Performance Metrics of High-Temperature Alloys in Power Generation

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Alloy Evolution and Objectives

High-temperature alloys have evolved significantly over the past century, with their development closely tied to advancements in power generation technologies. Initially emerging in the 1940s with the introduction of nickel-based superalloys for gas turbine applications, these materials have undergone continuous refinement to meet increasingly demanding operational environments. The progression from simple solid-solution strengthened alloys to complex precipitation-hardened systems represents a fundamental shift in metallurgical engineering approaches.

The evolution trajectory of high-temperature alloys can be characterized by four distinct generations. First-generation alloys focused primarily on creep resistance through solid-solution strengthening mechanisms. Second-generation alloys introduced precipitation hardening through γ' phase formation, dramatically improving high-temperature strength. Third-generation alloys incorporated complex carbide structures and grain boundary engineering to enhance creep resistance and oxidation behavior. Current fourth-generation alloys utilize sophisticated microstructural control and nano-scale precipitate distributions to achieve unprecedented performance metrics.

Recent technological advancements have pushed operating temperatures in power generation systems beyond 760°C, necessitating alloys capable of maintaining structural integrity under extreme thermal conditions. This temperature threshold represents a critical benchmark for modern power generation efficiency, with each 50°C increase in operating temperature potentially yielding 1-2% improvement in overall system efficiency.

The primary objectives for high-temperature alloy development in power generation applications center on four key performance metrics: creep resistance at service temperatures exceeding 700°C, oxidation resistance in aggressive combustion environments, long-term microstructural stability for service lives of 30,000+ hours, and cost-effective manufacturability to enable widespread implementation.

Looking forward, the technical roadmap for high-temperature alloys aims to achieve operating capabilities at 800-850°C for advanced ultra-supercritical (A-USC) power plants by 2030, representing a step-change in energy conversion efficiency. This ambitious target requires fundamental innovations in alloy design philosophy, moving beyond traditional strengthening mechanisms toward novel compositional strategies and processing techniques.

The convergence of computational materials science, advanced characterization techniques, and accelerated testing methodologies has created unprecedented opportunities for rapid alloy development. These technological enablers are expected to compress the traditional 15-20 year development cycle for new high-temperature alloys to potentially 5-7 years, dramatically accelerating innovation in this critical technology domain.

The evolution trajectory of high-temperature alloys can be characterized by four distinct generations. First-generation alloys focused primarily on creep resistance through solid-solution strengthening mechanisms. Second-generation alloys introduced precipitation hardening through γ' phase formation, dramatically improving high-temperature strength. Third-generation alloys incorporated complex carbide structures and grain boundary engineering to enhance creep resistance and oxidation behavior. Current fourth-generation alloys utilize sophisticated microstructural control and nano-scale precipitate distributions to achieve unprecedented performance metrics.

Recent technological advancements have pushed operating temperatures in power generation systems beyond 760°C, necessitating alloys capable of maintaining structural integrity under extreme thermal conditions. This temperature threshold represents a critical benchmark for modern power generation efficiency, with each 50°C increase in operating temperature potentially yielding 1-2% improvement in overall system efficiency.

The primary objectives for high-temperature alloy development in power generation applications center on four key performance metrics: creep resistance at service temperatures exceeding 700°C, oxidation resistance in aggressive combustion environments, long-term microstructural stability for service lives of 30,000+ hours, and cost-effective manufacturability to enable widespread implementation.

Looking forward, the technical roadmap for high-temperature alloys aims to achieve operating capabilities at 800-850°C for advanced ultra-supercritical (A-USC) power plants by 2030, representing a step-change in energy conversion efficiency. This ambitious target requires fundamental innovations in alloy design philosophy, moving beyond traditional strengthening mechanisms toward novel compositional strategies and processing techniques.

The convergence of computational materials science, advanced characterization techniques, and accelerated testing methodologies has created unprecedented opportunities for rapid alloy development. These technological enablers are expected to compress the traditional 15-20 year development cycle for new high-temperature alloys to potentially 5-7 years, dramatically accelerating innovation in this critical technology domain.

Power Generation Market Requirements Analysis

The global power generation market is experiencing significant transformation driven by increasing energy demands, sustainability concerns, and technological advancements. High-temperature alloys play a critical role in this sector, particularly in thermal power plants, gas turbines, and emerging clean energy technologies. Current market analysis indicates that the power generation equipment market is valued at approximately $265 billion globally, with steady growth projected at 4-5% annually through 2030.

