Future-Looking Laminar Flow Developments in Biotechnology

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Biotech Evolution and Objectives

Laminar flow technology has been a cornerstone in biotechnology for decades, evolving from simple applications to sophisticated systems that are revolutionizing the field. The journey of laminar flow in biotech began with its use in basic laboratory processes, such as cell culture and microfluidics. Over time, it has expanded to encompass a wide range of applications, including drug discovery, personalized medicine, and organ-on-a-chip technologies.

The evolution of laminar flow in biotechnology has been driven by the need for more precise control over cellular microenvironments and the desire to mimic in vivo conditions more accurately. Early developments focused on creating stable, predictable flow patterns for cell culture and analysis. As the technology progressed, researchers began to explore ways to integrate multiple laminar flows, leading to the development of complex microfluidic devices capable of performing multiple functions simultaneously.

Recent advancements have seen the integration of laminar flow principles with other cutting-edge technologies, such as 3D printing and artificial intelligence. This convergence has opened up new possibilities for creating highly customized and dynamic flow systems that can respond to real-time data and adjust conditions accordingly.

Looking to the future, the objectives for laminar flow in biotechnology are ambitious and far-reaching. One primary goal is to develop fully automated, high-throughput systems that can perform complex biological assays with minimal human intervention. These systems would significantly accelerate drug discovery processes and enable more efficient screening of potential therapeutic compounds.

Another key objective is the refinement of organ-on-a-chip technologies, which rely heavily on laminar flow principles to recreate the complex microenvironments of human organs. The aim is to create more accurate models of human physiology for drug testing and disease research, potentially reducing the need for animal testing and improving the success rate of clinical trials.

Researchers are also exploring the potential of laminar flow in the emerging field of synthetic biology. The precise control offered by laminar flow systems could enable the creation of artificial cellular networks and the development of novel biomaterials with programmable properties.

As we look to the future, the integration of laminar flow with advanced manufacturing techniques and smart materials is expected to yield new generations of biotech devices with unprecedented capabilities. These developments aim to push the boundaries of what is possible in biotechnology, paving the way for groundbreaking discoveries and innovations that could transform healthcare and biological research.

The evolution of laminar flow in biotechnology has been driven by the need for more precise control over cellular microenvironments and the desire to mimic in vivo conditions more accurately. Early developments focused on creating stable, predictable flow patterns for cell culture and analysis. As the technology progressed, researchers began to explore ways to integrate multiple laminar flows, leading to the development of complex microfluidic devices capable of performing multiple functions simultaneously.

Recent advancements have seen the integration of laminar flow principles with other cutting-edge technologies, such as 3D printing and artificial intelligence. This convergence has opened up new possibilities for creating highly customized and dynamic flow systems that can respond to real-time data and adjust conditions accordingly.

Looking to the future, the objectives for laminar flow in biotechnology are ambitious and far-reaching. One primary goal is to develop fully automated, high-throughput systems that can perform complex biological assays with minimal human intervention. These systems would significantly accelerate drug discovery processes and enable more efficient screening of potential therapeutic compounds.

Another key objective is the refinement of organ-on-a-chip technologies, which rely heavily on laminar flow principles to recreate the complex microenvironments of human organs. The aim is to create more accurate models of human physiology for drug testing and disease research, potentially reducing the need for animal testing and improving the success rate of clinical trials.

Researchers are also exploring the potential of laminar flow in the emerging field of synthetic biology. The precise control offered by laminar flow systems could enable the creation of artificial cellular networks and the development of novel biomaterials with programmable properties.

As we look to the future, the integration of laminar flow with advanced manufacturing techniques and smart materials is expected to yield new generations of biotech devices with unprecedented capabilities. These developments aim to push the boundaries of what is possible in biotechnology, paving the way for groundbreaking discoveries and innovations that could transform healthcare and biological research.

Bioprocess Market Demand Analysis

The bioprocess market is experiencing significant growth driven by the increasing demand for biopharmaceuticals, personalized medicine, and sustainable manufacturing processes. The global bioprocess market size was valued at $26.7 billion in 2020 and is projected to reach $72.3 billion by 2028, growing at a CAGR of 13.2% during the forecast period. This robust growth is primarily attributed to the rising prevalence of chronic diseases, advancements in biotechnology, and the shift towards bio-based products.

