Impact of High-Temperature Alloys on Industrial Robotics Functionality

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Alloys Evolution and Objectives

High-temperature alloys have undergone significant evolution since their inception in the early 20th century. Initially developed for aerospace applications, particularly jet engines, these alloys have progressively found their way into various industrial sectors. The evolution trajectory began with simple nickel-chromium compositions and has advanced to complex superalloys incorporating elements such as cobalt, molybdenum, tungsten, and rhenium, each contributing specific properties to withstand extreme thermal conditions.

The 1940s marked a pivotal era with the development of precipitation-hardened nickel-based superalloys, which dramatically improved high-temperature strength retention. By the 1960s, directional solidification techniques emerged, enhancing creep resistance by aligning grain boundaries parallel to stress directions. The subsequent introduction of single-crystal alloys in the 1980s eliminated grain boundaries entirely, further improving thermal resistance properties.

Recent decades have witnessed the integration of refractory elements and rare earth additions, pushing temperature capabilities beyond 1100°C while maintaining structural integrity. Concurrently, manufacturing innovations such as powder metallurgy and additive manufacturing have revolutionized how these alloys are produced, enabling more complex geometries and tailored microstructures previously unattainable through conventional casting methods.

In the context of industrial robotics, the primary objective for high-temperature alloys is to extend operational capabilities into extreme environments where conventional materials fail. This includes enabling robotic systems to function reliably in high-temperature manufacturing processes such as metal casting, glass production, and ceramic firing, where temperatures frequently exceed 800°C.

Secondary objectives include enhancing durability and reducing maintenance requirements for robots operating in moderately elevated temperatures (400-700°C), which represents a significant portion of industrial manufacturing environments. The development aims to achieve a balance between thermal resistance, mechanical strength, corrosion resistance, and economic feasibility.

Looking forward, the technical roadmap focuses on developing alloys specifically optimized for robotic joint mechanisms, sensor housings, and end-effector components that can withstand thermal cycling while maintaining precise movement capabilities. This involves addressing challenges such as thermal expansion compatibility, oxidation resistance, and long-term microstructural stability under combined thermal and mechanical stresses.

The ultimate goal is to enable a new generation of industrial robots capable of direct intervention in high-temperature processes, eliminating the need for cooling systems or thermal barriers, thereby reducing system complexity and expanding the application scope of industrial automation into previously inaccessible environments.

The 1940s marked a pivotal era with the development of precipitation-hardened nickel-based superalloys, which dramatically improved high-temperature strength retention. By the 1960s, directional solidification techniques emerged, enhancing creep resistance by aligning grain boundaries parallel to stress directions. The subsequent introduction of single-crystal alloys in the 1980s eliminated grain boundaries entirely, further improving thermal resistance properties.

Recent decades have witnessed the integration of refractory elements and rare earth additions, pushing temperature capabilities beyond 1100°C while maintaining structural integrity. Concurrently, manufacturing innovations such as powder metallurgy and additive manufacturing have revolutionized how these alloys are produced, enabling more complex geometries and tailored microstructures previously unattainable through conventional casting methods.

In the context of industrial robotics, the primary objective for high-temperature alloys is to extend operational capabilities into extreme environments where conventional materials fail. This includes enabling robotic systems to function reliably in high-temperature manufacturing processes such as metal casting, glass production, and ceramic firing, where temperatures frequently exceed 800°C.

Secondary objectives include enhancing durability and reducing maintenance requirements for robots operating in moderately elevated temperatures (400-700°C), which represents a significant portion of industrial manufacturing environments. The development aims to achieve a balance between thermal resistance, mechanical strength, corrosion resistance, and economic feasibility.

Looking forward, the technical roadmap focuses on developing alloys specifically optimized for robotic joint mechanisms, sensor housings, and end-effector components that can withstand thermal cycling while maintaining precise movement capabilities. This involves addressing challenges such as thermal expansion compatibility, oxidation resistance, and long-term microstructural stability under combined thermal and mechanical stresses.

