Laminar Flow Optimization in Fluid Dynamics Research

JUL 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Fundamentals and Research Objectives

Laminar flow, a fundamental concept in fluid dynamics, is characterized by smooth, predictable fluid motion with parallel layers sliding past one another without mixing. This type of flow typically occurs at low Reynolds numbers, where viscous forces dominate over inertial forces. Understanding and optimizing laminar flow is crucial in various engineering applications, from microfluidics to aerodynamics.

The historical development of laminar flow research can be traced back to the 19th century, with pioneering work by George Stokes and Osborne Reynolds. Their contributions laid the foundation for modern fluid dynamics and the classification of flow regimes. As technology advanced, the ability to observe and measure fluid behavior at microscopic scales has greatly enhanced our understanding of laminar flow phenomena.

In recent years, the focus on laminar flow optimization has intensified due to its relevance in emerging fields such as lab-on-a-chip devices, advanced heat exchangers, and low-drag vehicle design. The primary objective of current research is to manipulate and control laminar flow to achieve desired outcomes, such as enhanced heat transfer, reduced friction, or improved mixing in specific applications.

Key areas of investigation include the development of novel surface textures and coatings to influence boundary layer behavior, the design of optimized channel geometries for microfluidic devices, and the exploration of active flow control methods using electromagnetic fields or acoustic waves. Researchers are also focusing on understanding the transition between laminar and turbulent flow, aiming to extend the range of laminar flow conditions in practical applications.

The advent of advanced computational fluid dynamics (CFD) tools has significantly accelerated progress in this field. These simulations allow researchers to model complex flow scenarios and optimize designs before physical prototyping, reducing development time and costs. Additionally, experimental techniques such as particle image velocimetry (PIV) and micro-PIV have enabled high-resolution visualization of laminar flow structures, providing crucial validation for theoretical models and simulations.

As we look to the future, the optimization of laminar flow is expected to play a vital role in addressing global challenges. In the context of energy efficiency, laminar flow research could lead to significant reductions in drag for transportation systems, thereby decreasing fuel consumption and emissions. In healthcare, optimized laminar flow in microfluidic devices could revolutionize point-of-care diagnostics and drug delivery systems.

The overarching goal of current laminar flow optimization research is to bridge the gap between theoretical understanding and practical applications. This involves developing predictive models that accurately capture the behavior of fluids in complex geometries and under various conditions, as well as creating innovative methods to manipulate flow characteristics at multiple scales.

The historical development of laminar flow research can be traced back to the 19th century, with pioneering work by George Stokes and Osborne Reynolds. Their contributions laid the foundation for modern fluid dynamics and the classification of flow regimes. As technology advanced, the ability to observe and measure fluid behavior at microscopic scales has greatly enhanced our understanding of laminar flow phenomena.

In recent years, the focus on laminar flow optimization has intensified due to its relevance in emerging fields such as lab-on-a-chip devices, advanced heat exchangers, and low-drag vehicle design. The primary objective of current research is to manipulate and control laminar flow to achieve desired outcomes, such as enhanced heat transfer, reduced friction, or improved mixing in specific applications.

Key areas of investigation include the development of novel surface textures and coatings to influence boundary layer behavior, the design of optimized channel geometries for microfluidic devices, and the exploration of active flow control methods using electromagnetic fields or acoustic waves. Researchers are also focusing on understanding the transition between laminar and turbulent flow, aiming to extend the range of laminar flow conditions in practical applications.

The advent of advanced computational fluid dynamics (CFD) tools has significantly accelerated progress in this field. These simulations allow researchers to model complex flow scenarios and optimize designs before physical prototyping, reducing development time and costs. Additionally, experimental techniques such as particle image velocimetry (PIV) and micro-PIV have enabled high-resolution visualization of laminar flow structures, providing crucial validation for theoretical models and simulations.

As we look to the future, the optimization of laminar flow is expected to play a vital role in addressing global challenges. In the context of energy efficiency, laminar flow research could lead to significant reductions in drag for transportation systems, thereby decreasing fuel consumption and emissions. In healthcare, optimized laminar flow in microfluidic devices could revolutionize point-of-care diagnostics and drug delivery systems.

