How High-Temperature Alloys Impact Jet Engine Performance

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Alloys Evolution and Performance Goals

High-temperature alloys have undergone significant evolution since the 1940s when the first nickel-based superalloys were developed for military aircraft engines. These early alloys could withstand temperatures up to 700°C, representing a substantial improvement over conventional steel alloys. The technological trajectory has been characterized by continuous innovation in metallurgical composition and manufacturing processes, with each generation of alloys pushing temperature thresholds higher while enhancing mechanical properties.

The 1970s marked a pivotal advancement with the introduction of directionally solidified and single-crystal superalloys, which eliminated grain boundaries—the primary failure points under high-temperature stress conditions. This innovation enabled engines to operate at temperatures approaching 1000°C, dramatically improving thrust-to-weight ratios and fuel efficiency.

Current state-of-the-art nickel-based superalloys incorporate complex combinations of elements including cobalt, chromium, aluminum, titanium, and refractory metals such as rhenium and ruthenium. These sophisticated compositions can withstand temperatures exceeding 1150°C in the hottest sections of modern turbine engines, approaching 85% of their melting points—an extraordinary metallurgical achievement.

The performance goals for high-temperature alloys continue to evolve in response to aviation industry demands. Primary objectives include extending temperature capabilities to beyond 1200°C for turbine blade applications, improving creep resistance at elevated temperatures, enhancing oxidation and corrosion resistance in aggressive combustion environments, and reducing density to improve thrust-to-weight ratios.

Emerging trends focus on developing alloys with improved thermal stability, longer service life under cyclic loading conditions, and reduced reliance on strategic elements facing supply constraints. Research is increasingly directed toward ceramic matrix composites (CMCs) and intermetallic compounds as potential successors to conventional superalloys, offering temperature capabilities potentially exceeding 1300°C.

The technical evolution pathway is now moving toward integrated computational materials engineering approaches, where advanced modeling and simulation tools guide alloy design, significantly reducing development cycles. This shift represents a fundamental change from traditional empirical development methods to knowledge-based design strategies that can more efficiently target specific performance parameters.

The ultimate goal remains creating materials that enable higher operating temperatures in jet engines, directly translating to improved thermal efficiency, reduced fuel consumption, lower emissions, and extended component lifespans—all critical factors in next-generation aircraft propulsion systems.

The 1970s marked a pivotal advancement with the introduction of directionally solidified and single-crystal superalloys, which eliminated grain boundaries—the primary failure points under high-temperature stress conditions. This innovation enabled engines to operate at temperatures approaching 1000°C, dramatically improving thrust-to-weight ratios and fuel efficiency.

Current state-of-the-art nickel-based superalloys incorporate complex combinations of elements including cobalt, chromium, aluminum, titanium, and refractory metals such as rhenium and ruthenium. These sophisticated compositions can withstand temperatures exceeding 1150°C in the hottest sections of modern turbine engines, approaching 85% of their melting points—an extraordinary metallurgical achievement.

The performance goals for high-temperature alloys continue to evolve in response to aviation industry demands. Primary objectives include extending temperature capabilities to beyond 1200°C for turbine blade applications, improving creep resistance at elevated temperatures, enhancing oxidation and corrosion resistance in aggressive combustion environments, and reducing density to improve thrust-to-weight ratios.

Emerging trends focus on developing alloys with improved thermal stability, longer service life under cyclic loading conditions, and reduced reliance on strategic elements facing supply constraints. Research is increasingly directed toward ceramic matrix composites (CMCs) and intermetallic compounds as potential successors to conventional superalloys, offering temperature capabilities potentially exceeding 1300°C.

The technical evolution pathway is now moving toward integrated computational materials engineering approaches, where advanced modeling and simulation tools guide alloy design, significantly reducing development cycles. This shift represents a fundamental change from traditional empirical development methods to knowledge-based design strategies that can more efficiently target specific performance parameters.

The ultimate goal remains creating materials that enable higher operating temperatures in jet engines, directly translating to improved thermal efficiency, reduced fuel consumption, lower emissions, and extended component lifespans—all critical factors in next-generation aircraft propulsion systems.

