements like rhenium, hafnium, and rare earth metals. Supply chain vulnerabilities for these critical materials represent a significant constraint on industrial implementation, particularly as geopolitical tensions affect global trade in strategic materials.

Recent research has shown promising directions through computational alloy design, multi-component high-entropy alloys, and surface engineering approaches. However, the translation of laboratory successes to commercial-scale production remains a significant hurdle that requires coordinated efforts across the research-to-manufacturing pipeline.

Current Technical Solutions for Heat Exchanger Efficiency

01 Composition optimization for high-temperature performance

Specific alloy compositions can be engineered to enhance efficiency at elevated temperatures. These compositions typically include precise ratios of elements such as nickel, chromium, cobalt, and refractory metals to achieve optimal high-temperature strength, oxidation resistance, and thermal stability. Advanced alloying techniques focus on controlling microstructure through careful selection of primary elements and minor additions that create beneficial precipitates and grain boundary structures.- Nickel-based superalloys for high-temperature applications: Nickel-based superalloys are specifically designed for high-temperature environments, offering exceptional strength, creep resistance, and oxidation resistance at elevated temperatures. These alloys typically contain chromium, cobalt, aluminum, titanium, and other elements that form strengthening precipitates. The microstructure of these alloys, particularly the gamma prime (γ') precipitates, contributes significantly to their high-temperature performance and efficiency in applications such as gas turbines and aerospace components.

- Heat treatment processes for optimizing alloy performance: Various heat treatment processes can significantly enhance the efficiency and performance of high-temperature alloys. These processes include solution treatment, aging, annealing, and quenching, which are carefully controlled to develop optimal microstructures. The heat treatment parameters, such as temperature, time, and cooling rate, are critical for achieving desired properties like improved creep resistance, thermal stability, and mechanical strength at elevated temperatures, thereby increasing the overall efficiency of the alloy in high-temperature applications.

- Advanced manufacturing techniques for high-temperature alloys: Advanced manufacturing techniques play a crucial role in enhancing the efficiency of high-temperature alloys. Methods such as powder metallurgy, directional solidification, single crystal growth, and additive manufacturing enable the production of alloys with superior microstructural control and reduced defects. These techniques allow for the creation of complex geometries, optimized grain structures, and improved homogeneity, resulting in alloys with enhanced high-temperature properties, longer service life, and better overall performance in extreme environments.

- Refractory metal additions for enhanced high-temperature stability: The addition of refractory metals such as tungsten, molybdenum, niobium, tantalum, and rhenium significantly improves the high-temperature stability and efficiency of alloys. These elements have high melting points and contribute to solid solution strengthening, improving creep resistance and thermal stability. Refractory metal additions also enhance oxidation resistance and microstructural stability at elevated temperatures, making the alloys more suitable for extreme operating conditions in power generation, aerospace, and industrial applications.

- Surface treatments and coatings for high-temperature alloys: Surface treatments and specialized coatings significantly enhance the efficiency and longevity of high-temperature alloys. Thermal barrier coatings, aluminide coatings, and environmental barrier coatings protect the base alloy from oxidation, corrosion, and thermal degradation. These protective layers create thermal gradients that reduce the operating temperature of the underlying metal, improving efficiency and extending component life. Advanced surface engineering techniques also enhance wear resistance and reduce friction, further improving the performance of high-temperature alloy components in demanding applications.

02 Heat treatment processes for improved efficiency

Specialized heat treatment processes can significantly improve the efficiency of high-temperature alloys. These processes include solution treatment, aging, annealing, and quenching regimes designed to optimize microstructure, reduce internal stresses, and enhance mechanical properties. Controlled cooling rates and multi-stage heat treatments can produce specific phase distributions that maximize creep resistance and thermal stability during service at elevated temperatures.Expand Specific Solutions03 Surface treatments and coatings for enhanced performance

Surface treatments and specialized coatings can enhance the efficiency of high-temperature alloys by improving oxidation resistance, reducing friction, and creating thermal barriers. These include aluminide coatings, thermal barrier coatings (TBCs), diffusion treatments, and surface hardening processes. Such treatments protect the base alloy from environmental degradation while maintaining or improving thermal efficiency in high-temperature applications.Expand Specific Solutions04 Manufacturing techniques for optimized microstructure

Advanced manufacturing techniques can create high-temperature alloys with optimized microstructures for maximum efficiency. These include directional solidification, single crystal growth, powder metallurgy, additive manufacturing, and precision casting methods. These processes control grain size, orientation, and distribution of strengthening phases, resulting in alloys with superior creep resistance, thermal fatigue properties, and overall performance at elevated temperatures.Expand Specific Solutions05 Testing and performance evaluation methodologies