Thermal efficiency requirements continue to drive material specifications in power generation applications. Modern ultra-supercritical coal plants operate at temperatures exceeding 600°C and pressures above 30 MPa, demanding alloys that maintain structural integrity under these extreme conditions. Gas turbine inlet temperatures now commonly reach 1400-1600°C, necessitating advanced high-temperature alloys with exceptional creep resistance and oxidation protection.

Reliability metrics have become increasingly stringent across the power generation sector. Power plant operators typically require components manufactured from high-temperature alloys to demonstrate a minimum service life of 100,000 hours under full operating conditions. Unplanned downtime costs can exceed $500,000 per day for large power plants, making material reliability a critical economic factor. This has elevated the importance of alloys with predictable long-term performance characteristics.

Environmental regulations are reshaping material requirements across all power generation technologies. Emissions standards for NOx, SOx, and particulate matter have tightened globally, with the European Union's Industrial Emissions Directive and China's Ultra-Low Emission standards being particularly influential. These regulations indirectly impact alloy selection by necessitating higher operating temperatures for improved combustion efficiency and reduced emissions.

Cost sensitivity remains a significant market factor, with material costs representing 15-25% of total capital expenditure in conventional power plants. The volatility of key alloying elements like nickel, cobalt, and molybdenum has created market pressure for alloys with optimized compositions that maintain performance while reducing dependency on the most expensive elements.

Emerging renewable and hydrogen energy systems are creating new market requirements for high-temperature alloys. Concentrated solar power systems require materials capable of withstanding temperatures up to 800°C while handling thermal cycling. Similarly, hydrogen combustion turbines and solid oxide fuel cells operate at temperatures between 600-1000°C, creating demand for alloys with hydrogen embrittlement resistance alongside traditional high-temperature properties.

Thermal efficiency requirements continue to drive material specifications in power generation applications. Modern ultra-supercritical coal plants operate at temperatures exceeding 600°C and pressures above 30 MPa, demanding alloys that maintain structural integrity under these extreme conditions. Gas turbine inlet temperatures now commonly reach 1400-1600°C, necessitating advanced high-temperature alloys with exceptional creep resistance and oxidation protection.

Reliability metrics have become increasingly stringent across the power generation sector. Power plant operators typically require components manufactured from high-temperature alloys to demonstrate a minimum service life of 100,000 hours under full operating conditions. Unplanned downtime costs can exceed $500,000 per day for large power plants, making material reliability a critical economic factor. This has elevated the importance of alloys with predictable long-term performance characteristics.

Environmental regulations are reshaping material requirements across all power generation technologies. Emissions standards for NOx, SOx, and particulate matter have tightened globally, with the European Union's Industrial Emissions Directive and China's Ultra-Low Emission standards being particularly influential. These regulations indirectly impact alloy selection by necessitating higher operating temperatures for improved combustion efficiency and reduced emissions.

Cost sensitivity remains a significant market factor, with material costs representing 15-25% of total capital expenditure in conventional power plants. The volatility of key alloying elements like nickel, cobalt, and molybdenum has created market pressure for alloys with optimized compositions that maintain performance while reducing dependency on the most expensive elements.

Emerging renewable and hydrogen energy systems are creating new market requirements for high-temperature alloys. Concentrated solar power systems require materials capable of withstanding temperatures up to 800°C while handling thermal cycling. Similarly, hydrogen combustion turbines and solid oxide fuel cells operate at temperatures between 600-1000°C, creating demand for alloys with hydrogen embrittlement resistance alongside traditional high-temperature properties.

Global Status and Challenges of High-Temperature Materials

The global landscape of high-temperature materials exhibits significant regional disparities in research capabilities and industrial applications. North America, particularly the United States, maintains leadership in advanced nickel-based superalloys development, with major contributions from research institutions like NASA and corporations such as General Electric and Pratt & Whitney. The European Union demonstrates strength in collaborative research frameworks, with Germany and the United Kingdom spearheading innovations in single-crystal turbine blade technologies and oxide dispersion strengthened (ODS) alloys.

In Asia, Japan has established excellence in ceramic matrix composites and thermal barrier coatings, while China has rapidly expanded its capabilities in refractory metal alloys and intermetallics, significantly increasing research output and patent filings over the past decade. This global distribution reflects both historical industrial strengths and strategic national investments in critical materials technologies.