Aerospace Market Demand Analysis

The aerospace industry's demand for high-temperature alloys has experienced significant growth over the past decade, driven primarily by the expanding commercial aviation sector and increasing military aerospace investments. The global commercial aircraft fleet is projected to double by 2040, with over 40,000 new aircraft deliveries anticipated. This expansion directly correlates with increased demand for advanced jet engines capable of operating at higher temperatures for improved efficiency.

Market analysis reveals that fuel efficiency remains the primary driver for new engine development, with airlines seeking to reduce operating costs by 15-20% through next-generation propulsion systems. High-temperature alloys play a crucial role in this efficiency equation, as each 50°C increase in turbine operating temperature can yield approximately 1% improvement in fuel efficiency. This translates to substantial cost savings over an aircraft's operational lifetime.

The military aerospace segment presents another significant market for high-temperature alloys, with defense budgets allocating substantial resources toward advanced propulsion systems. Hypersonic flight initiatives have particularly accelerated demand for materials capable of withstanding extreme thermal conditions, with temperatures exceeding 1000°C during sustained operation.

Regional market distribution shows North America and Europe currently dominating demand for high-temperature alloy components, collectively accounting for approximately two-thirds of the global market. However, the Asia-Pacific region demonstrates the fastest growth rate, driven by China's expanding aerospace manufacturing capabilities and increasing domestic aircraft production.

Environmental regulations are reshaping market requirements, with international agreements mandating significant reductions in aviation emissions. The International Civil Aviation Organization has established targets to reduce carbon emissions by 50% by 2050 compared to 2005 levels. This regulatory pressure intensifies the need for higher-temperature-capable engines that can achieve better thermodynamic efficiency and lower emissions.

Maintenance, repair, and overhaul (MRO) services represent another substantial market segment for high-temperature alloys. The global aerospace MRO market values replacement parts and components at billions annually, with high-temperature components requiring more frequent replacement due to their operation in extreme conditions.

Market forecasts indicate that nickel-based superalloys currently dominate the high-temperature alloy market for aerospace applications, though ceramic matrix composites and intermetallic compounds are gaining traction for next-generation engines. Industry analysts project the global aerospace high-temperature alloy market to grow at a compound annual rate exceeding global GDP growth through 2030, reflecting the critical importance of these materials to future aircraft performance.

Market analysis reveals that fuel efficiency remains the primary driver for new engine development, with airlines seeking to reduce operating costs by 15-20% through next-generation propulsion systems. High-temperature alloys play a crucial role in this efficiency equation, as each 50°C increase in turbine operating temperature can yield approximately 1% improvement in fuel efficiency. This translates to substantial cost savings over an aircraft's operational lifetime.

The military aerospace segment presents another significant market for high-temperature alloys, with defense budgets allocating substantial resources toward advanced propulsion systems. Hypersonic flight initiatives have particularly accelerated demand for materials capable of withstanding extreme thermal conditions, with temperatures exceeding 1000°C during sustained operation.

Regional market distribution shows North America and Europe currently dominating demand for high-temperature alloy components, collectively accounting for approximately two-thirds of the global market. However, the Asia-Pacific region demonstrates the fastest growth rate, driven by China's expanding aerospace manufacturing capabilities and increasing domestic aircraft production.

Environmental regulations are reshaping market requirements, with international agreements mandating significant reductions in aviation emissions. The International Civil Aviation Organization has established targets to reduce carbon emissions by 50% by 2050 compared to 2005 levels. This regulatory pressure intensifies the need for higher-temperature-capable engines that can achieve better thermodynamic efficiency and lower emissions.

Maintenance, repair, and overhaul (MRO) services represent another substantial market segment for high-temperature alloys. The global aerospace MRO market values replacement parts and components at billions annually, with high-temperature components requiring more frequent replacement due to their operation in extreme conditions.

Market forecasts indicate that nickel-based superalloys currently dominate the high-temperature alloy market for aerospace applications, though ceramic matrix composites and intermetallic compounds are gaining traction for next-generation engines. Industry analysts project the global aerospace high-temperature alloy market to grow at a compound annual rate exceeding global GDP growth through 2030, reflecting the critical importance of these materials to future aircraft performance.

