Pioneering Laminar Flow in High-Impact Environmental Projects

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Evolution

Laminar flow, a fundamental concept in fluid dynamics, has undergone significant evolution since its initial discovery. The journey of laminar flow understanding began in the 19th century with the pioneering work of George Gabriel Stokes, who laid the foundation for the mathematical description of fluid motion. His contributions led to the formulation of the Navier-Stokes equations, which remain central to fluid dynamics today.

The early 20th century saw a surge in laminar flow research, driven by the growing aerospace industry. Ludwig Prandtl's boundary layer theory, introduced in 1904, revolutionized the understanding of fluid behavior near solid surfaces. This breakthrough enabled engineers to predict and control laminar flow in various applications, particularly in aircraft design.

As computational capabilities advanced in the mid-20th century, numerical methods for solving laminar flow problems emerged. The 1960s and 1970s witnessed the development of finite difference and finite element methods, allowing for more accurate simulations of complex flow scenarios. These computational tools significantly accelerated research and innovation in laminar flow applications.

The late 20th century brought renewed interest in laminar flow control (LFC) techniques. Engineers explored ways to maintain laminar flow over larger portions of aircraft surfaces, aiming to reduce drag and improve fuel efficiency. Passive LFC methods, such as carefully designed airfoil shapes, were complemented by active techniques like suction and blowing systems.

In recent decades, the focus has shifted towards micro- and nanoscale applications of laminar flow. Microfluidics, a field that emerged in the 1990s, leverages laminar flow properties for precise control of small fluid volumes. This has led to groundbreaking applications in lab-on-a-chip devices, biomedical diagnostics, and chemical analysis systems.

The 21st century has seen an integration of laminar flow principles with other cutting-edge technologies. Advanced materials science has enabled the creation of superhydrophobic surfaces that enhance laminar flow characteristics. Additionally, the advent of 3D printing has allowed for the rapid prototyping of complex geometries optimized for laminar flow, accelerating the design and testing process.

Most recently, the application of artificial intelligence and machine learning algorithms to laminar flow problems has opened new frontiers. These tools are being used to optimize flow designs, predict transition points, and develop novel control strategies. As environmental concerns take center stage, laminar flow research is increasingly focused on eco-friendly applications, such as improving the efficiency of wind turbines and reducing the environmental impact of marine vessels.

The early 20th century saw a surge in laminar flow research, driven by the growing aerospace industry. Ludwig Prandtl's boundary layer theory, introduced in 1904, revolutionized the understanding of fluid behavior near solid surfaces. This breakthrough enabled engineers to predict and control laminar flow in various applications, particularly in aircraft design.

As computational capabilities advanced in the mid-20th century, numerical methods for solving laminar flow problems emerged. The 1960s and 1970s witnessed the development of finite difference and finite element methods, allowing for more accurate simulations of complex flow scenarios. These computational tools significantly accelerated research and innovation in laminar flow applications.

The late 20th century brought renewed interest in laminar flow control (LFC) techniques. Engineers explored ways to maintain laminar flow over larger portions of aircraft surfaces, aiming to reduce drag and improve fuel efficiency. Passive LFC methods, such as carefully designed airfoil shapes, were complemented by active techniques like suction and blowing systems.

In recent decades, the focus has shifted towards micro- and nanoscale applications of laminar flow. Microfluidics, a field that emerged in the 1990s, leverages laminar flow properties for precise control of small fluid volumes. This has led to groundbreaking applications in lab-on-a-chip devices, biomedical diagnostics, and chemical analysis systems.

The 21st century has seen an integration of laminar flow principles with other cutting-edge technologies. Advanced materials science has enabled the creation of superhydrophobic surfaces that enhance laminar flow characteristics. Additionally, the advent of 3D printing has allowed for the rapid prototyping of complex geometries optimized for laminar flow, accelerating the design and testing process.