Despite these advancements, the field faces substantial technical challenges. Material degradation mechanisms at ultra-high temperatures (>1100°C) remain incompletely understood, particularly regarding creep behavior and oxidation resistance in complex service environments. The trade-off between high-temperature strength and room-temperature ductility continues to constrain design options for power generation applications, especially in components experiencing thermal cycling.

Manufacturing complexities present another significant barrier, with advanced processing techniques like directional solidification and additive manufacturing requiring further refinement to achieve consistent microstructural control in large-scale components. The cost-effectiveness of these specialized manufacturing processes remains problematic for widespread commercial adoption in power generation infrastructure.

Environmental sustainability poses an emerging challenge, as many high-performance alloys contain critical rare earth elements and strategic metals with supply chain vulnerabilities. Regulatory pressures regarding toxic elements like chromium and the carbon footprint of energy-intensive manufacturing processes are increasingly influencing material selection decisions.

Standardization issues further complicate global development efforts, with inconsistent testing methodologies and performance metrics making cross-comparison between different material systems difficult. This fragmentation hampers knowledge transfer between research institutions and industrial implementers, particularly across international boundaries.

The integration of computational materials science with experimental validation represents both a challenge and opportunity, as predictive modeling capabilities for complex multi-component systems under extreme conditions remain limited despite significant advances in simulation techniques and high-throughput experimental methodologies.

In Asia, Japan has established excellence in ceramic matrix composites and thermal barrier coatings, while China has rapidly expanded its capabilities in refractory metal alloys and intermetallics, significantly increasing research output and patent filings over the past decade. This global distribution reflects both historical industrial strengths and strategic national investments in critical materials technologies.

Despite these advancements, the field faces substantial technical challenges. Material degradation mechanisms at ultra-high temperatures (>1100°C) remain incompletely understood, particularly regarding creep behavior and oxidation resistance in complex service environments. The trade-off between high-temperature strength and room-temperature ductility continues to constrain design options for power generation applications, especially in components experiencing thermal cycling.

Manufacturing complexities present another significant barrier, with advanced processing techniques like directional solidification and additive manufacturing requiring further refinement to achieve consistent microstructural control in large-scale components. The cost-effectiveness of these specialized manufacturing processes remains problematic for widespread commercial adoption in power generation infrastructure.

Environmental sustainability poses an emerging challenge, as many high-performance alloys contain critical rare earth elements and strategic metals with supply chain vulnerabilities. Regulatory pressures regarding toxic elements like chromium and the carbon footprint of energy-intensive manufacturing processes are increasingly influencing material selection decisions.

Standardization issues further complicate global development efforts, with inconsistent testing methodologies and performance metrics making cross-comparison between different material systems difficult. This fragmentation hampers knowledge transfer between research institutions and industrial implementers, particularly across international boundaries.

The integration of computational materials science with experimental validation represents both a challenge and opportunity, as predictive modeling capabilities for complex multi-component systems under extreme conditions remain limited despite significant advances in simulation techniques and high-throughput experimental methodologies.

Current Performance Measurement Methodologies

01 Composition and structure of high-temperature alloys

High-temperature alloys are specifically designed with unique compositions and microstructures to withstand extreme operating conditions. These alloys typically contain elements such as nickel, cobalt, chromium, and various refractory metals that contribute to their exceptional thermal stability. The specific arrangement and proportion of these elements, along with controlled processing techniques, result in alloys with superior mechanical properties at elevated temperatures, including creep resistance, oxidation resistance, and thermal fatigue resistance.- Composition and structure of high-temperature alloys: High-temperature alloys are designed with specific compositions and microstructures to withstand extreme thermal conditions. These alloys typically contain elements such as nickel, cobalt, chromium, and various refractory metals that contribute to their thermal stability and oxidation resistance. The precise control of alloying elements and their proportions is crucial for achieving desired performance metrics such as creep resistance, thermal fatigue resistance, and microstructural stability at elevated temperatures.

- Mechanical property evaluation methods: Various testing methodologies are employed to evaluate the mechanical properties of high-temperature alloys under extreme conditions. These include creep testing, stress rupture testing, fatigue testing, and thermal cycling tests. Advanced measurement techniques allow for the quantification of key performance metrics such as yield strength, tensile strength, elongation, and hardness at elevated temperatures. These evaluation methods help in predicting the long-term performance and reliability of alloys in high-temperature applications.

