Exploring Laminar Flow for Industrial Process Optimization

JUL 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Fundamentals and Objectives

Laminar flow, a fundamental concept in fluid dynamics, has been a cornerstone of industrial process optimization for decades. This flow regime, characterized by smooth and predictable fluid motion, occurs when a fluid flows in parallel layers without disruption between the layers. The historical development of laminar flow understanding can be traced back to the 19th century, with significant contributions from scientists like George Gabriel Stokes and Osborne Reynolds.

The evolution of laminar flow applications in industry has been driven by the need for precise control and efficiency in various processes. From chemical manufacturing to microfluidics, the principles of laminar flow have been instrumental in enhancing product quality, reducing energy consumption, and minimizing waste. The technological trajectory has seen a shift from macro-scale applications to micro and nano-scale implementations, opening up new possibilities in fields such as lab-on-a-chip devices and advanced materials processing.

Current trends in laminar flow research and application focus on leveraging its properties for novel industrial solutions. These include the development of more efficient heat exchangers, improved separation processes in the pharmaceutical industry, and enhanced mixing techniques in microfluidic devices. The integration of laminar flow principles with emerging technologies like 3D printing and artificial intelligence is also paving the way for innovative manufacturing processes and smart fluid handling systems.

The primary objective of exploring laminar flow for industrial process optimization is to harness its predictable nature to achieve greater control, efficiency, and precision in various manufacturing and processing operations. Specific goals include minimizing turbulence-induced losses, enhancing heat and mass transfer rates, improving product uniformity, and reducing energy consumption across a wide range of industrial applications.

Key technical objectives in this field encompass the development of advanced modeling and simulation tools to predict and optimize laminar flow behavior in complex geometries, the creation of novel surface treatments and materials to manipulate flow characteristics, and the integration of real-time monitoring and control systems to maintain optimal flow conditions in dynamic industrial environments.

As industries strive for greater sustainability and efficiency, the exploration of laminar flow principles offers promising avenues for process improvement. By deepening our understanding of laminar flow dynamics and developing innovative applications, researchers and engineers aim to unlock new possibilities for industrial optimization, potentially revolutionizing sectors ranging from energy production to biotechnology.

The evolution of laminar flow applications in industry has been driven by the need for precise control and efficiency in various processes. From chemical manufacturing to microfluidics, the principles of laminar flow have been instrumental in enhancing product quality, reducing energy consumption, and minimizing waste. The technological trajectory has seen a shift from macro-scale applications to micro and nano-scale implementations, opening up new possibilities in fields such as lab-on-a-chip devices and advanced materials processing.

Current trends in laminar flow research and application focus on leveraging its properties for novel industrial solutions. These include the development of more efficient heat exchangers, improved separation processes in the pharmaceutical industry, and enhanced mixing techniques in microfluidic devices. The integration of laminar flow principles with emerging technologies like 3D printing and artificial intelligence is also paving the way for innovative manufacturing processes and smart fluid handling systems.

The primary objective of exploring laminar flow for industrial process optimization is to harness its predictable nature to achieve greater control, efficiency, and precision in various manufacturing and processing operations. Specific goals include minimizing turbulence-induced losses, enhancing heat and mass transfer rates, improving product uniformity, and reducing energy consumption across a wide range of industrial applications.

Key technical objectives in this field encompass the development of advanced modeling and simulation tools to predict and optimize laminar flow behavior in complex geometries, the creation of novel surface treatments and materials to manipulate flow characteristics, and the integration of real-time monitoring and control systems to maintain optimal flow conditions in dynamic industrial environments.

As industries strive for greater sustainability and efficiency, the exploration of laminar flow principles offers promising avenues for process improvement. By deepening our understanding of laminar flow dynamics and developing innovative applications, researchers and engineers aim to unlock new possibilities for industrial optimization, potentially revolutionizing sectors ranging from energy production to biotechnology.

Industrial Applications and Market Demand

Laminar flow technology has gained significant traction in various industrial sectors due to its potential for process optimization and efficiency improvement. The market demand for laminar flow solutions is driven by the increasing need for precise control over fluid dynamics in manufacturing, chemical processing, and other industrial applications.