Specialized testing methodologies are essential for evaluating and improving the efficiency of high-temperature alloys. These include accelerated aging tests, thermal cycling, creep testing, oxidation resistance evaluation, and microstructural stability assessments. Advanced characterization techniques such as electron microscopy, X-ray diffraction, and thermal analysis help identify degradation mechanisms and guide alloy development for enhanced high-temperature efficiency in industrial applications.Expand Specific Solutions

Key Industry Players in High-Temperature Alloy Manufacturing

The high-temperature alloy market for heat exchangers is currently in a growth phase, with increasing demand driven by energy efficiency requirements across industries. The global market size is estimated to exceed $5 billion, expanding at 6-8% CAGR. Technologically, the field shows varying maturity levels with established players like Kobe Steel, T.RAD, and MAHLE International offering commercial solutions, while research institutions such as Xi'an Jiaotong University and Fraunhofer-Gesellschaft push innovation boundaries. Asian manufacturers including Mitsubishi Shindoh, Baoshan Iron & Steel, and Gree Electric are rapidly advancing capabilities, while specialized players like Aerospace Hiwing focus on premium titanium-based solutions. Western companies such as Carrier Corp. and Constellium maintain competitive advantages through proprietary alloy formulations and manufacturing processes.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed KA-HT series high-temperature alloys specifically designed for industrial heat exchangers operating in extreme environments. Their flagship KA-HT800 alloy combines nickel, chromium, and molybdenum with precise additions of aluminum and titanium to form strengthening γ' precipitates that maintain structural integrity at temperatures up to 850°C. The company employs a proprietary heat treatment process that optimizes grain size distribution and precipitate morphology, resulting in exceptional thermal cycling resistance. Kobe's manufacturing process includes vacuum induction melting followed by electroslag remelting to minimize impurities and ensure homogeneous microstructure. Their heat exchangers feature specially designed tube geometries with internal turbulators that enhance heat transfer efficiency by up to 40% compared to conventional designs while maintaining structural integrity under thermal stress. The alloys also incorporate rare earth elements for improved oxidation resistance, extending service life in corrosive environments by forming protective oxide scales.

Strengths: Excellent balance between high-temperature strength and corrosion resistance, superior thermal cycling capability, and cost-effective manufacturing process for industrial applications. Weaknesses: Lower maximum operating temperature compared to nickel-based superalloys, limited formability for complex geometries, and requires specialized welding procedures.

UT-Battelle LLC

Technical Solution: UT-Battelle, operating Oak Ridge National Laboratory, has developed advanced refractory high-entropy alloys (RHEAs) for next-generation heat exchangers in extreme environments. Their innovative alloys combine five or more principal elements in near-equiatomic proportions, including combinations of niobium, tantalum, molybdenum, tungsten, and zirconium, creating unique solid-solution phases with exceptional thermodynamic stability. The laboratory employs advanced computational materials science approaches including CALPHAD modeling and first-principles calculations to predict phase stability and mechanical properties before physical synthesis. Their heat exchanger designs incorporate additively manufactured lattice structures that maximize surface area while minimizing pressure drop and material usage. UT-Battelle's manufacturing process includes field-assisted sintering technology (FAST) that achieves near-theoretical density while maintaining nanocrystalline grain structures for enhanced strength and creep resistance. The alloys demonstrate remarkable resistance to radiation damage, making them suitable for nuclear applications, with testing showing minimal void swelling after neutron irradiation at temperatures exceeding 800°C.

Strengths: Exceptional high-temperature strength retention (up to 1200°C), superior radiation resistance, and remarkable microstructural stability under extreme conditions. Weaknesses: Early development stage with limited commercial availability, high material costs due to refractory element content, and challenging manufacturability requiring specialized equipment.

Critical Patents and Innovations in High-Temperature Alloys

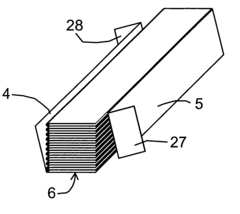

Heat exchanger made from a mixture of silicon carbide and molybedenum disilicide

PatentInactiveEP0986727A1

Innovation

- A ceramic recuperative high-temperature heat exchanger design featuring a stack of plates with truncated cone-like depressions forms flow channels, allowing for simple production and alignment, enhanced turbulence for improved heat transfer, and the use of SiC/MoSi2 materials for resistance to extreme temperatures and slag, enabling efficient heat exchange up to 1650 degrees Celsius.

