Laminar Flow Applications in Microfluidic Devices

JUL 10, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Laminar Flow Background and Objectives

Laminar flow in microfluidic devices has emerged as a cornerstone technology in the field of microfluidics, revolutionizing various applications in chemistry, biology, and biomedical engineering. This phenomenon, characterized by parallel layers of fluid flowing without lateral mixing, has been instrumental in the development of miniaturized analytical systems and lab-on-a-chip devices.

The concept of laminar flow in microfluidics can be traced back to the early 1990s when researchers began exploring the behavior of fluids at the microscale. The realization that fluid dynamics at this scale are dominated by viscous forces rather than inertial forces led to the exploitation of laminar flow for precise control and manipulation of fluids and particles.

Over the past three decades, the field has witnessed significant advancements in both theoretical understanding and practical applications. The ability to predict and control fluid behavior at the microscale has enabled the development of sophisticated microfluidic devices capable of performing complex analytical and diagnostic tasks with unprecedented precision and efficiency.

The primary objective of laminar flow applications in microfluidic devices is to leverage the unique properties of fluid behavior at the microscale to achieve specific functional outcomes. These include precise sample handling, efficient mixing of reagents, separation of particles or molecules, and creation of controlled microenvironments for biological studies.

As the field continues to evolve, researchers are exploring new frontiers in laminar flow applications. Current trends include the development of organ-on-a-chip systems, which utilize laminar flow to mimic physiological conditions, and the integration of laminar flow principles with other microfluidic technologies such as droplet microfluidics and inertial microfluidics.

The future trajectory of laminar flow applications in microfluidic devices is expected to focus on enhancing the scalability and robustness of existing technologies, as well as exploring novel applications in emerging fields such as personalized medicine, environmental monitoring, and advanced materials synthesis. Additionally, there is a growing emphasis on developing user-friendly, automated microfluidic platforms that can translate the benefits of laminar flow from laboratory settings to real-world applications.

The concept of laminar flow in microfluidics can be traced back to the early 1990s when researchers began exploring the behavior of fluids at the microscale. The realization that fluid dynamics at this scale are dominated by viscous forces rather than inertial forces led to the exploitation of laminar flow for precise control and manipulation of fluids and particles.

Over the past three decades, the field has witnessed significant advancements in both theoretical understanding and practical applications. The ability to predict and control fluid behavior at the microscale has enabled the development of sophisticated microfluidic devices capable of performing complex analytical and diagnostic tasks with unprecedented precision and efficiency.

The primary objective of laminar flow applications in microfluidic devices is to leverage the unique properties of fluid behavior at the microscale to achieve specific functional outcomes. These include precise sample handling, efficient mixing of reagents, separation of particles or molecules, and creation of controlled microenvironments for biological studies.

As the field continues to evolve, researchers are exploring new frontiers in laminar flow applications. Current trends include the development of organ-on-a-chip systems, which utilize laminar flow to mimic physiological conditions, and the integration of laminar flow principles with other microfluidic technologies such as droplet microfluidics and inertial microfluidics.

The future trajectory of laminar flow applications in microfluidic devices is expected to focus on enhancing the scalability and robustness of existing technologies, as well as exploring novel applications in emerging fields such as personalized medicine, environmental monitoring, and advanced materials synthesis. Additionally, there is a growing emphasis on developing user-friendly, automated microfluidic platforms that can translate the benefits of laminar flow from laboratory settings to real-world applications.

Market Analysis for Microfluidic Devices

The microfluidic devices market has been experiencing significant growth in recent years, driven by the increasing demand for point-of-care diagnostics, drug discovery applications, and personalized medicine. The global microfluidic devices market was valued at $13.5 billion in 2020 and is projected to reach $27.9 billion by 2026, growing at a CAGR of 12.7% during the forecast period.

The healthcare sector remains the largest end-user segment for microfluidic devices, accounting for over 40% of the market share. This is primarily due to the rising prevalence of chronic diseases and the need for rapid, accurate diagnostic tools. The pharmaceutical and biotechnology industries are also major contributors to market growth, as microfluidic devices offer advantages in drug screening and development processes.

Geographically, North America dominates the microfluidic devices market, followed by Europe and Asia-Pacific. The United States, in particular, holds the largest market share due to its advanced healthcare infrastructure and significant investments in research and development. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing healthcare expenditure and growing awareness of personalized medicine in countries like China and India.