In the pharmaceutical and biotechnology industries, laminar flow systems are crucial for maintaining sterile environments in cleanrooms and laboratories. The global cleanroom technology market, which heavily relies on laminar flow systems, is expected to grow substantially in the coming years. This growth is fueled by stringent regulatory requirements for product quality and safety, particularly in drug manufacturing and medical device production.

The semiconductor industry also presents a significant market for laminar flow technology. As chip manufacturers strive for smaller and more complex designs, the need for ultra-clean environments becomes paramount. Laminar flow systems play a vital role in reducing particle contamination during the fabrication process, thereby improving yield rates and product quality.

In the food and beverage sector, laminar flow technology is increasingly adopted for aseptic processing and packaging. This application ensures product safety and extends shelf life without compromising nutritional value or taste. The growing consumer demand for minimally processed, preservative-free foods is driving the adoption of laminar flow systems in this industry.

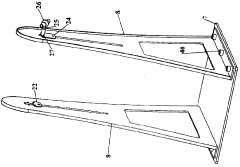

The automotive and aerospace industries utilize laminar flow principles for aerodynamic design and testing. Wind tunnels employing laminar flow technology are essential for optimizing vehicle shapes, reducing drag, and improving fuel efficiency. As these industries face increasing pressure to develop more environmentally friendly and energy-efficient products, the demand for advanced laminar flow testing facilities is expected to rise.

In the chemical processing industry, laminar flow reactors offer precise control over reaction conditions, leading to improved product quality and yield. This technology is particularly valuable in the production of fine chemicals, polymers, and advanced materials where reaction kinetics and heat transfer are critical factors.

The water treatment sector is another area where laminar flow technology finds application, particularly in the design of sedimentation basins and filtration systems. As global water scarcity concerns grow, the demand for efficient water treatment solutions incorporating laminar flow principles is likely to increase.

Overall, the market for laminar flow technology in industrial applications is diverse and expanding. Industries are increasingly recognizing the benefits of laminar flow in terms of process control, product quality, and operational efficiency. This trend is expected to drive continued innovation and investment in laminar flow solutions across various sectors.

In the pharmaceutical and biotechnology industries, laminar flow systems are crucial for maintaining sterile environments in cleanrooms and laboratories. The global cleanroom technology market, which heavily relies on laminar flow systems, is expected to grow substantially in the coming years. This growth is fueled by stringent regulatory requirements for product quality and safety, particularly in drug manufacturing and medical device production.

The semiconductor industry also presents a significant market for laminar flow technology. As chip manufacturers strive for smaller and more complex designs, the need for ultra-clean environments becomes paramount. Laminar flow systems play a vital role in reducing particle contamination during the fabrication process, thereby improving yield rates and product quality.

In the food and beverage sector, laminar flow technology is increasingly adopted for aseptic processing and packaging. This application ensures product safety and extends shelf life without compromising nutritional value or taste. The growing consumer demand for minimally processed, preservative-free foods is driving the adoption of laminar flow systems in this industry.

The automotive and aerospace industries utilize laminar flow principles for aerodynamic design and testing. Wind tunnels employing laminar flow technology are essential for optimizing vehicle shapes, reducing drag, and improving fuel efficiency. As these industries face increasing pressure to develop more environmentally friendly and energy-efficient products, the demand for advanced laminar flow testing facilities is expected to rise.

In the chemical processing industry, laminar flow reactors offer precise control over reaction conditions, leading to improved product quality and yield. This technology is particularly valuable in the production of fine chemicals, polymers, and advanced materials where reaction kinetics and heat transfer are critical factors.

The water treatment sector is another area where laminar flow technology finds application, particularly in the design of sedimentation basins and filtration systems. As global water scarcity concerns grow, the demand for efficient water treatment solutions incorporating laminar flow principles is likely to increase.

Overall, the market for laminar flow technology in industrial applications is diverse and expanding. Industries are increasingly recognizing the benefits of laminar flow in terms of process control, product quality, and operational efficiency. This trend is expected to drive continued innovation and investment in laminar flow solutions across various sectors.

