How High-Temperature Alloys Advance Heat-Treating Processes

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Alloy Evolution and Objectives

High-temperature alloys have evolved significantly over the past century, transforming from simple steel compositions to sophisticated multi-element systems engineered at the microstructural level. The journey began in the early 1900s with the development of stainless steels containing chromium for oxidation resistance. By the 1940s, nickel-based superalloys emerged to meet the demands of jet engines, marking a pivotal advancement in high-temperature metallurgy.

The 1950s-1970s witnessed revolutionary processing techniques including vacuum induction melting and directional solidification, enabling unprecedented control over alloy purity and microstructure. These developments facilitated the creation of single-crystal superalloys in the 1980s, which dramatically improved creep resistance and thermal stability at extreme temperatures exceeding 1000°C.

Recent decades have seen the integration of refractory elements like rhenium, ruthenium, and hafnium, pushing temperature capabilities even higher while enhancing mechanical properties. Parallel to composition advancements, coating technologies have evolved to provide thermal and environmental protection, extending component lifespans in aggressive environments.

The current technological frontier involves computational alloy design, leveraging artificial intelligence and machine learning to predict optimal compositions and processing parameters. This approach has accelerated development cycles while reducing experimental costs, enabling more rapid innovation in high-temperature alloy systems.

The primary objective of modern high-temperature alloy development is to enhance heat-treating process efficiency through materials that maintain structural integrity and performance at increasingly extreme temperatures. This includes improving thermal conductivity for more uniform heat distribution, reducing thermal expansion mismatches, and extending service life under cyclic thermal loading conditions.

Additional objectives include developing alloys with improved oxidation and corrosion resistance to withstand aggressive atmospheres in industrial furnaces, as well as enhancing thermal fatigue resistance for components subjected to rapid heating and cooling cycles. Cost optimization remains a critical goal, with efforts focused on reducing or substituting expensive elements while maintaining performance characteristics.

Environmental sustainability has emerged as a key objective, driving research into alloys that enable lower energy consumption during heat treatment processes and facilitate reduced emissions. The industry also aims to develop alloys compatible with emerging technologies such as additive manufacturing, opening new design possibilities for heat treatment equipment and fixtures with complex geometries and optimized thermal properties.

The 1950s-1970s witnessed revolutionary processing techniques including vacuum induction melting and directional solidification, enabling unprecedented control over alloy purity and microstructure. These developments facilitated the creation of single-crystal superalloys in the 1980s, which dramatically improved creep resistance and thermal stability at extreme temperatures exceeding 1000°C.

Recent decades have seen the integration of refractory elements like rhenium, ruthenium, and hafnium, pushing temperature capabilities even higher while enhancing mechanical properties. Parallel to composition advancements, coating technologies have evolved to provide thermal and environmental protection, extending component lifespans in aggressive environments.

The current technological frontier involves computational alloy design, leveraging artificial intelligence and machine learning to predict optimal compositions and processing parameters. This approach has accelerated development cycles while reducing experimental costs, enabling more rapid innovation in high-temperature alloy systems.

The primary objective of modern high-temperature alloy development is to enhance heat-treating process efficiency through materials that maintain structural integrity and performance at increasingly extreme temperatures. This includes improving thermal conductivity for more uniform heat distribution, reducing thermal expansion mismatches, and extending service life under cyclic thermal loading conditions.

Additional objectives include developing alloys with improved oxidation and corrosion resistance to withstand aggressive atmospheres in industrial furnaces, as well as enhancing thermal fatigue resistance for components subjected to rapid heating and cooling cycles. Cost optimization remains a critical goal, with efforts focused on reducing or substituting expensive elements while maintaining performance characteristics.

Environmental sustainability has emerged as a key objective, driving research into alloys that enable lower energy consumption during heat treatment processes and facilitate reduced emissions. The industry also aims to develop alloys compatible with emerging technologies such as additive manufacturing, opening new design possibilities for heat treatment equipment and fixtures with complex geometries and optimized thermal properties.

Market Demand Analysis for Advanced Heat-Treating Solutions

The global market for advanced heat-treating solutions has experienced significant growth in recent years, driven primarily by increasing demands across aerospace, automotive, energy, and industrial manufacturing sectors. These industries require materials capable of withstanding extreme operating conditions while maintaining structural integrity and performance characteristics. High-temperature alloys have emerged as critical components in this ecosystem, enabling more efficient and effective heat-treating processes.