Current State and Challenges of Superalloys

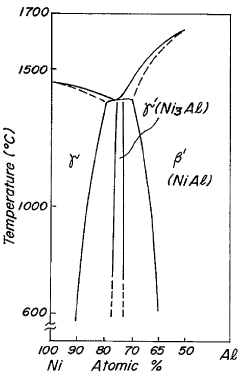

Superalloys, the backbone of modern jet engine technology, have reached a critical juncture in their development. Currently, nickel-based superalloys dominate the high-temperature components in jet engines, capable of withstanding temperatures up to 1,100°C while maintaining structural integrity. These materials represent decades of metallurgical advancement, with sophisticated microstructures featuring gamma prime (γ') precipitates embedded in a gamma matrix, providing exceptional creep resistance and thermal stability.

The global superalloy market is predominantly controlled by specialized manufacturers including Special Metals Corporation, Haynes International, and Carpenter Technology in the United States, along with European players like Aubert & Duval and Japanese firms such as Hitachi Metals. This concentration of expertise presents challenges for supply chain resilience and technology transfer.

Despite significant progress, superalloys face substantial technical challenges. The primary limitation remains their temperature capability ceiling, as jet engine efficiency directly correlates with operating temperatures. Current materials are approaching their theoretical limits, with melting points constraining further temperature increases. Additionally, the complex manufacturing processes for single-crystal superalloy components result in high production costs and limited scalability.

Environmental factors present another significant challenge. The critical elements required for superalloys—including nickel, cobalt, rhenium, and ruthenium—face supply constraints and geopolitical risks. Some of these elements are classified as critical raw materials with concentrated supply chains in politically sensitive regions, creating vulnerability for aerospace manufacturers.

Additive manufacturing presents both opportunities and challenges for superalloy development. While it offers design freedom and potential cost reductions for complex geometries, controlling microstructure and preventing defects during the printing process remains problematic for high-performance engine components.

The integration of computational materials science with experimental approaches has accelerated development, but the complexity of superalloy behavior under extreme conditions continues to challenge predictive models. The gap between theoretical predictions and actual performance under combined thermal, mechanical, and environmental stresses remains significant.

Emerging competitors to traditional superalloys include ceramic matrix composites (CMCs) and refractory high-entropy alloys (RHEAs), which demonstrate promising high-temperature capabilities but face significant hurdles in manufacturing readiness and long-term reliability validation required for flight-critical components.

The global superalloy market is predominantly controlled by specialized manufacturers including Special Metals Corporation, Haynes International, and Carpenter Technology in the United States, along with European players like Aubert & Duval and Japanese firms such as Hitachi Metals. This concentration of expertise presents challenges for supply chain resilience and technology transfer.

Despite significant progress, superalloys face substantial technical challenges. The primary limitation remains their temperature capability ceiling, as jet engine efficiency directly correlates with operating temperatures. Current materials are approaching their theoretical limits, with melting points constraining further temperature increases. Additionally, the complex manufacturing processes for single-crystal superalloy components result in high production costs and limited scalability.

Environmental factors present another significant challenge. The critical elements required for superalloys—including nickel, cobalt, rhenium, and ruthenium—face supply constraints and geopolitical risks. Some of these elements are classified as critical raw materials with concentrated supply chains in politically sensitive regions, creating vulnerability for aerospace manufacturers.

Additive manufacturing presents both opportunities and challenges for superalloy development. While it offers design freedom and potential cost reductions for complex geometries, controlling microstructure and preventing defects during the printing process remains problematic for high-performance engine components.

The integration of computational materials science with experimental approaches has accelerated development, but the complexity of superalloy behavior under extreme conditions continues to challenge predictive models. The gap between theoretical predictions and actual performance under combined thermal, mechanical, and environmental stresses remains significant.

Emerging competitors to traditional superalloys include ceramic matrix composites (CMCs) and refractory high-entropy alloys (RHEAs), which demonstrate promising high-temperature capabilities but face significant hurdles in manufacturing readiness and long-term reliability validation required for flight-critical components.