Key market trends include the integration of artificial intelligence and machine learning in microfluidic systems, the development of organ-on-a-chip devices for drug testing, and the increasing adoption of 3D-printed microfluidic devices. These advancements are expected to further expand the application scope of microfluidic technologies and drive market growth.

The competitive landscape of the microfluidic devices market is characterized by the presence of both established players and innovative startups. Major companies in this space include Danaher Corporation, Thermo Fisher Scientific, and Bio-Rad Laboratories. These companies are focusing on strategic collaborations, mergers and acquisitions, and product innovations to maintain their market positions.

Challenges facing the microfluidic devices market include the high cost of devices, lack of standardization, and concerns regarding the reproducibility of results. However, ongoing technological advancements and increasing investments in research and development are expected to address these issues and further propel market growth.

In conclusion, the microfluidic devices market presents significant opportunities for growth, driven by technological advancements and expanding applications across various industries. As the demand for precise, miniaturized analytical tools continues to rise, the market is poised for sustained expansion in the coming years.

The healthcare sector remains the largest end-user segment for microfluidic devices, accounting for over 40% of the market share. This is primarily due to the rising prevalence of chronic diseases and the need for rapid, accurate diagnostic tools. The pharmaceutical and biotechnology industries are also major contributors to market growth, as microfluidic devices offer advantages in drug screening and development processes.

Geographically, North America dominates the microfluidic devices market, followed by Europe and Asia-Pacific. The United States, in particular, holds the largest market share due to its advanced healthcare infrastructure and significant investments in research and development. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by increasing healthcare expenditure and growing awareness of personalized medicine in countries like China and India.

Key market trends include the integration of artificial intelligence and machine learning in microfluidic systems, the development of organ-on-a-chip devices for drug testing, and the increasing adoption of 3D-printed microfluidic devices. These advancements are expected to further expand the application scope of microfluidic technologies and drive market growth.

The competitive landscape of the microfluidic devices market is characterized by the presence of both established players and innovative startups. Major companies in this space include Danaher Corporation, Thermo Fisher Scientific, and Bio-Rad Laboratories. These companies are focusing on strategic collaborations, mergers and acquisitions, and product innovations to maintain their market positions.

Challenges facing the microfluidic devices market include the high cost of devices, lack of standardization, and concerns regarding the reproducibility of results. However, ongoing technological advancements and increasing investments in research and development are expected to address these issues and further propel market growth.

In conclusion, the microfluidic devices market presents significant opportunities for growth, driven by technological advancements and expanding applications across various industries. As the demand for precise, miniaturized analytical tools continues to rise, the market is poised for sustained expansion in the coming years.

Laminar Flow Challenges in Microfluidics

Laminar flow in microfluidic devices presents several significant challenges that researchers and engineers must address to optimize device performance and functionality. One of the primary issues is maintaining stable laminar flow conditions across various channel geometries and flow rates. The small dimensions of microfluidic channels often lead to increased surface-to-volume ratios, which can result in enhanced surface effects and potential flow disturbances.

Another challenge lies in controlling and predicting the behavior of fluid interfaces in laminar flow regimes. While laminar flow allows for the creation of stable fluid streams, precise manipulation of these streams for applications such as particle sorting or chemical reactions requires careful design considerations. Factors such as diffusion between adjacent fluid streams and the influence of channel wall properties on flow characteristics must be carefully managed.

The scaling effects in microfluidic devices also pose unique challenges for laminar flow applications. As channel dimensions decrease, viscous forces become increasingly dominant over inertial forces, leading to low Reynolds number flows. This can impact mixing efficiency and mass transfer processes, which are critical for many microfluidic applications. Researchers must develop innovative strategies to enhance mixing in laminar flow regimes without compromising the benefits of predictable fluid behavior.

Furthermore, the integration of external forces or fields, such as electrical, magnetic, or acoustic forces, into laminar flow systems introduces additional complexities. These external influences can perturb the laminar flow regime, requiring careful balancing to maintain desired flow characteristics while leveraging the benefits of these additional control mechanisms.

The fabrication of microfluidic devices with precise channel geometries and surface properties is another significant challenge. Variations in channel dimensions or surface roughness can lead to unexpected flow behaviors, compromising the predictability and reproducibility of laminar flow applications. Advanced manufacturing techniques and quality control measures are essential to ensure consistent device performance.