Market research indicates that the high-temperature alloy market for heat-treating applications is projected to grow at a compound annual growth rate of approximately 7% through 2028. This growth is particularly pronounced in regions with strong manufacturing bases such as North America, Western Europe, and East Asia, with emerging economies in South Asia and Latin America showing accelerated adoption rates.

The aerospace industry represents the largest market segment, accounting for nearly 35% of demand for advanced heat-treating solutions. This is attributed to the stringent performance requirements for components used in jet engines, exhaust systems, and structural elements that must withstand extreme thermal cycling. The automotive sector follows closely, driven by the transition toward more efficient combustion engines and the growing electric vehicle market requiring specialized thermal management systems.

Energy generation applications, particularly in power plants, oil and gas, and renewable energy sectors, constitute another significant market segment. These industries require materials capable of withstanding corrosive environments at elevated temperatures for extended periods, creating sustained demand for specialized high-temperature alloys and corresponding heat-treating processes.

Customer requirements are increasingly focused on process efficiency, with manufacturers seeking heat-treating solutions that reduce energy consumption, processing time, and overall operational costs. This has led to growing interest in precision heat-treating technologies that can deliver consistent results while minimizing resource utilization. Additionally, there is rising demand for heat-treating processes compatible with additive manufacturing techniques, as 3D printing of metal components gains traction across industries.

Regulatory factors are also shaping market demand, with stricter emissions standards and safety regulations driving the need for materials that can operate efficiently at higher temperatures. This is particularly evident in the automotive sector, where powertrain components must meet increasingly stringent performance and durability requirements while contributing to overall vehicle efficiency targets.

The market shows strong regional variations, with developed economies focusing on high-performance specialty alloys for critical applications, while developing markets prioritize cost-effective solutions that can improve manufacturing capabilities without requiring significant capital investment. This dichotomy presents both challenges and opportunities for technology providers operating across global markets.

Market research indicates that the high-temperature alloy market for heat-treating applications is projected to grow at a compound annual growth rate of approximately 7% through 2028. This growth is particularly pronounced in regions with strong manufacturing bases such as North America, Western Europe, and East Asia, with emerging economies in South Asia and Latin America showing accelerated adoption rates.

The aerospace industry represents the largest market segment, accounting for nearly 35% of demand for advanced heat-treating solutions. This is attributed to the stringent performance requirements for components used in jet engines, exhaust systems, and structural elements that must withstand extreme thermal cycling. The automotive sector follows closely, driven by the transition toward more efficient combustion engines and the growing electric vehicle market requiring specialized thermal management systems.

Energy generation applications, particularly in power plants, oil and gas, and renewable energy sectors, constitute another significant market segment. These industries require materials capable of withstanding corrosive environments at elevated temperatures for extended periods, creating sustained demand for specialized high-temperature alloys and corresponding heat-treating processes.

Customer requirements are increasingly focused on process efficiency, with manufacturers seeking heat-treating solutions that reduce energy consumption, processing time, and overall operational costs. This has led to growing interest in precision heat-treating technologies that can deliver consistent results while minimizing resource utilization. Additionally, there is rising demand for heat-treating processes compatible with additive manufacturing techniques, as 3D printing of metal components gains traction across industries.

Regulatory factors are also shaping market demand, with stricter emissions standards and safety regulations driving the need for materials that can operate efficiently at higher temperatures. This is particularly evident in the automotive sector, where powertrain components must meet increasingly stringent performance and durability requirements while contributing to overall vehicle efficiency targets.

The market shows strong regional variations, with developed economies focusing on high-performance specialty alloys for critical applications, while developing markets prioritize cost-effective solutions that can improve manufacturing capabilities without requiring significant capital investment. This dichotomy presents both challenges and opportunities for technology providers operating across global markets.

Current State and Challenges in Heat-Resistant Materials

The global landscape of heat-resistant materials has witnessed significant advancements in recent years, with high-temperature alloys emerging as critical components in modern industrial applications. Currently, nickel-based superalloys dominate the market, accounting for approximately 70% of high-temperature applications due to their exceptional mechanical strength and oxidation resistance at temperatures exceeding 1000°C. These materials form the backbone of aerospace engines, power generation turbines, and advanced heat-treating equipment.