The overarching goal of current laminar flow optimization research is to bridge the gap between theoretical understanding and practical applications. This involves developing predictive models that accurately capture the behavior of fluids in complex geometries and under various conditions, as well as creating innovative methods to manipulate flow characteristics at multiple scales.

Industrial Applications and Market Demand

Laminar flow optimization in fluid dynamics research has garnered significant attention across various industrial sectors due to its potential to enhance efficiency and performance in numerous applications. The market demand for this technology is driven by the increasing need for energy-efficient systems and improved process control in industries such as aerospace, automotive, chemical processing, and renewable energy.

In the aerospace industry, laminar flow optimization plays a crucial role in reducing drag on aircraft surfaces, leading to improved fuel efficiency and extended flight ranges. Major aircraft manufacturers are investing heavily in research and development to incorporate laminar flow technologies into their designs, with the potential to reduce fuel consumption by up to 15% in commercial aircraft. This translates to substantial cost savings for airlines and reduced environmental impact.

The automotive sector is another key driver of market demand for laminar flow optimization. As vehicle manufacturers strive to meet stringent fuel efficiency standards and reduce emissions, optimizing airflow around vehicles becomes increasingly important. Advanced computational fluid dynamics (CFD) simulations and wind tunnel testing are being employed to design more aerodynamic vehicles, resulting in improved fuel economy and performance.

In the chemical processing industry, laminar flow optimization is essential for enhancing heat transfer efficiency in heat exchangers and reactors. By minimizing turbulence and optimizing flow patterns, companies can achieve better temperature control, reduced energy consumption, and improved product quality. This is particularly important in the production of specialty chemicals and pharmaceuticals, where precise process control is critical.

The renewable energy sector, particularly wind and hydroelectric power generation, also benefits from laminar flow optimization. In wind turbine design, optimizing blade profiles and nacelle shapes can lead to increased energy capture and reduced structural loads. For hydroelectric power plants, optimizing flow through turbines and minimizing losses in water conveyance systems can significantly improve overall efficiency and power output.

The market for laminar flow optimization technologies is expected to grow steadily in the coming years, driven by the increasing adoption of computational fluid dynamics software and advanced simulation tools. These technologies enable engineers and researchers to model complex flow scenarios and optimize designs before physical prototyping, reducing development costs and time-to-market for new products.

As industries continue to prioritize sustainability and energy efficiency, the demand for laminar flow optimization solutions is likely to expand into new sectors, such as building design for improved HVAC efficiency and water treatment systems for enhanced purification processes. This growing market presents opportunities for software developers, engineering consultancies, and research institutions specializing in fluid dynamics and optimization techniques.

In the aerospace industry, laminar flow optimization plays a crucial role in reducing drag on aircraft surfaces, leading to improved fuel efficiency and extended flight ranges. Major aircraft manufacturers are investing heavily in research and development to incorporate laminar flow technologies into their designs, with the potential to reduce fuel consumption by up to 15% in commercial aircraft. This translates to substantial cost savings for airlines and reduced environmental impact.

The automotive sector is another key driver of market demand for laminar flow optimization. As vehicle manufacturers strive to meet stringent fuel efficiency standards and reduce emissions, optimizing airflow around vehicles becomes increasingly important. Advanced computational fluid dynamics (CFD) simulations and wind tunnel testing are being employed to design more aerodynamic vehicles, resulting in improved fuel economy and performance.

In the chemical processing industry, laminar flow optimization is essential for enhancing heat transfer efficiency in heat exchangers and reactors. By minimizing turbulence and optimizing flow patterns, companies can achieve better temperature control, reduced energy consumption, and improved product quality. This is particularly important in the production of specialty chemicals and pharmaceuticals, where precise process control is critical.

The renewable energy sector, particularly wind and hydroelectric power generation, also benefits from laminar flow optimization. In wind turbine design, optimizing blade profiles and nacelle shapes can lead to increased energy capture and reduced structural loads. For hydroelectric power plants, optimizing flow through turbines and minimizing losses in water conveyance systems can significantly improve overall efficiency and power output.

