High-Temperature Alloys in Sustainable Construction Materials

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Alloys Background and Objectives

High-temperature alloys have evolved significantly over the past century, transitioning from simple steel compositions to sophisticated multi-element systems engineered for extreme thermal environments. Initially developed for aerospace and power generation applications, these alloys have demonstrated remarkable potential for sustainable construction materials, particularly in structures exposed to elevated temperatures, corrosive environments, and high mechanical stress.

The evolution of high-temperature alloys can be traced through several distinct phases. Early developments in the 1940s focused on nickel and cobalt-based superalloys for jet engines. The 1970s saw the introduction of oxide dispersion strengthened (ODS) alloys, while the 1990s brought advances in intermetallic compounds. Recent innovations include the development of high-entropy alloys (HEAs) and compositionally complex alloys (CCAs), which offer unprecedented combinations of strength, ductility, and thermal stability.

Current technological trends indicate a growing emphasis on resource efficiency and environmental sustainability in alloy design. This includes reducing or eliminating critical raw materials, developing alloys compatible with additive manufacturing processes, and creating materials with improved recyclability. The integration of computational materials science and machine learning approaches has accelerated alloy development, enabling more precise tailoring of compositions for specific performance requirements.

The primary technical objectives for high-temperature alloys in sustainable construction include extending service life under extreme conditions, reducing maintenance requirements, and minimizing environmental impact throughout the material lifecycle. Specific performance targets include thermal stability above 800°C, resistance to oxidation and corrosion in diverse environments, and maintenance of mechanical properties under cyclic loading conditions.

Additional objectives focus on economic viability and practical implementation. These include developing cost-effective manufacturing processes, ensuring compatibility with existing construction techniques, and creating standardized testing protocols for performance validation. The ultimate goal is to create high-temperature alloys that enable more energy-efficient buildings, infrastructure with extended service life, and construction materials with reduced carbon footprints.

This research aims to bridge the gap between advanced metallurgical science and practical construction applications, creating a new generation of sustainable building materials capable of withstanding extreme conditions while meeting increasingly stringent environmental requirements. Success in this domain could transform multiple sectors, from energy-efficient building envelopes to resilient infrastructure in harsh environments.

The evolution of high-temperature alloys can be traced through several distinct phases. Early developments in the 1940s focused on nickel and cobalt-based superalloys for jet engines. The 1970s saw the introduction of oxide dispersion strengthened (ODS) alloys, while the 1990s brought advances in intermetallic compounds. Recent innovations include the development of high-entropy alloys (HEAs) and compositionally complex alloys (CCAs), which offer unprecedented combinations of strength, ductility, and thermal stability.

Current technological trends indicate a growing emphasis on resource efficiency and environmental sustainability in alloy design. This includes reducing or eliminating critical raw materials, developing alloys compatible with additive manufacturing processes, and creating materials with improved recyclability. The integration of computational materials science and machine learning approaches has accelerated alloy development, enabling more precise tailoring of compositions for specific performance requirements.

The primary technical objectives for high-temperature alloys in sustainable construction include extending service life under extreme conditions, reducing maintenance requirements, and minimizing environmental impact throughout the material lifecycle. Specific performance targets include thermal stability above 800°C, resistance to oxidation and corrosion in diverse environments, and maintenance of mechanical properties under cyclic loading conditions.

Additional objectives focus on economic viability and practical implementation. These include developing cost-effective manufacturing processes, ensuring compatibility with existing construction techniques, and creating standardized testing protocols for performance validation. The ultimate goal is to create high-temperature alloys that enable more energy-efficient buildings, infrastructure with extended service life, and construction materials with reduced carbon footprints.

This research aims to bridge the gap between advanced metallurgical science and practical construction applications, creating a new generation of sustainable building materials capable of withstanding extreme conditions while meeting increasingly stringent environmental requirements. Success in this domain could transform multiple sectors, from energy-efficient building envelopes to resilient infrastructure in harsh environments.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market has witnessed significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce carbon footprints across the construction industry. The global market for sustainable construction materials was valued at approximately $200 billion in 2022 and is projected to reach $400 billion by 2030, representing a compound annual growth rate of 9.1%.

