Exploration of High-Temperature Alloys in Laser Components Manufacturing

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Alloys Background and Objectives

High-temperature alloys have evolved significantly over the past century, with their development closely tied to advancements in aerospace, energy generation, and industrial manufacturing sectors. These specialized metal compositions, designed to maintain structural integrity and performance under extreme thermal conditions, have become increasingly critical in modern laser component manufacturing where operational temperatures can exceed 1000°C.

The historical trajectory of high-temperature alloy development began with simple nickel-based compositions in the early 20th century, progressing through several generations of superalloys with increasingly complex microstructures and elemental compositions. Recent decades have witnessed the emergence of refractory metal alloys, oxide dispersion strengthened (ODS) alloys, and intermetallic compounds specifically engineered for extreme thermal environments.

In laser component manufacturing, these alloys face unique challenges including thermal cycling, oxidation resistance, dimensional stability, and compatibility with precision optical systems. The technical objectives for high-temperature alloys in this application domain focus on developing compositions that offer superior thermal fatigue resistance, minimal thermal expansion coefficients, enhanced creep resistance, and extended service life under high-power laser operation.

Current research aims to achieve breakthrough performance metrics including operational stability at temperatures exceeding 1200°C, thermal cycling endurance beyond 10,000 cycles, and dimensional tolerances maintained within ±2μm under thermal load. Additionally, there are efforts to reduce manufacturing complexity and cost while improving the environmental sustainability of these specialized materials.

The convergence of computational materials science, advanced manufacturing techniques, and in-situ characterization methods has accelerated innovation in this field. Integrated computational materials engineering (ICME) approaches now enable rapid iteration of alloy compositions tailored specifically for laser component applications, reducing development cycles from years to months.

Global research initiatives are increasingly focused on developing alloys that can withstand the extreme conditions present in next-generation high-energy laser systems, ultrafast laser processing equipment, and directed energy applications. These efforts align with broader industry trends toward higher power densities, miniaturization, and improved energy efficiency in photonic systems.

The technical objectives for this exploration include identifying optimal alloy compositions for specific laser component applications, establishing processing-structure-property relationships for these materials, and developing cost-effective manufacturing methodologies that can be scaled for commercial implementation while meeting the stringent performance requirements of advanced laser systems.

The historical trajectory of high-temperature alloy development began with simple nickel-based compositions in the early 20th century, progressing through several generations of superalloys with increasingly complex microstructures and elemental compositions. Recent decades have witnessed the emergence of refractory metal alloys, oxide dispersion strengthened (ODS) alloys, and intermetallic compounds specifically engineered for extreme thermal environments.

In laser component manufacturing, these alloys face unique challenges including thermal cycling, oxidation resistance, dimensional stability, and compatibility with precision optical systems. The technical objectives for high-temperature alloys in this application domain focus on developing compositions that offer superior thermal fatigue resistance, minimal thermal expansion coefficients, enhanced creep resistance, and extended service life under high-power laser operation.

Current research aims to achieve breakthrough performance metrics including operational stability at temperatures exceeding 1200°C, thermal cycling endurance beyond 10,000 cycles, and dimensional tolerances maintained within ±2μm under thermal load. Additionally, there are efforts to reduce manufacturing complexity and cost while improving the environmental sustainability of these specialized materials.

The convergence of computational materials science, advanced manufacturing techniques, and in-situ characterization methods has accelerated innovation in this field. Integrated computational materials engineering (ICME) approaches now enable rapid iteration of alloy compositions tailored specifically for laser component applications, reducing development cycles from years to months.

Global research initiatives are increasingly focused on developing alloys that can withstand the extreme conditions present in next-generation high-energy laser systems, ultrafast laser processing equipment, and directed energy applications. These efforts align with broader industry trends toward higher power densities, miniaturization, and improved energy efficiency in photonic systems.

The technical objectives for this exploration include identifying optimal alloy compositions for specific laser component applications, establishing processing-structure-property relationships for these materials, and developing cost-effective manufacturing methodologies that can be scaled for commercial implementation while meeting the stringent performance requirements of advanced laser systems.

Market Demand Analysis for Laser Component Materials

The global market for laser components has witnessed substantial growth in recent years, driven primarily by increasing applications across diverse industries. High-temperature alloys for laser components represent a critical segment within this market, with demand projected to grow at a compound annual growth rate of 7.8% through 2028. This growth is predominantly fueled by expanding applications in industrial manufacturing, medical devices, aerospace, defense, and telecommunications sectors.