In the pharmaceutical sector, the demand for biopharmaceuticals continues to surge, with monoclonal antibodies, vaccines, and cell and gene therapies leading the way. The COVID-19 pandemic has further accelerated this trend, highlighting the importance of rapid and scalable bioprocessing capabilities. As a result, there is a growing need for innovative bioprocess technologies that can improve production efficiency, reduce costs, and ensure product quality.

The food and beverage industry is another key driver of bioprocess market demand. Consumers are increasingly seeking natural, clean-label products, driving the adoption of enzyme-based processing and fermentation technologies. This trend is particularly evident in the production of alternative proteins, probiotics, and functional ingredients, where bioprocessing plays a crucial role in developing sustainable and nutritious products.

Environmental concerns and the push for sustainability are also fueling demand for bioprocess technologies in various industries. Biofuels, bioplastics, and other bio-based materials are gaining traction as alternatives to traditional petrochemical products. This shift is creating new opportunities for bioprocess equipment and services providers, especially in developing economies where environmental regulations are becoming more stringent.

The pharmaceutical and biotechnology sectors remain the largest end-users of bioprocess technologies, accounting for over 60% of the market share. However, other industries such as food and beverage, agriculture, and environmental management are showing increasing adoption rates, diversifying the market landscape and opening up new avenues for growth.

Geographically, North America dominates the bioprocess market, followed by Europe and Asia-Pacific. However, emerging economies in Asia and Latin America are expected to witness the highest growth rates in the coming years, driven by increasing healthcare expenditure, growing biopharmaceutical manufacturing capabilities, and supportive government initiatives.

As the bioprocess market continues to evolve, there is a growing demand for advanced technologies that can address current challenges in bioprocessing. These include the need for real-time monitoring and control systems, single-use technologies, continuous bioprocessing, and scalable manufacturing solutions. The integration of artificial intelligence and machine learning in bioprocess development and optimization is also gaining traction, promising to revolutionize the industry further.

In the pharmaceutical sector, the demand for biopharmaceuticals continues to surge, with monoclonal antibodies, vaccines, and cell and gene therapies leading the way. The COVID-19 pandemic has further accelerated this trend, highlighting the importance of rapid and scalable bioprocessing capabilities. As a result, there is a growing need for innovative bioprocess technologies that can improve production efficiency, reduce costs, and ensure product quality.

The food and beverage industry is another key driver of bioprocess market demand. Consumers are increasingly seeking natural, clean-label products, driving the adoption of enzyme-based processing and fermentation technologies. This trend is particularly evident in the production of alternative proteins, probiotics, and functional ingredients, where bioprocessing plays a crucial role in developing sustainable and nutritious products.

Environmental concerns and the push for sustainability are also fueling demand for bioprocess technologies in various industries. Biofuels, bioplastics, and other bio-based materials are gaining traction as alternatives to traditional petrochemical products. This shift is creating new opportunities for bioprocess equipment and services providers, especially in developing economies where environmental regulations are becoming more stringent.

The pharmaceutical and biotechnology sectors remain the largest end-users of bioprocess technologies, accounting for over 60% of the market share. However, other industries such as food and beverage, agriculture, and environmental management are showing increasing adoption rates, diversifying the market landscape and opening up new avenues for growth.

Geographically, North America dominates the bioprocess market, followed by Europe and Asia-Pacific. However, emerging economies in Asia and Latin America are expected to witness the highest growth rates in the coming years, driven by increasing healthcare expenditure, growing biopharmaceutical manufacturing capabilities, and supportive government initiatives.

As the bioprocess market continues to evolve, there is a growing demand for advanced technologies that can address current challenges in bioprocessing. These include the need for real-time monitoring and control systems, single-use technologies, continuous bioprocessing, and scalable manufacturing solutions. The integration of artificial intelligence and machine learning in bioprocess development and optimization is also gaining traction, promising to revolutionize the industry further.

Current Laminar Flow Challenges in Biotech

Laminar flow technology in biotechnology faces several significant challenges that hinder its widespread adoption and optimal performance. One of the primary issues is maintaining consistent laminar flow conditions across various scales and geometries. As biotech applications often require scaling from laboratory to industrial levels, preserving laminar flow characteristics becomes increasingly difficult. This scaling challenge is particularly pronounced in bioreactors and microfluidic devices, where even minor disruptions can lead to turbulence and compromise the entire process.

Another critical challenge is the integration of laminar flow systems with complex biological processes. The delicate nature of many biotechnological applications, such as cell culture and protein production, demands precise control over environmental conditions. Achieving this level of control while maintaining laminar flow is often a delicate balancing act. Factors such as temperature gradients, pH variations, and nutrient distribution can disrupt laminar flow patterns, leading to suboptimal results or process failures.

