Laminar Flow Control for Turbulence Reduction

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Control Background and Objectives

Laminar flow control (LFC) has been a subject of intense research in aerodynamics for decades, driven by the potential for significant drag reduction and improved fuel efficiency in aircraft and other vehicles. The concept of LFC dates back to the early 20th century, with pioneering work by Ludwig Prandtl and his colleagues. Since then, the field has evolved through various stages of theoretical development, experimental validation, and practical implementation attempts.

The primary objective of LFC research is to delay or prevent the transition from laminar to turbulent flow over aerodynamic surfaces. This transition is a critical phenomenon in fluid dynamics, as turbulent flow generally results in higher skin friction drag compared to laminar flow. By maintaining laminar flow over a larger portion of an aircraft's surface, LFC techniques aim to reduce overall drag, leading to improved fuel efficiency and extended range.

Over the years, LFC research has explored various approaches, including passive and active control methods. Passive techniques often involve careful shaping of aerodynamic surfaces to create favorable pressure gradients that stabilize the laminar boundary layer. Active methods, on the other hand, employ mechanisms such as suction or blowing to directly influence the boundary layer behavior.

The development of LFC technology has been closely tied to advancements in materials science, computational fluid dynamics, and control systems. Modern LFC research benefits from sophisticated numerical simulations that allow for detailed analysis of flow behavior and optimization of control strategies. Additionally, progress in sensor technology and real-time data processing has opened up new possibilities for adaptive LFC systems that can respond dynamically to changing flow conditions.

Despite its long history, LFC remains a challenging and active area of research. Current objectives include improving the robustness and reliability of LFC systems, reducing their complexity and weight penalties, and expanding their effective operating envelope. Researchers are also exploring novel approaches, such as hybrid laminar flow control (HLFC) systems that combine passive and active techniques, and the integration of LFC with other drag reduction technologies.

The potential impact of successful LFC implementation is substantial. Estimates suggest that effective laminar flow control could reduce aircraft drag by up to 15%, translating to significant fuel savings and reduced emissions. This aligns well with the aviation industry's goals for sustainability and environmental responsibility. As such, LFC research continues to be a priority for aerospace companies, research institutions, and government agencies worldwide.

The primary objective of LFC research is to delay or prevent the transition from laminar to turbulent flow over aerodynamic surfaces. This transition is a critical phenomenon in fluid dynamics, as turbulent flow generally results in higher skin friction drag compared to laminar flow. By maintaining laminar flow over a larger portion of an aircraft's surface, LFC techniques aim to reduce overall drag, leading to improved fuel efficiency and extended range.

Over the years, LFC research has explored various approaches, including passive and active control methods. Passive techniques often involve careful shaping of aerodynamic surfaces to create favorable pressure gradients that stabilize the laminar boundary layer. Active methods, on the other hand, employ mechanisms such as suction or blowing to directly influence the boundary layer behavior.

The development of LFC technology has been closely tied to advancements in materials science, computational fluid dynamics, and control systems. Modern LFC research benefits from sophisticated numerical simulations that allow for detailed analysis of flow behavior and optimization of control strategies. Additionally, progress in sensor technology and real-time data processing has opened up new possibilities for adaptive LFC systems that can respond dynamically to changing flow conditions.

Despite its long history, LFC remains a challenging and active area of research. Current objectives include improving the robustness and reliability of LFC systems, reducing their complexity and weight penalties, and expanding their effective operating envelope. Researchers are also exploring novel approaches, such as hybrid laminar flow control (HLFC) systems that combine passive and active techniques, and the integration of LFC with other drag reduction technologies.

The potential impact of successful LFC implementation is substantial. Estimates suggest that effective laminar flow control could reduce aircraft drag by up to 15%, translating to significant fuel savings and reduced emissions. This aligns well with the aviation industry's goals for sustainability and environmental responsibility. As such, LFC research continues to be a priority for aerospace companies, research institutions, and government agencies worldwide.

Aerodynamic Efficiency Market Analysis

The market for aerodynamic efficiency technologies, particularly those focused on laminar flow control for turbulence reduction, has been experiencing significant growth in recent years. This growth is primarily driven by the aviation industry's increasing emphasis on fuel efficiency and environmental sustainability. As airlines and aircraft manufacturers face mounting pressure to reduce carbon emissions and operating costs, the demand for advanced aerodynamic solutions has surged.