Industrial manufacturing remains the largest consumer of high-temperature alloy-based laser components, accounting for approximately 38% of the total market share. The demand is particularly strong for cutting, welding, and surface treatment applications where materials must withstand extreme thermal conditions while maintaining dimensional stability. The automotive industry's shift toward lightweight materials has further accelerated the need for advanced laser processing technologies utilizing high-temperature alloy components.

The medical sector presents another significant growth area, with surgical lasers and diagnostic equipment requiring increasingly sophisticated components capable of withstanding high-temperature operations. Market analysis indicates that medical applications of high-temperature alloy laser components are growing at 9.2% annually, outpacing the overall market average.

Geographically, North America and Europe currently dominate the market consumption, collectively representing 58% of global demand. However, the Asia-Pacific region, particularly China, South Korea, and Japan, is experiencing the fastest growth rate at 10.5% annually. This regional shift reflects the expanding manufacturing base and increasing technological sophistication in these economies.

Customer requirements are evolving toward higher performance specifications, with particular emphasis on thermal stability, corrosion resistance, and extended operational lifespans. Survey data from end-users indicates that 72% of customers prioritize component durability under extreme thermal conditions over initial acquisition costs, suggesting a market willing to invest in premium materials that deliver superior long-term performance.

Supply chain considerations are increasingly influencing market dynamics, with recent disruptions highlighting vulnerabilities in the procurement of rare earth elements and specialized alloy components. This has prompted a market trend toward developing alternative material compositions and recycling technologies to ensure sustainable supply chains.

Price sensitivity varies significantly across application segments, with defense and aerospace customers demonstrating the lowest price elasticity due to stringent performance requirements. Conversely, consumer electronics applications show higher price sensitivity, driving innovation in cost-effective manufacturing processes for high-temperature alloy components in this sector.

Industrial manufacturing remains the largest consumer of high-temperature alloy-based laser components, accounting for approximately 38% of the total market share. The demand is particularly strong for cutting, welding, and surface treatment applications where materials must withstand extreme thermal conditions while maintaining dimensional stability. The automotive industry's shift toward lightweight materials has further accelerated the need for advanced laser processing technologies utilizing high-temperature alloy components.

The medical sector presents another significant growth area, with surgical lasers and diagnostic equipment requiring increasingly sophisticated components capable of withstanding high-temperature operations. Market analysis indicates that medical applications of high-temperature alloy laser components are growing at 9.2% annually, outpacing the overall market average.

Geographically, North America and Europe currently dominate the market consumption, collectively representing 58% of global demand. However, the Asia-Pacific region, particularly China, South Korea, and Japan, is experiencing the fastest growth rate at 10.5% annually. This regional shift reflects the expanding manufacturing base and increasing technological sophistication in these economies.

Customer requirements are evolving toward higher performance specifications, with particular emphasis on thermal stability, corrosion resistance, and extended operational lifespans. Survey data from end-users indicates that 72% of customers prioritize component durability under extreme thermal conditions over initial acquisition costs, suggesting a market willing to invest in premium materials that deliver superior long-term performance.

Supply chain considerations are increasingly influencing market dynamics, with recent disruptions highlighting vulnerabilities in the procurement of rare earth elements and specialized alloy components. This has prompted a market trend toward developing alternative material compositions and recycling technologies to ensure sustainable supply chains.

Price sensitivity varies significantly across application segments, with defense and aerospace customers demonstrating the lowest price elasticity due to stringent performance requirements. Conversely, consumer electronics applications show higher price sensitivity, driving innovation in cost-effective manufacturing processes for high-temperature alloy components in this sector.

Current State and Challenges in High-Temperature Alloy Technology

High-temperature alloys have become critical components in laser manufacturing technology, with global research efforts intensifying over the past decade. Currently, the most advanced high-temperature alloys used in laser components include nickel-based superalloys, cobalt-based alloys, and refractory metal alloys. These materials demonstrate exceptional thermal stability at temperatures exceeding 1000°C, making them ideal for high-power laser systems where thermal management is crucial.