The presence of particulates and biomolecules in biotech processes poses another significant hurdle for laminar flow systems. These elements can interfere with the smooth, predictable flow patterns essential for laminar flow. In applications like cell separation or protein purification, the presence of cellular debris or large biomolecules can create localized turbulence, reducing the efficiency and accuracy of the process. Developing methods to maintain laminar flow in the presence of these biological components remains a key area of research and development.

Energy efficiency is another pressing concern in laminar flow applications within biotechnology. Maintaining laminar flow often requires significant energy input, particularly in larger-scale operations. This high energy demand not only increases operational costs but also raises sustainability concerns. Finding ways to achieve and maintain laminar flow with reduced energy consumption is crucial for the broader adoption of this technology in industrial biotech settings.

Lastly, the design and fabrication of laminar flow devices for biotech applications present their own set of challenges. Creating surfaces and channels that promote laminar flow while being compatible with biological materials and sterilization processes is complex. Materials must be carefully selected to avoid interactions that could disrupt flow patterns or contaminate biological samples. Additionally, the need for precision in manufacturing these devices, especially at the microscale, adds to the complexity and cost of implementing laminar flow technologies in biotechnology.

Another critical challenge is the integration of laminar flow systems with complex biological processes. The delicate nature of many biotechnological applications, such as cell culture and protein production, demands precise control over environmental conditions. Achieving this level of control while maintaining laminar flow is often a delicate balancing act. Factors such as temperature gradients, pH variations, and nutrient distribution can disrupt laminar flow patterns, leading to suboptimal results or process failures.

The presence of particulates and biomolecules in biotech processes poses another significant hurdle for laminar flow systems. These elements can interfere with the smooth, predictable flow patterns essential for laminar flow. In applications like cell separation or protein purification, the presence of cellular debris or large biomolecules can create localized turbulence, reducing the efficiency and accuracy of the process. Developing methods to maintain laminar flow in the presence of these biological components remains a key area of research and development.

Energy efficiency is another pressing concern in laminar flow applications within biotechnology. Maintaining laminar flow often requires significant energy input, particularly in larger-scale operations. This high energy demand not only increases operational costs but also raises sustainability concerns. Finding ways to achieve and maintain laminar flow with reduced energy consumption is crucial for the broader adoption of this technology in industrial biotech settings.

Lastly, the design and fabrication of laminar flow devices for biotech applications present their own set of challenges. Creating surfaces and channels that promote laminar flow while being compatible with biological materials and sterilization processes is complex. Materials must be carefully selected to avoid interactions that could disrupt flow patterns or contaminate biological samples. Additionally, the need for precision in manufacturing these devices, especially at the microscale, adds to the complexity and cost of implementing laminar flow technologies in biotechnology.

Existing Laminar Flow Solutions

01 Measurement and analysis of laminar flow characteristics

Various methods and devices are used to measure and analyze laminar flow characteristics. These include optical systems, sensors, and flow meters that can detect and quantify flow patterns, velocities, and other properties of laminar flow. Advanced data processing techniques are often employed to interpret the measurements and provide detailed insights into flow behavior.- Measurement and analysis of laminar flow characteristics: Various methods and devices are used to measure and analyze laminar flow characteristics. These include optical systems, sensors, and computational techniques to determine flow patterns, velocity profiles, and other properties of laminar flow. Such measurements are crucial for understanding and optimizing fluid dynamics in various applications.

- Control and manipulation of laminar flow: Techniques and systems are developed to control and manipulate laminar flow characteristics. This includes the use of specialized nozzles, flow conditioners, and other devices to maintain or modify laminar flow conditions. These methods are important in applications such as spray systems, fluid dispensing, and aerodynamics.

- Laminar flow in microfluidic devices: Microfluidic devices utilize laminar flow characteristics for various applications. These devices exploit the predictable behavior of laminar flow at small scales to perform precise fluid handling, mixing, and separation tasks. The design of microchannels and flow paths is crucial for maintaining laminar flow conditions in these devices.

- Laminar flow in heat exchange and cooling systems: Laminar flow characteristics are utilized in heat exchange and cooling systems to improve efficiency and performance. The predictable nature of laminar flow allows for better control of heat transfer rates and fluid distribution. This is particularly important in applications such as electronic cooling and industrial heat exchangers.