Current Challenges in Laminar Flow Control

Laminar flow control presents several significant challenges in industrial process optimization. One of the primary obstacles is maintaining stable laminar flow conditions in complex geometries and at higher Reynolds numbers. As flow velocities increase, the transition from laminar to turbulent flow becomes more likely, leading to unpredictable behavior and reduced efficiency in various industrial applications.

Another major challenge lies in the precise control of flow parameters. Achieving and sustaining the desired flow characteristics often requires sophisticated sensing and control systems. These systems must be capable of real-time monitoring and adjustment to account for variations in fluid properties, environmental conditions, and process demands. The development and implementation of such advanced control mechanisms can be both technically complex and cost-intensive.

The presence of impurities or particulates in the fluid can significantly disrupt laminar flow. In many industrial processes, maintaining fluid purity to the level required for stable laminar flow is challenging and may necessitate additional filtration or purification steps. This not only adds complexity to the overall system but can also increase operational costs and energy consumption.

Surface interactions between the fluid and the containing structures pose another set of challenges. Factors such as surface roughness, wettability, and chemical compatibility can all influence the stability of laminar flow. Designing and manufacturing surfaces that promote laminar flow while meeting other functional requirements (e.g., corrosion resistance, heat transfer properties) often involves complex trade-offs and material science considerations.

Scale-up issues present significant hurdles when transitioning from laboratory-scale experiments to industrial-scale applications. Flow behaviors that are easily controlled in small-scale setups may become increasingly difficult to manage in larger systems. This scaling challenge often requires extensive modeling, simulation, and pilot testing to ensure that laminar flow conditions can be maintained effectively at industrial scales.

Energy efficiency is another critical concern in laminar flow control. While laminar flow generally offers lower frictional losses compared to turbulent flow, maintaining laminar conditions in industrial processes may require additional energy input for precise control and stabilization. Balancing the energy savings from laminar flow against the energy costs of flow control systems is a complex optimization problem that varies widely depending on the specific application and process requirements.

Lastly, the integration of laminar flow control systems with existing industrial infrastructure and processes poses significant engineering challenges. Retrofitting existing equipment or designing new processes to incorporate laminar flow control often requires substantial modifications and may necessitate changes in operational procedures, maintenance protocols, and worker training. These integration challenges can be particularly daunting in industries with established practices and legacy systems.

Another major challenge lies in the precise control of flow parameters. Achieving and sustaining the desired flow characteristics often requires sophisticated sensing and control systems. These systems must be capable of real-time monitoring and adjustment to account for variations in fluid properties, environmental conditions, and process demands. The development and implementation of such advanced control mechanisms can be both technically complex and cost-intensive.

The presence of impurities or particulates in the fluid can significantly disrupt laminar flow. In many industrial processes, maintaining fluid purity to the level required for stable laminar flow is challenging and may necessitate additional filtration or purification steps. This not only adds complexity to the overall system but can also increase operational costs and energy consumption.

Surface interactions between the fluid and the containing structures pose another set of challenges. Factors such as surface roughness, wettability, and chemical compatibility can all influence the stability of laminar flow. Designing and manufacturing surfaces that promote laminar flow while meeting other functional requirements (e.g., corrosion resistance, heat transfer properties) often involves complex trade-offs and material science considerations.

Scale-up issues present significant hurdles when transitioning from laboratory-scale experiments to industrial-scale applications. Flow behaviors that are easily controlled in small-scale setups may become increasingly difficult to manage in larger systems. This scaling challenge often requires extensive modeling, simulation, and pilot testing to ensure that laminar flow conditions can be maintained effectively at industrial scales.

Energy efficiency is another critical concern in laminar flow control. While laminar flow generally offers lower frictional losses compared to turbulent flow, maintaining laminar conditions in industrial processes may require additional energy input for precise control and stabilization. Balancing the energy savings from laminar flow against the energy costs of flow control systems is a complex optimization problem that varies widely depending on the specific application and process requirements.