The United States, Germany, Japan, and China lead in high-temperature alloy development for laser applications, with research clusters centered around major universities and industrial research facilities. Recent advancements have pushed the temperature threshold for these alloys to approximately 1200-1300°C for sustained operation, though performance degradation remains a significant concern beyond these limits.

Despite considerable progress, several technical challenges persist in this field. Thermal fatigue resistance remains problematic, with current alloys showing microstructural degradation after repeated thermal cycling. This limitation significantly impacts the operational lifespan of laser components, particularly in high-frequency applications where thermal stress is recurrent.

Oxidation resistance presents another major hurdle, especially in atmospheric conditions. Even advanced protective coatings demonstrate limited effectiveness at extreme temperatures, necessitating either improved coating technologies or alloy compositions with inherent oxidation resistance. The trade-off between oxidation resistance and mechanical properties continues to challenge materials scientists.

Manufacturing complexity also impedes widespread adoption, as these alloys typically require specialized processing techniques including vacuum induction melting, directional solidification, and precision heat treatments. These requirements increase production costs and limit scalability for mass production of laser components.

Additionally, the integration of these alloys with other materials in laser systems presents compatibility issues. Coefficient of thermal expansion mismatches and interfacial reactions during high-temperature operation can compromise system integrity. Current joining technologies, including advanced brazing and diffusion bonding, only partially address these concerns.

Resource constraints further complicate development efforts, as many high-temperature alloys incorporate critical elements like rhenium, hafnium, and rare earth metals. Supply chain vulnerabilities and price volatility for these materials create sustainability concerns for long-term production.

The environmental impact of processing these alloys also presents challenges, with energy-intensive manufacturing processes and potential toxic emissions requiring mitigation strategies to meet increasingly stringent environmental regulations worldwide.

The United States, Germany, Japan, and China lead in high-temperature alloy development for laser applications, with research clusters centered around major universities and industrial research facilities. Recent advancements have pushed the temperature threshold for these alloys to approximately 1200-1300°C for sustained operation, though performance degradation remains a significant concern beyond these limits.

Despite considerable progress, several technical challenges persist in this field. Thermal fatigue resistance remains problematic, with current alloys showing microstructural degradation after repeated thermal cycling. This limitation significantly impacts the operational lifespan of laser components, particularly in high-frequency applications where thermal stress is recurrent.

Oxidation resistance presents another major hurdle, especially in atmospheric conditions. Even advanced protective coatings demonstrate limited effectiveness at extreme temperatures, necessitating either improved coating technologies or alloy compositions with inherent oxidation resistance. The trade-off between oxidation resistance and mechanical properties continues to challenge materials scientists.

Manufacturing complexity also impedes widespread adoption, as these alloys typically require specialized processing techniques including vacuum induction melting, directional solidification, and precision heat treatments. These requirements increase production costs and limit scalability for mass production of laser components.

Additionally, the integration of these alloys with other materials in laser systems presents compatibility issues. Coefficient of thermal expansion mismatches and interfacial reactions during high-temperature operation can compromise system integrity. Current joining technologies, including advanced brazing and diffusion bonding, only partially address these concerns.

Resource constraints further complicate development efforts, as many high-temperature alloys incorporate critical elements like rhenium, hafnium, and rare earth metals. Supply chain vulnerabilities and price volatility for these materials create sustainability concerns for long-term production.

The environmental impact of processing these alloys also presents challenges, with energy-intensive manufacturing processes and potential toxic emissions requiring mitigation strategies to meet increasingly stringent environmental regulations worldwide.

Current Technical Solutions for Laser Component Materials

01 Nickel-based superalloys for extreme temperature applications

Nickel-based superalloys are specifically designed for applications requiring exceptional strength and corrosion resistance at extremely high temperatures. These alloys typically contain chromium, cobalt, molybdenum, and other elements that enhance their performance in aerospace engines, gas turbines, and power generation equipment. Their microstructure, characterized by gamma prime precipitates, provides excellent creep resistance and thermal stability at temperatures exceeding 1000°C.- Nickel-based superalloys for high-temperature applications: Nickel-based superalloys are widely used in high-temperature applications due to their excellent mechanical properties and oxidation resistance at elevated temperatures. These alloys typically contain chromium, cobalt, aluminum, titanium, and other elements to enhance their strength, creep resistance, and thermal stability. They are commonly used in gas turbines, aerospace engines, and other components that operate under extreme temperature conditions.