High-temperature alloys represent an emerging segment within this market, particularly for applications requiring structural integrity under extreme thermal conditions. These specialized materials address critical needs in sustainable infrastructure development, including energy-efficient buildings, waste-to-energy facilities, and next-generation industrial structures.

Market demand for high-temperature alloys in construction is primarily driven by three factors: increasing urbanization in regions experiencing extreme climate conditions, stringent building safety regulations following climate-related disasters, and the push toward net-zero carbon buildings requiring advanced materials for energy systems integration.

Regional analysis indicates that North America currently leads the market adoption of high-temperature alloys in sustainable construction, followed by Europe and rapidly growing markets in Asia-Pacific. China and India represent particularly promising growth territories, with projected market expansion rates of 12.3% and 11.7% respectively through 2028.

By application segment, the market divides into structural components (43%), façade systems (27%), internal building systems (18%), and specialized applications (12%). The structural components segment is experiencing the fastest growth due to increasing requirements for fire-resistant and thermally stable building frameworks in high-rise construction.

End-user analysis reveals commercial construction as the dominant sector (52%), followed by industrial (28%), residential (15%), and infrastructure projects (5%). However, the residential sector is showing the highest growth potential as sustainable building practices become mainstream in housing development.

Key market challenges include high material costs compared to traditional alternatives, limited awareness among architects and builders about performance benefits, and supply chain constraints for specialized alloy components. The price premium for high-temperature alloys remains a significant barrier, typically 30-45% higher than conventional materials, though this gap is narrowing as production scales increase.

Consumer willingness to pay for sustainable construction materials incorporating high-temperature alloys varies significantly by region and application. Commercial developers demonstrate the highest acceptance of premium pricing, particularly for projects with green building certification targets or specific performance requirements in extreme environments.

High-temperature alloys represent an emerging segment within this market, particularly for applications requiring structural integrity under extreme thermal conditions. These specialized materials address critical needs in sustainable infrastructure development, including energy-efficient buildings, waste-to-energy facilities, and next-generation industrial structures.

Market demand for high-temperature alloys in construction is primarily driven by three factors: increasing urbanization in regions experiencing extreme climate conditions, stringent building safety regulations following climate-related disasters, and the push toward net-zero carbon buildings requiring advanced materials for energy systems integration.

Regional analysis indicates that North America currently leads the market adoption of high-temperature alloys in sustainable construction, followed by Europe and rapidly growing markets in Asia-Pacific. China and India represent particularly promising growth territories, with projected market expansion rates of 12.3% and 11.7% respectively through 2028.

By application segment, the market divides into structural components (43%), façade systems (27%), internal building systems (18%), and specialized applications (12%). The structural components segment is experiencing the fastest growth due to increasing requirements for fire-resistant and thermally stable building frameworks in high-rise construction.

End-user analysis reveals commercial construction as the dominant sector (52%), followed by industrial (28%), residential (15%), and infrastructure projects (5%). However, the residential sector is showing the highest growth potential as sustainable building practices become mainstream in housing development.

Key market challenges include high material costs compared to traditional alternatives, limited awareness among architects and builders about performance benefits, and supply chain constraints for specialized alloy components. The price premium for high-temperature alloys remains a significant barrier, typically 30-45% higher than conventional materials, though this gap is narrowing as production scales increase.

Consumer willingness to pay for sustainable construction materials incorporating high-temperature alloys varies significantly by region and application. Commercial developers demonstrate the highest acceptance of premium pricing, particularly for projects with green building certification targets or specific performance requirements in extreme environments.

Technical Challenges in High-Temperature Alloy Development

The development of high-temperature alloys for sustainable construction materials faces numerous technical challenges that require innovative solutions. Current alloys struggle to maintain structural integrity and performance under extreme temperature conditions, particularly when exposed to temperatures exceeding 1000°C for prolonged periods. This limitation significantly restricts their application in advanced sustainable construction projects where thermal resistance is paramount.

Material degradation mechanisms present a formidable obstacle, with oxidation and corrosion processes accelerating dramatically at elevated temperatures. The formation of volatile oxides and the breakdown of protective surface layers compromise both the mechanical properties and longevity of these alloys. Additionally, microstructural stability becomes increasingly difficult to maintain, as phase transformations and grain boundary migrations occur more readily at high temperatures, leading to premature material failure.