Most recently, the application of artificial intelligence and machine learning algorithms to laminar flow problems has opened new frontiers. These tools are being used to optimize flow designs, predict transition points, and develop novel control strategies. As environmental concerns take center stage, laminar flow research is increasingly focused on eco-friendly applications, such as improving the efficiency of wind turbines and reducing the environmental impact of marine vessels.

Environmental Impact Analysis

The implementation of laminar flow technology in high-impact environmental projects has significant implications for both the natural environment and human communities. This analysis focuses on the potential environmental impacts of pioneering laminar flow applications in various sectors.

Laminar flow, characterized by smooth and predictable fluid motion, offers numerous benefits in environmental projects. When applied to water treatment systems, it can enhance the efficiency of filtration and purification processes, leading to improved water quality in both urban and rural areas. This has direct positive impacts on aquatic ecosystems, reducing the load of pollutants and contaminants entering natural water bodies. Consequently, it supports the preservation of biodiversity and the overall health of aquatic habitats.

In air quality management, laminar flow technology can be utilized in advanced ventilation and air purification systems. This application has the potential to significantly reduce indoor air pollution, particularly in urban environments where air quality is often compromised. By improving indoor air quality, it contributes to better public health outcomes and reduces the environmental burden associated with traditional air treatment methods.

The energy sector also stands to benefit from laminar flow innovations. In wind energy production, the application of laminar flow principles to turbine blade design can increase energy capture efficiency while reducing noise pollution. This dual benefit addresses both renewable energy goals and concerns about the environmental impact of wind farms on local wildlife and human communities.

However, the implementation of laminar flow technology is not without potential negative environmental impacts. The manufacturing processes for advanced laminar flow equipment may require specialized materials and energy-intensive production methods. This could lead to increased resource extraction and energy consumption in the short term, potentially offsetting some of the environmental gains in the operational phase.

Furthermore, the widespread adoption of laminar flow technology in water management systems may alter existing hydrological patterns. While this can lead to more efficient water use, it may also disrupt established ecosystems that have adapted to current flow regimes. Careful environmental impact assessments would be necessary to mitigate any unintended consequences on local flora and fauna.

In the context of urban planning and architecture, the integration of laminar flow principles in building design can contribute to more sustainable and energy-efficient structures. This approach can reduce the overall environmental footprint of urban areas by optimizing heating, cooling, and ventilation systems. However, the large-scale implementation of such designs may require significant changes to existing urban infrastructure, potentially leading to short-term environmental disruptions during construction and renovation phases.

The environmental impact of pioneering laminar flow in high-impact projects extends beyond immediate applications. As this technology advances, it has the potential to inspire and enable new approaches to environmental management and conservation. By demonstrating the effectiveness of precision fluid dynamics in addressing environmental challenges, it may catalyze further innovations in fields such as climate change mitigation, ecosystem restoration, and sustainable resource management.

Laminar flow, characterized by smooth and predictable fluid motion, offers numerous benefits in environmental projects. When applied to water treatment systems, it can enhance the efficiency of filtration and purification processes, leading to improved water quality in both urban and rural areas. This has direct positive impacts on aquatic ecosystems, reducing the load of pollutants and contaminants entering natural water bodies. Consequently, it supports the preservation of biodiversity and the overall health of aquatic habitats.

In air quality management, laminar flow technology can be utilized in advanced ventilation and air purification systems. This application has the potential to significantly reduce indoor air pollution, particularly in urban environments where air quality is often compromised. By improving indoor air quality, it contributes to better public health outcomes and reduces the environmental burden associated with traditional air treatment methods.

The energy sector also stands to benefit from laminar flow innovations. In wind energy production, the application of laminar flow principles to turbine blade design can increase energy capture efficiency while reducing noise pollution. This dual benefit addresses both renewable energy goals and concerns about the environmental impact of wind farms on local wildlife and human communities.

However, the implementation of laminar flow technology is not without potential negative environmental impacts. The manufacturing processes for advanced laminar flow equipment may require specialized materials and energy-intensive production methods. This could lead to increased resource extraction and energy consumption in the short term, potentially offsetting some of the environmental gains in the operational phase.