Current High-Temperature Alloy Solutions

01 Nickel-based superalloys for high-temperature applications

Nickel-based superalloys are widely used in high-temperature applications due to their excellent mechanical properties and oxidation resistance at elevated temperatures. These alloys typically contain chromium, cobalt, aluminum, and other elements that contribute to their high-temperature strength, creep resistance, and thermal stability. They are commonly used in gas turbines, aerospace components, and other applications requiring materials that can withstand extreme temperatures while maintaining structural integrity.- Nickel-based superalloys for high-temperature applications: Nickel-based superalloys are widely used in high-temperature applications due to their excellent mechanical properties and oxidation resistance at elevated temperatures. These alloys typically contain elements such as chromium, cobalt, aluminum, and titanium, which contribute to their high-temperature strength and corrosion resistance. The microstructure of these alloys, particularly the gamma prime precipitates, plays a crucial role in maintaining their mechanical properties at high temperatures, making them suitable for aerospace and power generation applications.

- Heat treatment processes for enhancing alloy performance: Various heat treatment processes can significantly improve the performance of high-temperature alloys. These processes include solution treatment, aging, annealing, and quenching, which can optimize the microstructure and phase distribution within the alloy. Controlled heat treatment can enhance properties such as creep resistance, fatigue strength, and thermal stability. The precise temperature, duration, and cooling rate during heat treatment are critical factors that determine the final performance characteristics of high-temperature alloys.

- Refractory metal additions for improved high-temperature strength: The addition of refractory metals such as tungsten, molybdenum, niobium, and tantalum to high-temperature alloys significantly enhances their strength and stability at elevated temperatures. These elements have high melting points and contribute to solid solution strengthening and the formation of stable carbides and intermetallic compounds. Refractory metal additions are particularly effective in improving creep resistance and maintaining structural integrity under extreme thermal conditions, making these alloys suitable for turbine components and other high-stress applications.

- Oxidation and corrosion resistance mechanisms: High-temperature alloys require excellent oxidation and corrosion resistance to maintain their structural integrity in aggressive environments. This is typically achieved through the formation of protective oxide scales, particularly chromia (Cr2O3) or alumina (Al2O3), which act as barriers against further oxidation. The addition of elements like chromium, aluminum, silicon, and rare earth elements promotes the formation of these protective scales. Advanced coating systems and surface modifications can further enhance the oxidation and corrosion resistance of high-temperature alloys, extending their service life in extreme environments.

- Advanced testing and characterization methods: Sophisticated testing and characterization methods are essential for evaluating the performance of high-temperature alloys. These include creep testing, thermal fatigue testing, high-temperature tensile testing, and various microstructural analysis techniques. Advanced non-destructive evaluation methods and in-situ monitoring systems allow for real-time assessment of alloy behavior under service conditions. Computational modeling and simulation techniques are increasingly being used to predict alloy performance and optimize compositions for specific applications, reducing the need for extensive experimental testing.

02 Refractory metal alloys for extreme temperature environments

Refractory metal alloys, including those based on tungsten, molybdenum, niobium, and tantalum, offer exceptional performance at extremely high temperatures. These alloys maintain their strength and structural stability at temperatures exceeding 2000°C, making them suitable for the most demanding thermal environments. Their applications include rocket nozzles, furnace components, and nuclear reactor parts. The addition of specific elements enhances their oxidation resistance and reduces brittleness, which are common challenges with refractory metals.Expand Specific Solutions03 Coating technologies for high-temperature alloy protection

Advanced coating systems are essential for protecting high-temperature alloys from oxidation, corrosion, and thermal degradation. These coatings typically include thermal barrier coatings (TBCs), diffusion aluminide coatings, and overlay coatings that create protective oxide layers. The coatings significantly extend the service life of components operating in extreme environments by reducing the metal temperature and providing a sacrificial barrier against environmental attack. Recent developments include nanostructured coatings that offer improved adhesion and thermal cycling resistance.Expand Specific Solutions04 Heat treatment processes for optimizing alloy performance

Specialized heat treatment processes are critical for optimizing the microstructure and properties of high-temperature alloys. These processes include solution treatment, aging, annealing, and precipitation hardening, which control grain size, phase distribution, and precipitate morphology. Proper heat treatment can significantly enhance creep resistance, fatigue life, and overall high-temperature stability. Advanced techniques such as controlled cooling rates and multi-stage heat treatments are employed to achieve the optimal balance of properties required for specific high-temperature applications.Expand Specific Solutions05 Novel alloy compositions for enhanced high-temperature performance