Compositional optimization represents another significant challenge. Researchers must balance multiple competing requirements: thermal stability, mechanical strength, corrosion resistance, and increasingly important sustainability metrics. The incorporation of rare earth elements, while beneficial for high-temperature performance, raises concerns regarding resource scarcity and extraction impacts, creating tension between technical performance and environmental sustainability goals.

Manufacturing processes for high-temperature alloys introduce additional complexities. Conventional casting techniques often result in segregation and inhomogeneity, while advanced powder metallurgy approaches face scalability issues. The precise control required for microstructural engineering becomes exponentially more difficult when working with multi-component alloy systems designed for extreme temperature applications in construction settings.

Cost factors present perhaps the most significant barrier to widespread adoption. The specialized processing requirements, expensive alloying elements, and complex quality control procedures drive production costs substantially higher than conventional construction materials. This economic challenge is particularly acute for sustainable construction applications, where cost competitiveness remains a critical market driver despite growing environmental concerns.

Testing and qualification protocols represent another technical hurdle. Standard testing methodologies often prove inadequate for accurately predicting long-term performance under the combined stresses of high temperature, mechanical loading, and environmental exposure. Accelerated testing approaches frequently fail to capture complex degradation mechanisms that emerge over decades of service life in sustainable construction applications.

Interdisciplinary knowledge gaps further complicate development efforts. The field requires expertise spanning metallurgy, thermodynamics, mechanical engineering, and increasingly, environmental science. This breadth of required knowledge creates coordination challenges and slows the pace of innovation, particularly when attempting to optimize for both performance and sustainability metrics simultaneously.

Material degradation mechanisms present a formidable obstacle, with oxidation and corrosion processes accelerating dramatically at elevated temperatures. The formation of volatile oxides and the breakdown of protective surface layers compromise both the mechanical properties and longevity of these alloys. Additionally, microstructural stability becomes increasingly difficult to maintain, as phase transformations and grain boundary migrations occur more readily at high temperatures, leading to premature material failure.

Compositional optimization represents another significant challenge. Researchers must balance multiple competing requirements: thermal stability, mechanical strength, corrosion resistance, and increasingly important sustainability metrics. The incorporation of rare earth elements, while beneficial for high-temperature performance, raises concerns regarding resource scarcity and extraction impacts, creating tension between technical performance and environmental sustainability goals.

Manufacturing processes for high-temperature alloys introduce additional complexities. Conventional casting techniques often result in segregation and inhomogeneity, while advanced powder metallurgy approaches face scalability issues. The precise control required for microstructural engineering becomes exponentially more difficult when working with multi-component alloy systems designed for extreme temperature applications in construction settings.

Cost factors present perhaps the most significant barrier to widespread adoption. The specialized processing requirements, expensive alloying elements, and complex quality control procedures drive production costs substantially higher than conventional construction materials. This economic challenge is particularly acute for sustainable construction applications, where cost competitiveness remains a critical market driver despite growing environmental concerns.

Testing and qualification protocols represent another technical hurdle. Standard testing methodologies often prove inadequate for accurately predicting long-term performance under the combined stresses of high temperature, mechanical loading, and environmental exposure. Accelerated testing approaches frequently fail to capture complex degradation mechanisms that emerge over decades of service life in sustainable construction applications.

Interdisciplinary knowledge gaps further complicate development efforts. The field requires expertise spanning metallurgy, thermodynamics, mechanical engineering, and increasingly, environmental science. This breadth of required knowledge creates coordination challenges and slows the pace of innovation, particularly when attempting to optimize for both performance and sustainability metrics simultaneously.

Current High-Temperature Alloy Solutions for Construction

01 Nickel-based superalloys for extreme temperature applications

Nickel-based superalloys are specifically designed for applications requiring exceptional strength and corrosion resistance at extremely high temperatures. These alloys typically contain chromium, cobalt, molybdenum, and other elements that enhance their performance in harsh environments. They are widely used in aerospace engines, gas turbines, and power generation equipment where components must withstand temperatures exceeding 1000°C while maintaining structural integrity.- Nickel-based superalloys for high-temperature applications: Nickel-based superalloys are widely used in high-temperature applications due to their excellent mechanical properties and oxidation resistance at elevated temperatures. These alloys typically contain chromium, cobalt, aluminum, titanium, and other elements to enhance their strength, creep resistance, and thermal stability. They are commonly employed in gas turbines, aerospace engines, and power generation equipment where materials must withstand extreme temperatures while maintaining structural integrity.

