Increasing Industrial Output with Laminar Flow Adoption

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Tech Evolution and Objectives

Laminar flow technology has evolved significantly over the past century, revolutionizing various industrial processes and contributing to increased efficiency and output. The concept of laminar flow, characterized by smooth, predictable fluid motion, was first described mathematically by George Gabriel Stokes in the mid-19th century. However, its practical applications in industry only began to gain traction in the mid-20th century.

The primary objective of adopting laminar flow technology in industrial settings is to optimize fluid dynamics, reduce turbulence, and enhance overall process control. This technology aims to minimize energy losses, improve heat transfer efficiency, and ensure precise fluid handling in various manufacturing and production processes. By achieving these goals, industries can significantly increase their output while reducing operational costs and improving product quality.

Throughout its evolution, laminar flow technology has seen several key milestones. In the 1960s and 1970s, the development of advanced computational fluid dynamics (CFD) models allowed for more accurate predictions of fluid behavior, leading to improved design of laminar flow systems. The 1980s and 1990s witnessed the integration of laminar flow principles in cleanroom technologies, revolutionizing semiconductor manufacturing and pharmaceutical production.

Recent advancements in materials science and nanotechnology have further expanded the applications of laminar flow. The development of specialized surfaces and coatings that promote laminar flow has enabled its adoption in previously challenging environments. Additionally, the miniaturization of fluid handling systems has led to the emergence of microfluidics, where laminar flow principles are crucial for precise control at microscopic scales.

Looking ahead, the objectives for laminar flow technology in industrial applications are multifaceted. One key goal is to extend its benefits to a broader range of industries, including those with traditionally turbulent flow regimes. Researchers and engineers are working on developing adaptive flow control systems that can maintain laminar flow under varying conditions, thereby increasing the technology's versatility and applicability.

Another important objective is to enhance the energy efficiency of laminar flow systems. This involves optimizing pump designs, improving pipe and channel geometries, and developing smart control systems that can dynamically adjust flow parameters to maintain optimal performance. By achieving these objectives, industries can expect to see further increases in output, reductions in energy consumption, and improvements in product quality.

The primary objective of adopting laminar flow technology in industrial settings is to optimize fluid dynamics, reduce turbulence, and enhance overall process control. This technology aims to minimize energy losses, improve heat transfer efficiency, and ensure precise fluid handling in various manufacturing and production processes. By achieving these goals, industries can significantly increase their output while reducing operational costs and improving product quality.

Throughout its evolution, laminar flow technology has seen several key milestones. In the 1960s and 1970s, the development of advanced computational fluid dynamics (CFD) models allowed for more accurate predictions of fluid behavior, leading to improved design of laminar flow systems. The 1980s and 1990s witnessed the integration of laminar flow principles in cleanroom technologies, revolutionizing semiconductor manufacturing and pharmaceutical production.

Recent advancements in materials science and nanotechnology have further expanded the applications of laminar flow. The development of specialized surfaces and coatings that promote laminar flow has enabled its adoption in previously challenging environments. Additionally, the miniaturization of fluid handling systems has led to the emergence of microfluidics, where laminar flow principles are crucial for precise control at microscopic scales.

Looking ahead, the objectives for laminar flow technology in industrial applications are multifaceted. One key goal is to extend its benefits to a broader range of industries, including those with traditionally turbulent flow regimes. Researchers and engineers are working on developing adaptive flow control systems that can maintain laminar flow under varying conditions, thereby increasing the technology's versatility and applicability.

Another important objective is to enhance the energy efficiency of laminar flow systems. This involves optimizing pump designs, improving pipe and channel geometries, and developing smart control systems that can dynamically adjust flow parameters to maintain optimal performance. By achieving these objectives, industries can expect to see further increases in output, reductions in energy consumption, and improvements in product quality.

Industrial Demand for Laminar Flow Solutions

The industrial demand for laminar flow solutions has been steadily increasing across various sectors, driven by the need for enhanced efficiency, precision, and quality control in manufacturing processes. Laminar flow, characterized by smooth and predictable fluid motion, offers significant advantages in applications ranging from cleanroom environments to advanced manufacturing techniques.