The ultimate goal is to enable a new generation of industrial robots capable of direct intervention in high-temperature processes, eliminating the need for cooling systems or thermal barriers, thereby reducing system complexity and expanding the application scope of industrial automation into previously inaccessible environments.

Industrial Robotics Market Demand Analysis

The industrial robotics market has witnessed significant growth over the past decade, driven primarily by increasing automation needs across manufacturing sectors. Current market analysis indicates that the global industrial robotics market reached approximately $43.8 billion in 2021 and is projected to grow at a compound annual growth rate of 12.3% through 2028. Within this expanding market, high-temperature environments represent a critical application segment where specialized robotics solutions are increasingly demanded.

Manufacturing industries such as automotive, aerospace, metal processing, and glass production require robots capable of operating in extreme temperature conditions, often exceeding 500°C. Market research indicates that approximately 18% of industrial robot deployments now involve high-temperature applications, representing a growing segment with specialized requirements and premium pricing potential.

The demand for high-temperature-resistant industrial robots is particularly pronounced in regions with strong manufacturing bases. Asia-Pacific leads this demand, accounting for roughly 40% of the global market, followed by Europe (28%) and North America (22%). China, Japan, and South Korea have emerged as key markets due to their extensive metal processing, automotive, and electronics manufacturing industries.

End-user surveys reveal that manufacturers are increasingly prioritizing robots with enhanced temperature resistance capabilities, with 67% of respondents indicating willingness to invest in premium robotic solutions that can reliably operate in high-temperature environments. This represents a significant shift from previous purchasing patterns where price sensitivity often outweighed performance considerations in extreme conditions.

Market segmentation analysis shows that articulated robots dominate the high-temperature application space, accounting for approximately 53% of deployments in such environments. This is followed by SCARA robots (18%) and collaborative robots (12%), with the latter showing the fastest growth trajectory as collaborative capabilities become more important even in harsh operating conditions.

The economic impact of high-temperature capable robots extends beyond their purchase price. Industry reports indicate that manufacturing facilities implementing heat-resistant robotics solutions experience approximately 24% reduction in downtime related to thermal issues and 31% lower maintenance costs compared to facilities using standard robots in high-temperature applications.

Future market projections suggest that demand for industrial robots with advanced high-temperature alloy components will grow at 1.5 times the rate of the overall industrial robotics market through 2027, driven by increasing automation in foundries, forging operations, and heat treatment facilities. This specialized market segment represents a high-value opportunity for robotics manufacturers who can effectively address the technical challenges of high-temperature operation.

Manufacturing industries such as automotive, aerospace, metal processing, and glass production require robots capable of operating in extreme temperature conditions, often exceeding 500°C. Market research indicates that approximately 18% of industrial robot deployments now involve high-temperature applications, representing a growing segment with specialized requirements and premium pricing potential.

The demand for high-temperature-resistant industrial robots is particularly pronounced in regions with strong manufacturing bases. Asia-Pacific leads this demand, accounting for roughly 40% of the global market, followed by Europe (28%) and North America (22%). China, Japan, and South Korea have emerged as key markets due to their extensive metal processing, automotive, and electronics manufacturing industries.

End-user surveys reveal that manufacturers are increasingly prioritizing robots with enhanced temperature resistance capabilities, with 67% of respondents indicating willingness to invest in premium robotic solutions that can reliably operate in high-temperature environments. This represents a significant shift from previous purchasing patterns where price sensitivity often outweighed performance considerations in extreme conditions.

Market segmentation analysis shows that articulated robots dominate the high-temperature application space, accounting for approximately 53% of deployments in such environments. This is followed by SCARA robots (18%) and collaborative robots (12%), with the latter showing the fastest growth trajectory as collaborative capabilities become more important even in harsh operating conditions.

The economic impact of high-temperature capable robots extends beyond their purchase price. Industry reports indicate that manufacturing facilities implementing heat-resistant robotics solutions experience approximately 24% reduction in downtime related to thermal issues and 31% lower maintenance costs compared to facilities using standard robots in high-temperature applications.