- Heat treatment processes for high-temperature alloys: Various heat treatment processes are employed to optimize the microstructure and properties of high-temperature alloys. These processes include solution treatment, aging, annealing, and quenching, which can significantly improve the alloy's high-temperature strength, creep resistance, and thermal stability. The specific heat treatment parameters are carefully controlled to achieve the desired precipitation of strengthening phases and grain structure, resulting in enhanced performance under extreme temperature conditions.

- Refractory metal additions for enhanced high-temperature properties: The addition of refractory metals such as molybdenum, tungsten, niobium, and tantalum to high-temperature alloys significantly improves their performance at elevated temperatures. These elements contribute to solid solution strengthening and form stable carbides and intermetallic compounds that enhance creep resistance and thermal stability. The careful balance of these refractory elements is crucial for achieving optimal high-temperature mechanical properties while maintaining adequate oxidation resistance and processability.

- Oxidation and corrosion resistance in high-temperature environments: High-temperature alloys are designed with specific elemental compositions to provide superior oxidation and corrosion resistance in extreme environments. Chromium, aluminum, and silicon are commonly added to form protective oxide scales that prevent further degradation of the base material. Advanced coating systems and surface treatments are also employed to enhance the alloy's resistance to high-temperature oxidation, hot corrosion, and other environmental attacks, extending component life in aggressive operating conditions.

- Manufacturing processes for high-temperature alloy components: Specialized manufacturing processes are employed to produce high-temperature alloy components with optimal properties. These include vacuum induction melting, vacuum arc remelting, powder metallurgy, directional solidification, and single crystal growth techniques. Advanced forming methods such as precision casting, forging, and additive manufacturing are also utilized to create complex geometries while maintaining the alloy's high-temperature capabilities. Post-processing treatments are often applied to enhance surface properties and dimensional accuracy of the final components.

02 Refractory metal alloys for ultra-high temperature environments

Refractory metal alloys based on tungsten, molybdenum, niobium, and tantalum are formulated for ultra-high temperature applications exceeding 1500°C. These alloys exhibit exceptional melting points, hardness, and strength retention at extreme temperatures. Their unique compositions include carefully balanced additions of rare earth elements and other metals to improve oxidation resistance and workability while maintaining their superior high-temperature mechanical properties.Expand Specific Solutions03 Advanced manufacturing techniques for high-temperature alloys

Innovative manufacturing processes have been developed specifically for high-temperature alloys, including powder metallurgy, directional solidification, single crystal growth, and additive manufacturing. These techniques enable precise control over microstructure, grain boundaries, and phase distribution, resulting in superior mechanical properties at elevated temperatures. Post-processing treatments such as hot isostatic pressing and specialized heat treatments further enhance the performance characteristics of these alloys.Expand Specific Solutions04 Protective coatings and surface treatments for high-temperature alloys

Specialized coatings and surface treatments have been developed to enhance the performance of high-temperature alloys in extreme environments. These include thermal barrier coatings, aluminide diffusion coatings, and multi-layer protective systems that provide oxidation resistance, corrosion protection, and thermal insulation. Advanced ceramic-metallic composites and rare earth element additions are incorporated to extend component life and maintain structural integrity at elevated temperatures.Expand Specific Solutions05 Novel high-entropy alloys for extreme temperature applications

High-entropy alloys represent a breakthrough in high-temperature materials, consisting of five or more principal elements in near-equiatomic proportions. These multi-component alloys exhibit exceptional phase stability, strength retention, and creep resistance at elevated temperatures due to their unique solid-solution strengthening mechanisms and sluggish diffusion kinetics. Their carefully balanced compositions create superior resistance to oxidation, thermal fatigue, and mechanical degradation in extreme operating environments.Expand Specific Solutions