Innovative alloy compositions are being developed to meet increasingly demanding high-temperature requirements. These include intermetallic compounds, oxide dispersion strengthened (ODS) alloys, and high-entropy alloys that offer superior combinations of strength, oxidation resistance, and thermal stability. The careful addition of rare earth elements, refractory metals, and ceramic particles creates unique microstructures that resist deformation at elevated temperatures. These next-generation materials push the boundaries of what's possible in extreme thermal environments while maintaining acceptable manufacturability and cost-effectiveness.Expand Specific Solutions

Key Players in Aerospace Alloy Manufacturing

The high-temperature alloy market for jet engines is in a mature growth phase with increasing demand driven by aviation expansion and performance requirements. The global market is projected to reach significant value due to the critical role these alloys play in enhancing engine efficiency, durability, and thrust-to-weight ratios. Major aerospace players like Rolls-Royce, GE, Safran, RTX (formerly Raytheon), and MTU Aero Engines dominate the landscape, with specialized materials companies such as Aubert & Duval and Hexcel providing essential supply chain support. Chinese entities including Beijing Beiye Functional Materials and Gaona Aero Material are rapidly advancing their capabilities, supported by research partnerships with institutions like Beihang University and Xi'an Jiaotong University, indicating a shifting competitive landscape in this strategically important technology sector.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced high-temperature alloys for jet engines through their aerospace division that significantly enhance performance and efficiency. Their proprietary nickel-based superalloys incorporate precise amounts of refractory elements and rare earth additions to achieve exceptional high-temperature strength and oxidation resistance[1]. Honeywell employs vacuum precision investment casting to produce turbine blades with directionally solidified and single-crystal microstructures capable of operating at temperatures exceeding 1,100°C (2,012°F)[2]. Their thermal barrier coating systems utilize advanced ceramic compositions with engineered microstructures that can reduce metal surface temperatures by up to 170°C, significantly extending component life in extreme environments[3]. Honeywell has pioneered additive manufacturing techniques for high-temperature alloy components, enabling complex geometries that optimize cooling efficiency while reducing weight by up to 25% compared to conventional manufacturing methods[4]. Their integrated approach combines advanced materials with sophisticated cooling systems, allowing turbine inlet temperatures to exceed 1,600°C while maintaining structural integrity of components.

Strengths: Advanced manufacturing capabilities including additive techniques for complex geometries; integrated systems approach combining materials and cooling technologies; extensive experience in coating systems for extreme environments. Weaknesses: Higher production costs for specialized alloys; complex manufacturing processes requiring significant capital investment; longer development cycles for new material implementations.

General Electric Company

Technical Solution: GE's high-temperature alloy technology for jet engines centers on nickel-based superalloys with advanced cooling systems. Their CMC (Ceramic Matrix Composites) technology allows engine components to operate at temperatures up to 2400°F (1315°C), significantly higher than traditional metal alloys[1]. GE's proprietary TiAl (Titanium Aluminide) alloys used in low-pressure turbine blades reduce weight by up to 50% compared to nickel-based alternatives while maintaining high-temperature performance[2]. The company has pioneered directionally solidified and single-crystal superalloys that eliminate grain boundaries, the weakest points in conventional alloys, enabling operation at temperatures reaching 90% of their melting point[3]. GE's advanced thermal barrier coatings provide additional protection, extending component life by up to 300% in extreme temperature environments[4].

Strengths: Industry-leading CMC technology provides exceptional temperature resistance; proprietary manufacturing processes for single-crystal components; integrated cooling system design expertise. Weaknesses: Higher production costs compared to conventional alloys; complex manufacturing processes requiring specialized equipment; longer development cycles for new alloy formulations.

Critical Patents and Innovations in Superalloy Development

High temperature iron-containing gas turbine alloys containing gold

PatentInactiveUS5449489A

Innovation

- The addition of gold (Au) to niobium and other high-temperature alloys, ranging from 0.02 to 20 weight percent, significantly reduces oxidation rates and improves mechanical properties, creating a more effective alloy system for high-temperature applications.