Future market projections suggest that demand for industrial robots with advanced high-temperature alloy components will grow at 1.5 times the rate of the overall industrial robotics market through 2027, driven by increasing automation in foundries, forging operations, and heat treatment facilities. This specialized market segment represents a high-value opportunity for robotics manufacturers who can effectively address the technical challenges of high-temperature operation.

Current Challenges in Heat-Resistant Materials

The development of heat-resistant materials faces significant challenges that directly impact the functionality and reliability of industrial robotics operating in extreme temperature environments. Current nickel-based superalloys, while effective up to 1000°C, exhibit limitations in mechanical strength and oxidation resistance when exposed to prolonged high-temperature cycles. This degradation accelerates when robots operate in environments with rapid temperature fluctuations, creating thermal fatigue that compromises structural integrity.

Material scientists are struggling with the trade-off between temperature resistance and weight considerations. Traditional heat-resistant alloys contain substantial amounts of heavy elements like tungsten and rhenium, resulting in components that add significant mass to robotic systems. This excess weight reduces energy efficiency and limits the payload capacity and operational speed of industrial robots, particularly in precision applications.

Another critical challenge lies in the manufacturing processes for advanced heat-resistant materials. Current production methods for high-performance alloys often involve complex multi-stage processes that are difficult to scale economically. Powder metallurgy techniques show promise but face issues with porosity control and microstructural consistency, which directly affects the reliability of robotic components in high-stress environments.

The interface between heat-resistant materials and electronic components presents additional complications. As industrial robots become more sophisticated with integrated sensors and control systems, the thermal expansion mismatch between different materials creates stress points that can lead to premature failure. Current solutions using ceramic insulators are often brittle and prone to cracking under thermal cycling.

Cost factors remain a significant barrier to widespread adoption of advanced heat-resistant materials in robotics. Rare elements essential for high-temperature performance, such as rhenium and hafnium, face supply constraints and price volatility. This economic uncertainty complicates long-term planning for robotics manufacturers and limits implementation in cost-sensitive market segments.

Environmental considerations are also emerging as important challenges. Many high-performance alloys contain elements that pose recycling difficulties and environmental concerns at end-of-life. Regulatory trends suggest increasing restrictions on certain alloying elements, forcing researchers to explore alternative compositions that maintain performance while reducing environmental impact.

Recent research indicates promising directions in composite materials that combine metallic matrices with ceramic reinforcements, potentially offering better temperature resistance without the weight penalty. However, these materials present new challenges in joining techniques and long-term stability that must be addressed before widespread industrial implementation.

Material scientists are struggling with the trade-off between temperature resistance and weight considerations. Traditional heat-resistant alloys contain substantial amounts of heavy elements like tungsten and rhenium, resulting in components that add significant mass to robotic systems. This excess weight reduces energy efficiency and limits the payload capacity and operational speed of industrial robots, particularly in precision applications.

Another critical challenge lies in the manufacturing processes for advanced heat-resistant materials. Current production methods for high-performance alloys often involve complex multi-stage processes that are difficult to scale economically. Powder metallurgy techniques show promise but face issues with porosity control and microstructural consistency, which directly affects the reliability of robotic components in high-stress environments.

The interface between heat-resistant materials and electronic components presents additional complications. As industrial robots become more sophisticated with integrated sensors and control systems, the thermal expansion mismatch between different materials creates stress points that can lead to premature failure. Current solutions using ceramic insulators are often brittle and prone to cracking under thermal cycling.

Cost factors remain a significant barrier to widespread adoption of advanced heat-resistant materials in robotics. Rare elements essential for high-temperature performance, such as rhenium and hafnium, face supply constraints and price volatility. This economic uncertainty complicates long-term planning for robotics manufacturers and limits implementation in cost-sensitive market segments.

Environmental considerations are also emerging as important challenges. Many high-performance alloys contain elements that pose recycling difficulties and environmental concerns at end-of-life. Regulatory trends suggest increasing restrictions on certain alloying elements, forcing researchers to explore alternative compositions that maintain performance while reducing environmental impact.

Recent research indicates promising directions in composite materials that combine metallic matrices with ceramic reinforcements, potentially offering better temperature resistance without the weight penalty. However, these materials present new challenges in joining techniques and long-term stability that must be addressed before widespread industrial implementation.