- Cobalt-based high-temperature alloys: Cobalt-based alloys offer exceptional hot corrosion resistance and thermal fatigue properties at high temperatures. These alloys typically contain chromium, tungsten, and other elements to improve their performance in extreme environments. They maintain their strength and structural integrity at elevated temperatures and are commonly used in gas turbine components, industrial furnaces, and other high-temperature applications where resistance to thermal cycling is critical.

- Refractory metal alloys for ultra-high temperature applications: Refractory metal alloys based on tungsten, molybdenum, niobium, and tantalum are designed for ultra-high temperature applications exceeding 1200°C. These alloys offer exceptional melting points and strength retention at extreme temperatures. They are used in aerospace components, nuclear reactors, and specialized industrial equipment where conventional superalloys would fail. Recent developments have focused on improving their oxidation resistance and processability while maintaining their superior high-temperature properties.

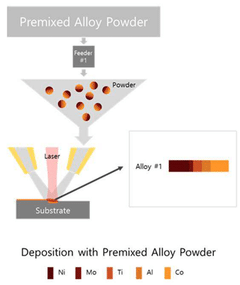

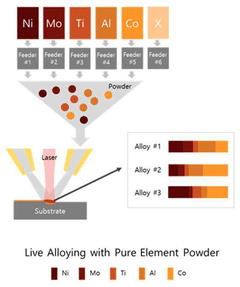

- Advanced manufacturing techniques for high-temperature alloys: Innovative manufacturing techniques have been developed to enhance the performance of high-temperature alloys. These include powder metallurgy, directional solidification, single crystal growth, and additive manufacturing. These processes enable precise control over microstructure, grain orientation, and composition distribution, resulting in alloys with superior creep resistance, thermal fatigue properties, and overall performance at elevated temperatures. These techniques have revolutionized the production of components for aerospace, power generation, and other high-temperature applications.

- Surface treatments and coatings for high-temperature alloys: Various surface treatments and coating technologies have been developed to enhance the performance of high-temperature alloys. These include thermal barrier coatings, aluminide diffusion coatings, overlay coatings, and environmental barrier coatings. These protective layers improve oxidation resistance, hot corrosion resistance, and thermal insulation properties of the base alloys. Advanced coating systems often employ multiple layers with different compositions to provide comprehensive protection against the various degradation mechanisms encountered in high-temperature environments.

02 Refractory metal alloys for ultra-high temperature environments

Refractory metal alloys based on tungsten, molybdenum, niobium, and tantalum are formulated for ultra-high temperature applications where conventional superalloys fail. These materials maintain structural integrity at temperatures above 1200°C and feature exceptional resistance to thermal shock and creep. Key applications include rocket nozzles, furnace components, and specialized tooling for extreme environments. Recent innovations focus on improving their oxidation resistance through protective coatings and compositional modifications.Expand Specific Solutions03 Advanced manufacturing techniques for high-temperature alloys

Novel manufacturing processes have been developed to enhance the performance of high-temperature alloys. These include powder metallurgy, directional solidification, single crystal growth, and additive manufacturing techniques. These methods enable precise control over microstructure, grain orientation, and compositional homogeneity, resulting in superior mechanical properties at elevated temperatures. Post-processing treatments such as hot isostatic pressing and specialized heat treatments further optimize the alloy performance for specific high-temperature applications.Expand Specific Solutions04 Intermetallic compounds for structural applications

Intermetallic compounds such as titanium aluminides, nickel aluminides, and iron aluminides offer unique combinations of low density and high-temperature strength. These ordered structures maintain their strength at elevated temperatures due to their strong atomic bonding. Recent developments have focused on improving their room temperature ductility and processing characteristics through alloying additions and microstructural control. These materials are increasingly used in aerospace components, automotive valves, and industrial heating elements where weight reduction and temperature resistance are critical.Expand Specific Solutions05 Protective coatings and surface treatments for high-temperature alloys

Specialized coatings and surface treatments have been developed to extend the service life of high-temperature alloys in aggressive environments. These include thermal barrier coatings, aluminide diffusion coatings, and overlay coatings that provide protection against oxidation, hot corrosion, and erosion. Multi-layer coating systems combine different materials to address multiple degradation mechanisms simultaneously. Recent innovations include self-healing coatings that can repair damage during service and nanostructured coatings with enhanced durability at extreme temperatures.Expand Specific Solutions

