How to Ensure Optimal Conditions for Laminar Flow?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Fundamentals and Objectives

Laminar flow, characterized by smooth and predictable fluid motion, is a fundamental concept in fluid dynamics with critical applications across various industries. The evolution of laminar flow technology has been driven by the need for precise control over fluid behavior in fields such as aerospace, microfluidics, and biomedical engineering. As research progresses, the focus has shifted towards optimizing conditions to maintain and enhance laminar flow in increasingly complex systems.

The primary objective in laminar flow research is to develop methods and technologies that ensure stable and consistent fluid behavior under a wide range of conditions. This includes minimizing turbulence, reducing boundary layer effects, and controlling flow parameters with high precision. Achieving these goals is essential for improving the efficiency and reliability of numerous processes, from fuel injection systems in engines to drug delivery mechanisms in medical devices.

Recent technological advancements have expanded the scope of laminar flow applications, particularly in micro and nanoscale systems. The ability to manipulate fluids at these scales has opened up new possibilities in areas such as lab-on-a-chip devices, where laminar flow is crucial for accurate sample analysis and controlled reactions. Consequently, research efforts are increasingly focused on understanding and controlling laminar flow behavior in confined spaces and at interfaces between different materials.

One of the key trends in laminar flow technology is the development of smart materials and adaptive surfaces that can dynamically adjust to maintain optimal flow conditions. These innovations aim to create self-regulating systems capable of responding to changes in fluid properties or external factors, ensuring consistent laminar flow even in variable environments. This approach holds promise for enhancing the reliability and efficiency of fluid systems in diverse applications, from industrial processes to environmental monitoring.

The pursuit of optimal conditions for laminar flow also intersects with computational fluid dynamics (CFD) and machine learning technologies. Advanced simulation tools and predictive models are being developed to analyze complex flow scenarios and optimize system designs before physical prototyping. This integration of computational methods with experimental research is accelerating the pace of innovation in laminar flow technology, enabling more rapid development and refinement of flow control strategies.

As the field progresses, interdisciplinary collaboration is becoming increasingly important. Engineers, physicists, and materials scientists are working together to address the multifaceted challenges of maintaining laminar flow in diverse applications. This collaborative approach is driving the development of novel solutions that combine insights from multiple disciplines, pushing the boundaries of what is possible in fluid control and manipulation.

The primary objective in laminar flow research is to develop methods and technologies that ensure stable and consistent fluid behavior under a wide range of conditions. This includes minimizing turbulence, reducing boundary layer effects, and controlling flow parameters with high precision. Achieving these goals is essential for improving the efficiency and reliability of numerous processes, from fuel injection systems in engines to drug delivery mechanisms in medical devices.

Recent technological advancements have expanded the scope of laminar flow applications, particularly in micro and nanoscale systems. The ability to manipulate fluids at these scales has opened up new possibilities in areas such as lab-on-a-chip devices, where laminar flow is crucial for accurate sample analysis and controlled reactions. Consequently, research efforts are increasingly focused on understanding and controlling laminar flow behavior in confined spaces and at interfaces between different materials.

One of the key trends in laminar flow technology is the development of smart materials and adaptive surfaces that can dynamically adjust to maintain optimal flow conditions. These innovations aim to create self-regulating systems capable of responding to changes in fluid properties or external factors, ensuring consistent laminar flow even in variable environments. This approach holds promise for enhancing the reliability and efficiency of fluid systems in diverse applications, from industrial processes to environmental monitoring.

The pursuit of optimal conditions for laminar flow also intersects with computational fluid dynamics (CFD) and machine learning technologies. Advanced simulation tools and predictive models are being developed to analyze complex flow scenarios and optimize system designs before physical prototyping. This integration of computational methods with experimental research is accelerating the pace of innovation in laminar flow technology, enabling more rapid development and refinement of flow control strategies.

As the field progresses, interdisciplinary collaboration is becoming increasingly important. Engineers, physicists, and materials scientists are working together to address the multifaceted challenges of maintaining laminar flow in diverse applications. This collaborative approach is driving the development of novel solutions that combine insights from multiple disciplines, pushing the boundaries of what is possible in fluid control and manipulation.