Despite these achievements, the field faces substantial technical challenges. The primary limitation remains the operational ceiling temperature, with most commercial alloys struggling to maintain structural integrity beyond 1100°C. This temperature constraint directly impacts the efficiency of heat-treating processes, where higher temperatures could potentially reduce processing times and energy consumption by up to 30%.

Material degradation mechanisms present another significant hurdle. High-temperature environments accelerate creep deformation, thermal fatigue, and oxidation processes. Research data indicates that oxidation rates double with every 50°C increase in operating temperature, creating a complex engineering challenge for extending component lifespan in extreme thermal conditions.

The geographical distribution of heat-resistant materials technology shows concentration in specific regions. North America and Europe lead in research and development, holding approximately 65% of relevant patents. However, China has demonstrated the fastest growth rate in the past decade, increasing its patent filings in this domain by 300% since 2012, particularly in refractory metal alloys and ceramic matrix composites.

Manufacturing constraints further complicate advancement in this field. The production of advanced heat-resistant alloys often requires specialized processes such as vacuum induction melting and hot isostatic pressing, which significantly increase production costs. Current manufacturing techniques struggle with complex geometries and large-scale production, limiting widespread adoption in heat-treating equipment.

Sustainability concerns have also emerged as a critical challenge. Many high-performance alloys contain strategic elements like rhenium, hafnium, and rare earth metals, which face supply chain vulnerabilities and environmental extraction concerns. The industry is actively seeking alternatives that reduce dependency on these critical materials while maintaining performance characteristics.

Interdisciplinary barriers between materials science, mechanical engineering, and process technology have slowed innovation cycles. The complex relationship between alloy microstructure, mechanical properties, and heat-treating performance requires integrated research approaches that are not yet standardized across the industry, creating knowledge gaps that impede rapid technological progress.

Despite these achievements, the field faces substantial technical challenges. The primary limitation remains the operational ceiling temperature, with most commercial alloys struggling to maintain structural integrity beyond 1100°C. This temperature constraint directly impacts the efficiency of heat-treating processes, where higher temperatures could potentially reduce processing times and energy consumption by up to 30%.

Material degradation mechanisms present another significant hurdle. High-temperature environments accelerate creep deformation, thermal fatigue, and oxidation processes. Research data indicates that oxidation rates double with every 50°C increase in operating temperature, creating a complex engineering challenge for extending component lifespan in extreme thermal conditions.

The geographical distribution of heat-resistant materials technology shows concentration in specific regions. North America and Europe lead in research and development, holding approximately 65% of relevant patents. However, China has demonstrated the fastest growth rate in the past decade, increasing its patent filings in this domain by 300% since 2012, particularly in refractory metal alloys and ceramic matrix composites.

Manufacturing constraints further complicate advancement in this field. The production of advanced heat-resistant alloys often requires specialized processes such as vacuum induction melting and hot isostatic pressing, which significantly increase production costs. Current manufacturing techniques struggle with complex geometries and large-scale production, limiting widespread adoption in heat-treating equipment.

Sustainability concerns have also emerged as a critical challenge. Many high-performance alloys contain strategic elements like rhenium, hafnium, and rare earth metals, which face supply chain vulnerabilities and environmental extraction concerns. The industry is actively seeking alternatives that reduce dependency on these critical materials while maintaining performance characteristics.

Interdisciplinary barriers between materials science, mechanical engineering, and process technology have slowed innovation cycles. The complex relationship between alloy microstructure, mechanical properties, and heat-treating performance requires integrated research approaches that are not yet standardized across the industry, creating knowledge gaps that impede rapid technological progress.

Contemporary Alloy Solutions for Heat-Treating Processes

01 Solution Heat Treatment for High-Temperature Alloys

Solution heat treatment is a critical process for high-temperature alloys that involves heating the material to a specific temperature to dissolve precipitates into the matrix, followed by rapid cooling to maintain the solid solution. This process enhances the mechanical properties of the alloys, including strength and corrosion resistance, by creating a homogeneous microstructure. The treatment parameters, including temperature, holding time, and cooling rate, are carefully controlled to achieve optimal properties for high-temperature applications.- Solution Heat Treatment for High-Temperature Alloys: Solution heat treatment is a critical process for high-temperature alloys that involves heating the material to a specific temperature to dissolve precipitates into the matrix, followed by rapid cooling to maintain the solid solution. This process enhances the mechanical properties of the alloys, including strength and corrosion resistance, by creating a homogeneous microstructure. The temperature and duration of the treatment are carefully controlled to achieve optimal results for different alloy compositions.