The global commercial aviation market, which is the primary beneficiary of laminar flow control technologies, is projected to grow substantially over the next decade. This growth is fueled by increasing air travel demand, especially in emerging markets, and the need for fleet modernization in developed regions. The push for more fuel-efficient aircraft has become a key driver in this market, with airlines seeking to reduce their fuel consumption by implementing cutting-edge aerodynamic technologies.

Laminar flow control systems, which aim to reduce drag by maintaining smooth airflow over aircraft surfaces, have garnered significant attention from both aircraft manufacturers and airlines. The potential fuel savings offered by these technologies can range from 5% to 15%, depending on the specific implementation and flight conditions. This translates to substantial cost savings for airlines and a significant reduction in greenhouse gas emissions.

The market for laminar flow control technologies extends beyond commercial aviation. Military aviation, business jets, and even high-performance automobiles are exploring the benefits of advanced aerodynamic efficiency solutions. This diversification of applications is expected to further drive market growth and technological innovation in the coming years.

However, the market faces several challenges. The implementation of laminar flow control systems often requires significant upfront investment in research, development, and integration. Additionally, the complexity of these systems can lead to increased maintenance requirements and potential reliability issues, which may deter some potential adopters.

Despite these challenges, the long-term economic and environmental benefits of improved aerodynamic efficiency are driving continued investment in this field. Major aircraft manufacturers are incorporating laminar flow control technologies into their latest designs, while retrofit solutions are being developed for existing aircraft. This trend is expected to accelerate as regulatory pressures to reduce aviation's environmental impact intensify.

In conclusion, the market for aerodynamic efficiency technologies, particularly those focused on laminar flow control, is poised for substantial growth. The combination of economic incentives, environmental regulations, and technological advancements is creating a favorable environment for innovation and adoption in this field. As the aviation industry continues to prioritize fuel efficiency and sustainability, the demand for advanced aerodynamic solutions is expected to remain strong, driving further research and development in laminar flow control and related technologies.

The global commercial aviation market, which is the primary beneficiary of laminar flow control technologies, is projected to grow substantially over the next decade. This growth is fueled by increasing air travel demand, especially in emerging markets, and the need for fleet modernization in developed regions. The push for more fuel-efficient aircraft has become a key driver in this market, with airlines seeking to reduce their fuel consumption by implementing cutting-edge aerodynamic technologies.

Laminar flow control systems, which aim to reduce drag by maintaining smooth airflow over aircraft surfaces, have garnered significant attention from both aircraft manufacturers and airlines. The potential fuel savings offered by these technologies can range from 5% to 15%, depending on the specific implementation and flight conditions. This translates to substantial cost savings for airlines and a significant reduction in greenhouse gas emissions.

The market for laminar flow control technologies extends beyond commercial aviation. Military aviation, business jets, and even high-performance automobiles are exploring the benefits of advanced aerodynamic efficiency solutions. This diversification of applications is expected to further drive market growth and technological innovation in the coming years.

However, the market faces several challenges. The implementation of laminar flow control systems often requires significant upfront investment in research, development, and integration. Additionally, the complexity of these systems can lead to increased maintenance requirements and potential reliability issues, which may deter some potential adopters.

Despite these challenges, the long-term economic and environmental benefits of improved aerodynamic efficiency are driving continued investment in this field. Major aircraft manufacturers are incorporating laminar flow control technologies into their latest designs, while retrofit solutions are being developed for existing aircraft. This trend is expected to accelerate as regulatory pressures to reduce aviation's environmental impact intensify.

In conclusion, the market for aerodynamic efficiency technologies, particularly those focused on laminar flow control, is poised for substantial growth. The combination of economic incentives, environmental regulations, and technological advancements is creating a favorable environment for innovation and adoption in this field. As the aviation industry continues to prioritize fuel efficiency and sustainability, the demand for advanced aerodynamic solutions is expected to remain strong, driving further research and development in laminar flow control and related technologies.

Current Challenges in Turbulence Reduction

Despite significant advancements in turbulence reduction techniques, several challenges persist in the field of laminar flow control. One of the primary obstacles is the complexity of turbulent flow dynamics, which makes it difficult to predict and control flow behavior accurately. The non-linear nature of turbulence and its multiscale characteristics pose significant challenges in developing effective control strategies.

Another major challenge is the practical implementation of laminar flow control systems in real-world applications. While many theoretical models and laboratory experiments have shown promising results, scaling these solutions to full-scale aircraft or other industrial applications remains problematic. Issues such as weight penalties, increased system complexity, and maintenance requirements often offset the potential benefits of laminar flow control.