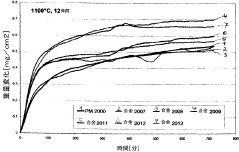

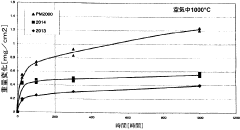

- Oxidation and corrosion resistance metrics: The performance of high-temperature alloys is significantly influenced by their resistance to oxidation and corrosion in aggressive environments. Key metrics include oxidation rate, scale adhesion, hot corrosion resistance, and stability of protective oxide layers. Specialized testing protocols involve exposure to simulated service environments, cyclic oxidation tests, and electrochemical measurements to quantify these properties. The formation of stable, adherent oxide scales is essential for extending component life in high-temperature applications.

- Thermal stability and phase transformation characteristics: High-temperature alloys must maintain microstructural stability during prolonged exposure to elevated temperatures. Performance metrics in this category include phase stability, precipitation kinetics, grain growth behavior, and resistance to detrimental phase transformations. Advanced characterization techniques such as differential thermal analysis, dilatometry, and in-situ microscopy are used to evaluate these properties. The ability to retain desirable microstructures and prevent formation of embrittling phases is critical for long-term performance in high-temperature service.

- Computational modeling and performance prediction: Advanced computational methods are increasingly used to predict and optimize the performance of high-temperature alloys. These include thermodynamic modeling, finite element analysis, machine learning algorithms, and integrated computational materials engineering approaches. These techniques enable the prediction of key performance metrics without extensive physical testing, accelerating alloy development and optimization. Performance models can simulate service conditions and predict alloy behavior, including creep deformation, fatigue life, and microstructural evolution over time.

02 Performance testing methodologies for high-temperature alloys

Various testing methodologies are employed to evaluate the performance metrics of high-temperature alloys. These include creep testing, thermal cycling, oxidation resistance testing, and mechanical property assessments at elevated temperatures. Advanced techniques such as thermomechanical fatigue testing and microstructural analysis help in understanding the behavior of these alloys under service conditions. These testing protocols are essential for validating the performance of alloys before their application in critical high-temperature environments.Expand Specific Solutions03 Computational modeling and prediction of alloy performance

Computational methods play a crucial role in predicting the performance of high-temperature alloys. Advanced modeling techniques, including finite element analysis, computational thermodynamics, and machine learning algorithms, are used to simulate the behavior of alloys under various operating conditions. These computational approaches enable researchers to optimize alloy compositions and processing parameters without extensive experimental trials, accelerating the development of new high-temperature alloys with enhanced performance characteristics.Expand Specific Solutions04 Performance monitoring systems for high-temperature applications

Real-time monitoring systems are developed to track the performance of high-temperature alloys during service. These systems utilize sensors, data acquisition technologies, and analytics to continuously assess the condition of components made from these alloys. By monitoring parameters such as temperature distribution, stress levels, and microstructural changes, these systems can predict potential failures and optimize maintenance schedules, thereby extending the service life of high-temperature alloy components in critical applications.Expand Specific Solutions05 Enhancement techniques for high-temperature alloy performance

Various techniques are employed to enhance the performance of high-temperature alloys. These include surface treatments, coatings, and microstructural modifications that improve oxidation resistance, thermal barrier properties, and mechanical strength. Advanced processing methods such as directional solidification, single crystal growth, and powder metallurgy are utilized to create alloys with optimized grain structures and phase distributions. Additionally, the incorporation of ceramic particles or fibers can create composite materials with superior high-temperature capabilities compared to conventional alloys.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

The high-temperature alloys market for power generation is currently in a mature growth phase with increasing demand driven by energy infrastructure expansion. The global market size is estimated at $4-5 billion annually with projected 5-7% CAGR through 2030. Technologically, the field shows varying maturity levels across applications, with established players like Siemens AG, Mitsubishi Hitachi Power Systems, and Westinghouse Electric leading conventional power applications, while Xi'an Thermal Power Research Institute, China Huaneng Group, and Huaneng Power International are advancing rapidly in emerging markets. Research institutions including Dalian University of Technology and Central South University collaborate with industrial partners like voestalpine BÖHLER Edelstahl and Kobe Steel to develop next-generation alloys with enhanced high-temperature performance, corrosion resistance, and extended operational lifespans for advanced power generation systems.