- Laminar flow in aerodynamics and vehicle design: Laminar flow principles are applied in aerodynamics and vehicle design to reduce drag and improve efficiency. This includes the design of airfoils, body shapes, and surface treatments that promote laminar flow conditions. Understanding and controlling laminar flow characteristics is crucial for optimizing the performance of aircraft, automobiles, and other vehicles.

02 Control and manipulation of laminar flow

Techniques and apparatus for controlling and manipulating laminar flow are developed to achieve desired flow characteristics. This includes the use of specialized nozzles, flow conditioners, and other devices that can modify flow patterns, reduce turbulence, and maintain laminar conditions. These methods are crucial in various applications where precise flow control is required.Expand Specific Solutions03 Laminar flow in aerodynamics and fluid dynamics

Laminar flow plays a significant role in aerodynamics and fluid dynamics. Research focuses on understanding and optimizing laminar flow characteristics in aircraft design, wind tunnels, and other fluid systems. This includes studying boundary layer behavior, transition points, and methods to maintain laminar flow over surfaces to reduce drag and improve efficiency.Expand Specific Solutions04 Applications of laminar flow in industrial processes

Laminar flow characteristics are utilized in various industrial processes and equipment. This includes applications in chemical processing, filtration systems, heat exchangers, and precision manufacturing. The controlled nature of laminar flow allows for more predictable and efficient operations in these contexts.Expand Specific Solutions05 Modeling and simulation of laminar flow

Advanced computational methods and simulation techniques are employed to model laminar flow characteristics. These models help in predicting flow behavior, optimizing system designs, and understanding complex flow phenomena. Computational fluid dynamics (CFD) and other numerical methods are commonly used in this field of study.Expand Specific Solutions

Key Biotech Laminar Flow Players

The field of laminar flow developments in biotechnology is currently in a growth phase, with increasing market size and technological advancements. The global market for microfluidics, which heavily relies on laminar flow principles, is expected to reach significant value in the coming years. Companies like Corning, Inc. and Sony Group Corp. are investing in research and development to improve laminar flow technologies for various biotechnology applications. Academic institutions such as Zhejiang University and the University of Washington are also contributing to the field's advancement. While the technology is maturing, there is still room for innovation, particularly in areas like lab-on-a-chip devices and organ-on-a-chip systems, indicating a competitive landscape with opportunities for both established players and new entrants.

University of Washington

Technical Solution: The University of Washington has pioneered a laminar flow-based microfluidic system for single-cell analysis in biotechnology applications. Their innovative approach utilizes hydrodynamic focusing to precisely position individual cells within laminar flow streams, allowing for high-resolution analysis of cellular properties and behaviors[2]. The system incorporates advanced optical detection methods, including fluorescence and Raman spectroscopy, to characterize cells at the molecular level. Additionally, the University of Washington has developed novel surface functionalization techniques to prevent cell adhesion and maintain laminar flow conditions, enabling long-term studies of cellular dynamics[4].

Strengths: High-resolution single-cell analysis capabilities, integration of multiple detection modalities, and potential for long-term cellular studies. Weaknesses: Possible limitations in throughput compared to bulk analysis methods and challenges in analyzing rare cell populations.

Corning, Inc.

Technical Solution: Corning has developed advanced microfluidic devices that leverage laminar flow for various biotechnology applications. Their technology focuses on creating highly uniform and controllable microenvironments for cell culture and analysis. Corning's devices incorporate proprietary surface treatments that enhance cell adhesion and growth while maintaining stable laminar flow conditions[9]. The company has also developed novel manufacturing techniques to produce large-scale, high-throughput microfluidic systems suitable for industrial applications. These systems integrate seamlessly with existing laboratory automation platforms, enabling efficient scaling of laminar flow-based assays and processes[10].

Strengths: Scalability for industrial applications, integration with existing laboratory infrastructure, and advanced surface modification technologies. Weaknesses: Potential limitations in flexibility for custom applications and dependence on proprietary materials and manufacturing processes.