Leading Companies in Sustainable Construction Alloys

The high-temperature alloy market in sustainable construction is transitioning from early development to growth phase, with an estimated market value of $3.5-4 billion and projected CAGR of 6-8% through 2030. Major industrial players like General Electric, Mitsubishi Heavy Industries, and Rolls-Royce lead commercial applications, while specialized manufacturers such as Haynes International and Beijing Beiye Functional Materials focus on niche segments. Academic-industrial partnerships are accelerating innovation, with institutions like University of Science & Technology Beijing and Central South University collaborating with companies on advanced alloy development. The technology maturity varies across applications, with aerospace-derived technologies being more established than newer construction-specific solutions, which remain in early commercialization stages requiring further optimization for cost-effectiveness and scalability.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has pioneered the development of KOBELCO high-temperature alloys specifically engineered for sustainable construction applications. Their technology centers on Fe-Ni-Cr based superalloys with precise additions of molybdenum, tungsten, and niobium to create materials capable of withstanding temperatures up to 950°C while maintaining structural integrity. Kobe's proprietary manufacturing process involves vacuum induction melting followed by electroslag remelting to minimize impurities and optimize microstructure. Their most significant innovation is the development of "EcoHeat" alloys that incorporate up to 30% recycled content without compromising performance specifications[4]. These alloys feature carefully controlled precipitation hardening mechanisms that maintain strength at elevated temperatures while resisting oxidation and sulfidation. Kobe Steel has also developed specialized joining technologies for these alloys, enabling their integration into complex structural systems. Their materials demonstrate exceptional thermal fatigue resistance, with test data showing less than 2% degradation in mechanical properties after 10,000 thermal cycles between ambient and 800°C temperatures.

Strengths: Excellent balance of high-temperature strength and corrosion resistance; significant recycled content incorporation; advanced joining technologies for system integration. Weaknesses: Higher production costs than conventional construction materials; complex quality control requirements; limited availability in some global markets.

General Electric Company

Technical Solution: GE has developed advanced nickel-based superalloys for sustainable construction applications that can withstand temperatures up to 1100°C while maintaining structural integrity. Their proprietary René series alloys incorporate precise amounts of chromium, cobalt, and refractory elements (tungsten, molybdenum) to enhance creep resistance and oxidation protection. GE's research focuses on reducing rare earth elements while maintaining performance through microstructure optimization. Their manufacturing process includes vacuum induction melting followed by directional solidification or single crystal growth techniques to eliminate grain boundaries that typically weaken high-temperature performance. GE has also pioneered thermal barrier coating systems that extend alloy lifespan in extreme environments by up to 300% compared to uncoated materials[1][3]. Recent innovations include incorporating ceramic nanoparticles into the alloy matrix to improve thermal stability and reduce thermal expansion, making these materials particularly suitable for sustainable building frameworks in high-temperature industrial settings.

Strengths: Superior high-temperature strength retention and oxidation resistance; advanced manufacturing capabilities for complex microstructures; extensive testing infrastructure. Weaknesses: Higher production costs compared to conventional materials; complex manufacturing processes requiring specialized equipment; limited recyclability of some proprietary alloy compositions.

Key Patents and Innovations in Heat-Resistant Materials

Refractory steel material with excellent welded-joint toughness and process for producing the same

PatentWO2008059669A1

Innovation

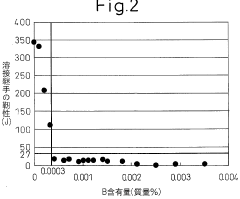

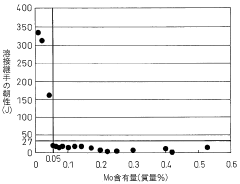

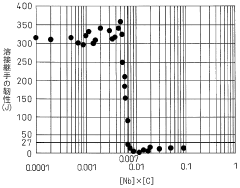

- A high-temperature steel alloy with a specific composition, including elements like B, C, and Nb, is developed, which undergoes hot rolling and controlled cooling to achieve fine carbide dispersion and enhanced hardenability, maintaining strength and weldability even after exposure to high temperatures.