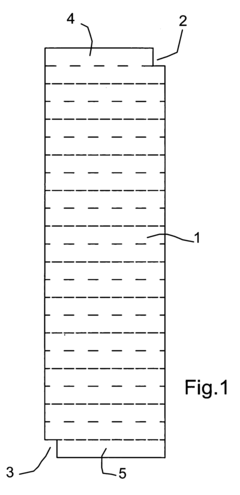

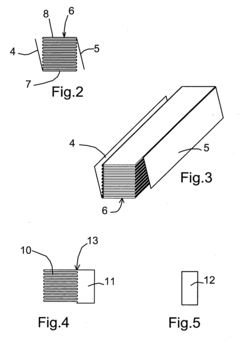

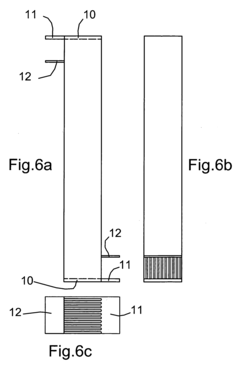

Low-cost high-temperature heat exchanger

PatentInactiveUS20070056717A1

Innovation

- A heat exchanger design utilizing a monolith formed from folded metal foil with combs and duct boxes, sealed by laser welding, allowing for the use of inexpensive iron-based materials like Fecralloy, and enabling the application of catalytic coatings for separate reactions in distinct regions.

Environmental Impact and Sustainability Considerations

The environmental impact of high-temperature alloys used in heat exchangers represents a critical consideration in modern industrial applications. Traditional heat exchanger materials often contain significant amounts of rare earth elements and environmentally problematic metals such as chromium, nickel, and cobalt. The extraction and processing of these materials generate substantial carbon emissions, with estimates suggesting that specialty alloy production contributes approximately 2-3% of global industrial carbon emissions.

Manufacturing processes for high-temperature alloys typically require energy-intensive methods including vacuum induction melting and hot isostatic pressing, further increasing their environmental footprint. A life cycle assessment of nickel-based superalloys indicates that their production generates 12-18 kg CO2 equivalent per kilogram of finished material, significantly higher than conventional steel production.

Water consumption and pollution present additional environmental challenges. The processing of high-temperature alloys often involves water-intensive cooling and cleaning procedures, with some manufacturing facilities consuming up to 20,000 gallons of water per ton of alloy produced. Chemical treatments and surface preparations can introduce hexavalent chromium and other hazardous compounds into wastewater streams if not properly managed.

Recent advancements in sustainable alloy development show promising directions. Reduced-nickel alloys that maintain high-temperature performance while decreasing reliance on energy-intensive nickel extraction have demonstrated up to 30% lower environmental impact. Additionally, manufacturing innovations such as additive manufacturing techniques can reduce material waste by 50-70% compared to traditional subtractive manufacturing methods.

End-of-life considerations for heat exchanger alloys present both challenges and opportunities. While many high-performance alloys are technically recyclable, specialized composition often complicates the recycling process. Current recycling rates for specialty heat-resistant alloys remain below 40%, compared to over 70% for conventional steel. However, closed-loop recycling systems implemented by several industry leaders have demonstrated the potential to recover up to 85% of critical elements from decommissioned heat exchangers.

The development of bio-inspired alloy designs represents an emerging frontier in sustainable materials science. Biomimetic approaches that replicate natural heat-transfer structures have shown potential to reduce material requirements by up to 25% while maintaining thermal efficiency, thereby decreasing the overall environmental footprint of heat exchanger systems throughout their operational lifetime.

Manufacturing processes for high-temperature alloys typically require energy-intensive methods including vacuum induction melting and hot isostatic pressing, further increasing their environmental footprint. A life cycle assessment of nickel-based superalloys indicates that their production generates 12-18 kg CO2 equivalent per kilogram of finished material, significantly higher than conventional steel production.

Water consumption and pollution present additional environmental challenges. The processing of high-temperature alloys often involves water-intensive cooling and cleaning procedures, with some manufacturing facilities consuming up to 20,000 gallons of water per ton of alloy produced. Chemical treatments and surface preparations can introduce hexavalent chromium and other hazardous compounds into wastewater streams if not properly managed.

Recent advancements in sustainable alloy development show promising directions. Reduced-nickel alloys that maintain high-temperature performance while decreasing reliance on energy-intensive nickel extraction have demonstrated up to 30% lower environmental impact. Additionally, manufacturing innovations such as additive manufacturing techniques can reduce material waste by 50-70% compared to traditional subtractive manufacturing methods.