voestalpine BÖHLER Edelstahl GmbH & Co. KG

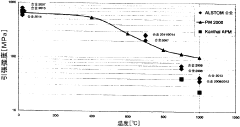

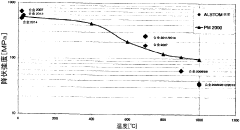

Technical Solution: voestalpine BÖHLER Edelstahl has developed specialized high-temperature alloy solutions focused on powder metallurgy and advanced processing techniques. Their technical approach centers on PM-BÖHLER series alloys produced through hot isostatic pressing (HIP) that achieve exceptional microstructural homogeneity and significantly reduced segregation compared to conventional cast and wrought processes. These materials demonstrate superior creep resistance at temperatures up to 750°C through carefully engineered distributions of carbide and intermetallic strengthening phases. Their manufacturing process enables complex near-net-shape components with internal cooling features that would be impossible with conventional manufacturing. Performance testing has shown their PM superalloys maintain consistent mechanical properties after thermal cycling, with creep rupture strengths 15-20% higher than conventional equivalents at service temperatures. The company has also developed specialized welding consumables and procedures specifically designed for repair and joining of these advanced alloys in power generation applications.

Strengths: Industry-leading powder metallurgy expertise; ability to produce complex geometries with consistent properties; excellent high-temperature fatigue resistance. Weaknesses: Higher production costs compared to conventional manufacturing; limited production capacity for large components; longer lead times for specialized compositions.

Kobe Steel, Ltd.

Technical Solution: Kobe Steel has developed proprietary high-temperature alloy technologies specifically for advanced thermal power generation systems. Their technical solution centers on SUPER304H and HR3C austenitic stainless steels with carefully controlled additions of copper, niobium, and nitrogen that create nano-scale precipitation strengthening while maintaining excellent oxidation resistance. These materials demonstrate exceptional creep rupture strength exceeding 100 MPa at 650°C for 100,000 hours. Kobe's manufacturing process includes specialized thermomechanical treatments that optimize grain structure and precipitate distribution, resulting in superior long-term microstructural stability. Their alloys feature carefully engineered surface treatments and shot peening processes that induce beneficial compressive residual stresses, significantly improving fatigue resistance under thermal cycling conditions. Performance testing in actual power plants has demonstrated these materials maintain excellent steam oxidation resistance with oxide scale growth rates below 0.1 mm per year at operating temperatures.

Strengths: Extensive experience in large-scale production of specialized tubing for boiler applications; excellent balance of creep strength and fabricability; proven long-term performance data from multiple installations. Weaknesses: Higher material costs compared to conventional ferritic steels; more complex welding procedures required; limited experience with the most extreme ultra-supercritical conditions above 700°C.