The market for laminar flow optimization technologies is expected to grow steadily in the coming years, driven by the increasing adoption of computational fluid dynamics software and advanced simulation tools. These technologies enable engineers and researchers to model complex flow scenarios and optimize designs before physical prototyping, reducing development costs and time-to-market for new products.

As industries continue to prioritize sustainability and energy efficiency, the demand for laminar flow optimization solutions is likely to expand into new sectors, such as building design for improved HVAC efficiency and water treatment systems for enhanced purification processes. This growing market presents opportunities for software developers, engineering consultancies, and research institutions specializing in fluid dynamics and optimization techniques.

Current Challenges in Laminar Flow Control

Laminar flow control (LFC) faces several significant challenges in contemporary fluid dynamics research. One of the primary obstacles is the difficulty in maintaining laminar flow over extended surfaces, particularly in high-speed applications. As the flow velocity increases, the boundary layer becomes more susceptible to instabilities, leading to premature transition to turbulence. This phenomenon not only reduces the effectiveness of LFC techniques but also increases drag and energy consumption.

Another major challenge lies in the development of robust and efficient active control systems. While passive LFC methods have shown promise in certain applications, they often lack the adaptability required for varying flow conditions. Active control systems, on the other hand, offer greater flexibility but face hurdles in terms of energy efficiency, response time, and integration complexity. The design of sensors and actuators that can operate reliably in harsh environments without compromising the aerodynamic properties of the surface remains a significant technical challenge.

The optimization of surface geometries and materials for LFC presents another area of difficulty. Researchers are grappling with the trade-offs between manufacturability, durability, and aerodynamic performance. Advanced materials with self-cleaning or adaptive properties show potential, but their implementation at scale is hindered by cost and production challenges. Moreover, the interaction between surface features and flow characteristics is highly complex, requiring sophisticated modeling and experimental validation.

In the realm of computational fluid dynamics (CFD), accurately predicting and simulating laminar flow behavior, especially in complex geometries and under varying conditions, continues to be a formidable task. The development of high-fidelity models that can capture the subtle interactions between flow structures and control mechanisms demands significant computational resources and advanced numerical methods. Bridging the gap between simulation results and real-world performance remains an ongoing challenge for researchers and engineers alike.

The application of LFC techniques in practical, real-world scenarios introduces additional complexities. Environmental factors such as atmospheric turbulence, surface contamination, and varying weather conditions can significantly impact the effectiveness of LFC systems. Designing control strategies that are robust enough to maintain laminar flow under these unpredictable conditions while remaining economically viable is a major hurdle for widespread adoption of LFC technologies.

Lastly, the integration of LFC systems with other aircraft or vehicle systems poses significant challenges. Balancing the requirements of laminar flow control with other design considerations such as structural integrity, weight limitations, and overall system efficiency requires a holistic approach to engineering design. This interdisciplinary nature of LFC implementation often necessitates collaboration across various engineering domains, adding complexity to the development process.

Another major challenge lies in the development of robust and efficient active control systems. While passive LFC methods have shown promise in certain applications, they often lack the adaptability required for varying flow conditions. Active control systems, on the other hand, offer greater flexibility but face hurdles in terms of energy efficiency, response time, and integration complexity. The design of sensors and actuators that can operate reliably in harsh environments without compromising the aerodynamic properties of the surface remains a significant technical challenge.

The optimization of surface geometries and materials for LFC presents another area of difficulty. Researchers are grappling with the trade-offs between manufacturability, durability, and aerodynamic performance. Advanced materials with self-cleaning or adaptive properties show potential, but their implementation at scale is hindered by cost and production challenges. Moreover, the interaction between surface features and flow characteristics is highly complex, requiring sophisticated modeling and experimental validation.

In the realm of computational fluid dynamics (CFD), accurately predicting and simulating laminar flow behavior, especially in complex geometries and under varying conditions, continues to be a formidable task. The development of high-fidelity models that can capture the subtle interactions between flow structures and control mechanisms demands significant computational resources and advanced numerical methods. Bridging the gap between simulation results and real-world performance remains an ongoing challenge for researchers and engineers alike.