The energy efficiency of laminar flow control systems is also a concern. Active control methods, such as suction or blowing, require additional power input, which can negate the drag reduction benefits in some cases. Developing passive control techniques that are both effective and energy-efficient remains an ongoing challenge in the field.

Furthermore, the robustness of laminar flow control systems in varying operational conditions is a significant hurdle. Environmental factors such as atmospheric turbulence, temperature variations, and surface contamination can disrupt the effectiveness of laminar flow control techniques. Designing systems that can adapt to these changing conditions while maintaining performance is a complex task.

The integration of laminar flow control with other aircraft systems and structures presents additional challenges. Compatibility issues with de-icing systems, noise reduction technologies, and structural requirements must be addressed to ensure the overall performance and safety of the aircraft are not compromised.

Lastly, the cost-effectiveness of laminar flow control technologies remains a significant barrier to widespread adoption. The initial investment and ongoing maintenance costs associated with these systems can be substantial, and the long-term economic benefits are not always clear, particularly for commercial aviation applications.

Addressing these challenges requires a multidisciplinary approach, combining advances in fluid dynamics, materials science, control theory, and systems engineering. Continued research and development efforts are necessary to overcome these obstacles and fully realize the potential of laminar flow control for turbulence reduction in practical applications.

Another major challenge is the practical implementation of laminar flow control systems in real-world applications. While many theoretical models and laboratory experiments have shown promising results, scaling these solutions to full-scale aircraft or other industrial applications remains problematic. Issues such as weight penalties, increased system complexity, and maintenance requirements often offset the potential benefits of laminar flow control.

The energy efficiency of laminar flow control systems is also a concern. Active control methods, such as suction or blowing, require additional power input, which can negate the drag reduction benefits in some cases. Developing passive control techniques that are both effective and energy-efficient remains an ongoing challenge in the field.

Furthermore, the robustness of laminar flow control systems in varying operational conditions is a significant hurdle. Environmental factors such as atmospheric turbulence, temperature variations, and surface contamination can disrupt the effectiveness of laminar flow control techniques. Designing systems that can adapt to these changing conditions while maintaining performance is a complex task.

The integration of laminar flow control with other aircraft systems and structures presents additional challenges. Compatibility issues with de-icing systems, noise reduction technologies, and structural requirements must be addressed to ensure the overall performance and safety of the aircraft are not compromised.

Lastly, the cost-effectiveness of laminar flow control technologies remains a significant barrier to widespread adoption. The initial investment and ongoing maintenance costs associated with these systems can be substantial, and the long-term economic benefits are not always clear, particularly for commercial aviation applications.

Addressing these challenges requires a multidisciplinary approach, combining advances in fluid dynamics, materials science, control theory, and systems engineering. Continued research and development efforts are necessary to overcome these obstacles and fully realize the potential of laminar flow control for turbulence reduction in practical applications.

Existing Laminar Flow Control Solutions

01 Laminar flow control systems for aircraft

Laminar flow control systems are used in aircraft to reduce drag and improve fuel efficiency. These systems typically involve suction or blowing mechanisms on the aircraft's surfaces to maintain laminar flow and prevent turbulence. The technology can be applied to various parts of the aircraft, including wings, fuselage, and tail surfaces.- Laminar flow control systems for aircraft: Laminar flow control systems are used in aircraft to reduce drag and improve fuel efficiency. These systems typically involve suction or blowing mechanisms on the aircraft's surfaces to maintain laminar flow and prevent turbulence. The technology can be applied to various parts of the aircraft, including wings, fuselage, and tail surfaces.

- Turbulence detection and measurement techniques: Various methods and devices are employed to detect and measure turbulence in fluid flows. These techniques may involve sensors, imaging systems, or other measurement tools to analyze flow patterns and identify areas of turbulence. The data collected can be used to optimize flow control systems and improve overall performance in various applications.

- Flow control in industrial processes: Laminar flow control and turbulence management are crucial in many industrial processes, such as chemical manufacturing, water treatment, and HVAC systems. Techniques may include the use of specialized equipment, flow straighteners, or surface modifications to maintain desired flow characteristics and minimize turbulence-induced inefficiencies.

- Microfluidic devices for laminar flow control: Microfluidic devices utilize laminar flow control principles to manipulate small volumes of fluids. These devices often employ specialized channel designs, surface treatments, or external forces to maintain laminar flow and prevent turbulence at the microscale. Applications include lab-on-a-chip technologies, medical diagnostics, and chemical analysis.

