Laminar Flow Solutions for Reducing Energy Consumption

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Tech Evolution and Objectives

Laminar flow technology has evolved significantly over the past century, driven by the need for energy-efficient fluid transport systems. The concept of laminar flow, characterized by smooth, parallel layers of fluid moving with minimal mixing, has been a cornerstone in fluid dynamics since the pioneering work of Osborne Reynolds in the late 19th century. Initially, the focus was on understanding the fundamental principles governing laminar flow behavior in various geometries and flow conditions.

As industrial applications grew more complex, the emphasis shifted towards harnessing laminar flow for practical purposes, particularly in reducing energy consumption. The oil crisis of the 1970s sparked renewed interest in laminar flow solutions as a means to improve fuel efficiency in transportation and industrial processes. This period saw significant advancements in computational fluid dynamics (CFD) and experimental techniques, enabling more accurate modeling and analysis of laminar flow phenomena.

The advent of microfluidics in the 1990s opened up new avenues for laminar flow applications, particularly in biomedical and chemical engineering fields. Researchers began exploring ways to manipulate laminar flow at microscale levels, leading to innovations in lab-on-a-chip devices and precision fluid control systems. Concurrently, the aerospace industry intensified efforts to develop laminar flow control technologies for aircraft, aiming to reduce drag and improve fuel efficiency.

In recent years, the focus has expanded to include the development of smart materials and surface treatments that can induce or enhance laminar flow conditions. Biomimetic approaches, inspired by natural phenomena such as shark skin or lotus leaves, have led to novel surface designs that promote laminar flow and reduce friction. Additionally, advances in nanotechnology have enabled the creation of nanostructured surfaces that can maintain laminar flow under conditions where turbulence would typically occur.

The current objectives in laminar flow technology for energy reduction are multifaceted. Researchers aim to develop more sophisticated control systems that can actively maintain laminar flow in dynamic environments, such as variable-speed pumps or adaptive aircraft wings. There is also a push towards integrating laminar flow solutions with other energy-saving technologies, creating synergistic effects in overall system efficiency. Furthermore, efforts are underway to scale up laminar flow technologies for large-scale industrial applications, particularly in sectors like oil and gas, where even small improvements in flow efficiency can lead to substantial energy savings.

Looking ahead, the field is poised for further breakthroughs, with emerging technologies like artificial intelligence and machine learning expected to play a crucial role in optimizing laminar flow systems. The ultimate goal is to create intelligent, adaptive flow systems that can automatically adjust to changing conditions, maximizing energy efficiency across a wide range of applications.

As industrial applications grew more complex, the emphasis shifted towards harnessing laminar flow for practical purposes, particularly in reducing energy consumption. The oil crisis of the 1970s sparked renewed interest in laminar flow solutions as a means to improve fuel efficiency in transportation and industrial processes. This period saw significant advancements in computational fluid dynamics (CFD) and experimental techniques, enabling more accurate modeling and analysis of laminar flow phenomena.

The advent of microfluidics in the 1990s opened up new avenues for laminar flow applications, particularly in biomedical and chemical engineering fields. Researchers began exploring ways to manipulate laminar flow at microscale levels, leading to innovations in lab-on-a-chip devices and precision fluid control systems. Concurrently, the aerospace industry intensified efforts to develop laminar flow control technologies for aircraft, aiming to reduce drag and improve fuel efficiency.

In recent years, the focus has expanded to include the development of smart materials and surface treatments that can induce or enhance laminar flow conditions. Biomimetic approaches, inspired by natural phenomena such as shark skin or lotus leaves, have led to novel surface designs that promote laminar flow and reduce friction. Additionally, advances in nanotechnology have enabled the creation of nanostructured surfaces that can maintain laminar flow under conditions where turbulence would typically occur.

The current objectives in laminar flow technology for energy reduction are multifaceted. Researchers aim to develop more sophisticated control systems that can actively maintain laminar flow in dynamic environments, such as variable-speed pumps or adaptive aircraft wings. There is also a push towards integrating laminar flow solutions with other energy-saving technologies, creating synergistic effects in overall system efficiency. Furthermore, efforts are underway to scale up laminar flow technologies for large-scale industrial applications, particularly in sectors like oil and gas, where even small improvements in flow efficiency can lead to substantial energy savings.