Lastly, the transition between laminar and turbulent flow regimes in microfluidic devices presents a challenge for applications that require operation across a range of flow conditions. Understanding and controlling this transition is crucial for designing robust microfluidic systems that can maintain laminar flow characteristics under varying operational parameters.

Another challenge lies in controlling and predicting the behavior of fluid interfaces in laminar flow regimes. While laminar flow allows for the creation of stable fluid streams, precise manipulation of these streams for applications such as particle sorting or chemical reactions requires careful design considerations. Factors such as diffusion between adjacent fluid streams and the influence of channel wall properties on flow characteristics must be carefully managed.

The scaling effects in microfluidic devices also pose unique challenges for laminar flow applications. As channel dimensions decrease, viscous forces become increasingly dominant over inertial forces, leading to low Reynolds number flows. This can impact mixing efficiency and mass transfer processes, which are critical for many microfluidic applications. Researchers must develop innovative strategies to enhance mixing in laminar flow regimes without compromising the benefits of predictable fluid behavior.

Furthermore, the integration of external forces or fields, such as electrical, magnetic, or acoustic forces, into laminar flow systems introduces additional complexities. These external influences can perturb the laminar flow regime, requiring careful balancing to maintain desired flow characteristics while leveraging the benefits of these additional control mechanisms.

The fabrication of microfluidic devices with precise channel geometries and surface properties is another significant challenge. Variations in channel dimensions or surface roughness can lead to unexpected flow behaviors, compromising the predictability and reproducibility of laminar flow applications. Advanced manufacturing techniques and quality control measures are essential to ensure consistent device performance.

Lastly, the transition between laminar and turbulent flow regimes in microfluidic devices presents a challenge for applications that require operation across a range of flow conditions. Understanding and controlling this transition is crucial for designing robust microfluidic systems that can maintain laminar flow characteristics under varying operational parameters.

Current Laminar Flow Control Solutions

01 Measurement and analysis of laminar flow characteristics

Various methods and devices are used to measure and analyze laminar flow characteristics. These include optical systems, sensors, and flow meters that can detect and quantify flow patterns, velocity profiles, and other parameters associated with laminar flow. Advanced data processing techniques are often employed to interpret the collected information and provide accurate flow characterization.- Measurement and analysis of laminar flow characteristics: Various methods and devices are used to measure and analyze laminar flow characteristics. These include optical systems, sensors, and flow meters that can detect and quantify flow patterns, velocities, and other properties of laminar flow. Such measurements are crucial for understanding and optimizing fluid dynamics in various applications.

- Control and manipulation of laminar flow: Techniques and systems for controlling and manipulating laminar flow are developed to achieve desired flow characteristics. This includes the use of flow control devices, surface modifications, and specialized geometries to influence flow behavior. These methods are applied in various fields such as aerodynamics, hydrodynamics, and microfluidics.

- Laminar flow in specific applications: Laminar flow characteristics are studied and utilized in specific applications such as aircraft design, fluid handling systems, and medical devices. Understanding and leveraging laminar flow properties can lead to improved efficiency, reduced drag, and enhanced performance in these specialized fields.

- Simulation and modeling of laminar flow: Advanced computational methods and software tools are employed to simulate and model laminar flow characteristics. These simulations help in predicting flow behavior, optimizing designs, and understanding complex fluid dynamics without the need for physical experiments in every case.

- Transition between laminar and turbulent flow: Research focuses on understanding and controlling the transition between laminar and turbulent flow regimes. This includes studying the factors that influence this transition, such as Reynolds number, surface roughness, and flow disturbances. Techniques to maintain laminar flow or induce controlled turbulence are developed for various applications.

02 Control and manipulation of laminar flow

Techniques and apparatus for controlling and manipulating laminar flow are developed to achieve desired flow characteristics. This includes the use of specialized nozzles, flow conditioners, and surface treatments to maintain or modify laminar flow conditions. These methods are applied in various fields such as aerodynamics, fluid dynamics, and industrial processes to optimize flow performance and efficiency.Expand Specific Solutions03 Laminar flow in microfluidic devices

Microfluidic devices utilize laminar flow properties for various applications. The small scale of these devices allows for precise control of fluid behavior, enabling applications in chemical analysis, biological research, and medical diagnostics. Laminar flow characteristics in microchannels are exploited to achieve particle separation, mixing, and other fluid manipulation tasks at the microscale level.Expand Specific Solutions04 Laminar flow in aerodynamic applications