Industrial Applications and Market Demand

Laminar flow technology has gained significant traction across various industrial sectors due to its ability to enhance process efficiency and product quality. The market demand for laminar flow solutions continues to grow, driven by stringent regulatory requirements and the increasing need for contamination control in critical manufacturing processes.

In the pharmaceutical and biotechnology industries, laminar flow systems are essential for maintaining sterile environments during drug production and research activities. The global pharmaceutical market, valued at over $1.4 trillion in 2021, is expected to expand further, fueling the demand for advanced laminar flow technologies. Cleanroom applications in these sectors require precise control of airflow to prevent particle contamination, making laminar flow systems indispensable.

The semiconductor industry, another major consumer of laminar flow technology, relies heavily on ultra-clean environments for chip manufacturing. With the global semiconductor market projected to reach $803 billion by 2028, the demand for sophisticated laminar flow solutions is set to increase. The push for smaller, more powerful chips necessitates even stricter contamination control measures, driving innovation in laminar flow systems.

In the food and beverage sector, laminar flow technology plays a crucial role in ensuring product safety and quality. As consumers become more health-conscious and regulatory bodies impose stricter hygiene standards, food manufacturers are increasingly adopting laminar flow systems in their production lines. This trend is particularly evident in the dairy, ready-to-eat meals, and beverage segments.

The aerospace industry also presents significant opportunities for laminar flow applications. In aircraft manufacturing, laminar flow is critical for creating aerodynamic surfaces that reduce drag and improve fuel efficiency. As the aviation industry focuses on developing more sustainable aircraft, the demand for advanced laminar flow solutions in wing and fuselage design is expected to grow.

Healthcare facilities, including hospitals and research laboratories, represent another substantial market for laminar flow technology. The need for sterile environments in operating rooms, intensive care units, and isolation wards drives the adoption of laminar flow systems. The global healthcare market's steady growth, coupled with increasing awareness of hospital-acquired infections, further boosts demand in this sector.

As industries continue to prioritize product quality, process efficiency, and regulatory compliance, the market for laminar flow solutions is poised for sustained growth. Manufacturers are increasingly seeking customized laminar flow systems that can be integrated into their existing production lines, creating opportunities for innovation and specialization in the field.

In the pharmaceutical and biotechnology industries, laminar flow systems are essential for maintaining sterile environments during drug production and research activities. The global pharmaceutical market, valued at over $1.4 trillion in 2021, is expected to expand further, fueling the demand for advanced laminar flow technologies. Cleanroom applications in these sectors require precise control of airflow to prevent particle contamination, making laminar flow systems indispensable.

The semiconductor industry, another major consumer of laminar flow technology, relies heavily on ultra-clean environments for chip manufacturing. With the global semiconductor market projected to reach $803 billion by 2028, the demand for sophisticated laminar flow solutions is set to increase. The push for smaller, more powerful chips necessitates even stricter contamination control measures, driving innovation in laminar flow systems.

In the food and beverage sector, laminar flow technology plays a crucial role in ensuring product safety and quality. As consumers become more health-conscious and regulatory bodies impose stricter hygiene standards, food manufacturers are increasingly adopting laminar flow systems in their production lines. This trend is particularly evident in the dairy, ready-to-eat meals, and beverage segments.

The aerospace industry also presents significant opportunities for laminar flow applications. In aircraft manufacturing, laminar flow is critical for creating aerodynamic surfaces that reduce drag and improve fuel efficiency. As the aviation industry focuses on developing more sustainable aircraft, the demand for advanced laminar flow solutions in wing and fuselage design is expected to grow.

Healthcare facilities, including hospitals and research laboratories, represent another substantial market for laminar flow technology. The need for sterile environments in operating rooms, intensive care units, and isolation wards drives the adoption of laminar flow systems. The global healthcare market's steady growth, coupled with increasing awareness of hospital-acquired infections, further boosts demand in this sector.

As industries continue to prioritize product quality, process efficiency, and regulatory compliance, the market for laminar flow solutions is poised for sustained growth. Manufacturers are increasingly seeking customized laminar flow systems that can be integrated into their existing production lines, creating opportunities for innovation and specialization in the field.