Looking ahead, the field is poised for further breakthroughs, with emerging technologies like artificial intelligence and machine learning expected to play a crucial role in optimizing laminar flow systems. The ultimate goal is to create intelligent, adaptive flow systems that can automatically adjust to changing conditions, maximizing energy efficiency across a wide range of applications.

Energy Efficiency Market Analysis

The energy efficiency market has experienced significant growth in recent years, driven by increasing awareness of environmental issues and the need to reduce operational costs across various industries. The global energy efficiency market was valued at approximately $240 billion in 2020 and is projected to reach $344 billion by 2026, growing at a CAGR of 6.1% during the forecast period.

The market for laminar flow solutions in energy efficiency applications is a subset of this larger market, focusing on reducing energy consumption in fluid systems. This segment has gained traction due to its potential to significantly decrease energy usage in industries such as HVAC, manufacturing, and transportation.

In the HVAC sector, laminar flow solutions have shown promising results in improving the efficiency of air conditioning and ventilation systems. The commercial building sector, in particular, has been a key driver for adoption, as businesses seek to reduce their energy costs and carbon footprint. The industrial sector has also shown increasing interest in laminar flow technologies for process cooling and ventilation applications.

The transportation industry, especially aerospace and automotive, has been exploring laminar flow solutions to reduce drag and improve fuel efficiency. This has led to a growing demand for advanced materials and design techniques that can maintain laminar flow over larger surface areas.

Geographically, North America and Europe lead the market for laminar flow energy efficiency solutions, owing to stringent energy regulations and high adoption rates of advanced technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization and increasing energy demands in countries like China and India.

Key market drivers include government regulations promoting energy efficiency, rising energy costs, and growing corporate sustainability initiatives. The implementation of energy performance standards and labeling programs has further stimulated market growth by creating awareness and incentivizing the adoption of energy-efficient technologies.

Challenges in the market include high initial investment costs for implementing laminar flow solutions and the need for specialized expertise in design and implementation. Additionally, the complexity of retrofitting existing systems with laminar flow technologies can be a barrier to adoption in some cases.

Despite these challenges, the market outlook remains positive, with ongoing research and development efforts focused on improving the cost-effectiveness and applicability of laminar flow solutions across various industries. As energy efficiency continues to be a priority for businesses and governments worldwide, the demand for innovative laminar flow technologies is expected to grow, presenting significant opportunities for market players in the coming years.

The market for laminar flow solutions in energy efficiency applications is a subset of this larger market, focusing on reducing energy consumption in fluid systems. This segment has gained traction due to its potential to significantly decrease energy usage in industries such as HVAC, manufacturing, and transportation.

In the HVAC sector, laminar flow solutions have shown promising results in improving the efficiency of air conditioning and ventilation systems. The commercial building sector, in particular, has been a key driver for adoption, as businesses seek to reduce their energy costs and carbon footprint. The industrial sector has also shown increasing interest in laminar flow technologies for process cooling and ventilation applications.

The transportation industry, especially aerospace and automotive, has been exploring laminar flow solutions to reduce drag and improve fuel efficiency. This has led to a growing demand for advanced materials and design techniques that can maintain laminar flow over larger surface areas.

Geographically, North America and Europe lead the market for laminar flow energy efficiency solutions, owing to stringent energy regulations and high adoption rates of advanced technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization and increasing energy demands in countries like China and India.

Key market drivers include government regulations promoting energy efficiency, rising energy costs, and growing corporate sustainability initiatives. The implementation of energy performance standards and labeling programs has further stimulated market growth by creating awareness and incentivizing the adoption of energy-efficient technologies.

Challenges in the market include high initial investment costs for implementing laminar flow solutions and the need for specialized expertise in design and implementation. Additionally, the complexity of retrofitting existing systems with laminar flow technologies can be a barrier to adoption in some cases.

Despite these challenges, the market outlook remains positive, with ongoing research and development efforts focused on improving the cost-effectiveness and applicability of laminar flow solutions across various industries. As energy efficiency continues to be a priority for businesses and governments worldwide, the demand for innovative laminar flow technologies is expected to grow, presenting significant opportunities for market players in the coming years.