The application of LFC techniques in practical, real-world scenarios introduces additional complexities. Environmental factors such as atmospheric turbulence, surface contamination, and varying weather conditions can significantly impact the effectiveness of LFC systems. Designing control strategies that are robust enough to maintain laminar flow under these unpredictable conditions while remaining economically viable is a major hurdle for widespread adoption of LFC technologies.

Lastly, the integration of LFC systems with other aircraft or vehicle systems poses significant challenges. Balancing the requirements of laminar flow control with other design considerations such as structural integrity, weight limitations, and overall system efficiency requires a holistic approach to engineering design. This interdisciplinary nature of LFC implementation often necessitates collaboration across various engineering domains, adding complexity to the development process.

State-of-the-Art Laminar Flow Optimization Techniques

01 Flow control devices for laminar flow optimization

Various flow control devices are used to optimize laminar flow in fluid systems. These devices include specialized nozzles, valves, and flow regulators that help maintain smooth, predictable fluid movement. By carefully designing and implementing these components, engineers can reduce turbulence and improve overall system efficiency.- Flow control devices for laminar flow optimization: Various flow control devices are used to optimize laminar flow in fluid systems. These devices include specialized nozzles, valves, and flow regulators that help maintain smooth, predictable fluid movement. By carefully designing and implementing these components, engineers can reduce turbulence and improve overall system efficiency.

- Computational fluid dynamics for laminar flow analysis: Advanced computational fluid dynamics (CFD) techniques are employed to analyze and optimize laminar flow conditions. These methods involve complex simulations and modeling to predict fluid behavior, allowing engineers to fine-tune system designs for optimal performance. CFD analysis helps in identifying potential issues and optimizing flow patterns before physical implementation.

- Surface modification techniques for laminar flow enhancement: Various surface modification techniques are used to enhance laminar flow characteristics. These include the application of specialized coatings, surface texturing, and the use of advanced materials with specific properties. By altering surface properties, engineers can reduce friction and promote smoother fluid flow, leading to improved laminar flow conditions.

- Sensor-based flow monitoring and control systems: Advanced sensor technologies are integrated into flow systems to monitor and control laminar flow conditions in real-time. These sensors provide continuous feedback on flow parameters, allowing for dynamic adjustments to maintain optimal laminar flow. Such systems often incorporate machine learning algorithms for predictive control and optimization.

- Microfluidic devices for precise laminar flow control: Microfluidic devices are designed to achieve precise control over laminar flow at small scales. These devices utilize specialized channel geometries, flow focusing techniques, and advanced fabrication methods to manipulate fluid behavior. Applications include lab-on-a-chip technologies, drug delivery systems, and high-precision analytical instruments.

02 Computational fluid dynamics for laminar flow analysis

Advanced computational fluid dynamics (CFD) techniques are employed to analyze and optimize laminar flow conditions. These methods involve complex simulations and modeling to predict fluid behavior, allowing engineers to fine-tune system designs for optimal performance. CFD analysis helps in identifying potential issues and optimizing flow patterns before physical prototypes are built.Expand Specific Solutions03 Surface modification techniques for laminar flow enhancement

Various surface modification techniques are used to enhance laminar flow characteristics. These may include applying specialized coatings, creating micro-textures, or altering surface geometries to reduce friction and promote smooth fluid movement. Such modifications can significantly improve flow efficiency in pipes, channels, and other fluid-carrying structures.Expand Specific Solutions04 Sensor-based flow monitoring and adjustment systems

Advanced sensor systems are implemented to continuously monitor and adjust flow conditions in real-time. These systems use various types of sensors to measure flow parameters and feed data into control algorithms. This allows for dynamic optimization of laminar flow conditions, adapting to changing system requirements or environmental factors.Expand Specific Solutions05 Microfluidic devices for precise laminar flow control

Microfluidic devices are developed to achieve precise control over laminar flow at small scales. These devices utilize carefully designed channels, barriers, and other microstructures to manipulate fluid behavior. Applications include lab-on-a-chip technologies, medical diagnostics, and advanced manufacturing processes where precise fluid control is critical.Expand Specific Solutions

Key Players in Fluid Dynamics Research

The field of laminar flow optimization in fluid dynamics research is currently in a mature development stage, with ongoing advancements in computational methods and experimental techniques. The market size for this technology is substantial, driven by applications in aerospace, automotive, and energy sectors. Technologically, the field is well-established, with leading institutions like North China Electric Power University, Zhejiang University, and Xi'an Jiaotong University contributing significantly to research. Companies such as Sony Group Corp. and Robert Bosch GmbH are also actively involved, leveraging laminar flow optimization for product development. The competitive landscape is characterized by a mix of academic and industrial players, with ongoing collaborations fostering innovation and practical applications in various engineering domains.