Critical Patents and Research in Alloy Performance Testing

Nickel-based heat-resistant wrought alloy and article made from same

PatentWO2021246908A1

Innovation

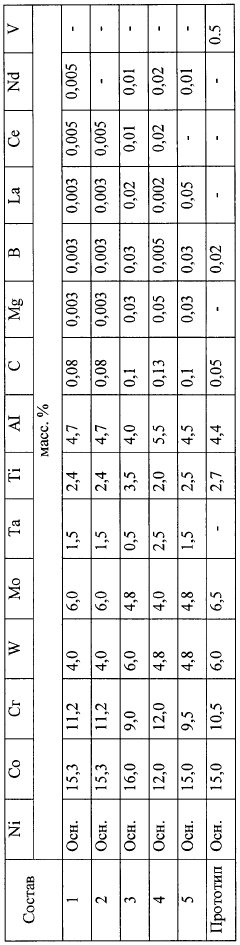

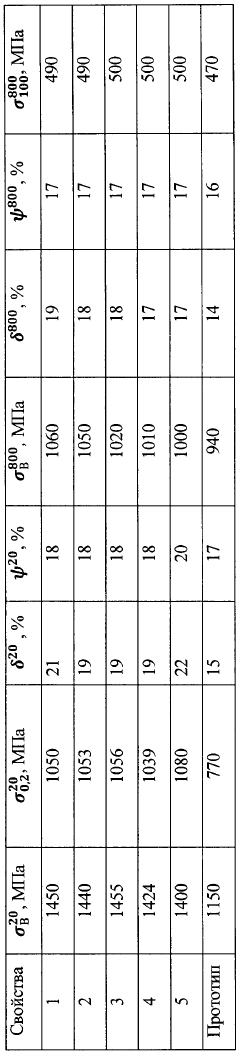

- A nickel-based heat-resistant wrought alloy with a composition of Co 12.0 - 16.0, Cr 9.0 - 12.0, W 4.0 - 6.0, Mo 4.0 - 6.0, Al 4.0 - 5.5, Ti 2.0 - 3.5, Ta 0.5 - 2.5, C 0.08 - 0.13, Mg 0.003 - 0.05, La 0.002 - 0.05, and Ce/Nd 0.005 - 0.02, which includes a g'-phase based on (Ni,Co,Cr)3(Al,Ti,Ta,W) and nickel cobalt carbides, enhancing ductility and mechanical properties through complex microalloying and the removal of harmful impurities.

High-temperature alloy

PatentInactiveJP2009057633A

Innovation

- A high-temperature FeCrAl alloy with a specific chemical composition comprising Cr20, Al4-8, Ta and Mo (total 4-8%), Zr 0.2, B 0.02-0.05, Y 0.1-0.2, Si 0-0.5, and the remainder Fe, which provides improved mechanical properties and oxidation resistance at reduced costs compared to PM 2000 and Kanthal APM.

Environmental Impact and Sustainability Considerations

The environmental footprint of high-temperature alloys in power generation extends far beyond their operational performance metrics. These specialized materials, while critical for efficiency improvements, present significant sustainability challenges throughout their lifecycle. The extraction and processing of constituent elements like nickel, cobalt, and rare earth metals involve energy-intensive operations that generate substantial greenhouse gas emissions and can lead to habitat destruction in mining regions.

During power plant operations, high-temperature alloys contribute to environmental sustainability through improved thermal efficiency, which reduces fuel consumption and associated emissions per unit of electricity generated. Advanced alloys enabling ultra-supercritical and advanced ultra-supercritical power plants have demonstrated potential for reducing CO2 emissions by 15-20% compared to conventional plants. This efficiency advantage represents a crucial environmental benefit that must be weighed against production impacts.

End-of-life considerations for these alloys present both challenges and opportunities. The complex metallurgical compositions that provide their exceptional heat resistance also complicate recycling processes. However, the high value of constituent elements creates strong economic incentives for recovery. Current recycling rates for high-temperature alloys from power generation applications range from 60-85%, significantly higher than many other industrial materials.

Lifecycle assessment studies indicate that the environmental payback period for high-temperature alloys varies between 2-7 years depending on application specifics and operational parameters. This relatively short environmental return on investment strengthens their sustainability case despite initial production impacts. Furthermore, emerging technologies for cleaner extraction and processing of constituent metals show promise for reducing the environmental footprint by up to 30% in coming decades.

Water usage represents another critical environmental consideration, with cooling systems in power generation facilities consuming substantial resources. High-temperature alloys enabling closed-loop and advanced cooling systems can reduce water consumption by 25-40% compared to conventional designs, addressing growing concerns about water scarcity in many regions.

The sustainability profile of these materials must also account for their role in enabling renewable energy integration. High-temperature alloys used in concentrated solar power and advanced energy storage systems facilitate greater renewable penetration into power grids, potentially offsetting their production impacts through system-level benefits to the energy transition.

During power plant operations, high-temperature alloys contribute to environmental sustainability through improved thermal efficiency, which reduces fuel consumption and associated emissions per unit of electricity generated. Advanced alloys enabling ultra-supercritical and advanced ultra-supercritical power plants have demonstrated potential for reducing CO2 emissions by 15-20% compared to conventional plants. This efficiency advantage represents a crucial environmental benefit that must be weighed against production impacts.

End-of-life considerations for these alloys present both challenges and opportunities. The complex metallurgical compositions that provide their exceptional heat resistance also complicate recycling processes. However, the high value of constituent elements creates strong economic incentives for recovery. Current recycling rates for high-temperature alloys from power generation applications range from 60-85%, significantly higher than many other industrial materials.

Lifecycle assessment studies indicate that the environmental payback period for high-temperature alloys varies between 2-7 years depending on application specifics and operational parameters. This relatively short environmental return on investment strengthens their sustainability case despite initial production impacts. Furthermore, emerging technologies for cleaner extraction and processing of constituent metals show promise for reducing the environmental footprint by up to 30% in coming decades.