Laminar Flow Challenges and Limitations

Laminar flow solutions for reducing energy consumption face several significant challenges and limitations. One of the primary obstacles is the difficulty in maintaining laminar flow conditions in real-world applications. While laminar flow can be achieved in controlled laboratory settings, practical environments often introduce disturbances that disrupt the smooth, parallel layers characteristic of laminar flow.

The transition from laminar to turbulent flow is a major concern. As flow velocity increases or the fluid encounters obstacles, the laminar regime can quickly break down, leading to turbulence. This transition point is often unpredictable and can vary depending on factors such as surface roughness, temperature gradients, and fluid properties. Consequently, designing systems that consistently operate within the laminar flow regime across a range of conditions poses a substantial engineering challenge.

Another limitation is the inherent trade-off between laminar flow and heat transfer efficiency. While laminar flow reduces energy consumption by minimizing friction losses, it also decreases the rate of heat transfer between the fluid and its surroundings. This can be problematic in applications where both energy efficiency and effective heat exchange are required, such as in cooling systems or heat exchangers.

The scale-up of laminar flow solutions from laboratory prototypes to industrial applications presents additional hurdles. As the size of the system increases, maintaining laminar flow becomes increasingly difficult due to the higher Reynolds numbers associated with larger flow volumes. This scaling issue often necessitates compromises in design or the implementation of complex flow control mechanisms, which can offset some of the energy savings gained from laminar flow.

Material limitations also play a role in the challenges faced by laminar flow solutions. Surfaces must be exceptionally smooth to promote laminar flow, which can be costly to manufacture and maintain. Over time, wear and corrosion can increase surface roughness, potentially disrupting laminar flow conditions and reducing the long-term effectiveness of the solution.

Furthermore, the implementation of laminar flow solutions often requires significant modifications to existing systems or entirely new designs. This can result in high initial costs and potential disruptions to operations during installation or retrofitting. The return on investment for such modifications may be slow, particularly in industries with tight profit margins or long equipment lifecycles.

Lastly, the limited applicability of laminar flow solutions across different fluid types and operating conditions restricts their widespread adoption. Many industrial processes involve fluids with complex rheological properties or operate under conditions that are not conducive to maintaining laminar flow. This narrow range of applicability means that laminar flow solutions may not be viable for a significant portion of energy-intensive industrial processes, limiting their overall impact on global energy consumption reduction efforts.

The transition from laminar to turbulent flow is a major concern. As flow velocity increases or the fluid encounters obstacles, the laminar regime can quickly break down, leading to turbulence. This transition point is often unpredictable and can vary depending on factors such as surface roughness, temperature gradients, and fluid properties. Consequently, designing systems that consistently operate within the laminar flow regime across a range of conditions poses a substantial engineering challenge.

Another limitation is the inherent trade-off between laminar flow and heat transfer efficiency. While laminar flow reduces energy consumption by minimizing friction losses, it also decreases the rate of heat transfer between the fluid and its surroundings. This can be problematic in applications where both energy efficiency and effective heat exchange are required, such as in cooling systems or heat exchangers.

The scale-up of laminar flow solutions from laboratory prototypes to industrial applications presents additional hurdles. As the size of the system increases, maintaining laminar flow becomes increasingly difficult due to the higher Reynolds numbers associated with larger flow volumes. This scaling issue often necessitates compromises in design or the implementation of complex flow control mechanisms, which can offset some of the energy savings gained from laminar flow.

Material limitations also play a role in the challenges faced by laminar flow solutions. Surfaces must be exceptionally smooth to promote laminar flow, which can be costly to manufacture and maintain. Over time, wear and corrosion can increase surface roughness, potentially disrupting laminar flow conditions and reducing the long-term effectiveness of the solution.

Furthermore, the implementation of laminar flow solutions often requires significant modifications to existing systems or entirely new designs. This can result in high initial costs and potential disruptions to operations during installation or retrofitting. The return on investment for such modifications may be slow, particularly in industries with tight profit margins or long equipment lifecycles.

Lastly, the limited applicability of laminar flow solutions across different fluid types and operating conditions restricts their widespread adoption. Many industrial processes involve fluids with complex rheological properties or operate under conditions that are not conducive to maintaining laminar flow. This narrow range of applicability means that laminar flow solutions may not be viable for a significant portion of energy-intensive industrial processes, limiting their overall impact on global energy consumption reduction efforts.