In the semiconductor industry, the demand for laminar flow solutions has surged due to the ever-increasing requirements for contamination control in chip production. As semiconductor manufacturers push towards smaller node sizes and more complex designs, the need for ultra-clean environments becomes paramount. Laminar flow systems play a crucial role in maintaining particle-free zones, ensuring higher yields and reducing defects in semiconductor fabrication.

The pharmaceutical and biotechnology sectors have also witnessed a growing demand for laminar flow technologies. With stringent regulatory requirements and the need for aseptic processing in drug manufacturing, laminar flow systems are essential for maintaining sterile conditions. The adoption of these solutions has been particularly pronounced in the production of biologics, vaccines, and cell therapies, where even minor contamination can have severe consequences.

In the automotive industry, laminar flow solutions are increasingly sought after for paint booths and coating applications. The technology enables uniform air distribution, resulting in improved paint finish quality, reduced overspray, and enhanced energy efficiency. As automakers strive for higher quality standards and environmental compliance, the demand for advanced laminar flow systems continues to rise.

The food and beverage industry has also recognized the benefits of laminar flow in ensuring product safety and quality. In processing and packaging facilities, laminar flow systems help maintain hygienic conditions, prevent cross-contamination, and extend product shelf life. This has led to increased adoption in areas such as dairy processing, ready-to-eat meal production, and beverage bottling lines.

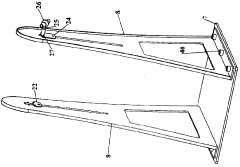

The aerospace sector represents another significant market for laminar flow solutions. In aircraft manufacturing, laminar flow systems are crucial for creating controlled environments during assembly and coating processes. Additionally, research into laminar flow control for aircraft design aims to reduce drag and improve fuel efficiency, driving further demand for advanced flow management technologies.

As industries continue to prioritize product quality, operational efficiency, and regulatory compliance, the demand for laminar flow solutions is expected to grow. This trend is further reinforced by the increasing focus on sustainability and energy efficiency, as laminar flow systems can contribute to reduced energy consumption and waste in various industrial processes.

In the semiconductor industry, the demand for laminar flow solutions has surged due to the ever-increasing requirements for contamination control in chip production. As semiconductor manufacturers push towards smaller node sizes and more complex designs, the need for ultra-clean environments becomes paramount. Laminar flow systems play a crucial role in maintaining particle-free zones, ensuring higher yields and reducing defects in semiconductor fabrication.

The pharmaceutical and biotechnology sectors have also witnessed a growing demand for laminar flow technologies. With stringent regulatory requirements and the need for aseptic processing in drug manufacturing, laminar flow systems are essential for maintaining sterile conditions. The adoption of these solutions has been particularly pronounced in the production of biologics, vaccines, and cell therapies, where even minor contamination can have severe consequences.

In the automotive industry, laminar flow solutions are increasingly sought after for paint booths and coating applications. The technology enables uniform air distribution, resulting in improved paint finish quality, reduced overspray, and enhanced energy efficiency. As automakers strive for higher quality standards and environmental compliance, the demand for advanced laminar flow systems continues to rise.

The food and beverage industry has also recognized the benefits of laminar flow in ensuring product safety and quality. In processing and packaging facilities, laminar flow systems help maintain hygienic conditions, prevent cross-contamination, and extend product shelf life. This has led to increased adoption in areas such as dairy processing, ready-to-eat meal production, and beverage bottling lines.

The aerospace sector represents another significant market for laminar flow solutions. In aircraft manufacturing, laminar flow systems are crucial for creating controlled environments during assembly and coating processes. Additionally, research into laminar flow control for aircraft design aims to reduce drag and improve fuel efficiency, driving further demand for advanced flow management technologies.