Current Challenges in Laminar Flow Control

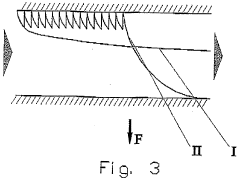

Laminar flow control faces several significant challenges in both research and practical applications. One of the primary obstacles is maintaining stable laminar flow conditions in complex geometries and under varying environmental factors. The transition from laminar to turbulent flow can occur due to subtle disturbances, making it difficult to predict and control flow behavior consistently.

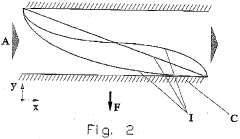

Surface roughness presents another major challenge. Even minor imperfections or contamination on surfaces can trigger premature transition to turbulent flow. This is particularly problematic in aerospace applications, where maintaining laminar flow over aircraft wings is crucial for reducing drag and improving fuel efficiency. Developing materials and manufacturing techniques that can produce and maintain ultra-smooth surfaces at scale remains an ongoing challenge.

The interaction between laminar flow and external disturbances poses significant difficulties. Atmospheric turbulence, acoustic waves, and vibrations can all disrupt laminar flow. In industrial settings, such as chemical processing or microfluidics, these external factors can be particularly challenging to mitigate, requiring sophisticated isolation and damping systems.

Temperature gradients and heat transfer effects also complicate laminar flow control. Variations in temperature can lead to density changes in fluids, potentially triggering flow instabilities. Managing these thermal effects, especially in high-speed flows or in processes involving heat exchange, requires advanced modeling and control strategies.

The scaling of laminar flow control techniques from laboratory conditions to real-world applications remains a significant hurdle. Solutions that work well in controlled environments may not be feasible or effective at larger scales or under more variable conditions. This scaling challenge affects the development of practical laminar flow control systems for aircraft, pipelines, and industrial processes.

Measurement and monitoring of laminar flow conditions in real-time present technical challenges. Current sensor technologies may not be sufficiently sensitive or non-intrusive to detect subtle flow changes without disturbing the flow itself. Developing advanced, non-invasive measurement techniques is crucial for effective laminar flow control systems.

Finally, the computational challenges in modeling and predicting laminar flow behavior, especially in complex geometries or multi-phase flows, remain significant. While computational fluid dynamics (CFD) has advanced considerably, accurately simulating the transition between laminar and turbulent regimes and predicting the effects of various control strategies still requires substantial computational resources and sophisticated algorithms.

Surface roughness presents another major challenge. Even minor imperfections or contamination on surfaces can trigger premature transition to turbulent flow. This is particularly problematic in aerospace applications, where maintaining laminar flow over aircraft wings is crucial for reducing drag and improving fuel efficiency. Developing materials and manufacturing techniques that can produce and maintain ultra-smooth surfaces at scale remains an ongoing challenge.

The interaction between laminar flow and external disturbances poses significant difficulties. Atmospheric turbulence, acoustic waves, and vibrations can all disrupt laminar flow. In industrial settings, such as chemical processing or microfluidics, these external factors can be particularly challenging to mitigate, requiring sophisticated isolation and damping systems.

Temperature gradients and heat transfer effects also complicate laminar flow control. Variations in temperature can lead to density changes in fluids, potentially triggering flow instabilities. Managing these thermal effects, especially in high-speed flows or in processes involving heat exchange, requires advanced modeling and control strategies.

The scaling of laminar flow control techniques from laboratory conditions to real-world applications remains a significant hurdle. Solutions that work well in controlled environments may not be feasible or effective at larger scales or under more variable conditions. This scaling challenge affects the development of practical laminar flow control systems for aircraft, pipelines, and industrial processes.

Measurement and monitoring of laminar flow conditions in real-time present technical challenges. Current sensor technologies may not be sufficiently sensitive or non-intrusive to detect subtle flow changes without disturbing the flow itself. Developing advanced, non-invasive measurement techniques is crucial for effective laminar flow control systems.

Finally, the computational challenges in modeling and predicting laminar flow behavior, especially in complex geometries or multi-phase flows, remain significant. While computational fluid dynamics (CFD) has advanced considerably, accurately simulating the transition between laminar and turbulent regimes and predicting the effects of various control strategies still requires substantial computational resources and sophisticated algorithms.