Core Laminar Flow Biotech Innovations

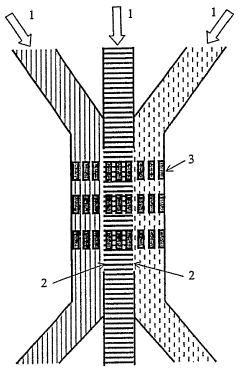

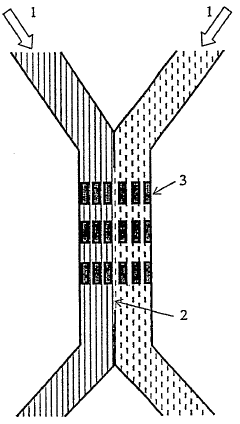

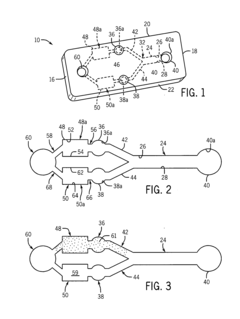

Method for transferring molecules from a chemically reacting first flow into an adjacent chemically second reacting flow

PatentWO2003099440A1

Innovation

- A method involving laminar flows with transverse electric fields is used to selectively transfer molecules between chemically incompatible streams in microreactors, allowing for parallel processing of biopolymers under different conditions without mixing, using electrodes to direct biomolecules across the flow boundary layer, thereby avoiding complex separation and mechanical steps.

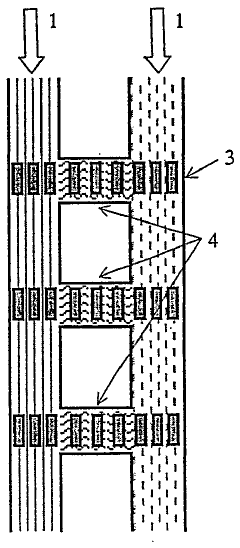

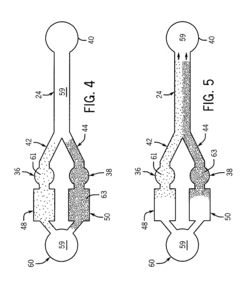

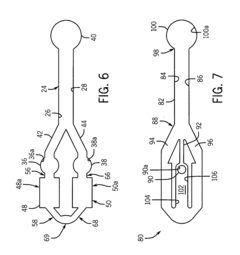

Method And Device For Controlled Laminar Flow Patterning Within A Channel

PatentActiveUS20130276890A1

Innovation

- A microfluidic device with a channel network that includes a main channel and input channels with fluidic resistances, buffering channels, and a fluidic capacitor, utilizing surface tension-generated pressures to achieve controlled laminar flow by depositing buffer and sample fluids through input ports, allowing for asynchronous loading and synchronized flow paths.

Regulatory Framework for Biotech Processes

The regulatory framework for biotech processes involving laminar flow technologies is evolving to keep pace with rapid advancements in the field. Regulatory bodies worldwide are adapting their guidelines to address the unique challenges and opportunities presented by these innovative techniques. The U.S. Food and Drug Administration (FDA) has been at the forefront, developing specific guidance documents for the use of laminar flow in biopharmaceutical manufacturing processes. These guidelines emphasize the importance of maintaining sterile conditions and product quality throughout the production cycle.

In the European Union, the European Medicines Agency (EMA) has also been proactive in addressing the regulatory aspects of laminar flow technologies in biotechnology. Their focus has been on ensuring that these processes meet Good Manufacturing Practice (GMP) standards while promoting innovation in the industry. The EMA has established working groups to continuously assess and update regulations as new laminar flow applications emerge in biotech processes.

International harmonization efforts, such as those led by the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH), are working to create globally consistent regulatory standards for laminar flow technologies in biotechnology. This approach aims to streamline the approval process for new biotech products and processes across different regions, reducing regulatory barriers and accelerating innovation.

Regulatory bodies are particularly focused on the validation and qualification of laminar flow systems in biotech processes. This includes establishing protocols for regular monitoring and testing of air quality, particle counts, and microbial contamination levels. The regulations also emphasize the importance of proper training for personnel operating these systems and maintaining detailed documentation of all processes and quality control measures.

As laminar flow technologies continue to advance, regulators are also considering the potential environmental impacts and sustainability aspects of these processes. This has led to the development of guidelines for energy efficiency and waste reduction in laminar flow systems used in biotechnology applications. Additionally, regulatory frameworks are being expanded to address the use of laminar flow in emerging areas such as cell and gene therapies, where maintaining precise environmental conditions is critical for product efficacy and safety.

In the European Union, the European Medicines Agency (EMA) has also been proactive in addressing the regulatory aspects of laminar flow technologies in biotechnology. Their focus has been on ensuring that these processes meet Good Manufacturing Practice (GMP) standards while promoting innovation in the industry. The EMA has established working groups to continuously assess and update regulations as new laminar flow applications emerge in biotech processes.

International harmonization efforts, such as those led by the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH), are working to create globally consistent regulatory standards for laminar flow technologies in biotechnology. This approach aims to streamline the approval process for new biotech products and processes across different regions, reducing regulatory barriers and accelerating innovation.