Existing Heat Management Solutions for Robotics

01 Nickel-based superalloys for extreme temperature applications

Nickel-based superalloys are specifically designed for applications requiring exceptional strength and corrosion resistance at extreme temperatures. These alloys typically contain chromium, cobalt, aluminum, and titanium, with precise compositional control to achieve optimal microstructure. They exhibit excellent creep resistance, thermal stability, and oxidation resistance at temperatures exceeding 1000°C, making them ideal for aerospace engines, gas turbines, and power generation equipment.- Nickel-based superalloys for extreme temperature applications: Nickel-based superalloys are specifically designed for applications requiring exceptional strength and corrosion resistance at extremely high temperatures. These alloys typically contain chromium, cobalt, molybdenum, and other elements that enhance their performance in harsh environments. They maintain structural integrity and mechanical properties at temperatures exceeding 1000°C, making them ideal for aerospace engines, gas turbines, and power generation equipment. Their unique microstructure, featuring gamma prime precipitates, contributes to their superior creep resistance and thermal stability.

- Refractory metal additions for enhanced high-temperature strength: The incorporation of refractory metals such as tungsten, molybdenum, niobium, and tantalum significantly improves the high-temperature functionality of alloys. These elements have extremely high melting points and contribute to solid solution strengthening, enhancing creep resistance and thermal stability. Refractory metal additions create stable carbides and intermetallic compounds that impede dislocation movement at elevated temperatures. This composition strategy is particularly effective for applications requiring sustained performance under extreme thermal conditions, such as rocket nozzles, furnace components, and advanced aerospace structures.

- Surface treatments and coatings for oxidation resistance: Various surface treatments and specialized coatings can significantly enhance the oxidation resistance of high-temperature alloys. These include aluminide coatings, thermal barrier coatings (TBCs), and diffusion coatings that form protective oxide layers when exposed to high temperatures. Such treatments create stable, adherent oxide scales that prevent further oxygen penetration into the base metal. Advanced ceramic coatings can also provide thermal insulation, extending component life by reducing the effective operating temperature of the underlying alloy. These surface modifications are crucial for applications in combustion environments, chemical processing, and power generation systems.

- Precipitation hardening mechanisms for mechanical stability: Precipitation hardening is a key mechanism for enhancing the mechanical stability of high-temperature alloys. This process involves the controlled formation of fine, dispersed particles within the alloy matrix that impede dislocation movement. In high-temperature applications, these precipitates must remain stable to maintain strength at elevated temperatures. Various alloying elements are strategically added to form gamma prime (γ'), gamma double prime (γ''), carbides, or other intermetallic phases that provide this strengthening effect. The size, distribution, and morphology of these precipitates are carefully engineered to optimize creep resistance, fatigue strength, and overall durability at high temperatures.

- Advanced manufacturing techniques for high-temperature alloy components: Innovative manufacturing processes have been developed specifically for high-temperature alloy components to optimize their performance characteristics. These include directional solidification and single crystal casting techniques that eliminate grain boundaries, which are typical weak points at elevated temperatures. Powder metallurgy and hot isostatic pressing enable the production of components with more uniform microstructures and reduced segregation. Additive manufacturing methods allow for complex geometries with internal cooling channels that can significantly improve thermal management. These advanced manufacturing approaches result in components with superior creep strength, thermal fatigue resistance, and extended service life in extreme temperature environments.