Furthermore, the widespread adoption of laminar flow technology in water management systems may alter existing hydrological patterns. While this can lead to more efficient water use, it may also disrupt established ecosystems that have adapted to current flow regimes. Careful environmental impact assessments would be necessary to mitigate any unintended consequences on local flora and fauna.

In the context of urban planning and architecture, the integration of laminar flow principles in building design can contribute to more sustainable and energy-efficient structures. This approach can reduce the overall environmental footprint of urban areas by optimizing heating, cooling, and ventilation systems. However, the large-scale implementation of such designs may require significant changes to existing urban infrastructure, potentially leading to short-term environmental disruptions during construction and renovation phases.

The environmental impact of pioneering laminar flow in high-impact projects extends beyond immediate applications. As this technology advances, it has the potential to inspire and enable new approaches to environmental management and conservation. By demonstrating the effectiveness of precision fluid dynamics in addressing environmental challenges, it may catalyze further innovations in fields such as climate change mitigation, ecosystem restoration, and sustainable resource management.

Laminar Flow Challenges

Laminar flow, characterized by smooth and predictable fluid motion, presents significant challenges in high-impact environmental projects. One of the primary obstacles is maintaining laminar flow conditions in large-scale applications, where turbulence often becomes dominant. Environmental projects typically involve complex geometries and varying flow rates, making it difficult to sustain laminar flow over extended distances or areas.

The sensitivity of laminar flow to external disturbances poses another major challenge. Environmental factors such as temperature fluctuations, pressure changes, and surface irregularities can disrupt the delicate balance required for laminar flow. This sensitivity necessitates precise control mechanisms and robust design considerations, which can be particularly challenging in outdoor or variable environments common in environmental projects.

Scaling up laminar flow systems from laboratory conditions to real-world environmental applications introduces additional complexities. The Reynolds number, a key parameter in fluid dynamics, tends to increase with scale, potentially pushing the flow regime towards turbulence. Overcoming this scale-up challenge requires innovative engineering solutions and careful consideration of fluid properties and flow geometries.

Energy efficiency is another critical concern in laminar flow applications for environmental projects. Maintaining laminar flow often requires more energy input compared to turbulent flow systems, particularly in scenarios involving fluid transport over long distances. Balancing the benefits of laminar flow with energy consumption is crucial for the sustainability and economic viability of environmental initiatives.

The interaction between laminar flow and various environmental contaminants or particles presents unique challenges. In water treatment or air purification projects, the presence of suspended solids or pollutants can disrupt laminar flow patterns. Developing systems that can maintain laminar conditions while effectively handling these contaminants is a complex engineering task.

Material selection and surface engineering play vital roles in addressing laminar flow challenges. The choice of materials with appropriate surface properties can significantly impact the stability of laminar flow. However, finding materials that meet both the flow requirements and environmental compatibility standards (such as corrosion resistance or eco-friendliness) can be challenging.

Monitoring and control systems for laminar flow in environmental projects face their own set of challenges. Developing sensors and feedback mechanisms that can accurately detect and respond to deviations from laminar flow conditions in real-time, often in harsh or variable environmental settings, requires advanced technological solutions.

The sensitivity of laminar flow to external disturbances poses another major challenge. Environmental factors such as temperature fluctuations, pressure changes, and surface irregularities can disrupt the delicate balance required for laminar flow. This sensitivity necessitates precise control mechanisms and robust design considerations, which can be particularly challenging in outdoor or variable environments common in environmental projects.

Scaling up laminar flow systems from laboratory conditions to real-world environmental applications introduces additional complexities. The Reynolds number, a key parameter in fluid dynamics, tends to increase with scale, potentially pushing the flow regime towards turbulence. Overcoming this scale-up challenge requires innovative engineering solutions and careful consideration of fluid properties and flow geometries.

Energy efficiency is another critical concern in laminar flow applications for environmental projects. Maintaining laminar flow often requires more energy input compared to turbulent flow systems, particularly in scenarios involving fluid transport over long distances. Balancing the benefits of laminar flow with energy consumption is crucial for the sustainability and economic viability of environmental initiatives.