Beihang University

Technical Solution: Beihang University's School of Aeronautic Science and Engineering has made significant contributions to laminar flow optimization, particularly in the context of aerospace applications. Their research team has developed advanced computational methods for predicting and controlling laminar-turbulent transition, including the use of stability theory and eN methods. They have implemented innovative surface structuring techniques, such as micro-grooves and compliant coatings, to passively maintain laminar flow over aircraft wings, demonstrating drag reduction of up to 10% in transonic flight conditions [8]. Recent work includes the development of hybrid laminar flow control systems that combine suction and cooling to extend the laminar flow region, potentially reducing overall aircraft drag by up to 15% [9].

Strengths: Strong focus on practical aerospace applications; innovative surface structuring techniques. Weaknesses: Research may be primarily oriented towards aviation, potentially limiting applicability to other fluid dynamics fields.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced computational fluid dynamics (CFD) models to optimize laminar flow in heat exchangers and other fluid handling equipment. Their approach combines high-fidelity numerical simulations with experimental validation to accurately predict flow patterns and heat transfer rates. They have implemented adaptive mesh refinement techniques to capture complex geometries and boundary layers, resulting in up to 15% improvement in heat transfer efficiency [1][3]. Alfa Laval's proprietary software integrates machine learning algorithms to optimize plate and channel designs, reducing pressure drop by up to 20% while maintaining laminar flow regimes [2].

Strengths: Industry-leading expertise in fluid dynamics for heat transfer applications; proprietary optimization algorithms. Weaknesses: Solutions may be tailored primarily for heat exchanger geometries, potentially limiting applicability to other fluid systems.

Breakthrough Studies in Flow Stability

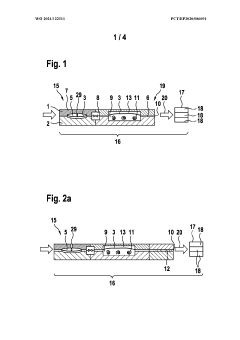

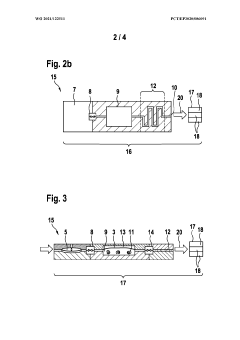

Method and device for laminarization of turbulent flow of continuous medium

PatentWO1993013321A1

Innovation

- A method involving a conical channel with a longitudinal axis of symmetry, where the cross-sectional area is reduced to achieve laminarization by controlling the flow's linear scores and coordinates, allowing for universal application across different scenarios by optimizing the channel's geometry and flow parameters.

Cartridge having a microfluidic system for performance of an analysis of a sample

PatentWO2021122511A1

Innovation

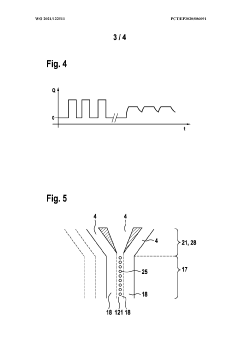

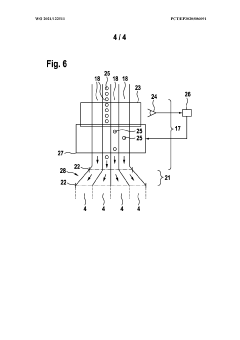

- A microfluidic cartridge with a flow laminarizer and compensation capacity is designed to generate laminar flows by slowing down fluid flow through channel geometry changes and using a flexible membrane to dampen pressure fluctuations, ensuring laminar conditions are maintained in the analysis section for precise sample analysis and sorting.