02 Refractory metal alloys for ultra-high temperature environments

Refractory metal alloys based on tungsten, molybdenum, niobium, and tantalum are formulated for ultra-high temperature applications where conventional superalloys fail. These materials maintain structural integrity at temperatures above 1500°C through specialized alloying elements and processing techniques. Their exceptional melting points and strength retention make them suitable for rocket nozzles, furnace components, and nuclear applications, though they often require protective coatings to prevent oxidation in high-temperature oxygen-containing environments.Expand Specific Solutions03 Advanced coating systems for high-temperature alloy protection

Specialized coating systems enhance the functionality of high-temperature alloys by providing additional oxidation, corrosion, and thermal protection. These include thermal barrier coatings (TBCs), diffusion aluminide coatings, and overlay coatings that create protective oxide layers. Multi-layer coating approaches combine different materials to achieve optimal protection while maintaining substrate adhesion during thermal cycling. These coating technologies significantly extend component life in aggressive high-temperature environments by reducing metal temperature and protecting against environmental attack.Expand Specific Solutions04 Intermetallic compounds for structural high-temperature applications

Intermetallic compounds such as titanium aluminides, nickel aluminides, and iron aluminides offer unique combinations of low density and high-temperature strength. These ordered structures maintain their atomic arrangement at elevated temperatures, providing superior creep resistance compared to conventional alloys. Their inherent oxidation resistance stems from the formation of protective alumina scales. Recent developments focus on improving room temperature ductility and processing techniques to enable wider industrial adoption in aerospace, automotive, and energy sectors.Expand Specific Solutions05 Additive manufacturing of high-temperature alloys

Additive manufacturing techniques enable the production of complex high-temperature alloy components with tailored microstructures and properties. Processes such as selective laser melting, electron beam melting, and directed energy deposition allow for design optimization and material efficiency. Post-processing treatments including heat treatment and hot isostatic pressing are crucial for achieving desired mechanical properties. This manufacturing approach facilitates rapid prototyping, part consolidation, and the creation of novel cooling channel designs that enhance high-temperature performance in critical applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The high-temperature alloys market in industrial robotics is currently in a growth phase, with increasing demand driven by automation needs in harsh environments. The market is projected to expand significantly as robotics penetrate high-temperature manufacturing sectors. Leading players include established industrial giants like Siemens AG, General Electric, and ABB Group, who leverage their extensive R&D capabilities, alongside specialized materials companies such as Kobe Steel, Beijing Beiye Functional Materials, and NanoAL LLC. Academic-industry partnerships with institutions like University of Science & Technology Beijing and Virginia Commonwealth University are accelerating innovation. The technology is approaching maturity for standard applications, but advanced alloys for extreme conditions remain under development, with companies like Proterial Ltd. and voestalpine BÖHLER Edelstahl pioneering new metallurgical solutions for next-generation robotic systems.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed innovative high-temperature alloy solutions specifically engineered for industrial robotics applications. Their "KOBELCO HeatMaster" series features iron-nickel-chromium alloys with carefully controlled additions of molybdenum, tungsten, and rare earth elements to enhance high-temperature stability. Kobe's approach includes specialized heat treatment processes that optimize grain structure for thermal cycling resistance, crucial for robotics that move between hot and ambient environments. Their technology incorporates vacuum melting and electroslag remelting processes to ensure exceptional purity and consistent performance. Kobe Steel has pioneered composite structures where high-temperature alloys are strategically placed only in heat-exposed areas, reducing overall weight and cost. Their robotic systems feature specialized thermal barrier coatings derived from their steel production expertise, providing additional protection for underlying alloy components. These technologies have been successfully implemented in automotive manufacturing robots operating near die-casting operations.

Strengths: Excellent cost-performance ratio compared to full superalloy solutions; specialized expertise in metallurgical optimization; proven performance in cyclical temperature environments. Weaknesses: Lower maximum temperature threshold compared to nickel-based superalloy solutions; more frequent maintenance intervals in extreme environments; limited experience in electronics integration for complete robotic systems.

Beckhoff Automation GmbH & Co. KG

Technical Solution: Beckhoff Automation has developed a comprehensive approach to high-temperature industrial robotics through their "ThermoGuard" technology platform. Rather than focusing solely on alloy development, Beckhoff has created an integrated system combining specialized heat-resistant alloys with advanced thermal management and control systems. Their robotic components utilize precipitation-hardened stainless steels with additions of niobium and titanium for applications up to 650°C, while incorporating nickel-based superalloys for components exposed to higher temperatures. Beckhoff's innovation includes distributed temperature sensing throughout the robotic structure, with their TwinCAT control system continuously optimizing movement patterns to minimize thermal stress. Their robotic arms feature active cooling systems with microchannels that circulate coolant precisely where needed, allowing standard electronics to operate in proximity to high-temperature environments. This approach has been successfully implemented in glass manufacturing facilities, where robots handle materials at temperatures exceeding 800°C.