- Precipitation Hardening Processes: Precipitation hardening is a heat treatment technique used to strengthen high-temperature alloys through the formation of fine precipitates within the metal matrix. The process typically involves solution treatment followed by aging at intermediate temperatures, allowing controlled precipitation of secondary phases. This treatment significantly improves the mechanical properties of the alloys, particularly their high-temperature strength and creep resistance, making them suitable for demanding applications in aerospace and power generation industries.

- Controlled Cooling Techniques: Controlled cooling techniques are essential in the heat treatment of high-temperature alloys to achieve desired microstructures and properties. These methods include quenching in various media (water, oil, or gas), step cooling, and programmed cooling rates. The cooling rate significantly affects the final properties of the alloy by controlling phase transformations and precipitation. Advanced cooling techniques help minimize distortion and residual stresses while maximizing the alloy's performance characteristics at elevated temperatures.

- Vacuum and Protective Atmosphere Heat Treatment: Heat treating high-temperature alloys in vacuum or protective atmospheres prevents oxidation and contamination during the process. This technique is particularly important for reactive elements in superalloys and other high-performance materials. Vacuum heat treatment allows for precise temperature control and eliminates the formation of detrimental surface oxides. Protective atmospheres such as argon, nitrogen, or hydrogen can also be used depending on the specific alloy composition and desired properties, ensuring optimal microstructural development without surface degradation.

- Hot Isostatic Pressing (HIP) Treatment: Hot Isostatic Pressing combines high temperature and isostatic gas pressure to eliminate internal porosity and improve the mechanical properties of high-temperature alloys. This process is particularly valuable for cast components and powder metallurgy products, where internal defects can significantly impact performance. HIP treatment enhances fatigue resistance, ductility, and overall component reliability by healing internal voids and achieving near-theoretical density. The process parameters, including temperature, pressure, and duration, are tailored to specific alloy compositions to optimize microstructural development and mechanical properties.

02 Precipitation Hardening Processes for Superalloys

Precipitation hardening is a key heat treatment process for high-temperature superalloys that involves the formation of fine precipitates within the alloy matrix. This multi-stage process typically includes solution treatment followed by aging treatments at specific temperatures to control the size, distribution, and morphology of strengthening precipitates. The carefully controlled precipitation of phases such as gamma prime (γ') or gamma double prime (γ'') significantly enhances the high-temperature strength, creep resistance, and thermal stability of the alloys used in aerospace and power generation applications.Expand Specific Solutions03 Vacuum Heat Treatment Techniques

Vacuum heat treatment is an advanced processing technique for high-temperature alloys that eliminates atmospheric contamination during thermal processing. By conducting heat treatments in a vacuum environment, oxidation and other surface reactions are minimized, resulting in superior surface quality and consistent mechanical properties throughout the component. This technique is particularly important for reactive alloys and precision components used in aerospace, medical, and nuclear applications where surface integrity and dimensional stability are critical requirements.Expand Specific Solutions04 Controlled Cooling Methods for Alloy Microstructure Development

Controlled cooling methods are essential in the heat treatment of high-temperature alloys to develop specific microstructures and properties. These techniques include quenching, air cooling, furnace cooling, and programmed cooling rates that are precisely managed to control grain size, phase formation, and residual stress levels. Advanced cooling methods such as gas fan cooling, polymer quenching, and directional solidification enable tailored microstructures that optimize the balance between strength, ductility, and thermal stability for demanding high-temperature applications.Expand Specific Solutions05 Hot Isostatic Pressing (HIP) Combined with Heat Treatment