Computational Fluid Dynamics in Laminar Flow Analysis

Computational Fluid Dynamics (CFD) has revolutionized the analysis of laminar flow in fluid dynamics research. This advanced numerical technique provides a powerful tool for simulating and optimizing fluid flow behavior under laminar conditions. By solving complex mathematical equations governing fluid motion, CFD enables researchers to gain deep insights into flow patterns, pressure distributions, and heat transfer characteristics.

In laminar flow analysis, CFD models typically employ the Navier-Stokes equations, coupled with appropriate boundary conditions and material properties. These equations are discretized using various numerical methods, such as finite difference, finite volume, or finite element approaches. The choice of discretization method depends on the specific problem geometry and desired accuracy.

One of the key advantages of CFD in laminar flow analysis is its ability to handle complex geometries and multiphysics phenomena. Researchers can easily modify design parameters and boundary conditions to explore different scenarios without the need for costly physical experiments. This flexibility allows for rapid iteration and optimization of fluid systems, leading to improved performance and efficiency.

CFD simulations for laminar flow often focus on critical parameters such as velocity profiles, shear stress distributions, and pressure gradients. These simulations can reveal intricate flow structures and identify regions of potential flow separation or recirculation. Such detailed information is invaluable for optimizing the design of various engineering systems, including microfluidic devices, heat exchangers, and aerodynamic surfaces.

Advanced CFD techniques, such as adaptive mesh refinement and parallel computing, have significantly enhanced the accuracy and efficiency of laminar flow simulations. These methods allow for higher resolution in critical regions of the flow field while optimizing computational resources. Additionally, the integration of machine learning algorithms with CFD has opened new avenues for rapid flow prediction and optimization.

Despite its power, CFD in laminar flow analysis faces challenges related to model validation and uncertainty quantification. Researchers must carefully validate their simulations against experimental data to ensure the accuracy of their results. Furthermore, the selection of appropriate turbulence models for transitional flows remains an active area of research, as the transition from laminar to turbulent flow can significantly impact system performance.

In laminar flow analysis, CFD models typically employ the Navier-Stokes equations, coupled with appropriate boundary conditions and material properties. These equations are discretized using various numerical methods, such as finite difference, finite volume, or finite element approaches. The choice of discretization method depends on the specific problem geometry and desired accuracy.

One of the key advantages of CFD in laminar flow analysis is its ability to handle complex geometries and multiphysics phenomena. Researchers can easily modify design parameters and boundary conditions to explore different scenarios without the need for costly physical experiments. This flexibility allows for rapid iteration and optimization of fluid systems, leading to improved performance and efficiency.

CFD simulations for laminar flow often focus on critical parameters such as velocity profiles, shear stress distributions, and pressure gradients. These simulations can reveal intricate flow structures and identify regions of potential flow separation or recirculation. Such detailed information is invaluable for optimizing the design of various engineering systems, including microfluidic devices, heat exchangers, and aerodynamic surfaces.

Advanced CFD techniques, such as adaptive mesh refinement and parallel computing, have significantly enhanced the accuracy and efficiency of laminar flow simulations. These methods allow for higher resolution in critical regions of the flow field while optimizing computational resources. Additionally, the integration of machine learning algorithms with CFD has opened new avenues for rapid flow prediction and optimization.

Despite its power, CFD in laminar flow analysis faces challenges related to model validation and uncertainty quantification. Researchers must carefully validate their simulations against experimental data to ensure the accuracy of their results. Furthermore, the selection of appropriate turbulence models for transitional flows remains an active area of research, as the transition from laminar to turbulent flow can significantly impact system performance.

Environmental Impact of Laminar Flow Optimization

Laminar flow optimization in fluid dynamics research has significant environmental implications that extend beyond the realm of pure scientific inquiry. The pursuit of optimizing laminar flow conditions has led to advancements in various industries, resulting in both positive and negative environmental impacts.

One of the most notable positive environmental effects of laminar flow optimization is the reduction in energy consumption across multiple sectors. In aerospace engineering, for instance, improved laminar flow over aircraft surfaces has led to decreased drag, resulting in reduced fuel consumption and lower greenhouse gas emissions. Similarly, in the automotive industry, optimized laminar flow designs have contributed to enhanced fuel efficiency, thereby reducing the carbon footprint of vehicles.