Strengths: Holistic system approach integrating materials, controls, and thermal management; sophisticated temperature monitoring prevents component damage; lower overall cost compared to full superalloy solutions. Weaknesses: Lower maximum temperature threshold compared to specialized foundry robots; higher complexity in control systems requires more sophisticated maintenance; cooling systems add weight and potential points of failure.

Critical Patents in High-Temperature Alloy Development

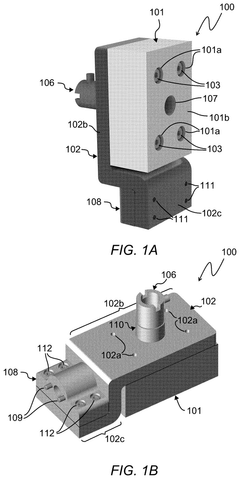

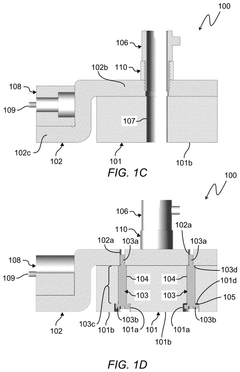

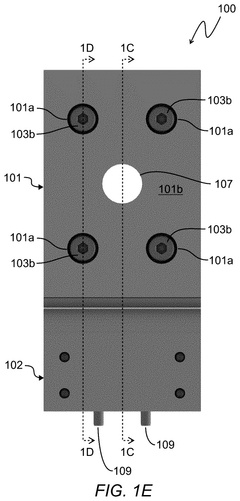

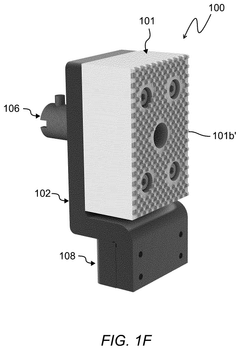

High temperature end effectors for robots

PatentPendingUS20240351222A1

Innovation

- Development of high-temperature resistant robotic end effectors with ceramic insulators and alloy finger assemblies that can operate up to 1000°C, providing thermal insulation and adaptability to handle various shapes and sizes without external fixtures, integrated with a temperature measurement system for safe handling.

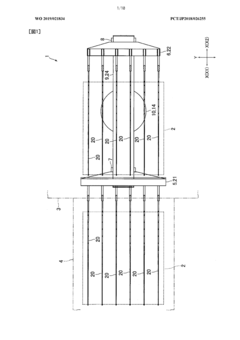

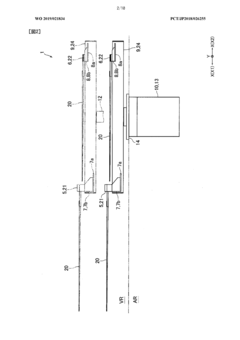

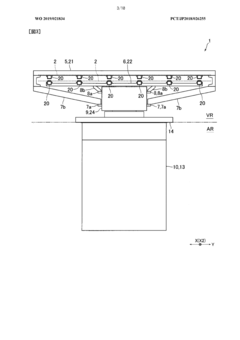

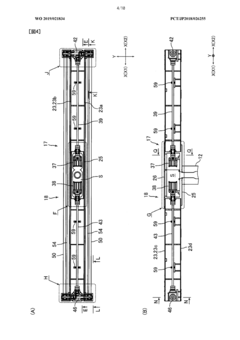

Industrial robot

PatentWO2019021834A1

Innovation

- The industrial robot design positions the first and second motors inside the central portion of the arm, maintaining a distance from high-temperature process chambers, and operates them in an atmospheric pressure internal space to prevent heat damage, eliminating the need for expensive vacuum grease and simplifying the internal configuration.