Key Industry Players in High-Temperature Alloy Manufacturing

The high-temperature alloys market in laser components manufacturing is currently in a growth phase, with increasing demand driven by aerospace, defense, and industrial applications. The market is characterized by a mix of established players and emerging specialists. Companies like General Electric, RTX Corp (formerly United Technologies), and Rolls-Royce Deutschland lead with mature technologies, while specialized firms such as Kanthal AB and Praxair S.T. Technology offer niche expertise. Academic-industry partnerships are accelerating innovation, with institutions like Northwestern Polytechnical University and Xi'an Jiaotong University collaborating with companies like Xian Bright Laser Technologies. Technical challenges remain in developing alloys that maintain structural integrity under extreme laser operating conditions, with research focusing on novel compositions and manufacturing processes to enhance performance and reliability.

United Technologies Corp.

Technical Solution: United Technologies Corp. has developed sophisticated high-temperature alloys specifically designed for laser component manufacturing in aerospace and industrial applications. Their technology centers on nickel and cobalt-based superalloys with carefully controlled microstructures to maintain dimensional stability at temperatures exceeding 1100°C. UTC's manufacturing process combines vacuum precision casting with hot isostatic pressing to eliminate porosity and optimize grain structure. For laser mirror substrates and optical mounts, they've engineered specialized alloys with low coefficients of thermal expansion and high thermal conductivity to manage heat dissipation while maintaining optical alignment. Their proprietary alloy compositions incorporate precise amounts of refractory elements like tungsten, tantalum, and rhenium to enhance creep resistance at elevated temperatures. UTC has also pioneered advanced coating systems that protect the base alloys from oxidation while enhancing surface properties for laser applications. Their materials testing protocols include accelerated thermal cycling under simulated laser conditions to predict long-term performance and reliability in operational environments.

Strengths: Extensive experience in aerospace materials, comprehensive testing facilities, and vertical integration from alloy development to component manufacturing. Weaknesses: Higher material costs compared to conventional alloys, complex manufacturing processes requiring specialized equipment, and challenges in scaling production for certain specialized compositions.

General Electric Company

Technical Solution: General Electric has developed advanced high-temperature alloys specifically designed for laser component manufacturing in aerospace and power generation applications. Their technology focuses on nickel-based superalloys with enhanced creep resistance at temperatures exceeding 1000°C. GE's approach involves precise control of microstructure through directional solidification and single crystal growth techniques, which are critical for laser components operating in extreme environments. The company has pioneered the integration of additive manufacturing with these high-temperature alloys, using direct metal laser melting (DMLM) to create complex geometries with internal cooling channels that were previously impossible to manufacture. Their proprietary TiAl (titanium aluminide) alloys offer exceptional strength-to-weight ratios at elevated temperatures, making them ideal for laser mirror substrates and optical mounts in high-power laser systems. GE has also developed specialized coating technologies to protect these alloys from oxidation and hot corrosion, extending component life in harsh operating conditions.

Strengths: Exceptional high-temperature mechanical properties, advanced manufacturing capabilities combining traditional and additive techniques, and comprehensive material testing facilities. Weaknesses: Higher production costs compared to conventional alloys, longer development cycles for new alloy compositions, and challenges in scaling production for specialized applications.

Core Innovations in High-Temperature Alloy Development

High-entropy alloy and manufacturing method for high-temperature applications

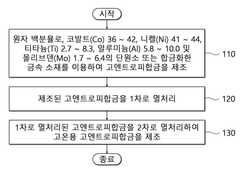

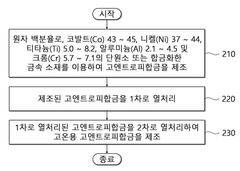

PatentActiveKR1020240009527A

Innovation

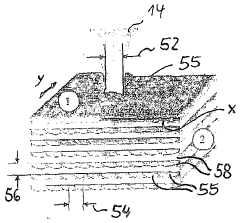

- Development of high-entropy alloys with specific compositions and manufacturing processes, including 3D printing and laser cladding, to create alloys with a gamma and gamma prime phase structure, optimized through primary and secondary heat treatments, achieving enhanced solvus temperatures and lattice misfits.