Super heat reistant alloys having high ductility at room temperature and high strength at high temperatures

PatentInactiveGB2037322B

Innovation

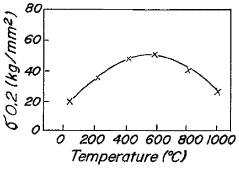

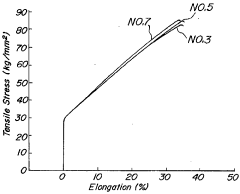

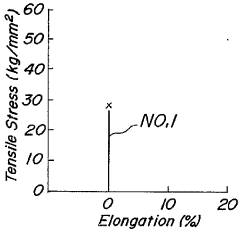

- Development of Ni3Al intermetallic compound-based super heat resistant alloys with additives (B, Nb, Sr, Mo) that maintain high ductility at room temperature while preserving high strength at elevated temperatures.

- Strategic weight percentage limitations for additives (3% for single addition, 4.5% total for multiple additives) to achieve optimal mechanical properties for high-temperature applications.

- Application-specific formulation designed for long-term high-temperature exposure in critical aerospace components such as gas turbines, jet engines, and missile systems.

Environmental Impact and Sustainability Considerations

The development and application of high-temperature alloys in jet engines present significant environmental implications that warrant careful consideration. These specialized materials enable engines to operate at higher temperatures, resulting in improved fuel efficiency and reduced greenhouse gas emissions per unit of thrust. Studies indicate that modern jet engines utilizing advanced high-temperature alloys can achieve up to 15-20% better fuel efficiency compared to older generation engines, translating to substantial reductions in carbon dioxide, nitrogen oxides, and particulate matter emissions across the aviation sector.

However, the environmental benefits during operation must be balanced against the ecological footprint of producing these sophisticated alloys. The extraction and processing of constituent elements such as nickel, cobalt, chromium, and rare earth metals involve energy-intensive mining operations that generate considerable carbon emissions and can lead to habitat disruption. Furthermore, the refining processes for these metals often require substantial energy inputs and may involve hazardous chemicals, creating additional environmental challenges.

The manufacturing of high-temperature alloys also raises sustainability concerns regarding resource scarcity. Several critical elements used in these alloys face potential supply constraints due to geopolitical factors, limited natural reserves, or concentrated production in specific regions. This situation has prompted increased research into alternative alloy compositions and recycling technologies to ensure long-term sustainability of the aerospace supply chain.

End-of-life management represents another crucial environmental consideration. The complex composition of high-temperature alloys can complicate recycling efforts, though their long service life partially mitigates this concern. Advanced recycling technologies are being developed to recover valuable elements from decommissioned engine components, potentially creating a more circular materials economy for the aerospace industry.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of aerospace materials. The European Union's REACH regulations and similar initiatives globally are imposing stricter requirements on the use of certain elements found in high-temperature alloys, driving innovation toward more environmentally benign alternatives while maintaining performance characteristics.

Looking forward, the industry is exploring bio-inspired design principles and additive manufacturing techniques that could reduce material waste during production. Additionally, research into self-healing alloys may extend component lifespans, further enhancing the sustainability profile of jet engines. These innovations, coupled with ongoing improvements in alloy performance, suggest a trajectory toward more environmentally responsible aviation propulsion systems despite the inherent challenges of high-temperature materials.

However, the environmental benefits during operation must be balanced against the ecological footprint of producing these sophisticated alloys. The extraction and processing of constituent elements such as nickel, cobalt, chromium, and rare earth metals involve energy-intensive mining operations that generate considerable carbon emissions and can lead to habitat disruption. Furthermore, the refining processes for these metals often require substantial energy inputs and may involve hazardous chemicals, creating additional environmental challenges.

The manufacturing of high-temperature alloys also raises sustainability concerns regarding resource scarcity. Several critical elements used in these alloys face potential supply constraints due to geopolitical factors, limited natural reserves, or concentrated production in specific regions. This situation has prompted increased research into alternative alloy compositions and recycling technologies to ensure long-term sustainability of the aerospace supply chain.

End-of-life management represents another crucial environmental consideration. The complex composition of high-temperature alloys can complicate recycling efforts, though their long service life partially mitigates this concern. Advanced recycling technologies are being developed to recover valuable elements from decommissioned engine components, potentially creating a more circular materials economy for the aerospace industry.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of aerospace materials. The European Union's REACH regulations and similar initiatives globally are imposing stricter requirements on the use of certain elements found in high-temperature alloys, driving innovation toward more environmentally benign alternatives while maintaining performance characteristics.