As industries continue to prioritize product quality, operational efficiency, and regulatory compliance, the demand for laminar flow solutions is expected to grow. This trend is further reinforced by the increasing focus on sustainability and energy efficiency, as laminar flow systems can contribute to reduced energy consumption and waste in various industrial processes.

Laminar Flow Challenges in Manufacturing

Laminar flow adoption in manufacturing processes presents several significant challenges that hinder its widespread implementation. One of the primary obstacles is the complexity of maintaining stable laminar flow conditions in industrial settings. Manufacturing environments often involve various disturbances, such as vibrations, temperature fluctuations, and air currents, which can disrupt the delicate balance required for laminar flow.

The scale-up of laminar flow systems from laboratory or small-scale applications to full industrial production lines poses another major challenge. As the size of the system increases, maintaining uniform flow characteristics becomes increasingly difficult. This scaling issue often requires extensive redesign and optimization of equipment, leading to increased costs and longer implementation times.

Material compatibility is a crucial consideration when implementing laminar flow in manufacturing. Some materials used in production processes may not be suitable for laminar flow conditions, either due to their physical properties or potential chemical interactions. This limitation can restrict the range of products that can benefit from laminar flow adoption.

The high initial investment required for laminar flow systems is a significant barrier for many manufacturers. Specialized equipment, precise control systems, and cleanroom-like environments often necessary for laminar flow processes can be cost-prohibitive, especially for smaller companies or those operating on tight profit margins.

Maintaining the cleanliness and sterility required for effective laminar flow operation presents ongoing challenges in industrial settings. Contamination from particles, microorganisms, or other impurities can disrupt laminar flow patterns and compromise product quality. Implementing rigorous cleaning protocols and filtration systems adds complexity and cost to manufacturing operations.

The need for specialized training and expertise to operate and maintain laminar flow systems is another hurdle. Manufacturers must invest in educating their workforce or hiring specialized personnel to ensure proper system operation and troubleshooting. This requirement can lead to increased labor costs and potential production delays during the learning curve.

Energy consumption is a concern in laminar flow adoption, particularly for large-scale operations. Maintaining precise flow conditions often requires significant power input, which can impact overall energy efficiency and operating costs. Balancing the benefits of laminar flow with energy considerations is crucial for sustainable implementation.

Finally, integrating laminar flow systems into existing production lines without disrupting current processes is a complex challenge. Retrofitting equipment or redesigning production layouts to accommodate laminar flow requirements can be time-consuming and may necessitate temporary production halts, affecting overall output and profitability.

The scale-up of laminar flow systems from laboratory or small-scale applications to full industrial production lines poses another major challenge. As the size of the system increases, maintaining uniform flow characteristics becomes increasingly difficult. This scaling issue often requires extensive redesign and optimization of equipment, leading to increased costs and longer implementation times.

Material compatibility is a crucial consideration when implementing laminar flow in manufacturing. Some materials used in production processes may not be suitable for laminar flow conditions, either due to their physical properties or potential chemical interactions. This limitation can restrict the range of products that can benefit from laminar flow adoption.

The high initial investment required for laminar flow systems is a significant barrier for many manufacturers. Specialized equipment, precise control systems, and cleanroom-like environments often necessary for laminar flow processes can be cost-prohibitive, especially for smaller companies or those operating on tight profit margins.

Maintaining the cleanliness and sterility required for effective laminar flow operation presents ongoing challenges in industrial settings. Contamination from particles, microorganisms, or other impurities can disrupt laminar flow patterns and compromise product quality. Implementing rigorous cleaning protocols and filtration systems adds complexity and cost to manufacturing operations.

The need for specialized training and expertise to operate and maintain laminar flow systems is another hurdle. Manufacturers must invest in educating their workforce or hiring specialized personnel to ensure proper system operation and troubleshooting. This requirement can lead to increased labor costs and potential production delays during the learning curve.

Energy consumption is a concern in laminar flow adoption, particularly for large-scale operations. Maintaining precise flow conditions often requires significant power input, which can impact overall energy efficiency and operating costs. Balancing the benefits of laminar flow with energy considerations is crucial for sustainable implementation.