The interaction between laminar flow and various environmental contaminants or particles presents unique challenges. In water treatment or air purification projects, the presence of suspended solids or pollutants can disrupt laminar flow patterns. Developing systems that can maintain laminar conditions while effectively handling these contaminants is a complex engineering task.

Material selection and surface engineering play vital roles in addressing laminar flow challenges. The choice of materials with appropriate surface properties can significantly impact the stability of laminar flow. However, finding materials that meet both the flow requirements and environmental compatibility standards (such as corrosion resistance or eco-friendliness) can be challenging.

Monitoring and control systems for laminar flow in environmental projects face their own set of challenges. Developing sensors and feedback mechanisms that can accurately detect and respond to deviations from laminar flow conditions in real-time, often in harsh or variable environmental settings, requires advanced technological solutions.

Current Laminar Solutions

01 Laminar flow measurement and control

Various methods and devices are used to measure and control laminar flow in different applications. These include optical systems, flow sensors, and specialized valves that help maintain stable laminar flow conditions. Such technologies are crucial in industries requiring precise fluid control.- Laminar flow measurement and control: Various techniques and devices are used to measure and control laminar flow in different applications. These include specialized sensors, flow meters, and control systems that maintain stable laminar flow conditions. Such systems are crucial in industries requiring precise fluid handling and analysis.

- Laminar flow in fluid delivery systems: Laminar flow principles are applied in fluid delivery systems to ensure smooth and controlled distribution of liquids or gases. This includes designs for nozzles, pipes, and channels that promote laminar flow, reducing turbulence and improving efficiency in various industrial and medical applications.

- Laminar flow in aerodynamics and hydrodynamics: Laminar flow concepts are utilized in the design of aerodynamic and hydrodynamic structures. This includes applications in vehicle design, marine technology, and aerospace engineering to reduce drag and improve efficiency. Specialized testing and simulation methods are employed to optimize laminar flow characteristics.

- Laminar flow in environmental control systems: Laminar flow is crucial in environmental control systems, particularly in clean rooms, laboratories, and healthcare facilities. These systems use laminar airflow to maintain sterile conditions, control particle distribution, and manage air quality. Specialized equipment and design principles are employed to create and maintain laminar flow environments.

- Laminar flow in microfluidic devices: Microfluidic devices leverage laminar flow properties for various applications in biotechnology, chemical analysis, and medical diagnostics. These devices use precisely controlled laminar flow to manipulate small volumes of fluids, enabling functions such as particle separation, chemical reactions, and biosensing on a miniature scale.

02 Laminar flow in fluid delivery systems

Laminar flow principles are applied in fluid delivery systems to ensure smooth and controlled distribution of liquids or gases. This includes designs for nozzles, pipes, and channels that promote laminar flow, reducing turbulence and improving efficiency in various industrial and medical applications.Expand Specific Solutions03 Laminar flow in air handling and ventilation

Laminar flow is utilized in air handling and ventilation systems to create controlled environments with minimal air turbulence. This is particularly important in clean rooms, laboratories, and medical facilities where air purity and directional flow are critical for maintaining sterile conditions.Expand Specific Solutions04 Laminar flow in fluid analysis and separation

Laminar flow properties are exploited in fluid analysis and separation techniques. This includes microfluidic devices and flow cytometry systems where precise control of fluid streams is essential for accurate analysis and separation of particles or cells.Expand Specific Solutions05 Laminar flow in manufacturing processes

Laminar flow principles are applied in various manufacturing processes to improve product quality and process efficiency. This includes applications in coating technologies, material extrusion, and chemical reactions where controlled fluid dynamics are crucial for achieving desired outcomes.Expand Specific Solutions