Manufacturing process for high-temperature components and component manufactured therewith

PatentInactiveDE102007018126A1

Innovation

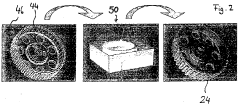

- A method involving selective melting of a powder mixture containing high-temperature metals, using laser or electron beam sintering to build components layer-by-layer based on 3D CAD data, ensuring homogeneous distribution and rapid solidification, avoiding crucible contamination and demixing, and allowing for complex geometries.

Thermal Management Strategies in Laser Systems

Thermal management represents a critical challenge in laser systems, particularly when incorporating high-temperature alloys in component manufacturing. The thermal loads generated during laser operation can reach several hundred degrees Celsius, necessitating sophisticated heat dissipation strategies to maintain system integrity and performance. Conventional cooling methods often prove inadequate when dealing with the extreme thermal conditions present in high-power laser applications.

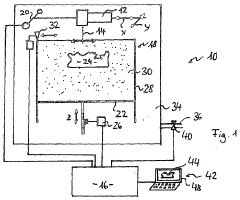

Active cooling systems have emerged as the primary approach for thermal management in advanced laser systems. These typically incorporate liquid cooling channels strategically positioned around critical components manufactured from high-temperature alloys. The integration of microchannels directly within component structures has shown particular promise, allowing for more efficient heat transfer while maintaining the structural integrity of alloy-based components.

Material selection plays a pivotal role in thermal management strategy development. High-temperature alloys with superior thermal conductivity properties, such as nickel-chromium superalloys and specialized cobalt-based compositions, enable more effective heat dissipation while maintaining mechanical stability under extreme conditions. Recent advancements in powder metallurgy have facilitated the creation of alloys with optimized thermal expansion coefficients, reducing thermal stress during operational cycles.

Computational fluid dynamics (CFD) modeling has revolutionized thermal management design processes for laser systems utilizing high-temperature alloys. These simulation tools enable engineers to predict thermal gradients, identify potential hotspots, and optimize cooling channel geometries before physical prototyping. The integration of machine learning algorithms with CFD has further enhanced predictive capabilities, allowing for rapid iteration of thermal management solutions tailored to specific alloy properties.

Phase-change materials (PCMs) represent an emerging approach for passive thermal management in laser systems. When incorporated into component housings manufactured from high-temperature alloys, these materials absorb excess heat during operation through latent heat of fusion, effectively stabilizing temperatures during peak load conditions. Silicon-carbide and aluminum-nitride ceramic composites have demonstrated particular effectiveness when paired with nickel-based superalloys in high-power laser applications.

Surface treatment technologies, including advanced coatings and micro-texturing processes, offer additional thermal management capabilities for high-temperature alloy components. Specialized ceramic thermal barrier coatings can reduce heat transfer to sensitive optical components, while precision-engineered surface textures increase effective surface area for enhanced convective cooling without compromising the mechanical properties of the underlying alloy structure.

Active cooling systems have emerged as the primary approach for thermal management in advanced laser systems. These typically incorporate liquid cooling channels strategically positioned around critical components manufactured from high-temperature alloys. The integration of microchannels directly within component structures has shown particular promise, allowing for more efficient heat transfer while maintaining the structural integrity of alloy-based components.

Material selection plays a pivotal role in thermal management strategy development. High-temperature alloys with superior thermal conductivity properties, such as nickel-chromium superalloys and specialized cobalt-based compositions, enable more effective heat dissipation while maintaining mechanical stability under extreme conditions. Recent advancements in powder metallurgy have facilitated the creation of alloys with optimized thermal expansion coefficients, reducing thermal stress during operational cycles.

Computational fluid dynamics (CFD) modeling has revolutionized thermal management design processes for laser systems utilizing high-temperature alloys. These simulation tools enable engineers to predict thermal gradients, identify potential hotspots, and optimize cooling channel geometries before physical prototyping. The integration of machine learning algorithms with CFD has further enhanced predictive capabilities, allowing for rapid iteration of thermal management solutions tailored to specific alloy properties.

Phase-change materials (PCMs) represent an emerging approach for passive thermal management in laser systems. When incorporated into component housings manufactured from high-temperature alloys, these materials absorb excess heat during operation through latent heat of fusion, effectively stabilizing temperatures during peak load conditions. Silicon-carbide and aluminum-nitride ceramic composites have demonstrated particular effectiveness when paired with nickel-based superalloys in high-power laser applications.