Laminar flow principles are crucial in aerodynamic design, particularly in aviation and automotive industries. Techniques to maintain laminar flow over surfaces are developed to reduce drag and improve fuel efficiency. This includes the design of airfoils, body shapes, and surface treatments that promote laminar flow and delay the transition to turbulent flow.Expand Specific Solutions05 Laminar flow in industrial processes and equipment

Laminar flow characteristics are important in various industrial processes and equipment design. This includes applications in heat exchangers, filtration systems, and chemical reactors. Understanding and controlling laminar flow in these contexts helps to optimize process efficiency, enhance heat transfer, and improve separation processes. Specialized equipment is designed to maintain laminar flow conditions for specific industrial applications.Expand Specific Solutions

Key Microfluidic Industry Players

The field of laminar flow applications in microfluidic devices is in a growth phase, with increasing market size and technological advancements. The global microfluidics market is expanding rapidly, driven by applications in pharmaceuticals, diagnostics, and life sciences. While the technology is maturing, there's still room for innovation. Key players like IBM, HP, and Robert Bosch are leveraging their expertise in engineering and electronics to develop sophisticated microfluidic systems. Academic institutions such as Colorado School of Mines and New York University are contributing to fundamental research, while companies like IDEX Health & Science are focusing on practical applications. The collaboration between industry and academia is accelerating progress in this field.

International Business Machines Corp.

Technical Solution: IBM has developed advanced microfluidic devices utilizing laminar flow for various applications. Their technology employs precise control of fluid dynamics to create "lab-on-a-chip" systems for biomedical and chemical analysis. IBM's approach integrates multiple functions on a single chip, including sample preparation, reaction, and detection[1]. They have pioneered the use of 3D-printed microfluidic devices with intricate channel designs that optimize laminar flow conditions[2]. This allows for highly efficient mixing, separation, and analysis of small sample volumes. IBM's microfluidic platforms have been applied to DNA sequencing, protein analysis, and drug discovery processes, significantly reducing analysis time and reagent consumption[3].

Strengths: Highly integrated systems, precise fluid control, and versatility across multiple applications. Weaknesses: Potential scalability issues for mass production and the need for specialized expertise to operate complex systems.

Revvity Health Sciences, Inc.

Technical Solution: Revvity Health Sciences (formerly part of PerkinElmer) has developed microfluidic technologies that utilize laminar flow for various life science and diagnostic applications. Their approach focuses on creating highly sensitive and automated analysis platforms. Revvity's microfluidic devices employ laminar flow to achieve precise sample and reagent handling, enabling applications such as single-cell analysis, rare cell detection, and high-sensitivity molecular diagnostics[7]. They have also developed microfluidic chips with integrated optical detection systems that leverage laminar flow for improved signal-to-noise ratios in fluorescence-based assays[8]. Revvity's laminar flow microfluidic technologies have been successfully applied in areas such as liquid biopsy, immunoassays, and next-generation sequencing sample preparation[9].

Strengths: Strong integration with analytical instrumentation, focus on high-sensitivity applications. Weaknesses: May have a narrower application focus compared to more diversified competitors.