- Active flow control systems: Active flow control systems use dynamic mechanisms to manipulate fluid flow and reduce turbulence. These may include actuators, plasma generators, or other devices that can be adjusted in real-time to respond to changing flow conditions. Such systems find applications in aerospace, automotive, and energy industries to improve efficiency and performance.

02 Turbulence detection and measurement techniques

Various methods and devices are employed to detect and measure turbulence in fluid flows. These techniques may involve sensors, optical systems, or other measurement tools to analyze flow characteristics and identify turbulent regions. Such information is crucial for optimizing laminar flow control systems and improving overall fluid dynamics in various applications.Expand Specific Solutions03 Microstructures and surface modifications for laminar flow

Specialized surface treatments and microstructures can be used to promote laminar flow and reduce turbulence. These may include riblets, dimples, or other textured surfaces that alter the boundary layer characteristics. Such modifications can be applied to various surfaces, including aircraft, marine vessels, and industrial equipment to improve fluid dynamics and efficiency.Expand Specific Solutions04 Active flow control systems

Active flow control systems use dynamic mechanisms to manipulate fluid flow and maintain laminar conditions. These systems may employ actuators, plasma generators, or other devices to introduce controlled disturbances or energy into the flow field. By actively managing the flow characteristics, these systems can adapt to changing conditions and maintain optimal performance.Expand Specific Solutions05 Computational methods for laminar flow analysis

Advanced computational techniques are used to model and analyze laminar flow and turbulence. These methods may include computational fluid dynamics (CFD) simulations, machine learning algorithms, or other numerical approaches to predict flow behavior and optimize laminar flow control strategies. Such computational tools are essential for designing and refining laminar flow control systems across various applications.Expand Specific Solutions

Key Players in Aerospace and Fluid Dynamics

The research on Laminar Flow Control for Turbulence Reduction is in a developing stage, with significant potential for growth in aerospace and automotive industries. The market size is expanding as more companies recognize the benefits of reducing drag and improving fuel efficiency. Technologically, it's progressing from theoretical concepts to practical applications. Leading institutions like California Institute of Technology, Massachusetts Institute of Technology, and Airbus Operations are at the forefront, developing advanced algorithms and materials. Companies such as Airbus Defence & Space and NASA are also contributing to the field, indicating a competitive landscape with both academic and industrial players driving innovation.

California Institute of Technology

Technical Solution: Caltech's approach to laminar flow control focuses on innovative passive techniques and advanced flow sensing technologies. Their researchers have developed micro-structured surfaces that can passively maintain laminar flow over extended regions[7]. These surfaces are designed using principles from nature, such as shark skin-inspired riblets. Caltech has also made significant advancements in flow sensor technology, creating MEMS-based shear stress sensors that can detect the onset of turbulence with high precision[8]. This allows for real-time monitoring and potential active control of laminar flow. Furthermore, Caltech's computational fluid dynamics group has developed high-fidelity simulations to predict and optimize laminar flow control strategies for complex geometries[9].

Strengths: Cutting-edge passive control techniques, advanced sensor technology, and strong computational capabilities. Weaknesses: Potential challenges in scaling up technologies for large-scale applications and integration with existing systems.

Airbus Operations Ltd.

Technical Solution: Airbus Operations Ltd. has developed an advanced Hybrid Laminar Flow Control (HLFC) system for turbulence reduction. This technology combines passive and active flow control methods to maintain laminar flow over larger portions of aircraft surfaces. The system utilizes a perforated skin with suction to remove the boundary layer, preventing transition to turbulent flow[1]. Airbus has successfully tested this technology on the vertical tail plane of an A340-300 test aircraft, demonstrating potential drag reduction of up to 2% on long-range aircraft[2]. The company is also exploring the integration of HLFC with other aerodynamic innovations, such as optimized wing designs and adaptive surfaces, to further enhance overall aircraft efficiency[3].

Strengths: Proven drag reduction capability, potential for significant fuel savings, and integration with existing aircraft designs. Weaknesses: Complexity of the system, potential maintenance challenges, and limited effectiveness in certain flight conditions.

Innovative Turbulence Reduction Techniques

Laminar water jet with pliant member

PatentInactiveUS20060102758A1

Innovation

- A compact laminar flow water jet apparatus featuring a housing with a pliant member, filter members, and a controller element that generates an energetic pulse wave to disrupt and columnarize the flow, using materials like closed cell foam or rubber compounds to absorb surges and enhance laminarity, while minimizing size and complexity.