End-of-life considerations for heat exchanger alloys present both challenges and opportunities. While many high-performance alloys are technically recyclable, specialized composition often complicates the recycling process. Current recycling rates for specialty heat-resistant alloys remain below 40%, compared to over 70% for conventional steel. However, closed-loop recycling systems implemented by several industry leaders have demonstrated the potential to recover up to 85% of critical elements from decommissioned heat exchangers.

The development of bio-inspired alloy designs represents an emerging frontier in sustainable materials science. Biomimetic approaches that replicate natural heat-transfer structures have shown potential to reduce material requirements by up to 25% while maintaining thermal efficiency, thereby decreasing the overall environmental footprint of heat exchanger systems throughout their operational lifetime.

Cost-Benefit Analysis of Advanced Alloy Implementation

Implementing advanced high-temperature alloys in heat exchangers requires thorough economic evaluation to justify the significant initial investment. The cost-benefit analysis reveals that while premium alloys like nickel-based superalloys and advanced stainless steels command prices 3-5 times higher than conventional materials, their extended operational lifespan (typically 2-3 times longer) provides substantial long-term value. For instance, a power plant implementing Inconel 740H alloy heat exchangers may face 40-60% higher upfront costs but can achieve 15-25% greater thermal efficiency and 30% longer service intervals.

The maintenance economics strongly favor advanced alloys, with studies indicating a 40-50% reduction in maintenance frequency and associated downtime costs. In continuous industrial processes, each day of unplanned downtime can cost $50,000-$200,000, making reliability improvements particularly valuable. Furthermore, the enhanced heat transfer efficiency translates to measurable energy savings—typically 8-12% reduction in fuel consumption for industrial boilers and heat recovery systems.

Environmental compliance benefits must also factor into the analysis. Advanced alloys enable operations at higher temperatures (850-1100°C versus 650-750°C for conventional materials), allowing more complete combustion and reduced emissions. This capability can reduce carbon emissions by 10-15% and lower the costs associated with emissions permits or carbon taxes in regulated markets.

The payback period analysis demonstrates that despite higher initial costs, advanced alloy heat exchangers typically achieve return on investment within 2.5-4 years in high-temperature applications. This timeline shortens considerably in corrosive environments where conventional materials fail prematurely. Sensitivity analysis shows that as energy prices increase, the economic case for advanced alloys strengthens proportionally.

Total cost of ownership calculations over a 15-year operational period indicate that advanced alloy systems provide 20-30% lower lifetime costs when accounting for all factors including acquisition, installation, maintenance, energy consumption, and end-of-life considerations. This advantage becomes more pronounced in critical applications where reliability and performance consistency are paramount.

For new installations, the incremental cost of specifying advanced alloys represents only 3-7% of total project costs while delivering disproportionate performance benefits. For retrofits and replacements, the business case is strongest when coordinated with scheduled maintenance shutdowns to minimize additional operational disruptions.

The maintenance economics strongly favor advanced alloys, with studies indicating a 40-50% reduction in maintenance frequency and associated downtime costs. In continuous industrial processes, each day of unplanned downtime can cost $50,000-$200,000, making reliability improvements particularly valuable. Furthermore, the enhanced heat transfer efficiency translates to measurable energy savings—typically 8-12% reduction in fuel consumption for industrial boilers and heat recovery systems.

Environmental compliance benefits must also factor into the analysis. Advanced alloys enable operations at higher temperatures (850-1100°C versus 650-750°C for conventional materials), allowing more complete combustion and reduced emissions. This capability can reduce carbon emissions by 10-15% and lower the costs associated with emissions permits or carbon taxes in regulated markets.

The payback period analysis demonstrates that despite higher initial costs, advanced alloy heat exchangers typically achieve return on investment within 2.5-4 years in high-temperature applications. This timeline shortens considerably in corrosive environments where conventional materials fail prematurely. Sensitivity analysis shows that as energy prices increase, the economic case for advanced alloys strengthens proportionally.

Total cost of ownership calculations over a 15-year operational period indicate that advanced alloy systems provide 20-30% lower lifetime costs when accounting for all factors including acquisition, installation, maintenance, energy consumption, and end-of-life considerations. This advantage becomes more pronounced in critical applications where reliability and performance consistency are paramount.

For new installations, the incremental cost of specifying advanced alloys represents only 3-7% of total project costs while delivering disproportionate performance benefits. For retrofits and replacements, the business case is strongest when coordinated with scheduled maintenance shutdowns to minimize additional operational disruptions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!