Innovative Laminar Flow Techniques

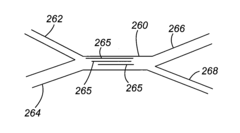

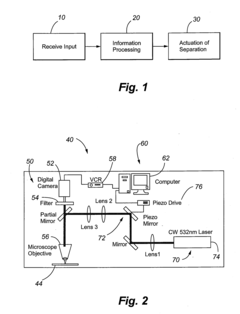

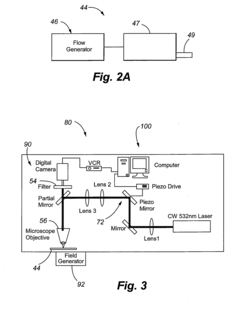

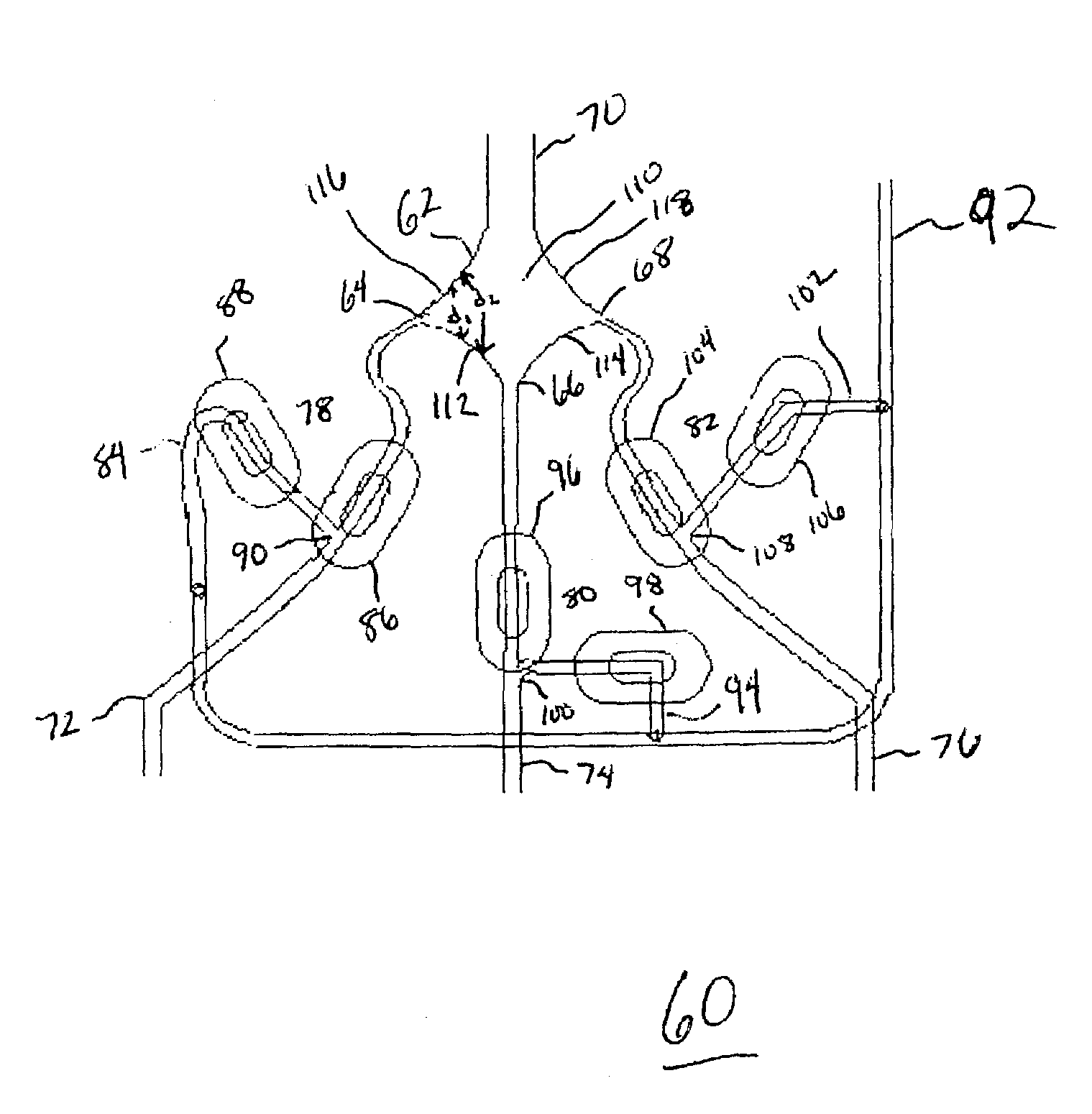

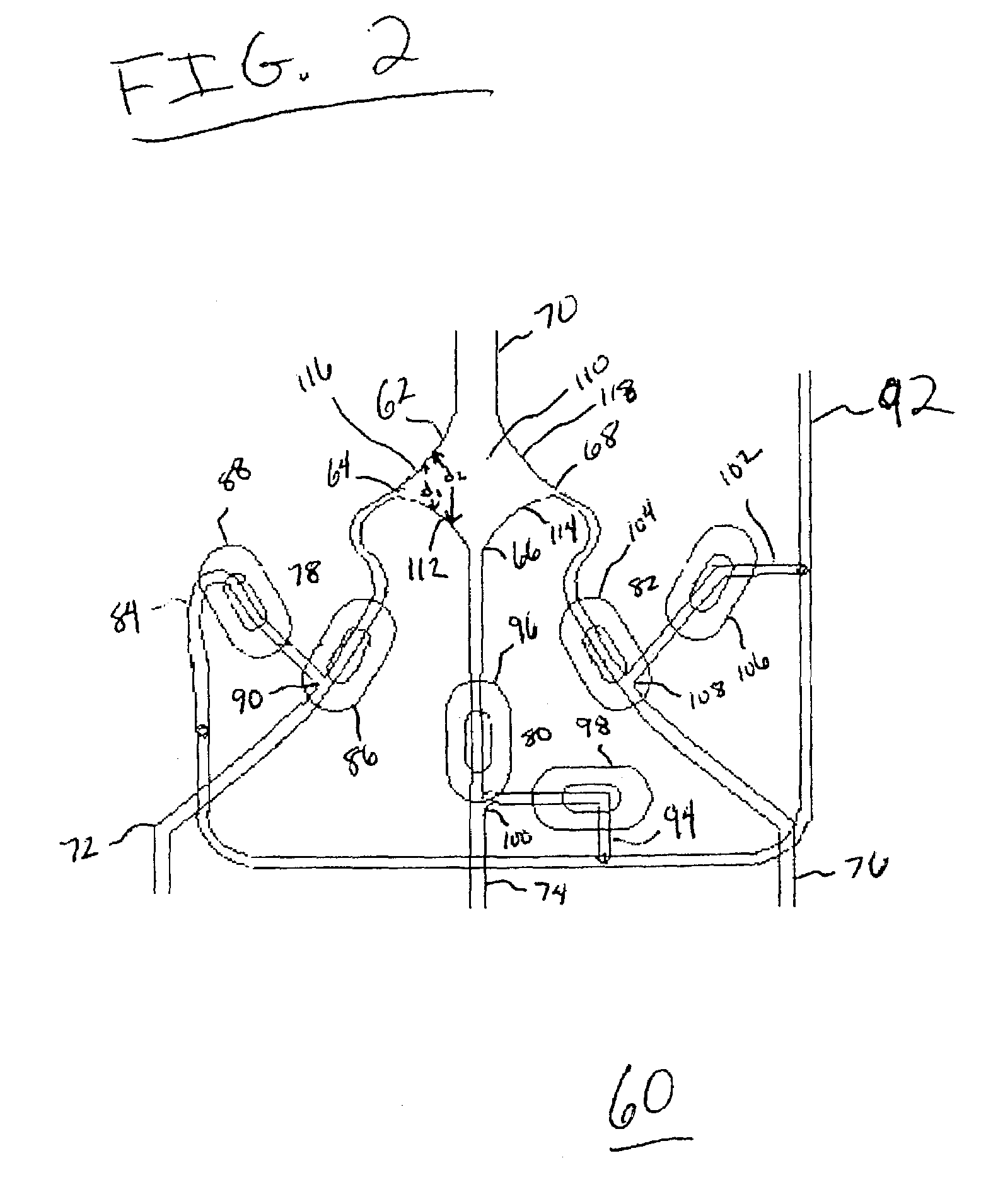

Laminar flow-based separations of colloidal and cellular particles

PatentInactiveUS7318902B2

Innovation

- The development of microfluidic flow devices with laminar flow channels, equipped with inlet and outlet ports, and actuation systems such as optical traps, electric fields, and magnetic fields, which allow for the precise separation and translation of particles by monitoring and processing the flow using detectors and information processors to direct particles into specific output streams.