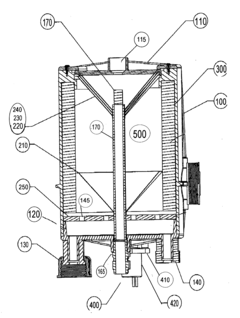

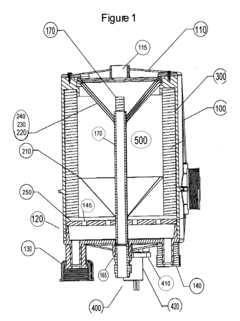

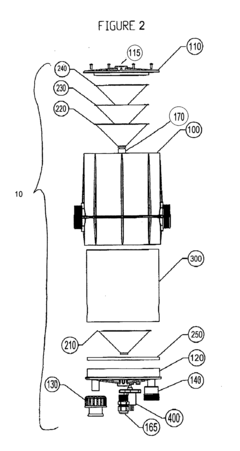

Method and device for laminarization of turbulent flow of continuous medium

PatentWO1993013321A1

Innovation

- A method involving a conical channel with a longitudinal axis of symmetry, where the cross-sectional area is reduced to achieve laminarization by controlling the flow's linear scores and coordinates, allowing for universal application across different scenarios by optimizing the channel's geometry and flow parameters.

Environmental Impact of Laminar Flow Technology

Laminar flow control technology, while primarily aimed at reducing turbulence and improving aerodynamic efficiency, also has significant environmental implications. The implementation of this technology in aircraft design can lead to substantial reductions in fuel consumption, which in turn results in decreased greenhouse gas emissions. Studies have shown that laminar flow control can potentially reduce aircraft drag by up to 15%, translating to a 7-10% reduction in overall fuel burn.

This reduction in fuel consumption has far-reaching environmental benefits. The aviation industry is responsible for approximately 2% of global CO2 emissions, and with air traffic projected to double every 15 years, the environmental impact of this sector is a growing concern. By implementing laminar flow control technologies, airlines can significantly reduce their carbon footprint, contributing to global efforts to mitigate climate change.

Moreover, the reduced fuel consumption also leads to a decrease in other pollutants such as nitrogen oxides (NOx) and particulate matter. These pollutants contribute to air quality degradation, particularly around airports and in flight corridors. By minimizing their release, laminar flow technology can help improve local air quality and reduce the health risks associated with air pollution.

The environmental benefits of laminar flow technology extend beyond emissions reduction. The improved fuel efficiency can also lead to a reduction in the overall demand for aviation fuel. This decreased demand can potentially slow the rate of fossil fuel extraction and refining, processes which themselves have significant environmental impacts including habitat destruction, water pollution, and greenhouse gas emissions.

However, it's important to consider the full lifecycle environmental impact of laminar flow technology. The manufacturing and maintenance of the specialized surfaces required for laminar flow control may involve energy-intensive processes or the use of materials with their own environmental footprints. Additionally, the disposal or recycling of these components at the end of their lifecycle must be taken into account when assessing the overall environmental impact.

In conclusion, while laminar flow control technology offers significant potential for reducing the environmental impact of aviation, a comprehensive lifecycle analysis is necessary to fully understand its net environmental effect. As research in this field progresses, it will be crucial to balance the benefits of reduced emissions with any potential environmental costs associated with the production and maintenance of this technology.

This reduction in fuel consumption has far-reaching environmental benefits. The aviation industry is responsible for approximately 2% of global CO2 emissions, and with air traffic projected to double every 15 years, the environmental impact of this sector is a growing concern. By implementing laminar flow control technologies, airlines can significantly reduce their carbon footprint, contributing to global efforts to mitigate climate change.

Moreover, the reduced fuel consumption also leads to a decrease in other pollutants such as nitrogen oxides (NOx) and particulate matter. These pollutants contribute to air quality degradation, particularly around airports and in flight corridors. By minimizing their release, laminar flow technology can help improve local air quality and reduce the health risks associated with air pollution.

The environmental benefits of laminar flow technology extend beyond emissions reduction. The improved fuel efficiency can also lead to a reduction in the overall demand for aviation fuel. This decreased demand can potentially slow the rate of fossil fuel extraction and refining, processes which themselves have significant environmental impacts including habitat destruction, water pollution, and greenhouse gas emissions.