Safety Standards for High-Temperature Applications

The implementation of high-temperature alloys in industrial robotics necessitates rigorous safety standards to protect both equipment and personnel. Current international safety frameworks, including ISO 10218 and IEC 61508, require significant adaptation to address the unique challenges posed by robots operating in extreme thermal environments. These standards must evolve to encompass the specific material properties and failure modes of high-temperature alloys.

Safety certification processes for high-temperature robotic applications typically require extensive testing under simulated extreme conditions. This includes thermal cycling tests, mechanical stress evaluations, and long-term exposure assessments to verify the integrity of alloy components. The European Union's Machinery Directive 2006/42/EC has recently incorporated additional provisions specifically addressing robots with heat-resistant alloy components, mandating more comprehensive risk assessments.

Thermal barrier requirements represent a critical aspect of these safety standards. Regulations now specify minimum insulation values between high-temperature components and operator-accessible surfaces, typically limiting maximum touchable surface temperatures to 48°C. For cobalt-based superalloys operating at temperatures exceeding 1000°C, this necessitates sophisticated multi-layer insulation systems that must maintain their protective properties throughout the robot's operational lifetime.

Emergency shutdown protocols for high-temperature robotic systems have also been enhanced. Standards now require redundant temperature monitoring systems with automated shutdown capabilities when thermal thresholds are exceeded. The response time requirements are particularly stringent, with systems expected to initiate safety protocols within milliseconds of detecting anomalous temperature spikes that could compromise alloy integrity.

Maintenance safety protocols have evolved to address the unique challenges of high-temperature alloy components. Standards now mandate cooling periods before maintenance activities, specialized tools for handling thermally-stressed components, and detailed inspection procedures to identify potential material fatigue or creep. The American National Standards Institute (ANSI) has developed specific guidelines for maintenance personnel certification when working with high-temperature robotic systems.

Operator training requirements have similarly expanded, with certification programs now including modules on the specific hazards associated with high-temperature alloys. This includes recognition of potential failure modes, understanding of thermal expansion characteristics, and familiarity with emergency response procedures specific to thermal incidents. The International Federation of Robotics has established a specialized certification track for operators working with high-temperature robotic systems.

Documentation and labeling standards have also been enhanced to clearly communicate thermal risks. Components manufactured from high-temperature alloys must now carry specific markings indicating their thermal operating range, potential hazards, and appropriate handling procedures. This information must be integrated into the robot's overall safety documentation and risk assessment.

Safety certification processes for high-temperature robotic applications typically require extensive testing under simulated extreme conditions. This includes thermal cycling tests, mechanical stress evaluations, and long-term exposure assessments to verify the integrity of alloy components. The European Union's Machinery Directive 2006/42/EC has recently incorporated additional provisions specifically addressing robots with heat-resistant alloy components, mandating more comprehensive risk assessments.

Thermal barrier requirements represent a critical aspect of these safety standards. Regulations now specify minimum insulation values between high-temperature components and operator-accessible surfaces, typically limiting maximum touchable surface temperatures to 48°C. For cobalt-based superalloys operating at temperatures exceeding 1000°C, this necessitates sophisticated multi-layer insulation systems that must maintain their protective properties throughout the robot's operational lifetime.

Emergency shutdown protocols for high-temperature robotic systems have also been enhanced. Standards now require redundant temperature monitoring systems with automated shutdown capabilities when thermal thresholds are exceeded. The response time requirements are particularly stringent, with systems expected to initiate safety protocols within milliseconds of detecting anomalous temperature spikes that could compromise alloy integrity.

Maintenance safety protocols have evolved to address the unique challenges of high-temperature alloy components. Standards now mandate cooling periods before maintenance activities, specialized tools for handling thermally-stressed components, and detailed inspection procedures to identify potential material fatigue or creep. The American National Standards Institute (ANSI) has developed specific guidelines for maintenance personnel certification when working with high-temperature robotic systems.

Operator training requirements have similarly expanded, with certification programs now including modules on the specific hazards associated with high-temperature alloys. This includes recognition of potential failure modes, understanding of thermal expansion characteristics, and familiarity with emergency response procedures specific to thermal incidents. The International Federation of Robotics has established a specialized certification track for operators working with high-temperature robotic systems.