Finally, integrating laminar flow systems into existing production lines without disrupting current processes is a complex challenge. Retrofitting equipment or redesigning production layouts to accommodate laminar flow requirements can be time-consuming and may necessitate temporary production halts, affecting overall output and profitability.

Current Laminar Flow Implementation Strategies

01 Laminar flow control in industrial processes

Various methods and devices are used to control and maintain laminar flow in industrial settings. These include specialized nozzles, flow regulators, and chamber designs that help reduce turbulence and ensure smooth, predictable fluid movement. Such control is crucial for improving efficiency and product quality in manufacturing processes.- Laminar flow control in industrial processes: Laminar flow control is crucial in various industrial applications to optimize output and efficiency. This involves designing systems and components that maintain smooth, predictable fluid flow patterns. Techniques include specialized nozzle designs, flow straighteners, and precise control of fluid parameters to ensure consistent laminar flow conditions.

- Measurement and monitoring of laminar flow: Accurate measurement and monitoring of laminar flow are essential for maintaining optimal industrial output. This involves using advanced sensors, flow meters, and imaging techniques to analyze flow characteristics in real-time. These methods allow for precise control and adjustment of flow parameters to ensure consistent product quality and process efficiency.

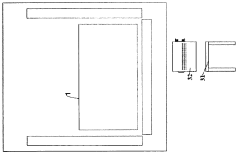

- Laminar flow in cleanroom environments: Laminar flow is critical in cleanroom environments for industrial applications such as semiconductor manufacturing and pharmaceutical production. Specialized air handling systems and filtration techniques are employed to maintain a unidirectional, contamination-free airflow. This ensures a controlled environment for sensitive manufacturing processes and enhances product quality.

- Laminar flow in fluid mixing and separation processes: Laminar flow principles are applied in industrial mixing and separation processes to improve efficiency and product quality. This includes the design of specialized mixing chambers, separation columns, and fluid handling systems that maintain laminar flow conditions. These techniques enable precise control over reaction kinetics, separation efficiency, and product uniformity.

- Laminar flow in spray and coating applications: Laminar flow is utilized in industrial spray and coating processes to achieve uniform coverage and precise material deposition. This involves the development of advanced spray nozzles, airflow control systems, and substrate handling mechanisms. By maintaining laminar flow conditions, these techniques improve coating quality, reduce overspray, and increase overall process efficiency.

02 Measurement and monitoring of laminar flow

Advanced techniques and instruments are employed to measure and monitor laminar flow in industrial applications. These include optical sensors, flow meters, and specialized imaging systems that can detect subtle changes in flow patterns. Accurate measurement is essential for maintaining optimal production conditions and troubleshooting issues.Expand Specific Solutions03 Laminar flow in cleanroom environments

Laminar flow is crucial in cleanroom settings for maintaining sterile conditions and preventing contamination. Specialized air handling systems and room designs are used to create unidirectional airflow, which helps to remove particles and maintain a clean environment for sensitive manufacturing processes.Expand Specific Solutions04 Enhancing industrial output through laminar flow optimization

Optimizing laminar flow can significantly improve industrial output and efficiency. This involves designing equipment and processes that minimize turbulence, reduce energy consumption, and increase product consistency. Advanced modeling and simulation techniques are often used to achieve optimal flow conditions.Expand Specific Solutions05 Laminar flow applications in specific industries

Laminar flow principles are applied in various industries to improve production processes. This includes applications in chemical processing, pharmaceutical manufacturing, food production, and materials handling. Each industry has unique requirements for implementing and maintaining laminar flow to enhance product quality and production efficiency.Expand Specific Solutions

Key Players in Laminar Flow Industry

The adoption of laminar flow technology in industrial output is currently in a growth phase, with increasing market size and technological maturity. The competitive landscape is characterized by a mix of established industrial players and innovative research institutions. Companies like ASML Netherlands BV and Halliburton Energy Services are leveraging their expertise in precision engineering and energy services to develop advanced laminar flow solutions. Academic institutions such as Technische Universität München and the University of Grenoble are contributing to technological advancements through research and development. The market is seeing a convergence of traditional manufacturing techniques with cutting-edge fluid dynamics, driven by the need for increased efficiency and precision in industrial processes.