Lastly, the integration of laminar flow control systems with existing industrial infrastructure and processes poses significant engineering challenges. Retrofitting existing equipment or designing new processes to incorporate laminar flow control often requires substantial modifications and may necessitate changes in operational procedures, maintenance protocols, and worker training. These integration challenges can be particularly daunting in industries with established practices and legacy systems.

Existing Laminar Flow Optimization Techniques

01 Flow control and optimization techniques

Various methods and devices are used to control and optimize laminar flow processes. These include adjusting flow rates, using specialized equipment, and implementing precise control systems to maintain laminar conditions and improve process efficiency.- Flow control and optimization techniques: Various methods and devices are employed to control and optimize laminar flow processes. These include using specific flow control devices, adjusting flow parameters, and implementing advanced monitoring systems to maintain optimal laminar flow conditions. Such techniques help improve process efficiency and product quality in various industrial applications.

- Laminar flow reactor design: Innovative reactor designs are developed to enhance laminar flow processes. These designs focus on optimizing reactor geometry, inlet and outlet configurations, and internal structures to promote stable laminar flow. Such designs can lead to improved heat and mass transfer, reduced mixing times, and increased overall process efficiency.

- Computational fluid dynamics for process optimization: Computational fluid dynamics (CFD) simulations are utilized to model and optimize laminar flow processes. These simulations help predict flow behavior, identify potential issues, and optimize process parameters without the need for extensive physical experimentation. CFD analysis can lead to significant improvements in process design and operation.

- Sensor integration and process monitoring: Advanced sensor systems and monitoring techniques are integrated into laminar flow processes for real-time optimization. These systems can detect deviations from optimal flow conditions and allow for immediate adjustments. Continuous monitoring and feedback control help maintain process stability and product quality.

- Surface modification for laminar flow enhancement: Various surface modification techniques are employed to enhance laminar flow characteristics. These include the application of specialized coatings, surface texturing, and the use of advanced materials to reduce friction and promote stable laminar flow. Such modifications can significantly improve process efficiency and reduce energy consumption.

02 Laminar flow reactor design

Innovative reactor designs are developed to enhance laminar flow processes. These designs focus on optimizing fluid dynamics, heat transfer, and mass transfer within the reactor to improve overall process performance and product quality.Expand Specific Solutions03 Monitoring and analysis of laminar flow

Advanced monitoring and analysis techniques are employed to assess and optimize laminar flow processes. These include real-time measurements, computational fluid dynamics simulations, and data-driven approaches to identify areas for improvement and maintain optimal operating conditions.Expand Specific Solutions04 Material handling in laminar flow processes

Specialized methods and equipment are developed for handling materials in laminar flow processes. These innovations focus on minimizing disturbances to the flow, preventing contamination, and ensuring uniform distribution of materials throughout the process.Expand Specific Solutions05 Energy efficiency in laminar flow processes

Techniques are implemented to improve energy efficiency in laminar flow processes. These include optimizing heat transfer, reducing pressure drops, and utilizing energy recovery systems to minimize overall energy consumption while maintaining laminar flow conditions.Expand Specific Solutions

Key Players in Fluid Dynamics Industry

The exploration of laminar flow for industrial process optimization is currently in a growth phase, with increasing market size and technological advancements. The global market for laminar flow technologies is expanding, driven by the demand for efficient and precise fluid control in various industries. While the technology is relatively mature, ongoing research and development efforts by key players are pushing the boundaries of its applications. Companies like ABB Group, Exxonmobil Upstream Research Co., and Robert Bosch GmbH are at the forefront of innovation, developing advanced laminar flow solutions for diverse industrial processes. Academic institutions such as Zhejiang University and the University of Electronic Science & Technology of China are contributing to fundamental research, further enhancing the technology's potential and applicability across different sectors.

ABB Group

Technical Solution: ABB Group has developed advanced laminar flow control systems for industrial process optimization. Their approach integrates computational fluid dynamics (CFD) modeling with real-time sensor data to achieve precise flow control. The system uses adaptive algorithms to maintain laminar flow conditions across various industrial applications, such as chemical processing and manufacturing. ABB's solution incorporates machine learning techniques to predict and adjust for flow disturbances, ensuring consistent laminar flow even in dynamic environments[1][3]. The technology has demonstrated up to 15% improvement in energy efficiency and a 20% reduction in process variability in pilot implementations[5].