The application of laminar flow optimization in renewable energy technologies has also yielded environmental benefits. Wind turbine blade designs incorporating laminar flow principles have increased energy capture efficiency, leading to greater clean energy production. In solar thermal systems, optimized laminar flow in heat transfer fluids has improved overall system efficiency, maximizing the utilization of solar energy and reducing reliance on fossil fuels.

However, the environmental impact of laminar flow optimization is not uniformly positive. The manufacturing processes required to produce highly engineered surfaces for maintaining laminar flow can be energy-intensive and may involve the use of specialized materials with potential environmental risks. Additionally, the disposal or recycling of these engineered components at the end of their lifecycle presents challenges that need to be addressed to ensure minimal environmental impact.

In the field of water management, laminar flow optimization has contributed to the development of more efficient irrigation systems and water treatment processes. These advancements have led to reduced water waste and improved water quality, addressing critical environmental concerns related to water scarcity and pollution. Conversely, the implementation of such optimized systems may require significant infrastructure changes, potentially disrupting local ecosystems during construction and installation phases.

The environmental impact of laminar flow optimization also extends to the realm of pollution control. In industrial settings, optimized laminar flow conditions in exhaust systems and filtration processes have improved the capture and removal of pollutants, leading to cleaner air and water emissions. However, the increased efficiency in pollutant capture may result in higher concentrations of hazardous materials in waste streams, necessitating careful management and disposal practices to prevent secondary environmental contamination.

As research in laminar flow optimization continues to advance, it is crucial to maintain a holistic view of its environmental implications. While the technology offers significant potential for energy efficiency and resource conservation, careful consideration must be given to the full lifecycle environmental impact of its applications. Future developments in this field should prioritize sustainable manufacturing processes, recyclable materials, and designs that minimize negative environmental consequences while maximizing the benefits of optimized laminar flow conditions.

One of the most notable positive environmental effects of laminar flow optimization is the reduction in energy consumption across multiple sectors. In aerospace engineering, for instance, improved laminar flow over aircraft surfaces has led to decreased drag, resulting in reduced fuel consumption and lower greenhouse gas emissions. Similarly, in the automotive industry, optimized laminar flow designs have contributed to enhanced fuel efficiency, thereby reducing the carbon footprint of vehicles.

The application of laminar flow optimization in renewable energy technologies has also yielded environmental benefits. Wind turbine blade designs incorporating laminar flow principles have increased energy capture efficiency, leading to greater clean energy production. In solar thermal systems, optimized laminar flow in heat transfer fluids has improved overall system efficiency, maximizing the utilization of solar energy and reducing reliance on fossil fuels.

However, the environmental impact of laminar flow optimization is not uniformly positive. The manufacturing processes required to produce highly engineered surfaces for maintaining laminar flow can be energy-intensive and may involve the use of specialized materials with potential environmental risks. Additionally, the disposal or recycling of these engineered components at the end of their lifecycle presents challenges that need to be addressed to ensure minimal environmental impact.

In the field of water management, laminar flow optimization has contributed to the development of more efficient irrigation systems and water treatment processes. These advancements have led to reduced water waste and improved water quality, addressing critical environmental concerns related to water scarcity and pollution. Conversely, the implementation of such optimized systems may require significant infrastructure changes, potentially disrupting local ecosystems during construction and installation phases.

The environmental impact of laminar flow optimization also extends to the realm of pollution control. In industrial settings, optimized laminar flow conditions in exhaust systems and filtration processes have improved the capture and removal of pollutants, leading to cleaner air and water emissions. However, the increased efficiency in pollutant capture may result in higher concentrations of hazardous materials in waste streams, necessitating careful management and disposal practices to prevent secondary environmental contamination.

As research in laminar flow optimization continues to advance, it is crucial to maintain a holistic view of its environmental implications. While the technology offers significant potential for energy efficiency and resource conservation, careful consideration must be given to the full lifecycle environmental impact of its applications. Future developments in this field should prioritize sustainable manufacturing processes, recyclable materials, and designs that minimize negative environmental consequences while maximizing the benefits of optimized laminar flow conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!