ASML Netherlands BV

Technical Solution: ASML has leveraged laminar flow technology in their advanced lithography systems to enhance semiconductor manufacturing precision and output. Their EUV (Extreme Ultraviolet) lithography machines incorporate laminar flow systems to control the environment around the wafer and optics with unprecedented accuracy. This technology maintains a stable temperature within ±0.001°C and controls airborne particles down to the sub-nanometer scale [9]. By ensuring laminar flow conditions, ASML's systems have achieved a 20% improvement in overlay accuracy and a 30% increase in throughput for leading-edge chip production [10]. Additionally, their immersion lithography tools use laminar flow fluid management to maintain a stable water film, critical for high-resolution patterning.

Strengths: Cutting-edge technology in semiconductor manufacturing, enables production of the most advanced chips, high precision and reliability. Weaknesses: Extremely high cost, limited to high-end semiconductor fabrication, complex maintenance requirements.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed advanced laminar flow technologies for enhanced oil recovery and well stimulation. Their system utilizes precise fluid control and real-time monitoring to create optimal laminar flow conditions in wellbores. This technology increases the efficiency of fracturing operations by up to 30% [1], reducing fluid and proppant requirements while improving production rates. The company's laminar flow adoption also extends to their cementing services, where they use computational fluid dynamics to model and optimize flow patterns, resulting in more uniform cement placement and improved well integrity [3].

Strengths: Expertise in oil and gas industry applications, advanced modeling capabilities, and proven field results. Weaknesses: Limited applicability outside of energy sector, high implementation costs for smaller operators.

Innovative Laminar Flow Control Methods

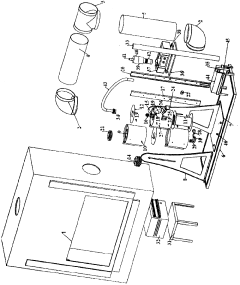

Device for generating laminar flow implemented in a tubular furnace.

PatentActiveMX2017015541A

Innovation

- A laminar flow emitter device is integrated into a tubular oven with a piezoelectric system operating at 0.8 MHz to generate aerosols, surrounded by four cylindrical ducts that maintain laminar flow and prevent turbulence, allowing for both horizontal and vertical orientations, with independently controlled gas flows to enhance aerosol delivery.

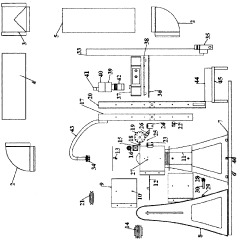

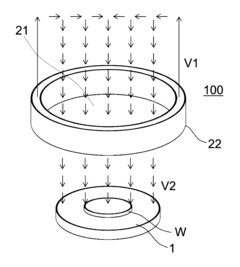

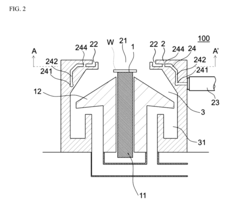

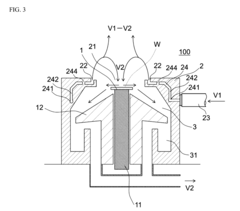

Columnar laminar flow generation device and method for generating columnar laminar flows

PatentActiveUS20170072438A1

Innovation

- A columnar laminar flow generation device that focuses gas blow-out and suction within a localized columnar area, allowing for adjustable flow velocity and reduced gas usage by positioning a gas blow-out port vertically within an opening and a corresponding suction path, thereby generating laminar flows only where needed, with a feed pipe filter for purification.