Current Laminar Flow Energy Solutions

01 Laminar flow control systems for energy efficiency

Laminar flow control systems are designed to reduce drag and improve energy efficiency in various applications. These systems can be applied to aircraft wings, vehicle bodies, or fluid transport systems to minimize turbulence and reduce energy consumption. By maintaining smooth, streamlined flow, these solutions can significantly decrease fuel consumption and operating costs.- Laminar flow control systems for energy efficiency: Laminar flow control systems are designed to reduce drag and improve energy efficiency in fluid dynamics applications. These systems can be applied to various fields such as aerospace, automotive, and industrial processes. By maintaining laminar flow, these solutions minimize turbulence and reduce energy consumption in fluid transport and aerodynamic applications.

- Energy-efficient laminar flow devices in HVAC systems: Laminar flow devices are integrated into HVAC systems to optimize airflow and reduce energy consumption. These solutions include specially designed air diffusers, vents, and ducts that promote laminar airflow, resulting in more efficient heating, cooling, and ventilation processes. The improved air distribution leads to reduced power requirements for fans and overall system operation.

- Laminar flow reactors for energy-efficient chemical processes: Laminar flow reactors are utilized in chemical engineering to enhance reaction efficiency and reduce energy consumption. These reactors maintain laminar flow conditions, allowing for precise control of reaction parameters and improved heat transfer. The controlled flow regime results in more uniform temperature distribution and reduced mixing times, leading to energy savings in chemical manufacturing processes.

- Energy-saving laminar flow solutions in fluid handling equipment: Fluid handling equipment, such as pumps and valves, incorporate laminar flow design principles to minimize energy losses. These solutions include streamlined flow paths, optimized geometries, and surface treatments that promote laminar flow. By reducing turbulence and friction, these designs lower the energy required for fluid transport and handling in various industrial applications.

- Laminar flow measurement and control for energy optimization: Advanced measurement and control systems are developed to monitor and maintain laminar flow conditions, optimizing energy consumption in various applications. These systems utilize sensors, actuators, and intelligent algorithms to detect flow characteristics and make real-time adjustments. By ensuring laminar flow is maintained, these solutions minimize energy losses and improve overall system efficiency across different industries.

02 Energy-efficient laminar flow devices in HVAC systems

Laminar flow devices are incorporated into HVAC systems to optimize airflow and reduce energy consumption. These devices can include specially designed air diffusers, vents, and ducts that promote smooth, uniform air distribution. By minimizing turbulence and improving air circulation, these solutions can enhance the overall efficiency of heating, cooling, and ventilation systems in buildings.Expand Specific Solutions03 Laminar flow solutions for fluid handling and processing

In fluid handling and processing applications, laminar flow solutions are employed to reduce energy consumption and improve efficiency. These can include specialized pipe designs, flow straighteners, and mixing devices that maintain laminar flow conditions. By minimizing turbulence and optimizing flow patterns, these solutions can reduce pumping energy requirements and enhance the overall performance of fluid systems.Expand Specific Solutions04 Energy-efficient laminar flow in renewable energy systems

Laminar flow principles are applied to renewable energy systems to maximize energy generation and minimize losses. This includes optimizing the design of wind turbine blades, hydroelectric turbines, and solar thermal collectors to maintain laminar flow conditions. By reducing turbulence and improving flow characteristics, these solutions can increase the efficiency of renewable energy systems and reduce overall energy consumption.Expand Specific Solutions05 Measurement and control systems for laminar flow energy optimization

Advanced measurement and control systems are developed to monitor and optimize laminar flow conditions for energy efficiency. These systems may include sensors, flow meters, and intelligent control algorithms that continuously adjust flow parameters to maintain optimal laminar conditions. By providing real-time feedback and automated adjustments, these solutions can significantly reduce energy consumption in various applications where laminar flow is critical.Expand Specific Solutions

Key Players in Laminar Flow Industry

The market for Laminar Flow Solutions for Reducing Energy Consumption is in a growth phase, driven by increasing focus on energy efficiency and sustainability. The global market size is expanding, with potential applications across various industries. Technologically, the field is advancing rapidly, with companies like ASML Holding NV and Toyota Motor Corp. leading innovation. ASML's expertise in semiconductor manufacturing equipment could contribute to precision flow control, while Toyota's automotive experience may apply to aerodynamic designs. Other players like Koninklijke Philips NV and BSH Hausgeräte GmbH are likely leveraging their consumer appliance knowledge to develop energy-efficient laminar flow solutions. The involvement of research institutions such as CNRS and universities indicates ongoing fundamental research, suggesting further technological advancements on the horizon.