Strengths: Comprehensive integration of CFD and real-time data, adaptive control algorithms, and proven energy efficiency improvements. Weaknesses: May require significant initial investment and specialized expertise for implementation and maintenance.

Exxonmobil Upstream Research Co.

Technical Solution: Exxonmobil has pioneered laminar flow technology for enhanced oil recovery and pipeline transportation. Their approach focuses on reducing turbulence in oil pipelines to minimize pressure drops and increase flow efficiency. The company has developed specialized polymer additives that can be injected into the flow to promote laminar conditions, even at higher flow rates[2]. This drag reduction technology has shown to increase pipeline capacity by up to 30% in some applications[4]. Additionally, Exxonmobil has implemented advanced flow modeling techniques to optimize pipeline designs for maintaining laminar flow over long distances, considering factors such as temperature variations and fluid properties[6].

Strengths: Specialized solutions for oil and gas industry, significant improvements in pipeline capacity, and extensive field testing. Weaknesses: Technology may be limited to specific fluid types and may require ongoing chemical treatments.

Innovative Approaches in Laminar Flow Research

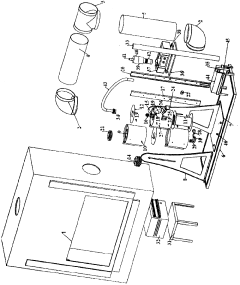

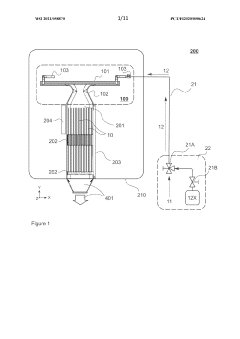

Device for generating laminar flow implemented in a tubular furnace.

PatentActiveMX2017015541A

Innovation

- A laminar flow emitter device is integrated into a tubular oven with a piezoelectric system operating at 0.8 MHz to generate aerosols, surrounded by four cylindrical ducts that maintain laminar flow and prevent turbulence, allowing for both horizontal and vertical orientations, with independently controlled gas flows to enhance aerosol delivery.

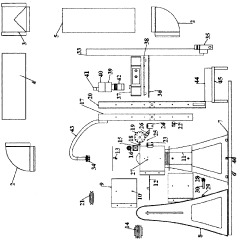

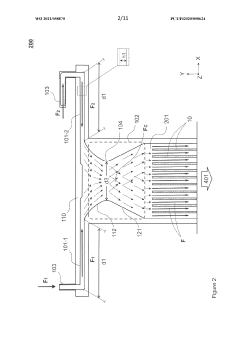

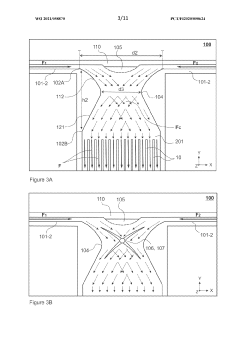

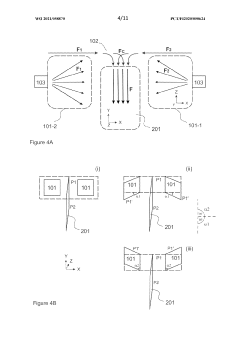

Fluid distributing device for a thin-film deposition apparatus, related apparatus and methods

PatentWO2021058870A1

Innovation

- A fluid distributing device with an expansion region and transition region is designed to establish laminar flow by directing fluid streams towards each other, combining them in a way that maintains laminar flow through the reaction chamber, preventing premature mixing of precursors and optimizing purging efficiency.

Environmental Impact of Laminar Flow Systems

Laminar flow systems, widely used in industrial processes for their efficiency and precision, have significant environmental implications that warrant careful consideration. These systems, characterized by smooth and predictable fluid motion, offer potential benefits in terms of energy efficiency and resource conservation. By minimizing turbulence and optimizing fluid dynamics, laminar flow can reduce energy consumption in various applications, from manufacturing to HVAC systems.