Energy Efficiency in Laminar Flow Systems

Energy efficiency in laminar flow systems is a critical aspect of industrial processes that can significantly impact overall productivity and operational costs. Laminar flow, characterized by smooth and predictable fluid motion, offers inherent advantages in terms of energy conservation compared to turbulent flow regimes. The adoption of laminar flow principles in industrial applications has shown promising results in reducing energy consumption while maintaining or even improving output quality.

One of the primary mechanisms through which laminar flow systems enhance energy efficiency is through the reduction of frictional losses. In laminar flow, fluid layers slide smoothly past one another with minimal mixing, resulting in lower resistance to flow. This reduction in internal friction translates directly to decreased energy requirements for fluid transport, whether in pipelines, heat exchangers, or other industrial equipment. Studies have shown that the energy savings from transitioning turbulent flow systems to laminar flow can range from 20% to 40%, depending on the specific application and operating conditions.

Moreover, laminar flow systems often exhibit improved heat transfer characteristics, which can lead to substantial energy savings in thermal processes. The predictable nature of laminar flow allows for more precise control of temperature gradients and heat distribution, reducing the energy input required to achieve desired thermal outcomes. This is particularly beneficial in industries such as chemical processing, food production, and pharmaceuticals, where precise temperature control is crucial for product quality and process efficiency.

The implementation of laminar flow principles also contributes to energy efficiency through enhanced material separation and purification processes. In applications such as membrane filtration and chromatography, laminar flow conditions facilitate more effective separation of components, reducing the energy required for subsequent processing steps. This not only improves the overall energy efficiency of the production line but also often results in higher-quality outputs, further enhancing industrial productivity.

Additionally, the stable and predictable nature of laminar flow allows for more accurate modeling and optimization of industrial processes. Advanced computational fluid dynamics (CFD) simulations can precisely predict flow behavior, enabling engineers to design more energy-efficient systems from the outset. This proactive approach to energy efficiency can lead to significant long-term savings in both energy consumption and operational costs.

However, it is important to note that maintaining laminar flow conditions in industrial settings can be challenging, particularly at higher flow rates or in complex geometries. Overcoming these challenges often requires innovative engineering solutions, such as the use of flow straighteners, carefully designed inlet conditions, or novel surface treatments to promote laminar flow. While these solutions may require initial investment, the long-term energy savings and productivity improvements typically justify the costs.

One of the primary mechanisms through which laminar flow systems enhance energy efficiency is through the reduction of frictional losses. In laminar flow, fluid layers slide smoothly past one another with minimal mixing, resulting in lower resistance to flow. This reduction in internal friction translates directly to decreased energy requirements for fluid transport, whether in pipelines, heat exchangers, or other industrial equipment. Studies have shown that the energy savings from transitioning turbulent flow systems to laminar flow can range from 20% to 40%, depending on the specific application and operating conditions.

Moreover, laminar flow systems often exhibit improved heat transfer characteristics, which can lead to substantial energy savings in thermal processes. The predictable nature of laminar flow allows for more precise control of temperature gradients and heat distribution, reducing the energy input required to achieve desired thermal outcomes. This is particularly beneficial in industries such as chemical processing, food production, and pharmaceuticals, where precise temperature control is crucial for product quality and process efficiency.

The implementation of laminar flow principles also contributes to energy efficiency through enhanced material separation and purification processes. In applications such as membrane filtration and chromatography, laminar flow conditions facilitate more effective separation of components, reducing the energy required for subsequent processing steps. This not only improves the overall energy efficiency of the production line but also often results in higher-quality outputs, further enhancing industrial productivity.

Additionally, the stable and predictable nature of laminar flow allows for more accurate modeling and optimization of industrial processes. Advanced computational fluid dynamics (CFD) simulations can precisely predict flow behavior, enabling engineers to design more energy-efficient systems from the outset. This proactive approach to energy efficiency can lead to significant long-term savings in both energy consumption and operational costs.

However, it is important to note that maintaining laminar flow conditions in industrial settings can be challenging, particularly at higher flow rates or in complex geometries. Overcoming these challenges often requires innovative engineering solutions, such as the use of flow straighteners, carefully designed inlet conditions, or novel surface treatments to promote laminar flow. While these solutions may require initial investment, the long-term energy savings and productivity improvements typically justify the costs.