Hot Isostatic Pressing (HIP) combined with heat treatment is an integrated process for high-temperature alloys that simultaneously applies high temperature and isostatic gas pressure to materials. This combined approach effectively eliminates internal porosity, heals defects, and promotes homogenization of the microstructure. The process is particularly valuable for cast components, powder metallurgy parts, and additively manufactured items where internal defects can significantly impact mechanical properties. The integration of HIP with conventional heat treatments creates a streamlined manufacturing process that enhances both the reliability and performance of high-temperature alloy components.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The high-temperature alloys market is currently in a growth phase, driven by increasing demand in heat-treating processes across aerospace, power generation, and industrial sectors. The global market size is estimated to exceed $9 billion, with projected annual growth of 5-7% through 2028. Leading players demonstrate varying levels of technological maturity, with RTX Corp., Siemens AG, and United Technologies showing advanced capabilities in superalloy development. Research institutions like the Institute of Metal Research Chinese Academy of Sciences and Central South University are making significant contributions to alloy innovation. Asian manufacturers including Xi'an Thermal Power Research Institute and Gaona Aero Material are rapidly advancing their technological capabilities, challenging traditional Western dominance. The industry is characterized by increasing collaboration between commercial entities and research institutions to develop next-generation alloys with enhanced heat resistance and durability.

Siemens AG

Technical Solution: Siemens has developed an integrated digital heat treatment solution for high-temperature alloys used in power generation turbines. Their approach combines advanced materials science with digital twin technology to simulate and optimize heat treatment parameters before physical implementation. The system utilizes AI-driven predictive models that can anticipate microstructural evolution during various heat treatment stages, allowing for real-time adjustments to processing parameters. Siemens' solution incorporates specialized induction heating systems that provide rapid, uniform heating with energy efficiency improvements of approximately 30% compared to conventional furnaces. Their digital monitoring platform tracks over 200 process variables simultaneously, creating comprehensive heat treatment profiles that ensure consistent material properties across large industrial components. The company has also pioneered hybrid heat treatment methods that combine conventional furnace processing with targeted induction heating for localized property enhancement in critical component areas.

Strengths: Industry-leading digital twin technology enables precise process optimization; energy-efficient induction heating systems; comprehensive process monitoring capabilities. Weaknesses: High implementation costs for full digital infrastructure; requires significant technical expertise to fully utilize the advanced simulation capabilities.

Institute of Metal Research Chinese Academy of Sciences

Technical Solution: The Institute of Metal Research (IMR) has developed innovative heat treatment protocols for advanced high-temperature alloys used in aerospace and energy applications. Their approach focuses on microstructural engineering through precisely controlled thermal cycling to optimize both creep resistance and fatigue properties. IMR's technology utilizes ultra-high temperature vacuum furnaces capable of processing at temperatures up to 1600°C with oxygen partial pressure control below 10^-6 Pa. Their research has pioneered the application of electromagnetic field-assisted heat treatment, which has demonstrated the ability to refine grain structures and improve homogeneity in complex nickel and cobalt-based superalloys. The institute has also developed specialized quenching technologies using high-pressure gas systems that achieve cooling rates between 50-200°C/second while minimizing distortion in complex geometries. Their process incorporates advanced in-situ monitoring techniques including acoustic emission analysis to detect microstructural changes during heat treatment cycles.

Strengths: Cutting-edge research capabilities in electromagnetic field-assisted processing; exceptional vacuum and atmosphere control; strong fundamental understanding of microstructural evolution. Weaknesses: Some technologies remain at laboratory scale and require further development for industrial implementation; limited commercial deployment experience compared to major industrial players.

Critical Metallurgical Innovations and Patents

Heat treatment method of heat-resistant alloy having excellent ultra-high-temperature mechanical property and alloy by same

PatentInactiveKR1020150017089A

Innovation

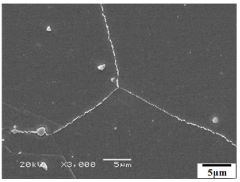

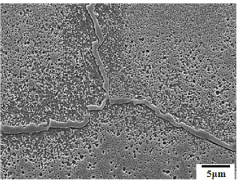

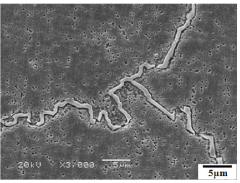

- A heat treatment process involving solution heat treatment at 1200 to 1250°C, followed by slow cooling to 800 to 1000°C at 15°C/min or less, aging treatment at 800 to 1000°C for a predetermined time, and air-cooling, which forms wavy grain boundaries and plate-shaped carbides to improve resistance to intergranular cracking.