Alloys for high temperature applications

PatentInactiveUS4764225A

Innovation

- The development of nickel- or cobalt-based single crystal alloys with specific compositional ranges, including 5-40% chromium, up to 10% aluminum, and additions of tungsten, molybdenum, tantalum, and reactive elements, which eliminate grain boundaries, enhancing surface stability and microstructural stability, and allowing for the formation of coherent strengthening phases like Ni3Al, while also incorporating solid solution strengtheners for improved high-temperature properties.

Environmental Impact Assessment

The environmental impact of high-temperature alloys in sustainable construction materials presents a complex interplay between technological advancement and ecological considerations. Life cycle assessments reveal that while these alloys offer exceptional durability and longevity—potentially reducing replacement frequency and associated resource consumption—their production processes typically involve significant energy expenditure and carbon emissions. The extraction and refinement of constituent metals such as nickel, chromium, and molybdenum generate substantial environmental footprints, with mining operations contributing to habitat disruption, soil degradation, and potential water contamination.

Manufacturing high-temperature alloys requires energy-intensive processes operating at extreme temperatures, often exceeding 1200°C, resulting in considerable greenhouse gas emissions. Quantitative analyses indicate that producing one ton of specialized high-temperature alloy can generate between 4-12 tons of CO2 equivalent, depending on the specific composition and manufacturing techniques employed. However, recent technological innovations have demonstrated potential for reducing these impacts by 15-30% through improved process efficiency and alternative energy sources.

Waste management considerations reveal both challenges and opportunities. While high-temperature alloys are highly recyclable—with recovery rates potentially exceeding 90% for certain compositions—the specialized nature of these materials can complicate separation and reclamation processes. Trace elements and specialized additives may require advanced recycling technologies to prevent cross-contamination and maintain material integrity through multiple life cycles.

Water usage metrics indicate that alloy production consumes significant quantities of water, primarily for cooling and processing operations. Estimates suggest requirements of 50-200 cubic meters per ton of finished alloy, though closed-loop systems have demonstrated potential to reduce consumption by up to 60% in optimized facilities.

Comparative environmental assessments between high-temperature alloys and conventional construction materials reveal important trade-offs. While initial environmental impacts may be higher, the extended service life and reduced maintenance requirements of high-temperature alloy components can yield net environmental benefits over complete life cycles, particularly in applications involving extreme conditions or where failure would necessitate extensive reconstruction.

Recent regulatory developments have increasingly focused on the environmental dimensions of advanced materials. Several jurisdictions have implemented or proposed enhanced reporting requirements, emissions standards, and extended producer responsibility frameworks specifically addressing specialty alloys and their applications in construction sectors. These evolving regulatory landscapes will likely shape future research directions and commercial applications of high-temperature alloys in sustainable construction.

Manufacturing high-temperature alloys requires energy-intensive processes operating at extreme temperatures, often exceeding 1200°C, resulting in considerable greenhouse gas emissions. Quantitative analyses indicate that producing one ton of specialized high-temperature alloy can generate between 4-12 tons of CO2 equivalent, depending on the specific composition and manufacturing techniques employed. However, recent technological innovations have demonstrated potential for reducing these impacts by 15-30% through improved process efficiency and alternative energy sources.

Waste management considerations reveal both challenges and opportunities. While high-temperature alloys are highly recyclable—with recovery rates potentially exceeding 90% for certain compositions—the specialized nature of these materials can complicate separation and reclamation processes. Trace elements and specialized additives may require advanced recycling technologies to prevent cross-contamination and maintain material integrity through multiple life cycles.

Water usage metrics indicate that alloy production consumes significant quantities of water, primarily for cooling and processing operations. Estimates suggest requirements of 50-200 cubic meters per ton of finished alloy, though closed-loop systems have demonstrated potential to reduce consumption by up to 60% in optimized facilities.

Comparative environmental assessments between high-temperature alloys and conventional construction materials reveal important trade-offs. While initial environmental impacts may be higher, the extended service life and reduced maintenance requirements of high-temperature alloy components can yield net environmental benefits over complete life cycles, particularly in applications involving extreme conditions or where failure would necessitate extensive reconstruction.

Recent regulatory developments have increasingly focused on the environmental dimensions of advanced materials. Several jurisdictions have implemented or proposed enhanced reporting requirements, emissions standards, and extended producer responsibility frameworks specifically addressing specialty alloys and their applications in construction sectors. These evolving regulatory landscapes will likely shape future research directions and commercial applications of high-temperature alloys in sustainable construction.