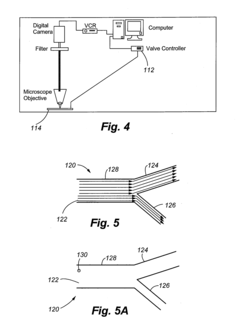

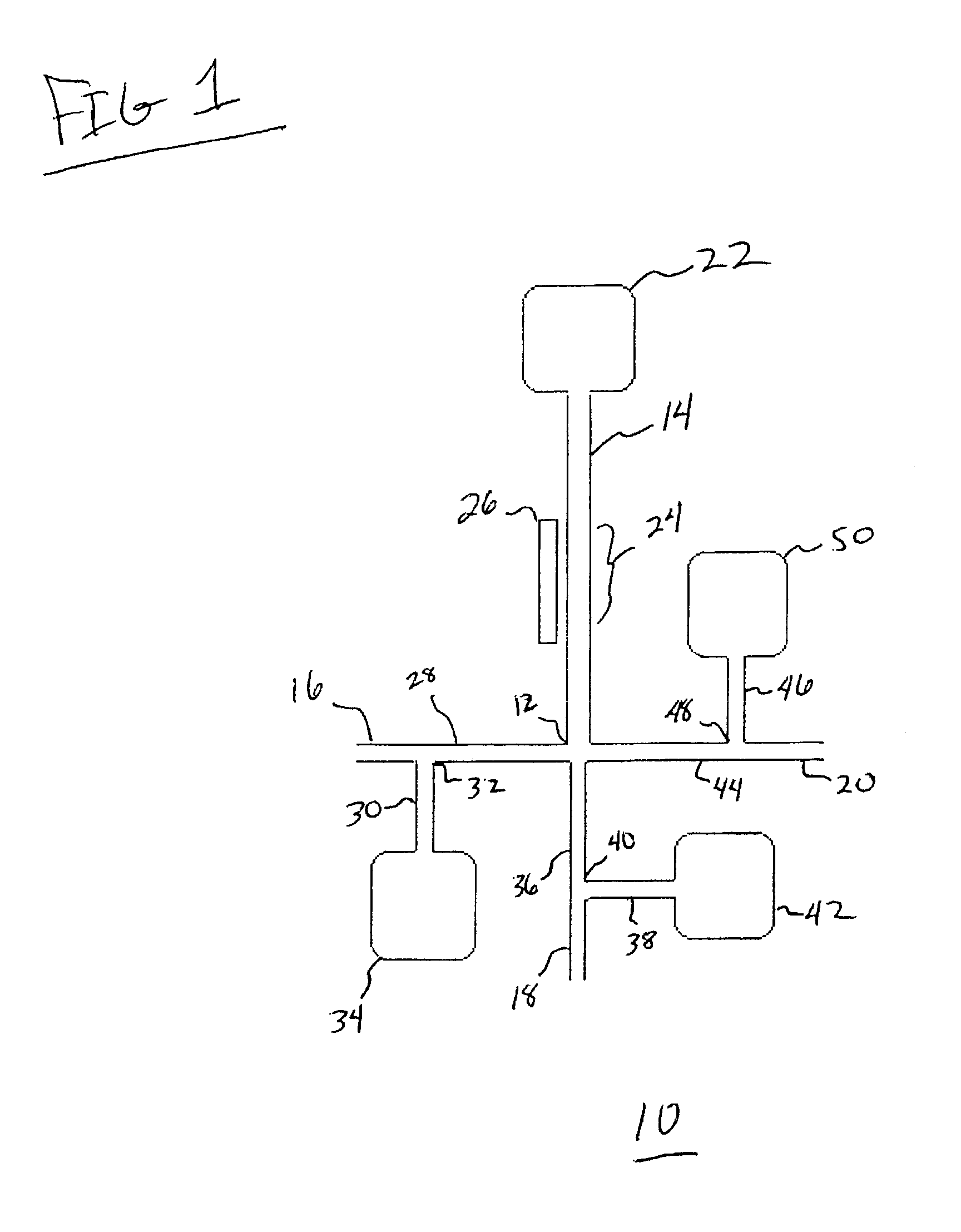

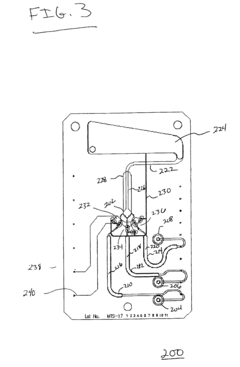

Microfluidic channel network device

PatentInactiveUS7223371B2

Innovation

- A microfluidic device with a microfluidic junction and outlet channel, featuring a plurality of circuit units with source and branch channels, and a flow diversion system, including pneumatic valves and valveless liquid microswitches, allows differential fluid direction and minimizes obstruction by optimizing fluid convergence and flow control.

Microfluidic Device Fabrication Methods

Microfluidic device fabrication methods have evolved significantly over the past few decades, enabling the production of increasingly sophisticated and precise devices for laminar flow applications. The most common fabrication techniques include photolithography, soft lithography, and micromachining.