Existing Methods for Laminar Flow Optimization

01 Flow control devices for laminar flow

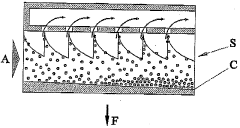

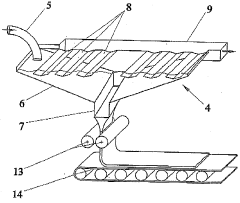

Various flow control devices are used to achieve and maintain laminar flow conditions. These devices may include specialized valves, regulators, and flow straighteners that help to reduce turbulence and ensure smooth, parallel fluid motion. Proper design and placement of these devices are crucial for optimizing laminar flow conditions in different applications.- Flow control devices for laminar flow: Various flow control devices are used to achieve and maintain laminar flow conditions. These devices may include specialized valves, regulators, and flow straighteners that help to reduce turbulence and ensure smooth, parallel fluid motion. The design and placement of these devices are crucial for optimizing laminar flow in different applications.

- Surface characteristics for laminar flow: The surface characteristics of channels or pipes play a significant role in achieving optimal laminar flow conditions. Smooth surfaces with minimal roughness and carefully designed geometries can reduce friction and prevent flow separation, thereby promoting laminar flow. Coatings or treatments may be applied to surfaces to enhance their laminar flow properties.

- Temperature and pressure control for laminar flow: Maintaining appropriate temperature and pressure conditions is essential for achieving optimal laminar flow. Precise control of these parameters helps to manage fluid viscosity and density, which directly impact the Reynolds number and the likelihood of maintaining laminar flow. Specialized equipment and monitoring systems may be employed to ensure stable conditions.

- Fluid properties optimization for laminar flow: The properties of the fluid itself are crucial for achieving laminar flow. Viscosity, density, and other rheological properties can be optimized through careful selection or modification of the fluid composition. Additives or treatments may be used to adjust fluid properties and promote laminar flow conditions in various applications.

- Measurement and monitoring techniques for laminar flow: Advanced measurement and monitoring techniques are employed to assess and maintain laminar flow conditions. These may include flow visualization methods, sensors, and data analysis tools that provide real-time feedback on flow characteristics. Such techniques allow for precise control and optimization of laminar flow in various systems and processes.

02 Temperature and pressure control for laminar flow

Maintaining optimal temperature and pressure conditions is essential for achieving laminar flow. Precise control of these parameters helps to minimize fluctuations in fluid properties and prevent the onset of turbulence. Advanced sensors and control systems are often employed to monitor and adjust temperature and pressure in real-time, ensuring stable laminar flow conditions.Expand Specific Solutions03 Surface characteristics for promoting laminar flow

The properties of surfaces in contact with the fluid play a significant role in maintaining laminar flow. Smooth, non-porous surfaces with low friction coefficients are preferred to reduce drag and prevent flow disturbances. Various surface treatments and coatings can be applied to optimize surface characteristics and promote laminar flow conditions.Expand Specific Solutions04 Fluid composition and properties for laminar flow

The composition and properties of the fluid itself are crucial factors in achieving laminar flow. Viscosity, density, and other rheological properties must be carefully controlled to maintain the desired flow regime. Additives or modifications to the fluid composition may be used to optimize these properties and enhance laminar flow characteristics.Expand Specific Solutions05 Geometric design considerations for laminar flow

The geometry of flow channels, pipes, or other containment structures significantly impacts the ability to achieve and maintain laminar flow. Careful design of inlet and outlet configurations, channel cross-sections, and overall flow path geometry is essential. Computational fluid dynamics (CFD) simulations and experimental testing are often used to optimize these geometric parameters for specific laminar flow applications.Expand Specific Solutions

Key Players in Fluid Dynamics Industry

The competition landscape for ensuring optimal conditions for laminar flow is characterized by a mature market with established players and ongoing technological advancements. The market size is substantial, driven by applications in various industries such as aerospace, automotive, and manufacturing. Companies like The Boeing Co., Airbus Operations GmbH, and ASML Netherlands BV are at the forefront of research and development in this field, leveraging their expertise in fluid dynamics and precision engineering. Academic institutions like ETH Zurich and University of Grenoble contribute significantly to the theoretical understanding and practical applications of laminar flow. The technology's maturity is evident, with continuous refinements focusing on efficiency improvements and cost reduction in industrial processes.