Water usage represents another critical environmental consideration, with cooling systems in power generation facilities consuming substantial resources. High-temperature alloys enabling closed-loop and advanced cooling systems can reduce water consumption by 25-40% compared to conventional designs, addressing growing concerns about water scarcity in many regions.

The sustainability profile of these materials must also account for their role in enabling renewable energy integration. High-temperature alloys used in concentrated solar power and advanced energy storage systems facilitate greater renewable penetration into power grids, potentially offsetting their production impacts through system-level benefits to the energy transition.

Lifecycle Assessment and Economic Viability

Lifecycle assessment (LCA) of high-temperature alloys in power generation applications reveals significant environmental impacts across their entire lifespan. The extraction and processing of raw materials—particularly nickel, chromium, and other specialty metals—requires substantial energy inputs and generates considerable emissions. Manufacturing processes, including melting, casting, and heat treatment, further contribute to the carbon footprint. During the operational phase, these alloys demonstrate exceptional longevity, with service lives typically ranging from 15-30 years depending on operating conditions and maintenance protocols. End-of-life considerations are increasingly important, with recycling rates for superalloys reaching 80-90% in developed markets, significantly reducing the environmental burden compared to primary production.

Economic viability analysis indicates that despite high initial capital costs, high-temperature alloys offer compelling long-term value propositions. Initial investment for nickel-based superalloys can be 3-5 times higher than conventional steel alternatives, representing a significant upfront expenditure for power generation facilities. However, lifecycle cost modeling demonstrates that these materials typically achieve break-even within 5-8 years of operation through multiple economic advantages. Reduced maintenance requirements translate to fewer planned outages, with inspection intervals often extended by 50-100% compared to conventional materials. Higher thermal efficiency enabled by elevated operating temperatures can improve fuel economy by 2-4%, yielding substantial operational savings over the installation lifetime.

Risk assessment frameworks must account for both technical and market uncertainties. Material degradation mechanisms such as creep, fatigue, and high-temperature corrosion remain challenging to predict with precision over decades of service. Commodity price volatility presents additional economic risks, with historical fluctuations in nickel prices exceeding 300% within five-year periods. Sensitivity analysis suggests that economic viability remains robust across most scenarios, though extreme price volatility can significantly impact payback periods.

Emerging sustainability metrics are increasingly incorporated into comprehensive assessments. Water consumption throughout the lifecycle, particularly during mining and processing phases, ranges from 30-45 cubic meters per ton of finished alloy. Carbon intensity metrics indicate emissions of 12-18 tons CO2-equivalent per ton of high-temperature alloy produced, though this investment is typically offset by efficiency gains during operation. Recent regulatory frameworks, including carbon pricing mechanisms and extended producer responsibility policies, are shifting economic calculations by internalizing previously externalized environmental costs.

Economic viability analysis indicates that despite high initial capital costs, high-temperature alloys offer compelling long-term value propositions. Initial investment for nickel-based superalloys can be 3-5 times higher than conventional steel alternatives, representing a significant upfront expenditure for power generation facilities. However, lifecycle cost modeling demonstrates that these materials typically achieve break-even within 5-8 years of operation through multiple economic advantages. Reduced maintenance requirements translate to fewer planned outages, with inspection intervals often extended by 50-100% compared to conventional materials. Higher thermal efficiency enabled by elevated operating temperatures can improve fuel economy by 2-4%, yielding substantial operational savings over the installation lifetime.

Risk assessment frameworks must account for both technical and market uncertainties. Material degradation mechanisms such as creep, fatigue, and high-temperature corrosion remain challenging to predict with precision over decades of service. Commodity price volatility presents additional economic risks, with historical fluctuations in nickel prices exceeding 300% within five-year periods. Sensitivity analysis suggests that economic viability remains robust across most scenarios, though extreme price volatility can significantly impact payback periods.

Emerging sustainability metrics are increasingly incorporated into comprehensive assessments. Water consumption throughout the lifecycle, particularly during mining and processing phases, ranges from 30-45 cubic meters per ton of finished alloy. Carbon intensity metrics indicate emissions of 12-18 tons CO2-equivalent per ton of high-temperature alloy produced, though this investment is typically offset by efficiency gains during operation. Recent regulatory frameworks, including carbon pricing mechanisms and extended producer responsibility policies, are shifting economic calculations by internalizing previously externalized environmental costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!