Method for heat-treating high-strength iron alloys

PatentWO2012069329A1

Innovation

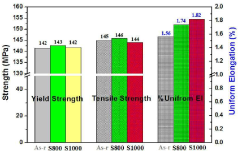

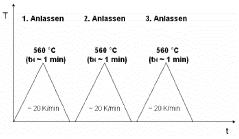

- A method involving rapid cooling of iron alloys at least 10 K/s, followed by multiple tempering cycles between 500°C and 600°C with controlled holding times and heating/cooling rates, and conducted in an oxygen-excluded argon atmosphere, to produce a microstructure with a high volume fraction of martensitic and austenitic phases, enhancing hardness, strength, and deformability.

Environmental Impact and Sustainability Considerations

The adoption of high-temperature alloys in heat-treating processes presents significant environmental implications that warrant careful consideration. These specialized materials enable more efficient thermal operations, potentially reducing energy consumption by 15-25% compared to conventional alloys. This efficiency gain directly translates to lower greenhouse gas emissions, with some industrial implementations reporting carbon footprint reductions of up to 3,000 metric tons annually per facility.

The extended service life of high-temperature alloys—often 2-3 times longer than traditional materials—contributes substantially to resource conservation. By reducing the frequency of replacement and maintenance, these alloys minimize waste generation and raw material extraction requirements. This longevity effect cascades through the supply chain, decreasing the environmental impacts associated with mining, processing, and manufacturing replacement components.

Recycling capabilities represent another environmental advantage of many high-temperature alloys. Nickel-based superalloys, for instance, maintain approximately 85-90% of their original properties after recycling, creating opportunities for closed-loop material systems in industrial applications. This recyclability significantly reduces the demand for virgin materials and the associated environmental burdens of extraction and processing.

Water conservation benefits emerge from advanced heat-treating processes utilizing high-temperature alloys. These processes typically require 30-40% less cooling water than conventional methods, addressing growing concerns about industrial water usage in water-stressed regions. Additionally, the reduced need for quenching operations minimizes the generation of contaminated wastewater requiring treatment.

However, the environmental profile is not without challenges. The production of high-temperature alloys often involves energy-intensive processes and rare elements with complex supply chains. The extraction of elements like rhenium, hafnium, and certain rare earth metals presents localized environmental impacts that must be balanced against the operational benefits.

Life cycle assessment studies indicate that the environmental payback period for implementing high-temperature alloy solutions in heat-treating processes typically ranges from 1.5 to 4 years, depending on application intensity and operational parameters. This favorable return on environmental investment supports the transition toward these advanced materials from a sustainability perspective.

As regulatory frameworks increasingly emphasize carbon reduction and resource efficiency, high-temperature alloys position heat-treating operations advantageously for compliance with emerging environmental standards. Their contribution to industrial decarbonization aligns with global sustainability initiatives and corporate environmental responsibility commitments.

The extended service life of high-temperature alloys—often 2-3 times longer than traditional materials—contributes substantially to resource conservation. By reducing the frequency of replacement and maintenance, these alloys minimize waste generation and raw material extraction requirements. This longevity effect cascades through the supply chain, decreasing the environmental impacts associated with mining, processing, and manufacturing replacement components.

Recycling capabilities represent another environmental advantage of many high-temperature alloys. Nickel-based superalloys, for instance, maintain approximately 85-90% of their original properties after recycling, creating opportunities for closed-loop material systems in industrial applications. This recyclability significantly reduces the demand for virgin materials and the associated environmental burdens of extraction and processing.

Water conservation benefits emerge from advanced heat-treating processes utilizing high-temperature alloys. These processes typically require 30-40% less cooling water than conventional methods, addressing growing concerns about industrial water usage in water-stressed regions. Additionally, the reduced need for quenching operations minimizes the generation of contaminated wastewater requiring treatment.

However, the environmental profile is not without challenges. The production of high-temperature alloys often involves energy-intensive processes and rare elements with complex supply chains. The extraction of elements like rhenium, hafnium, and certain rare earth metals presents localized environmental impacts that must be balanced against the operational benefits.

Life cycle assessment studies indicate that the environmental payback period for implementing high-temperature alloy solutions in heat-treating processes typically ranges from 1.5 to 4 years, depending on application intensity and operational parameters. This favorable return on environmental investment supports the transition toward these advanced materials from a sustainability perspective.