The Boeing Co.

Technical Solution: Boeing has developed advanced Computational Fluid Dynamics (CFD) techniques to ensure optimal conditions for laminar flow in aircraft design. Their approach involves using high-fidelity numerical simulations to predict and optimize airflow over wing surfaces. They employ adaptive mesh refinement algorithms to accurately capture boundary layer transitions and flow separation points[1]. Boeing's method also incorporates surface smoothness control and active flow control systems, such as micro-perforations or suction devices, to maintain laminar flow over larger portions of the wing[2]. Additionally, they have implemented machine learning algorithms to analyze vast amounts of flight test data, enabling real-time adjustments to maintain optimal laminar flow conditions during various flight phases[3].

Strengths: Extensive experience in aerospace applications, advanced CFD capabilities, and integration of active flow control systems. Weaknesses: High implementation costs and complexity in retrofitting existing aircraft.

Airbus Operations GmbH

Technical Solution: Airbus has pioneered the Natural Laminar Flow (NLF) technology for ensuring optimal laminar flow conditions. Their approach focuses on precise airfoil shaping and surface quality control to maximize the extent of laminar flow over aircraft surfaces. Airbus utilizes advanced manufacturing techniques, including high-precision milling and innovative coating technologies, to achieve the required surface smoothness[4]. They have also developed a hybrid laminar flow control (HLFC) system that combines passive shaping with active suction through micro-perforations on leading edges[5]. Airbus's method incorporates real-time sensors and adaptive control algorithms to maintain laminar flow under varying atmospheric conditions. Furthermore, they have implemented advanced boundary layer transition prediction tools, integrating factors such as surface imperfections and atmospheric particulates into their models[6].

Strengths: Proven NLF technology, integration of active and passive flow control methods, and advanced manufacturing capabilities. Weaknesses: Challenges in maintaining optimal surface conditions in operational environments and potential weight penalties from HLFC systems.

Innovative Approaches in Flow Stabilization

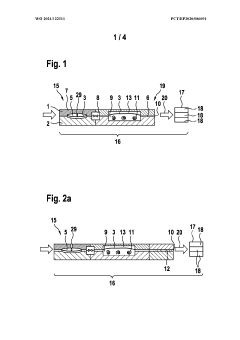

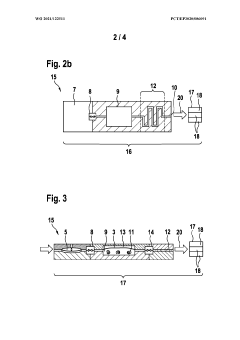

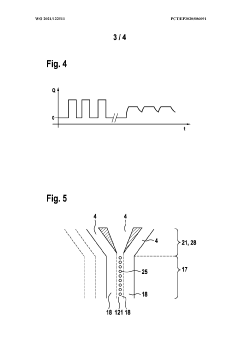

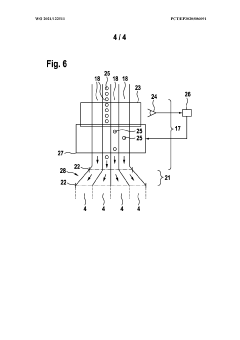

Cartridge having a microfluidic system for performance of an analysis of a sample

PatentWO2021122511A1

Innovation

- A microfluidic cartridge with a flow laminarizer and compensation capacity is designed to generate laminar flows by slowing down fluid flow through channel geometry changes and using a flexible membrane to dampen pressure fluctuations, ensuring laminar conditions are maintained in the analysis section for precise sample analysis and sorting.

Method and installation for separating a solid-liquid suspension

PatentWO2003011423A1

Innovation

- A process that forms a laminar flow of the liquid mixture at an angle between 60° and 90° to gravity, allowing particles to sediment and then withdraws the liquid phase adjacent to the sedimentation wall, reducing the sedimentation channel length and surface area needed, while maintaining high recovery efficiency of particles.