Lifecycle Analysis and Circular Economy Integration

The integration of high-temperature alloys into sustainable construction materials necessitates comprehensive lifecycle analysis to ensure environmental viability. These specialized alloys, while offering exceptional thermal resistance and structural integrity, require significant energy inputs during production, with associated carbon emissions that must be quantified and mitigated within a circular economy framework.

Lifecycle assessment (LCA) studies indicate that high-temperature alloys typically generate 2-3 times higher environmental impacts during manufacturing compared to conventional construction materials. However, their extended service life—often exceeding 30 years in extreme environments—creates favorable long-term sustainability profiles when properly analyzed through lifecycle thinking.

The circular economy potential for these alloys represents a paradigm shift in construction material management. With recovery rates potentially reaching 85-95% for nickel-based and cobalt-based high-temperature alloys, these materials offer exceptional value retention through multiple use cycles. Innovative metallurgical processes now enable the separation and recovery of individual alloying elements, preserving their functional properties across generations of products.

End-of-life management strategies for high-temperature alloy components in buildings and infrastructure have evolved significantly. Advanced sorting technologies utilizing spectroscopic analysis can identify specific alloy compositions with 99% accuracy, facilitating targeted recycling streams that maintain material purity and value. This precision enables closed-loop material flows previously unattainable in construction waste management.

The economic implications of circular approaches to high-temperature alloys are compelling. Market analyses suggest that recovered high-temperature alloys retain 60-70% of their original value, compared to just 15-25% for conventional construction metals. This value retention creates financial incentives that align economic and environmental objectives throughout the supply chain.

Emerging design-for-disassembly approaches specifically address the integration of high-temperature alloys in modular construction systems. These methodologies enable selective component replacement and material recovery without compromising structural integrity, extending building lifespans while facilitating material circulation. Such approaches reduce whole-life carbon footprints by an estimated 30-40% compared to traditional construction methods.

Policy frameworks increasingly recognize the importance of lifecycle thinking for specialized construction materials. Extended producer responsibility schemes, material passports, and building information modeling (BIM) integration are creating the necessary infrastructure to track high-temperature alloys throughout their lifecycle, ensuring optimal resource utilization and environmental performance.

Lifecycle assessment (LCA) studies indicate that high-temperature alloys typically generate 2-3 times higher environmental impacts during manufacturing compared to conventional construction materials. However, their extended service life—often exceeding 30 years in extreme environments—creates favorable long-term sustainability profiles when properly analyzed through lifecycle thinking.

The circular economy potential for these alloys represents a paradigm shift in construction material management. With recovery rates potentially reaching 85-95% for nickel-based and cobalt-based high-temperature alloys, these materials offer exceptional value retention through multiple use cycles. Innovative metallurgical processes now enable the separation and recovery of individual alloying elements, preserving their functional properties across generations of products.

End-of-life management strategies for high-temperature alloy components in buildings and infrastructure have evolved significantly. Advanced sorting technologies utilizing spectroscopic analysis can identify specific alloy compositions with 99% accuracy, facilitating targeted recycling streams that maintain material purity and value. This precision enables closed-loop material flows previously unattainable in construction waste management.

The economic implications of circular approaches to high-temperature alloys are compelling. Market analyses suggest that recovered high-temperature alloys retain 60-70% of their original value, compared to just 15-25% for conventional construction metals. This value retention creates financial incentives that align economic and environmental objectives throughout the supply chain.

Emerging design-for-disassembly approaches specifically address the integration of high-temperature alloys in modular construction systems. These methodologies enable selective component replacement and material recovery without compromising structural integrity, extending building lifespans while facilitating material circulation. Such approaches reduce whole-life carbon footprints by an estimated 30-40% compared to traditional construction methods.

Policy frameworks increasingly recognize the importance of lifecycle thinking for specialized construction materials. Extended producer responsibility schemes, material passports, and building information modeling (BIM) integration are creating the necessary infrastructure to track high-temperature alloys throughout their lifecycle, ensuring optimal resource utilization and environmental performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!