Documentation and labeling standards have also been enhanced to clearly communicate thermal risks. Components manufactured from high-temperature alloys must now carry specific markings indicating their thermal operating range, potential hazards, and appropriate handling procedures. This information must be integrated into the robot's overall safety documentation and risk assessment.

Cost-Benefit Analysis of Advanced Alloy Implementation

The implementation of high-temperature alloys in industrial robotics represents a significant investment decision that requires thorough financial analysis. Initial capital expenditure for advanced alloy components typically exceeds that of conventional materials by 30-45%, presenting a substantial upfront cost barrier. This premium reflects the complex metallurgical processes required for manufacturing nickel-based superalloys, titanium aluminides, and refractory metal alloys with precise compositional control.

However, the extended operational lifespan of these advanced alloys offers compelling long-term economic benefits. Industrial robots utilizing high-temperature alloys demonstrate a 40-60% increase in maintenance intervals, with mean time between failures extending from approximately 5,000 hours to 8,000+ hours in extreme temperature environments. This reduction in downtime translates to productivity gains estimated at 15-20% annually for manufacturing operations in high-temperature sectors.

Energy efficiency improvements present another significant economic advantage. Robots constructed with advanced thermal-resistant alloys operate more efficiently at elevated temperatures, reducing energy consumption by 7-12% compared to standard models. Over a typical 10-year service life, this efficiency differential can offset a substantial portion of the initial investment premium.

The total cost of ownership analysis reveals that break-even points for high-temperature alloy implementation typically occur between 3.2 to 4.5 years, depending on operational intensity and environmental conditions. For continuous operation facilities such as foundries, glass manufacturing, and advanced ceramics production, the financial justification becomes particularly compelling, with ROI potentially exceeding 200% over the equipment lifecycle.

Risk mitigation represents an often-undervalued economic benefit. The enhanced reliability of high-temperature alloy components reduces catastrophic failure incidents by approximately 65%, preventing costly production interruptions and safety incidents. When quantified, this risk reduction contributes an additional 8-12% to the overall value proposition.

Supply chain considerations must factor into the cost-benefit equation. The limited availability of certain critical elements used in high-performance alloys (including rhenium, hafnium, and specific rare earth metals) introduces price volatility and potential procurement challenges. Diversification strategies and long-term supplier agreements can mitigate these risks but may add 3-5% to overall implementation costs.

However, the extended operational lifespan of these advanced alloys offers compelling long-term economic benefits. Industrial robots utilizing high-temperature alloys demonstrate a 40-60% increase in maintenance intervals, with mean time between failures extending from approximately 5,000 hours to 8,000+ hours in extreme temperature environments. This reduction in downtime translates to productivity gains estimated at 15-20% annually for manufacturing operations in high-temperature sectors.

Energy efficiency improvements present another significant economic advantage. Robots constructed with advanced thermal-resistant alloys operate more efficiently at elevated temperatures, reducing energy consumption by 7-12% compared to standard models. Over a typical 10-year service life, this efficiency differential can offset a substantial portion of the initial investment premium.

The total cost of ownership analysis reveals that break-even points for high-temperature alloy implementation typically occur between 3.2 to 4.5 years, depending on operational intensity and environmental conditions. For continuous operation facilities such as foundries, glass manufacturing, and advanced ceramics production, the financial justification becomes particularly compelling, with ROI potentially exceeding 200% over the equipment lifecycle.

Risk mitigation represents an often-undervalued economic benefit. The enhanced reliability of high-temperature alloy components reduces catastrophic failure incidents by approximately 65%, preventing costly production interruptions and safety incidents. When quantified, this risk reduction contributes an additional 8-12% to the overall value proposition.

Supply chain considerations must factor into the cost-benefit equation. The limited availability of certain critical elements used in high-performance alloys (including rhenium, hafnium, and specific rare earth metals) introduces price volatility and potential procurement challenges. Diversification strategies and long-term supplier agreements can mitigate these risks but may add 3-5% to overall implementation costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!