Computational Fluid Dynamics in Flow Analysis

Computational Fluid Dynamics (CFD) has revolutionized the analysis and optimization of laminar flow conditions. This powerful numerical simulation technique allows engineers and researchers to model complex fluid dynamics scenarios with unprecedented accuracy and detail. By solving the Navier-Stokes equations and other governing equations of fluid motion, CFD provides valuable insights into flow behavior, pressure distributions, and velocity fields within various geometries and under different operating conditions.

In the context of ensuring optimal conditions for laminar flow, CFD plays a crucial role in several aspects. Firstly, it enables the precise prediction of flow patterns and transition points from laminar to turbulent regimes. This information is vital for designing systems that maintain laminar flow over desired regions, such as in microfluidic devices or aerodynamic surfaces. CFD simulations can accurately capture the effects of geometry, surface roughness, and fluid properties on flow stability, allowing for iterative design improvements without the need for costly physical prototypes.

Moreover, CFD facilitates the optimization of flow control strategies. By simulating various flow control mechanisms, such as suction, blowing, or surface modifications, researchers can evaluate their effectiveness in promoting and sustaining laminar flow. These simulations can reveal the optimal placement and intensity of control elements, leading to more efficient and robust laminar flow systems.

CFD also excels in analyzing the impact of external factors on laminar flow conditions. For instance, it can model the effects of temperature gradients, pressure fluctuations, or chemical reactions on flow stability. This capability is particularly valuable in applications where maintaining laminar flow is critical under varying environmental conditions, such as in heat exchangers or chemical reactors.

Furthermore, CFD enables the investigation of complex geometries and multi-physics phenomena that are challenging to study experimentally. It can simulate the interaction between fluid flow and structural deformation, heat transfer, or particle transport, providing a comprehensive understanding of system behavior. This holistic approach is essential for optimizing laminar flow in real-world applications where multiple physical processes are intertwined.

In recent years, advancements in CFD techniques, such as Large Eddy Simulation (LES) and Direct Numerical Simulation (DNS), have further enhanced the accuracy and reliability of laminar flow predictions. These methods offer higher fidelity simulations, capturing fine-scale flow structures and transient phenomena that are crucial for understanding laminar-turbulent transition mechanisms.

In the context of ensuring optimal conditions for laminar flow, CFD plays a crucial role in several aspects. Firstly, it enables the precise prediction of flow patterns and transition points from laminar to turbulent regimes. This information is vital for designing systems that maintain laminar flow over desired regions, such as in microfluidic devices or aerodynamic surfaces. CFD simulations can accurately capture the effects of geometry, surface roughness, and fluid properties on flow stability, allowing for iterative design improvements without the need for costly physical prototypes.

Moreover, CFD facilitates the optimization of flow control strategies. By simulating various flow control mechanisms, such as suction, blowing, or surface modifications, researchers can evaluate their effectiveness in promoting and sustaining laminar flow. These simulations can reveal the optimal placement and intensity of control elements, leading to more efficient and robust laminar flow systems.

CFD also excels in analyzing the impact of external factors on laminar flow conditions. For instance, it can model the effects of temperature gradients, pressure fluctuations, or chemical reactions on flow stability. This capability is particularly valuable in applications where maintaining laminar flow is critical under varying environmental conditions, such as in heat exchangers or chemical reactors.

Furthermore, CFD enables the investigation of complex geometries and multi-physics phenomena that are challenging to study experimentally. It can simulate the interaction between fluid flow and structural deformation, heat transfer, or particle transport, providing a comprehensive understanding of system behavior. This holistic approach is essential for optimizing laminar flow in real-world applications where multiple physical processes are intertwined.

In recent years, advancements in CFD techniques, such as Large Eddy Simulation (LES) and Direct Numerical Simulation (DNS), have further enhanced the accuracy and reliability of laminar flow predictions. These methods offer higher fidelity simulations, capturing fine-scale flow structures and transient phenomena that are crucial for understanding laminar-turbulent transition mechanisms.

Environmental Impact of Flow Control Systems

The environmental impact of flow control systems used to ensure optimal conditions for laminar flow is a critical consideration in various industries. These systems, while essential for maintaining precise flow characteristics, can have both positive and negative effects on the environment.