Advanced Industrial Science & Technology

Technical Solution: Advanced Industrial Science & Technology (AIST) has developed innovative laminar flow solutions for reducing energy consumption in various industrial applications. Their approach focuses on optimizing fluid dynamics to minimize turbulence and energy loss. AIST's technology utilizes advanced computational fluid dynamics (CFD) simulations to design and implement precise flow control mechanisms[1]. These mechanisms include micro-structured surfaces and active flow control devices that maintain laminar flow over extended distances, significantly reducing drag and energy requirements[2]. The institute has also pioneered the use of smart materials that can adapt to changing flow conditions, further enhancing energy efficiency[3].

Strengths: Cutting-edge research capabilities, interdisciplinary approach combining materials science and fluid dynamics. Weaknesses: Potential high implementation costs, may require significant modifications to existing systems.

ASML Netherlands BV

Technical Solution: ASML Netherlands BV has applied laminar flow solutions to reduce energy consumption in their advanced lithography systems for semiconductor manufacturing. Their approach focuses on precise environmental control within the lithography machines to maintain optimal conditions for nanoscale patterning. ASML has developed sophisticated laminar airflow systems that create ultra-clean, particle-free environments essential for high-precision chip manufacturing[1]. These systems utilize advanced computational fluid dynamics (CFD) modeling to design airflow patterns that minimize turbulence and energy consumption while maintaining strict cleanliness standards[2]. ASML has also implemented innovative thermal management solutions that leverage laminar flow principles to efficiently dissipate heat from critical components, reducing overall energy requirements[3]. Additionally, the company has developed laminar flow-based immersion systems for their lithography machines, which use precisely controlled fluid flows to enhance resolution and reduce energy consumption in the chip-making process[4].

Strengths: Highly specialized solutions for semiconductor industry, integration with cutting-edge lithography technologies. Weaknesses: Narrow focus on semiconductor manufacturing, potentially limited applicability to other industries.

Innovative Laminar Flow Patents

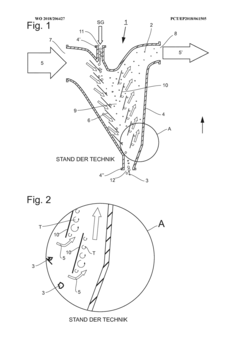

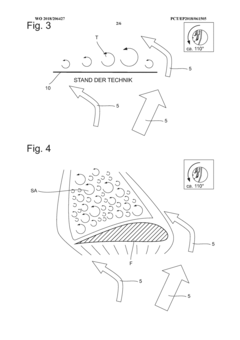

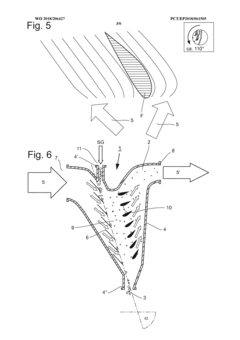

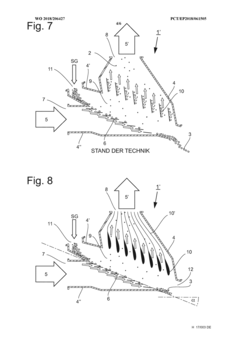

Separator having separating slats with wing profile

PatentWO2018206427A1

Innovation

- Designing the sifting streams with a wing profile to promote laminar flow, preventing the formation of turbulent zones and ensuring that smaller granules remain suspended in the classifying gas, thereby reducing energy consumption and wear on the classifier.