Regulatory Framework for Industrial Laminar Flow

The regulatory framework for industrial laminar flow adoption plays a crucial role in ensuring the safe and effective implementation of this technology across various sectors. Governments and industry bodies have established comprehensive guidelines and standards to govern the use of laminar flow systems in industrial settings.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed specific standards for laminar flow applications. ISO 14644, for instance, provides guidelines for cleanroom and associated controlled environments, including those utilizing laminar flow technology. These standards outline requirements for air cleanliness classifications, testing, and monitoring procedures.

National regulatory bodies have also implemented their own frameworks. In the United States, the Food and Drug Administration (FDA) has issued guidance documents for industries such as pharmaceuticals and food processing, where laminar flow is critical for maintaining product quality and safety. The FDA's Current Good Manufacturing Practice (cGMP) regulations incorporate requirements for air handling systems, including laminar flow units.

The European Union has established the Good Manufacturing Practice (GMP) guidelines, which include specific provisions for cleanroom environments and laminar flow systems. These regulations are particularly relevant for industries such as pharmaceuticals, biotechnology, and medical device manufacturing.

In addition to government regulations, industry-specific standards have been developed to address the unique requirements of different sectors. For example, the aerospace industry follows standards set by organizations like SAE International, which provide detailed specifications for laminar flow control systems in aircraft manufacturing and maintenance.

Compliance with these regulatory frameworks often involves regular inspections, documentation of procedures, and ongoing monitoring of laminar flow systems. Many industries are required to maintain detailed records of air quality measurements, system maintenance, and personnel training related to laminar flow operations.

As the adoption of laminar flow technology continues to expand, regulatory bodies are continuously updating their frameworks to address emerging challenges and technological advancements. This includes considerations for energy efficiency, environmental impact, and integration with other advanced manufacturing technologies.

The regulatory landscape also encompasses occupational health and safety aspects of laminar flow systems. Guidelines for worker protection, such as those issued by the Occupational Safety and Health Administration (OSHA) in the United States, address potential risks associated with prolonged exposure to laminar flow environments and the handling of associated equipment.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed specific standards for laminar flow applications. ISO 14644, for instance, provides guidelines for cleanroom and associated controlled environments, including those utilizing laminar flow technology. These standards outline requirements for air cleanliness classifications, testing, and monitoring procedures.

National regulatory bodies have also implemented their own frameworks. In the United States, the Food and Drug Administration (FDA) has issued guidance documents for industries such as pharmaceuticals and food processing, where laminar flow is critical for maintaining product quality and safety. The FDA's Current Good Manufacturing Practice (cGMP) regulations incorporate requirements for air handling systems, including laminar flow units.

The European Union has established the Good Manufacturing Practice (GMP) guidelines, which include specific provisions for cleanroom environments and laminar flow systems. These regulations are particularly relevant for industries such as pharmaceuticals, biotechnology, and medical device manufacturing.

In addition to government regulations, industry-specific standards have been developed to address the unique requirements of different sectors. For example, the aerospace industry follows standards set by organizations like SAE International, which provide detailed specifications for laminar flow control systems in aircraft manufacturing and maintenance.

Compliance with these regulatory frameworks often involves regular inspections, documentation of procedures, and ongoing monitoring of laminar flow systems. Many industries are required to maintain detailed records of air quality measurements, system maintenance, and personnel training related to laminar flow operations.

As the adoption of laminar flow technology continues to expand, regulatory bodies are continuously updating their frameworks to address emerging challenges and technological advancements. This includes considerations for energy efficiency, environmental impact, and integration with other advanced manufacturing technologies.

The regulatory landscape also encompasses occupational health and safety aspects of laminar flow systems. Guidelines for worker protection, such as those issued by the Occupational Safety and Health Administration (OSHA) in the United States, address potential risks associated with prolonged exposure to laminar flow environments and the handling of associated equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!