Looking forward, the industry is exploring bio-inspired design principles and additive manufacturing techniques that could reduce material waste during production. Additionally, research into self-healing alloys may extend component lifespans, further enhancing the sustainability profile of jet engines. These innovations, coupled with ongoing improvements in alloy performance, suggest a trajectory toward more environmentally responsible aviation propulsion systems despite the inherent challenges of high-temperature materials.

Material Testing Standards and Certification Requirements

The certification and standardization of high-temperature alloys for jet engine applications follow rigorous protocols established by international regulatory bodies. ASTM International's E1417 and E1444 standards govern non-destructive testing methods critical for detecting microscopic flaws in turbine components. These standards ensure that alloys maintain structural integrity under extreme thermal cycling conditions, with temperature differentials often exceeding 1000°C between startup and operational states.

Material certification for aerospace applications requires compliance with AMS (Aerospace Material Specifications) standards, particularly AMS 5544 for nickel-based superalloys and AMS 4928 for titanium alloys used in compressor sections. These specifications define precise chemical composition tolerances, with elements like rhenium and ruthenium controlled to within 0.05% to ensure consistent high-temperature performance.

Mechanical property verification follows ASTM E8 for tensile testing, with specialized high-temperature variants conducted under ASTM E21 protocols. Creep testing, governed by ASTM E139, represents a critical certification requirement, as it simulates the sustained loading conditions experienced during long-haul flights. Modern certification increasingly requires testing under simulated service environments, combining mechanical loading with thermal cycling and corrosive gas exposure.

The Nadcap (National Aerospace and Defense Contractors Accreditation Program) certification has become mandatory for suppliers of critical engine components, requiring specialized heat treatment facilities capable of maintaining temperature uniformity within ±5°C across large industrial furnaces. This precision ensures consistent microstructural development in complex alloy systems containing gamma prime and gamma double prime strengthening phases.

FAA Advisory Circular AC 33.15-1 provides regulatory guidance specific to materials used in rotating engine components, mandating comprehensive fatigue testing under representative centrifugal loading conditions. For new alloy compositions, certification pathways typically require 10,000+ hour endurance testing before approval for commercial flight applications.

European Aviation Safety Agency (EASA) certification adds requirements for environmental impact assessment, including end-of-life recyclability analysis and documentation of rare earth element content. This reflects growing regulatory concern about sustainable material sourcing in aerospace supply chains, particularly for elements like hafnium and tantalum used in advanced single-crystal turbine blades.

Material certification for aerospace applications requires compliance with AMS (Aerospace Material Specifications) standards, particularly AMS 5544 for nickel-based superalloys and AMS 4928 for titanium alloys used in compressor sections. These specifications define precise chemical composition tolerances, with elements like rhenium and ruthenium controlled to within 0.05% to ensure consistent high-temperature performance.

Mechanical property verification follows ASTM E8 for tensile testing, with specialized high-temperature variants conducted under ASTM E21 protocols. Creep testing, governed by ASTM E139, represents a critical certification requirement, as it simulates the sustained loading conditions experienced during long-haul flights. Modern certification increasingly requires testing under simulated service environments, combining mechanical loading with thermal cycling and corrosive gas exposure.

The Nadcap (National Aerospace and Defense Contractors Accreditation Program) certification has become mandatory for suppliers of critical engine components, requiring specialized heat treatment facilities capable of maintaining temperature uniformity within ±5°C across large industrial furnaces. This precision ensures consistent microstructural development in complex alloy systems containing gamma prime and gamma double prime strengthening phases.

FAA Advisory Circular AC 33.15-1 provides regulatory guidance specific to materials used in rotating engine components, mandating comprehensive fatigue testing under representative centrifugal loading conditions. For new alloy compositions, certification pathways typically require 10,000+ hour endurance testing before approval for commercial flight applications.

European Aviation Safety Agency (EASA) certification adds requirements for environmental impact assessment, including end-of-life recyclability analysis and documentation of rare earth element content. This reflects growing regulatory concern about sustainable material sourcing in aerospace supply chains, particularly for elements like hafnium and tantalum used in advanced single-crystal turbine blades.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!