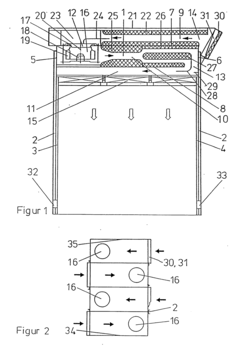

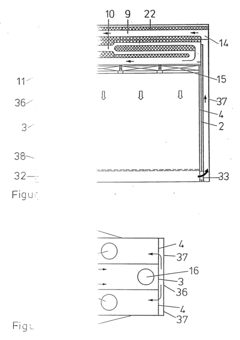

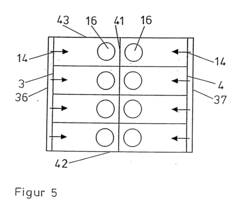

Tunnel module for creating a clean space by the laminar flow technique

PatentInactiveEP0340433A2

Innovation

- The tunnel module design features a fan placement in the middle chamber opposite the return air opening, combined with backward-curved blades and an external rotor motor, along with sound-damping baffles and a spoiler, to reduce energy consumption and turbulence, ensuring efficient conversion of dynamic to static pressure while minimizing noise and flow obstacles.

Environmental Impact Assessment

The implementation of laminar flow solutions for reducing energy consumption has significant environmental implications that warrant careful assessment. These technologies, designed to minimize turbulence and optimize fluid dynamics, offer substantial potential for energy savings across various industries. By reducing friction and enhancing flow efficiency, laminar flow solutions can lead to decreased power requirements in pumping systems, HVAC applications, and industrial processes.

One of the primary environmental benefits of laminar flow technologies is the reduction in greenhouse gas emissions associated with energy production. As these solutions enable systems to operate with lower energy inputs, they contribute to a decrease in fossil fuel consumption and, consequently, lower carbon dioxide emissions. This aligns with global efforts to mitigate climate change and transition towards more sustainable energy practices.

Furthermore, the adoption of laminar flow solutions can lead to a reduction in the overall environmental footprint of industrial operations. By optimizing fluid dynamics, these technologies can minimize the need for oversized equipment and reduce material waste in manufacturing processes. This not only conserves resources but also decreases the environmental impact associated with the production and disposal of industrial machinery.

In the context of water management, laminar flow solutions can play a crucial role in improving the efficiency of water treatment and distribution systems. By reducing energy consumption in pumping operations, these technologies can contribute to the conservation of water resources and minimize the environmental impact of water infrastructure.

However, it is essential to consider potential trade-offs and unintended consequences. The materials and manufacturing processes required to produce advanced laminar flow components may have their own environmental impacts. A comprehensive life cycle assessment would be necessary to fully understand the net environmental benefits of implementing these solutions across different applications.

Additionally, the long-term durability and maintenance requirements of laminar flow systems should be evaluated to ensure that their environmental benefits are sustained over time. Proper disposal and recycling strategies for components at the end of their lifecycle must also be considered to minimize waste and resource depletion.

In conclusion, while laminar flow solutions for reducing energy consumption offer promising environmental benefits, particularly in terms of energy savings and emissions reduction, a thorough environmental impact assessment is crucial. This assessment should encompass the entire lifecycle of these technologies, from production to implementation and eventual disposal, to ensure that their adoption truly contributes to sustainable development and environmental protection.

One of the primary environmental benefits of laminar flow technologies is the reduction in greenhouse gas emissions associated with energy production. As these solutions enable systems to operate with lower energy inputs, they contribute to a decrease in fossil fuel consumption and, consequently, lower carbon dioxide emissions. This aligns with global efforts to mitigate climate change and transition towards more sustainable energy practices.

Furthermore, the adoption of laminar flow solutions can lead to a reduction in the overall environmental footprint of industrial operations. By optimizing fluid dynamics, these technologies can minimize the need for oversized equipment and reduce material waste in manufacturing processes. This not only conserves resources but also decreases the environmental impact associated with the production and disposal of industrial machinery.

In the context of water management, laminar flow solutions can play a crucial role in improving the efficiency of water treatment and distribution systems. By reducing energy consumption in pumping operations, these technologies can contribute to the conservation of water resources and minimize the environmental impact of water infrastructure.

However, it is essential to consider potential trade-offs and unintended consequences. The materials and manufacturing processes required to produce advanced laminar flow components may have their own environmental impacts. A comprehensive life cycle assessment would be necessary to fully understand the net environmental benefits of implementing these solutions across different applications.