As regulatory frameworks increasingly emphasize carbon reduction and resource efficiency, high-temperature alloys position heat-treating operations advantageously for compliance with emerging environmental standards. Their contribution to industrial decarbonization aligns with global sustainability initiatives and corporate environmental responsibility commitments.

Energy Efficiency Improvements Through Advanced Alloys

High-temperature alloys have revolutionized energy efficiency in heat-treating processes through their exceptional thermal properties and structural integrity. These advanced materials, primarily composed of nickel, cobalt, and iron-based superalloys, enable operations at significantly higher temperatures than conventional metals, resulting in substantial energy savings across industrial applications.

The implementation of these alloys in furnace components, including radiant tubes, fixtures, and conveyor systems, has demonstrated energy consumption reductions of 15-30% compared to traditional materials. This efficiency gain stems from their ability to withstand higher operating temperatures while maintaining dimensional stability, thus allowing for more rapid heating cycles and reduced process times.

Thermal efficiency improvements are particularly notable in continuous heat-treating operations, where advanced alloys permit higher temperature gradients and more precise temperature control. Studies conducted across automotive and aerospace manufacturing facilities indicate that replacing conventional heat-resistant steels with nickel-based superalloys in critical components can reduce energy consumption by up to 25% while simultaneously extending equipment service life by 40-60%.

The enhanced thermal conductivity of specialized aluminum-based high-temperature alloys has proven especially valuable in heat exchanger applications, where they facilitate more effective heat recovery systems. These recovery systems capture and repurpose waste heat that would otherwise be lost, creating closed-loop energy systems that significantly reduce overall energy requirements for the heat-treating process.

Recent developments in oxide dispersion strengthened (ODS) alloys have further advanced energy efficiency capabilities. These materials, reinforced with nanoscale oxide particles, maintain exceptional strength at elevated temperatures while exhibiting superior resistance to thermal fatigue. Industrial implementation data shows that ODS alloy components in high-temperature furnaces can operate efficiently at temperatures 100-150°C higher than conventional alloys, enabling more energy-dense processing.

Economic analyses reveal that despite the higher initial investment in advanced alloy components, the return on investment typically occurs within 12-24 months through energy cost savings alone. Additional benefits include reduced maintenance downtime, lower greenhouse gas emissions, and improved product quality due to more consistent thermal processing.

The integration of these advanced alloys with smart manufacturing technologies and precise temperature monitoring systems creates synergistic efficiency improvements, allowing for real-time optimization of energy consumption based on processing requirements and thermal conditions.

The implementation of these alloys in furnace components, including radiant tubes, fixtures, and conveyor systems, has demonstrated energy consumption reductions of 15-30% compared to traditional materials. This efficiency gain stems from their ability to withstand higher operating temperatures while maintaining dimensional stability, thus allowing for more rapid heating cycles and reduced process times.

Thermal efficiency improvements are particularly notable in continuous heat-treating operations, where advanced alloys permit higher temperature gradients and more precise temperature control. Studies conducted across automotive and aerospace manufacturing facilities indicate that replacing conventional heat-resistant steels with nickel-based superalloys in critical components can reduce energy consumption by up to 25% while simultaneously extending equipment service life by 40-60%.

The enhanced thermal conductivity of specialized aluminum-based high-temperature alloys has proven especially valuable in heat exchanger applications, where they facilitate more effective heat recovery systems. These recovery systems capture and repurpose waste heat that would otherwise be lost, creating closed-loop energy systems that significantly reduce overall energy requirements for the heat-treating process.

Recent developments in oxide dispersion strengthened (ODS) alloys have further advanced energy efficiency capabilities. These materials, reinforced with nanoscale oxide particles, maintain exceptional strength at elevated temperatures while exhibiting superior resistance to thermal fatigue. Industrial implementation data shows that ODS alloy components in high-temperature furnaces can operate efficiently at temperatures 100-150°C higher than conventional alloys, enabling more energy-dense processing.

Economic analyses reveal that despite the higher initial investment in advanced alloy components, the return on investment typically occurs within 12-24 months through energy cost savings alone. Additional benefits include reduced maintenance downtime, lower greenhouse gas emissions, and improved product quality due to more consistent thermal processing.

The integration of these advanced alloys with smart manufacturing technologies and precise temperature monitoring systems creates synergistic efficiency improvements, allowing for real-time optimization of energy consumption based on processing requirements and thermal conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!