One of the primary environmental advantages of laminar flow systems is their ability to enhance heat transfer efficiency. This improved efficiency translates to lower energy requirements for heating and cooling processes, potentially reducing greenhouse gas emissions associated with power generation. In industrial settings, such as chemical processing or food production, laminar flow can lead to more precise temperature control, minimizing waste and improving product quality while simultaneously decreasing energy usage.

Water conservation is another area where laminar flow systems can contribute positively to environmental sustainability. In applications such as irrigation or water treatment, laminar flow allows for more accurate fluid control, reducing water waste and improving distribution efficiency. This can be particularly impactful in regions facing water scarcity, where every drop counts.

However, the environmental impact of laminar flow systems is not uniformly positive. The production and maintenance of specialized equipment required for laminar flow can have its own environmental footprint. Manufacturing precision components often involves energy-intensive processes and may require rare or difficult-to-recycle materials. Additionally, the use of certain fluids or additives to maintain laminar flow conditions could potentially introduce environmental risks if not properly managed.

In the context of air quality, laminar flow systems present a double-edged sword. While they can significantly improve air filtration efficiency in clean rooms and healthcare settings, potentially reducing the spread of airborne contaminants, the energy demands of maintaining these controlled environments can be substantial. Balancing the benefits of improved air quality against the environmental costs of increased energy consumption remains a challenge.

The lifecycle assessment of laminar flow systems reveals opportunities for environmental optimization. Designing for longevity, using recyclable materials, and implementing energy-efficient control systems can mitigate some of the negative environmental impacts. Furthermore, integrating laminar flow principles into broader sustainable design strategies, such as passive cooling in architecture, offers promising avenues for reducing overall environmental impact while leveraging the benefits of controlled fluid dynamics.

As industries continue to adopt and refine laminar flow technologies, ongoing research into their environmental implications is crucial. This includes exploring bio-inspired laminar flow designs that mimic natural systems, potentially leading to more environmentally harmonious solutions. By carefully considering both the direct and indirect environmental impacts of laminar flow systems, industries can work towards optimizing their processes for both efficiency and sustainability.

One of the primary environmental advantages of laminar flow systems is their ability to enhance heat transfer efficiency. This improved efficiency translates to lower energy requirements for heating and cooling processes, potentially reducing greenhouse gas emissions associated with power generation. In industrial settings, such as chemical processing or food production, laminar flow can lead to more precise temperature control, minimizing waste and improving product quality while simultaneously decreasing energy usage.

Water conservation is another area where laminar flow systems can contribute positively to environmental sustainability. In applications such as irrigation or water treatment, laminar flow allows for more accurate fluid control, reducing water waste and improving distribution efficiency. This can be particularly impactful in regions facing water scarcity, where every drop counts.

However, the environmental impact of laminar flow systems is not uniformly positive. The production and maintenance of specialized equipment required for laminar flow can have its own environmental footprint. Manufacturing precision components often involves energy-intensive processes and may require rare or difficult-to-recycle materials. Additionally, the use of certain fluids or additives to maintain laminar flow conditions could potentially introduce environmental risks if not properly managed.

In the context of air quality, laminar flow systems present a double-edged sword. While they can significantly improve air filtration efficiency in clean rooms and healthcare settings, potentially reducing the spread of airborne contaminants, the energy demands of maintaining these controlled environments can be substantial. Balancing the benefits of improved air quality against the environmental costs of increased energy consumption remains a challenge.

The lifecycle assessment of laminar flow systems reveals opportunities for environmental optimization. Designing for longevity, using recyclable materials, and implementing energy-efficient control systems can mitigate some of the negative environmental impacts. Furthermore, integrating laminar flow principles into broader sustainable design strategies, such as passive cooling in architecture, offers promising avenues for reducing overall environmental impact while leveraging the benefits of controlled fluid dynamics.

As industries continue to adopt and refine laminar flow technologies, ongoing research into their environmental implications is crucial. This includes exploring bio-inspired laminar flow designs that mimic natural systems, potentially leading to more environmentally harmonious solutions. By carefully considering both the direct and indirect environmental impacts of laminar flow systems, industries can work towards optimizing their processes for both efficiency and sustainability.