Additionally, the long-term durability and maintenance requirements of laminar flow systems should be evaluated to ensure that their environmental benefits are sustained over time. Proper disposal and recycling strategies for components at the end of their lifecycle must also be considered to minimize waste and resource depletion.

In conclusion, while laminar flow solutions for reducing energy consumption offer promising environmental benefits, particularly in terms of energy savings and emissions reduction, a thorough environmental impact assessment is crucial. This assessment should encompass the entire lifecycle of these technologies, from production to implementation and eventual disposal, to ensure that their adoption truly contributes to sustainable development and environmental protection.

Cost-Benefit Analysis of Implementation

The implementation of laminar flow solutions for reducing energy consumption requires a comprehensive cost-benefit analysis to determine its economic viability and long-term advantages. Initial investment costs for laminar flow systems can be substantial, including expenses for design modifications, equipment upgrades, and installation of specialized components. These upfront costs may include the integration of advanced flow control devices, surface treatments, and monitoring systems to maintain laminar flow conditions.

However, the potential benefits of implementing laminar flow solutions are significant and multifaceted. The primary advantage is the reduction in energy consumption, which can lead to substantial cost savings over time. By minimizing turbulence and drag, laminar flow systems can significantly decrease the power required for fluid transport in various applications, such as pipelines, HVAC systems, and industrial processes. This reduction in energy usage translates directly into lower operational costs and improved efficiency.

Additionally, the implementation of laminar flow solutions can lead to reduced wear and tear on equipment, potentially extending the lifespan of system components. This can result in lower maintenance costs and fewer replacements over time, further enhancing the long-term economic benefits of the technology.

Environmental benefits should also be factored into the cost-benefit analysis. The reduction in energy consumption leads to a decrease in carbon emissions, which can have both environmental and economic advantages in terms of regulatory compliance and potential carbon credits.

When evaluating the return on investment (ROI), it is crucial to consider the specific application and scale of implementation. Large-scale industrial applications may see more rapid returns due to the significant energy savings potential, while smaller-scale implementations may have a longer payback period. Factors such as energy prices, operational hours, and system complexity will influence the ROI timeline.

It is also important to consider potential challenges and additional costs associated with maintaining laminar flow conditions in real-world applications. This may include ongoing monitoring, periodic adjustments, and specialized maintenance procedures to ensure the system continues to operate at peak efficiency.

In conclusion, while the initial investment in laminar flow solutions can be substantial, the long-term benefits in energy savings, reduced maintenance costs, and environmental impact often outweigh the upfront expenses. A detailed, case-specific analysis is essential to accurately assess the cost-benefit ratio and determine the optimal implementation strategy for each unique application.

However, the potential benefits of implementing laminar flow solutions are significant and multifaceted. The primary advantage is the reduction in energy consumption, which can lead to substantial cost savings over time. By minimizing turbulence and drag, laminar flow systems can significantly decrease the power required for fluid transport in various applications, such as pipelines, HVAC systems, and industrial processes. This reduction in energy usage translates directly into lower operational costs and improved efficiency.

Additionally, the implementation of laminar flow solutions can lead to reduced wear and tear on equipment, potentially extending the lifespan of system components. This can result in lower maintenance costs and fewer replacements over time, further enhancing the long-term economic benefits of the technology.

Environmental benefits should also be factored into the cost-benefit analysis. The reduction in energy consumption leads to a decrease in carbon emissions, which can have both environmental and economic advantages in terms of regulatory compliance and potential carbon credits.

When evaluating the return on investment (ROI), it is crucial to consider the specific application and scale of implementation. Large-scale industrial applications may see more rapid returns due to the significant energy savings potential, while smaller-scale implementations may have a longer payback period. Factors such as energy prices, operational hours, and system complexity will influence the ROI timeline.

It is also important to consider potential challenges and additional costs associated with maintaining laminar flow conditions in real-world applications. This may include ongoing monitoring, periodic adjustments, and specialized maintenance procedures to ensure the system continues to operate at peak efficiency.

In conclusion, while the initial investment in laminar flow solutions can be substantial, the long-term benefits in energy savings, reduced maintenance costs, and environmental impact often outweigh the upfront expenses. A detailed, case-specific analysis is essential to accurately assess the cost-benefit ratio and determine the optimal implementation strategy for each unique application.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!