Surface treatment technologies, including advanced coatings and micro-texturing processes, offer additional thermal management capabilities for high-temperature alloy components. Specialized ceramic thermal barrier coatings can reduce heat transfer to sensitive optical components, while precision-engineered surface textures increase effective surface area for enhanced convective cooling without compromising the mechanical properties of the underlying alloy structure.

Environmental Impact of High-Temperature Alloy Production

The production of high-temperature alloys for laser component manufacturing carries significant environmental implications across multiple stages of their lifecycle. The extraction and processing of raw materials—including nickel, cobalt, chromium, and rare earth elements—involves energy-intensive mining operations that contribute substantially to habitat disruption, soil erosion, and groundwater contamination. These activities typically generate approximately 2-3 tons of waste material per ton of usable metal extracted.

During the manufacturing phase, the melting and casting processes for these specialized alloys require temperatures exceeding 1500°C, consuming between 8-12 MWh of energy per ton of finished alloy. This energy demand translates to considerable carbon emissions, with estimates suggesting 5-7 tons of CO2 equivalent per ton of high-temperature alloy produced when using conventional energy sources. Additionally, the precision machining and finishing operations generate metal particulates and utilize chemical solutions that require careful management to prevent air and water pollution.

The application of advanced recycling technologies has demonstrated potential for reducing these environmental impacts. Closed-loop recycling systems can recover up to 85% of scrap material from manufacturing processes, while hydrometallurgical recovery methods have shown promise in reclaiming valuable elements from end-of-life components with reduced energy requirements compared to primary production.

Regulatory frameworks governing high-temperature alloy production vary significantly across regions, with the European Union's REACH regulations and RoHS directive imposing stringent controls on hazardous substances. Meanwhile, countries with rapidly expanding manufacturing capabilities often operate under less restrictive environmental oversight, creating challenges for global environmental governance in this sector.

Recent innovations in production methodologies offer pathways to sustainability improvement. Powder metallurgy techniques reduce material waste by up to 40% compared to traditional casting methods. Similarly, additive manufacturing approaches for high-temperature alloys can decrease energy consumption by 25-30% while enabling more complex geometries that enhance component performance in laser applications.

The industry is increasingly adopting life cycle assessment (LCA) methodologies to quantify environmental impacts comprehensively. These assessments reveal that while production phase impacts are substantial, the extended service life and high performance of these alloys in laser systems can offset initial environmental costs through operational efficiency gains over product lifetimes, particularly when components are designed for eventual recyclability.

During the manufacturing phase, the melting and casting processes for these specialized alloys require temperatures exceeding 1500°C, consuming between 8-12 MWh of energy per ton of finished alloy. This energy demand translates to considerable carbon emissions, with estimates suggesting 5-7 tons of CO2 equivalent per ton of high-temperature alloy produced when using conventional energy sources. Additionally, the precision machining and finishing operations generate metal particulates and utilize chemical solutions that require careful management to prevent air and water pollution.

The application of advanced recycling technologies has demonstrated potential for reducing these environmental impacts. Closed-loop recycling systems can recover up to 85% of scrap material from manufacturing processes, while hydrometallurgical recovery methods have shown promise in reclaiming valuable elements from end-of-life components with reduced energy requirements compared to primary production.

Regulatory frameworks governing high-temperature alloy production vary significantly across regions, with the European Union's REACH regulations and RoHS directive imposing stringent controls on hazardous substances. Meanwhile, countries with rapidly expanding manufacturing capabilities often operate under less restrictive environmental oversight, creating challenges for global environmental governance in this sector.

Recent innovations in production methodologies offer pathways to sustainability improvement. Powder metallurgy techniques reduce material waste by up to 40% compared to traditional casting methods. Similarly, additive manufacturing approaches for high-temperature alloys can decrease energy consumption by 25-30% while enabling more complex geometries that enhance component performance in laser applications.

The industry is increasingly adopting life cycle assessment (LCA) methodologies to quantify environmental impacts comprehensively. These assessments reveal that while production phase impacts are substantial, the extended service life and high performance of these alloys in laser systems can offset initial environmental costs through operational efficiency gains over product lifetimes, particularly when components are designed for eventual recyclability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!