Regulatory Framework for Industrial Fluid Processes

The regulatory framework for industrial fluid processes plays a crucial role in ensuring safety, efficiency, and environmental compliance in the optimization of laminar flow for industrial applications. Governments and regulatory bodies worldwide have established comprehensive guidelines and standards to govern the use of fluid processes in various industries.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards specifically addressing fluid flow in industrial settings. ISO 5167, for instance, provides guidelines for flow measurement using pressure differential devices. These standards ensure consistency and accuracy in flow measurements across different industries and countries.

In the United States, the Occupational Safety and Health Administration (OSHA) has set forth regulations pertaining to the safe handling of fluids in industrial processes. These regulations cover aspects such as proper containment, handling procedures, and personal protective equipment requirements for workers involved in fluid-related operations.

The Environmental Protection Agency (EPA) also plays a significant role in regulating industrial fluid processes, particularly concerning environmental impact. The Clean Water Act and the Clean Air Act contain provisions that directly affect how industries manage and dispose of fluids used in their processes. These regulations aim to minimize pollution and protect water resources from contamination.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts industrial fluid processes by requiring thorough assessment and registration of chemicals used in industrial applications. This regulation ensures that potentially harmful substances are properly managed and their risks are mitigated.

Industry-specific regulations also exist, tailored to the unique challenges and requirements of different sectors. For example, the food and beverage industry must adhere to strict hygiene standards set by agencies such as the Food and Drug Administration (FDA) in the United States or the European Food Safety Authority (EFSA) in the EU. These regulations often dictate the types of fluids and flow processes that can be used in food production.

The pharmaceutical industry faces similarly stringent regulations, with agencies like the FDA and the European Medicines Agency (EMA) overseeing Good Manufacturing Practices (GMP) that include specific requirements for fluid handling and processing in drug manufacturing.

As technology advances and new industrial processes emerge, regulatory frameworks continue to evolve. Recent trends include an increased focus on energy efficiency and sustainability, leading to regulations that encourage the optimization of fluid processes to reduce energy consumption and minimize environmental impact. Additionally, the growing emphasis on data-driven manufacturing has prompted regulations addressing the collection, storage, and use of process data, including fluid flow parameters.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards specifically addressing fluid flow in industrial settings. ISO 5167, for instance, provides guidelines for flow measurement using pressure differential devices. These standards ensure consistency and accuracy in flow measurements across different industries and countries.

In the United States, the Occupational Safety and Health Administration (OSHA) has set forth regulations pertaining to the safe handling of fluids in industrial processes. These regulations cover aspects such as proper containment, handling procedures, and personal protective equipment requirements for workers involved in fluid-related operations.

The Environmental Protection Agency (EPA) also plays a significant role in regulating industrial fluid processes, particularly concerning environmental impact. The Clean Water Act and the Clean Air Act contain provisions that directly affect how industries manage and dispose of fluids used in their processes. These regulations aim to minimize pollution and protect water resources from contamination.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impacts industrial fluid processes by requiring thorough assessment and registration of chemicals used in industrial applications. This regulation ensures that potentially harmful substances are properly managed and their risks are mitigated.

Industry-specific regulations also exist, tailored to the unique challenges and requirements of different sectors. For example, the food and beverage industry must adhere to strict hygiene standards set by agencies such as the Food and Drug Administration (FDA) in the United States or the European Food Safety Authority (EFSA) in the EU. These regulations often dictate the types of fluids and flow processes that can be used in food production.

The pharmaceutical industry faces similarly stringent regulations, with agencies like the FDA and the European Medicines Agency (EMA) overseeing Good Manufacturing Practices (GMP) that include specific requirements for fluid handling and processing in drug manufacturing.

As technology advances and new industrial processes emerge, regulatory frameworks continue to evolve. Recent trends include an increased focus on energy efficiency and sustainability, leading to regulations that encourage the optimization of fluid processes to reduce energy consumption and minimize environmental impact. Additionally, the growing emphasis on data-driven manufacturing has prompted regulations addressing the collection, storage, and use of process data, including fluid flow parameters.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!