Industry Leaders

The field of laminar flow in high-impact environmental projects is currently in a growth phase, with increasing market size driven by rising environmental concerns and stringent regulations. The technology is moderately mature, with ongoing advancements in efficiency and application. Key players like Cytonome/ST LLC and Siemens Healthcare Diagnostics are leading innovation in fluid dynamics and precision control. Research institutions such as the Naval Research Laboratory and Fudan University contribute significantly to fundamental research. The market is characterized by a mix of established companies and emerging startups, with collaborations between industry and academia driving technological progress.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has developed advanced laminar flow control techniques for high-impact environmental projects, particularly focusing on marine applications. Their approach involves using micro-textured surfaces and active flow control systems to reduce drag and improve energy efficiency in naval vessels. The lab has successfully implemented a combination of passive and active flow control methods, including micro-grooves and synthetic jet actuators, to maintain laminar flow over extended surfaces[1][3]. This technology has shown potential to reduce fuel consumption by up to 30% in certain maritime operations, significantly decreasing the environmental impact of naval activities[2].

Strengths: Expertise in marine-specific laminar flow applications, potential for significant fuel savings. Weaknesses: Limited to maritime environments, may require complex implementation in existing vessels.

Government of the United States of America

Technical Solution: The U.S. Government, through agencies like NASA and the Department of Energy, has been pioneering laminar flow technologies for environmental projects. NASA's research has focused on developing laminar flow control systems for aircraft, which can potentially reduce drag by up to 50%[4]. This technology involves a combination of surface shaping, suction systems, and advanced materials to maintain laminar flow over wings and fuselages. The Department of Energy has been exploring laminar flow applications in wind turbines, aiming to increase energy output and reduce noise pollution. Their approach includes using specially designed airfoils and active flow control mechanisms to optimize wind energy capture[5].

Strengths: Broad research scope covering multiple environmental applications, significant government funding. Weaknesses: Long development cycles, challenges in translating research to commercial applications.

Key Laminar Innovations

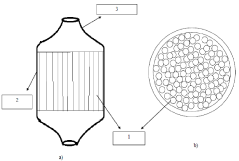

A novel nozzle to produce laminar flow

PatentInactiveIN202011051350A

Innovation

- A nozzle design featuring plastic tubes as the core and a stainless steel outer shell with rubber openings, which converts turbulent flow into laminar flow without significant pressure loss, utilizing the plastic tubes to straighten the flow and the stainless steel to maintain structural integrity while minimizing obstruction.

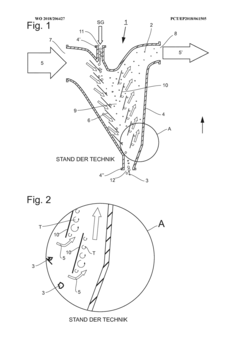

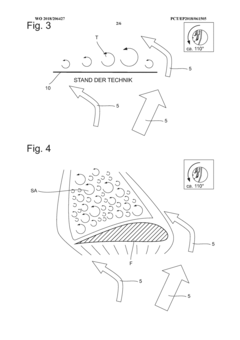

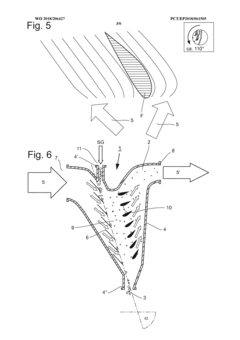

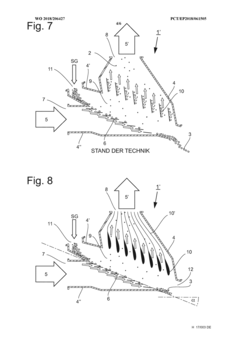

Separator having separating slats with wing profile

PatentWO2018206427A1

Innovation

- Designing the sifting streams with a wing profile to promote laminar flow, preventing the formation of turbulent zones and ensuring that smaller granules remain suspended in the classifying gas, thereby reducing energy consumption and wear on the classifier.

Regulatory Framework

The regulatory framework surrounding laminar flow in high-impact environmental projects is complex and multifaceted, encompassing various levels of governance and environmental protection standards. At the international level, organizations such as the United Nations Environment Programme (UNEP) and the International Organization for Standardization (ISO) provide guidelines and standards that influence the implementation of laminar flow technologies in environmental projects.