Regulatory bodies are particularly focused on the validation and qualification of laminar flow systems in biotech processes. This includes establishing protocols for regular monitoring and testing of air quality, particle counts, and microbial contamination levels. The regulations also emphasize the importance of proper training for personnel operating these systems and maintaining detailed documentation of all processes and quality control measures.

As laminar flow technologies continue to advance, regulators are also considering the potential environmental impacts and sustainability aspects of these processes. This has led to the development of guidelines for energy efficiency and waste reduction in laminar flow systems used in biotechnology applications. Additionally, regulatory frameworks are being expanded to address the use of laminar flow in emerging areas such as cell and gene therapies, where maintaining precise environmental conditions is critical for product efficacy and safety.

Sustainability in Laminar Flow Biotech

Sustainability in laminar flow biotechnology is becoming increasingly crucial as the industry evolves to meet global challenges. The integration of sustainable practices in this field not only addresses environmental concerns but also enhances operational efficiency and long-term viability. One key aspect of sustainability in laminar flow biotech is the optimization of resource utilization. This includes the development of more energy-efficient laminar flow systems that reduce power consumption without compromising performance.

Water conservation is another critical area of focus. Advanced recycling and purification technologies are being implemented to minimize water usage in laminar flow processes. These systems not only reduce the environmental footprint but also lead to significant cost savings for biotech facilities. Additionally, the use of eco-friendly materials in the construction of laminar flow equipment is gaining traction. Biodegradable and recyclable components are being incorporated wherever possible, reducing waste and promoting a circular economy approach.

The adoption of smart technologies and automation in laminar flow systems is contributing to sustainability efforts. Intelligent control systems optimize flow rates and adjust parameters in real-time, ensuring minimal resource wastage and maximum efficiency. This not only reduces energy consumption but also extends the lifespan of equipment, reducing the need for frequent replacements.

Biotechnology companies are also exploring the use of renewable energy sources to power laminar flow operations. Solar panels and wind turbines are being integrated into facility designs, providing clean energy for these energy-intensive processes. This shift towards renewable energy not only reduces carbon emissions but also provides long-term cost benefits and energy security.

Waste management is another crucial aspect of sustainability in laminar flow biotech. Advanced filtration and treatment systems are being developed to handle biological waste more effectively, minimizing environmental impact. These systems not only ensure compliance with stringent regulations but also open up possibilities for byproduct recovery and utilization.

As the biotechnology sector continues to grow, the importance of sustainable laminar flow practices cannot be overstated. The industry is witnessing a paradigm shift towards holistic sustainability, where environmental responsibility is seamlessly integrated with technological advancement and economic viability. This approach not only ensures regulatory compliance but also enhances brand reputation and opens up new market opportunities in an increasingly eco-conscious global economy.

Water conservation is another critical area of focus. Advanced recycling and purification technologies are being implemented to minimize water usage in laminar flow processes. These systems not only reduce the environmental footprint but also lead to significant cost savings for biotech facilities. Additionally, the use of eco-friendly materials in the construction of laminar flow equipment is gaining traction. Biodegradable and recyclable components are being incorporated wherever possible, reducing waste and promoting a circular economy approach.

The adoption of smart technologies and automation in laminar flow systems is contributing to sustainability efforts. Intelligent control systems optimize flow rates and adjust parameters in real-time, ensuring minimal resource wastage and maximum efficiency. This not only reduces energy consumption but also extends the lifespan of equipment, reducing the need for frequent replacements.

Biotechnology companies are also exploring the use of renewable energy sources to power laminar flow operations. Solar panels and wind turbines are being integrated into facility designs, providing clean energy for these energy-intensive processes. This shift towards renewable energy not only reduces carbon emissions but also provides long-term cost benefits and energy security.

Waste management is another crucial aspect of sustainability in laminar flow biotech. Advanced filtration and treatment systems are being developed to handle biological waste more effectively, minimizing environmental impact. These systems not only ensure compliance with stringent regulations but also open up possibilities for byproduct recovery and utilization.

As the biotechnology sector continues to grow, the importance of sustainable laminar flow practices cannot be overstated. The industry is witnessing a paradigm shift towards holistic sustainability, where environmental responsibility is seamlessly integrated with technological advancement and economic viability. This approach not only ensures regulatory compliance but also enhances brand reputation and opens up new market opportunities in an increasingly eco-conscious global economy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!