One of the primary environmental benefits of effective laminar flow control is the potential for increased energy efficiency. By maintaining optimal flow conditions, these systems can reduce turbulence and minimize energy losses, leading to lower power consumption in industrial processes, HVAC systems, and fluid transport applications. This reduction in energy usage translates to decreased greenhouse gas emissions and a smaller carbon footprint for the facilities employing these technologies.

However, the materials and manufacturing processes used in the production of flow control systems can have adverse environmental impacts. Many components, such as sensors, actuators, and control units, may contain rare earth elements or toxic materials that require careful handling and disposal. The production of these components often involves energy-intensive processes and may generate hazardous waste, contributing to environmental pollution if not managed properly.

The use of certain flow control techniques, particularly those involving chemical additives or surface treatments, can introduce pollutants into the environment. For example, drag-reducing agents used in pipelines to enhance laminar flow may leach into surrounding soil or water systems if not contained effectively. Similarly, specialized coatings applied to surfaces to promote laminar flow may release harmful substances during their lifecycle or disposal.

On the other hand, advanced flow control systems can contribute to environmental protection by enabling more precise fluid handling and reducing the risk of spills or leaks. In industries such as oil and gas or chemical processing, maintaining laminar flow conditions can enhance safety and minimize the potential for environmental contamination due to accidents or equipment failures.

The lifecycle impact of flow control systems must also be considered. While these systems may offer environmental benefits during operation, the disposal of obsolete or damaged equipment can pose challenges. Electronic components, in particular, require specialized recycling processes to prevent the release of harmful substances into the environment.

Innovations in flow control technology are increasingly focusing on environmentally friendly solutions. This includes the development of bio-based materials for flow control surfaces, energy-harvesting sensors that reduce the need for external power sources, and intelligent systems that optimize flow conditions in real-time, further reducing energy consumption and environmental impact.

In conclusion, while flow control systems for ensuring optimal laminar flow conditions offer significant environmental benefits through improved energy efficiency and process control, their overall environmental impact is complex. Balancing the positive effects with the potential negative consequences requires careful consideration of materials, manufacturing processes, operational practices, and end-of-life management to minimize ecological harm and maximize sustainability.

One of the primary environmental benefits of effective laminar flow control is the potential for increased energy efficiency. By maintaining optimal flow conditions, these systems can reduce turbulence and minimize energy losses, leading to lower power consumption in industrial processes, HVAC systems, and fluid transport applications. This reduction in energy usage translates to decreased greenhouse gas emissions and a smaller carbon footprint for the facilities employing these technologies.

However, the materials and manufacturing processes used in the production of flow control systems can have adverse environmental impacts. Many components, such as sensors, actuators, and control units, may contain rare earth elements or toxic materials that require careful handling and disposal. The production of these components often involves energy-intensive processes and may generate hazardous waste, contributing to environmental pollution if not managed properly.

The use of certain flow control techniques, particularly those involving chemical additives or surface treatments, can introduce pollutants into the environment. For example, drag-reducing agents used in pipelines to enhance laminar flow may leach into surrounding soil or water systems if not contained effectively. Similarly, specialized coatings applied to surfaces to promote laminar flow may release harmful substances during their lifecycle or disposal.

On the other hand, advanced flow control systems can contribute to environmental protection by enabling more precise fluid handling and reducing the risk of spills or leaks. In industries such as oil and gas or chemical processing, maintaining laminar flow conditions can enhance safety and minimize the potential for environmental contamination due to accidents or equipment failures.

The lifecycle impact of flow control systems must also be considered. While these systems may offer environmental benefits during operation, the disposal of obsolete or damaged equipment can pose challenges. Electronic components, in particular, require specialized recycling processes to prevent the release of harmful substances into the environment.

Innovations in flow control technology are increasingly focusing on environmentally friendly solutions. This includes the development of bio-based materials for flow control surfaces, energy-harvesting sensors that reduce the need for external power sources, and intelligent systems that optimize flow conditions in real-time, further reducing energy consumption and environmental impact.

In conclusion, while flow control systems for ensuring optimal laminar flow conditions offer significant environmental benefits through improved energy efficiency and process control, their overall environmental impact is complex. Balancing the positive effects with the potential negative consequences requires careful consideration of materials, manufacturing processes, operational practices, and end-of-life management to minimize ecological harm and maximize sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!