National regulatory bodies play a crucial role in shaping the adoption and implementation of laminar flow technologies. In the United States, the Environmental Protection Agency (EPA) sets standards for air and water quality that directly impact the use of laminar flow in environmental applications. The Clean Air Act and Clean Water Act provide the legislative foundation for many of these regulations, requiring industries to implement best available control technologies, which often include laminar flow systems.

European Union regulations, such as the Industrial Emissions Directive (IED), set stringent requirements for industrial processes, encouraging the use of advanced technologies like laminar flow to minimize environmental impact. The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also influences the materials and processes used in laminar flow systems, ensuring their safety and environmental compatibility.

In emerging economies, regulatory frameworks are evolving rapidly to address environmental concerns. Countries like China and India are implementing stricter environmental regulations, often modeled after Western standards, which is driving the adoption of laminar flow technologies in various industries.

Local and regional regulations also play a significant role, particularly in areas with sensitive ecosystems or densely populated urban centers. These regulations often impose additional requirements on environmental projects, necessitating the use of advanced laminar flow systems to meet stringent emission and effluent standards.

The regulatory landscape is not static, with ongoing updates and revisions to keep pace with technological advancements and emerging environmental challenges. This dynamic nature requires companies and project developers to stay informed about regulatory changes and adapt their laminar flow implementations accordingly.

Compliance with these regulations often requires extensive documentation, monitoring, and reporting. Many jurisdictions mandate regular audits and inspections to ensure that laminar flow systems are operating as designed and meeting the required environmental standards. This regulatory oversight has led to the development of sophisticated monitoring and control systems integrated with laminar flow technologies.

As environmental concerns continue to grow globally, it is anticipated that regulatory frameworks will become increasingly stringent, further driving innovation in laminar flow technologies for high-impact environmental projects. This trend is likely to accelerate the development of more efficient, cost-effective, and environmentally friendly laminar flow solutions across various industries and applications.

National regulatory bodies play a crucial role in shaping the adoption and implementation of laminar flow technologies. In the United States, the Environmental Protection Agency (EPA) sets standards for air and water quality that directly impact the use of laminar flow in environmental applications. The Clean Air Act and Clean Water Act provide the legislative foundation for many of these regulations, requiring industries to implement best available control technologies, which often include laminar flow systems.

European Union regulations, such as the Industrial Emissions Directive (IED), set stringent requirements for industrial processes, encouraging the use of advanced technologies like laminar flow to minimize environmental impact. The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation also influences the materials and processes used in laminar flow systems, ensuring their safety and environmental compatibility.

In emerging economies, regulatory frameworks are evolving rapidly to address environmental concerns. Countries like China and India are implementing stricter environmental regulations, often modeled after Western standards, which is driving the adoption of laminar flow technologies in various industries.

Local and regional regulations also play a significant role, particularly in areas with sensitive ecosystems or densely populated urban centers. These regulations often impose additional requirements on environmental projects, necessitating the use of advanced laminar flow systems to meet stringent emission and effluent standards.

The regulatory landscape is not static, with ongoing updates and revisions to keep pace with technological advancements and emerging environmental challenges. This dynamic nature requires companies and project developers to stay informed about regulatory changes and adapt their laminar flow implementations accordingly.

Compliance with these regulations often requires extensive documentation, monitoring, and reporting. Many jurisdictions mandate regular audits and inspections to ensure that laminar flow systems are operating as designed and meeting the required environmental standards. This regulatory oversight has led to the development of sophisticated monitoring and control systems integrated with laminar flow technologies.

As environmental concerns continue to grow globally, it is anticipated that regulatory frameworks will become increasingly stringent, further driving innovation in laminar flow technologies for high-impact environmental projects. This trend is likely to accelerate the development of more efficient, cost-effective, and environmentally friendly laminar flow solutions across various industries and applications.