However, it's important to consider the full lifecycle environmental impact of laminar flow technology. The manufacturing and maintenance of the specialized surfaces required for laminar flow control may involve energy-intensive processes or the use of materials with their own environmental footprints. Additionally, the disposal or recycling of these components at the end of their lifecycle must be taken into account when assessing the overall environmental impact.

In conclusion, while laminar flow control technology offers significant potential for reducing the environmental impact of aviation, a comprehensive lifecycle analysis is necessary to fully understand its net environmental effect. As research in this field progresses, it will be crucial to balance the benefits of reduced emissions with any potential environmental costs associated with the production and maintenance of this technology.

Regulatory Framework for Aerospace Innovations

The regulatory framework for aerospace innovations plays a crucial role in shaping the development and implementation of laminar flow control technologies for turbulence reduction. As the aviation industry continues to push the boundaries of efficiency and performance, regulatory bodies must adapt to ensure safety while fostering innovation.

The International Civil Aviation Organization (ICAO) sets global standards for aviation safety and environmental protection. In the context of laminar flow control, ICAO's Standards and Recommended Practices (SARPs) provide guidelines for aircraft design and operation. These standards are continuously updated to incorporate new technologies, including those related to aerodynamics and fuel efficiency.

National aviation authorities, such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA), are responsible for implementing and enforcing these regulations within their respective jurisdictions. These agencies work closely with industry stakeholders to develop certification processes for new technologies, including laminar flow control systems.

The certification process for laminar flow control technologies involves rigorous testing and validation to ensure compliance with safety standards. This includes extensive wind tunnel testing, computational fluid dynamics simulations, and flight tests to demonstrate the effectiveness and reliability of the technology. Regulatory bodies require manufacturers to provide comprehensive data on the performance, durability, and maintenance requirements of laminar flow control systems.

Environmental regulations also play a significant role in driving the development of laminar flow control technologies. The ICAO's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) sets ambitious targets for reducing aviation's carbon footprint. This regulatory framework incentivizes the adoption of fuel-efficient technologies, including laminar flow control, as airlines seek to meet emissions reduction goals.

Intellectual property regulations are another important aspect of the regulatory landscape. Patents and trade secrets related to laminar flow control technologies are protected by international agreements, such as the World Trade Organization's Agreement on Trade-Related Aspects of Intellectual Property Rights (TRIPS). These protections encourage innovation by ensuring that companies can benefit from their research and development investments.

As laminar flow control technologies continue to evolve, regulatory bodies must maintain a balance between ensuring safety and promoting innovation. This requires ongoing collaboration between regulators, industry stakeholders, and research institutions to develop appropriate standards and certification processes. The regulatory framework must be flexible enough to accommodate new technological advancements while maintaining the highest levels of safety and environmental protection in the aerospace industry.

The International Civil Aviation Organization (ICAO) sets global standards for aviation safety and environmental protection. In the context of laminar flow control, ICAO's Standards and Recommended Practices (SARPs) provide guidelines for aircraft design and operation. These standards are continuously updated to incorporate new technologies, including those related to aerodynamics and fuel efficiency.

National aviation authorities, such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA), are responsible for implementing and enforcing these regulations within their respective jurisdictions. These agencies work closely with industry stakeholders to develop certification processes for new technologies, including laminar flow control systems.

The certification process for laminar flow control technologies involves rigorous testing and validation to ensure compliance with safety standards. This includes extensive wind tunnel testing, computational fluid dynamics simulations, and flight tests to demonstrate the effectiveness and reliability of the technology. Regulatory bodies require manufacturers to provide comprehensive data on the performance, durability, and maintenance requirements of laminar flow control systems.

Environmental regulations also play a significant role in driving the development of laminar flow control technologies. The ICAO's Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) sets ambitious targets for reducing aviation's carbon footprint. This regulatory framework incentivizes the adoption of fuel-efficient technologies, including laminar flow control, as airlines seek to meet emissions reduction goals.

Intellectual property regulations are another important aspect of the regulatory landscape. Patents and trade secrets related to laminar flow control technologies are protected by international agreements, such as the World Trade Organization's Agreement on Trade-Related Aspects of Intellectual Property Rights (TRIPS). These protections encourage innovation by ensuring that companies can benefit from their research and development investments.

As laminar flow control technologies continue to evolve, regulatory bodies must maintain a balance between ensuring safety and promoting innovation. This requires ongoing collaboration between regulators, industry stakeholders, and research institutions to develop appropriate standards and certification processes. The regulatory framework must be flexible enough to accommodate new technological advancements while maintaining the highest levels of safety and environmental protection in the aerospace industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!