Sustainability Integration

The integration of sustainability principles into laminar flow technologies for high-impact environmental projects represents a crucial step towards achieving long-term ecological balance and resource efficiency. This approach combines the benefits of laminar flow, characterized by smooth and predictable fluid motion, with sustainable practices to create environmentally friendly solutions.

In the context of environmental projects, laminar flow can be harnessed to optimize various processes, such as water treatment, air purification, and energy generation. By incorporating sustainability principles, these applications can be further enhanced to minimize resource consumption, reduce waste, and lower overall environmental impact.

One key aspect of sustainability integration in laminar flow projects is the focus on energy efficiency. Laminar flow systems can be designed to minimize energy losses due to turbulence, resulting in reduced power requirements for fluid transport and processing. This energy-saving potential aligns well with sustainability goals and can lead to significant reductions in carbon emissions over the lifecycle of environmental projects.

Water conservation is another critical area where laminar flow and sustainability intersect. In water treatment facilities, laminar flow principles can be applied to improve the efficiency of filtration and purification processes. By optimizing flow patterns, these systems can achieve higher throughput with lower water and chemical usage, contributing to more sustainable water management practices.

The integration of sustainable materials in laminar flow systems is also gaining traction. Researchers are exploring bio-based and recyclable materials for constructing flow channels and components, reducing the reliance on non-renewable resources and minimizing the environmental footprint of these technologies.

Furthermore, the application of laminar flow in sustainable building design is showing promise. By incorporating laminar flow principles into ventilation and cooling systems, buildings can achieve better energy efficiency and indoor air quality. This approach aligns with green building certifications and contributes to the overall sustainability of urban environments.

In the realm of renewable energy, laminar flow concepts are being applied to improve the efficiency of solar thermal collectors and wind turbines. These advancements not only enhance energy production but also extend the lifespan of equipment, aligning with sustainability goals for long-term resource management.

As environmental challenges continue to grow, the synergy between laminar flow technologies and sustainability principles offers a pathway to develop more effective and eco-friendly solutions. This integration not only addresses immediate environmental concerns but also contributes to the long-term resilience and sustainability of our ecosystems and resources.

In the context of environmental projects, laminar flow can be harnessed to optimize various processes, such as water treatment, air purification, and energy generation. By incorporating sustainability principles, these applications can be further enhanced to minimize resource consumption, reduce waste, and lower overall environmental impact.

One key aspect of sustainability integration in laminar flow projects is the focus on energy efficiency. Laminar flow systems can be designed to minimize energy losses due to turbulence, resulting in reduced power requirements for fluid transport and processing. This energy-saving potential aligns well with sustainability goals and can lead to significant reductions in carbon emissions over the lifecycle of environmental projects.

Water conservation is another critical area where laminar flow and sustainability intersect. In water treatment facilities, laminar flow principles can be applied to improve the efficiency of filtration and purification processes. By optimizing flow patterns, these systems can achieve higher throughput with lower water and chemical usage, contributing to more sustainable water management practices.

The integration of sustainable materials in laminar flow systems is also gaining traction. Researchers are exploring bio-based and recyclable materials for constructing flow channels and components, reducing the reliance on non-renewable resources and minimizing the environmental footprint of these technologies.

Furthermore, the application of laminar flow in sustainable building design is showing promise. By incorporating laminar flow principles into ventilation and cooling systems, buildings can achieve better energy efficiency and indoor air quality. This approach aligns with green building certifications and contributes to the overall sustainability of urban environments.

In the realm of renewable energy, laminar flow concepts are being applied to improve the efficiency of solar thermal collectors and wind turbines. These advancements not only enhance energy production but also extend the lifespan of equipment, aligning with sustainability goals for long-term resource management.

As environmental challenges continue to grow, the synergy between laminar flow technologies and sustainability principles offers a pathway to develop more effective and eco-friendly solutions. This integration not only addresses immediate environmental concerns but also contributes to the long-term resilience and sustainability of our ecosystems and resources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!