Photolithography, a process borrowed from the semiconductor industry, is widely used for creating microfluidic channels and structures. This method involves coating a substrate with a photoresist, exposing it to UV light through a mask, and then developing the pattern. The resulting structures can achieve resolutions down to the sub-micron scale, making it ideal for creating intricate channel networks.

Soft lithography, pioneered by George Whitesides and colleagues, has become a cornerstone of microfluidic device fabrication. This technique uses elastomeric materials, typically polydimethylsiloxane (PDMS), to create devices through molding and replication. PDMS offers several advantages, including optical transparency, biocompatibility, and ease of fabrication. The process involves creating a master mold, usually through photolithography, and then casting PDMS over the mold to replicate the features.

Micromachining techniques, such as reactive ion etching (RIE) and deep reactive ion etching (DRIE), are employed for creating microfluidic structures in hard materials like silicon and glass. These methods offer high precision and the ability to create high-aspect-ratio structures, which are particularly useful for certain laminar flow applications.

More recently, 3D printing has emerged as a promising fabrication method for microfluidic devices. While currently limited in resolution compared to traditional methods, 3D printing offers rapid prototyping capabilities and the potential for creating complex 3D channel geometries that are challenging to achieve with conventional techniques.

Each fabrication method has its strengths and limitations, and the choice often depends on the specific requirements of the laminar flow application. Factors such as channel dimensions, material properties, surface chemistry, and integration with other components all play a role in determining the most suitable fabrication approach.

As the field of microfluidics continues to advance, hybrid fabrication methods combining multiple techniques are becoming more common. These approaches aim to leverage the strengths of different methods to create devices with enhanced functionality and performance for laminar flow applications.

Photolithography, a process borrowed from the semiconductor industry, is widely used for creating microfluidic channels and structures. This method involves coating a substrate with a photoresist, exposing it to UV light through a mask, and then developing the pattern. The resulting structures can achieve resolutions down to the sub-micron scale, making it ideal for creating intricate channel networks.

Soft lithography, pioneered by George Whitesides and colleagues, has become a cornerstone of microfluidic device fabrication. This technique uses elastomeric materials, typically polydimethylsiloxane (PDMS), to create devices through molding and replication. PDMS offers several advantages, including optical transparency, biocompatibility, and ease of fabrication. The process involves creating a master mold, usually through photolithography, and then casting PDMS over the mold to replicate the features.

Micromachining techniques, such as reactive ion etching (RIE) and deep reactive ion etching (DRIE), are employed for creating microfluidic structures in hard materials like silicon and glass. These methods offer high precision and the ability to create high-aspect-ratio structures, which are particularly useful for certain laminar flow applications.

More recently, 3D printing has emerged as a promising fabrication method for microfluidic devices. While currently limited in resolution compared to traditional methods, 3D printing offers rapid prototyping capabilities and the potential for creating complex 3D channel geometries that are challenging to achieve with conventional techniques.

Each fabrication method has its strengths and limitations, and the choice often depends on the specific requirements of the laminar flow application. Factors such as channel dimensions, material properties, surface chemistry, and integration with other components all play a role in determining the most suitable fabrication approach.

As the field of microfluidics continues to advance, hybrid fabrication methods combining multiple techniques are becoming more common. These approaches aim to leverage the strengths of different methods to create devices with enhanced functionality and performance for laminar flow applications.

Regulatory Considerations for Microfluidic Applications

The regulatory landscape for microfluidic applications is complex and evolving, reflecting the diverse range of industries and applications that utilize this technology. In the medical and diagnostic fields, microfluidic devices are subject to stringent regulations due to their potential impact on patient health. The U.S. Food and Drug Administration (FDA) classifies many microfluidic devices as in vitro diagnostic (IVD) devices, which must undergo rigorous testing and validation before market approval. The regulatory pathway depends on the device's intended use, with higher-risk applications requiring more extensive clinical trials and documentation.

In the European Union, microfluidic devices fall under the In Vitro Diagnostic Medical Devices Regulation (IVDR), which came into full effect in May 2022. This regulation introduces a new risk-based classification system and more stringent requirements for clinical evidence and post-market surveillance. Manufacturers must also comply with the General Data Protection Regulation (GDPR) when handling patient data in microfluidic diagnostic applications.

For environmental monitoring applications, microfluidic devices must adhere to standards set by environmental protection agencies. In the United States, the Environmental Protection Agency (EPA) provides guidelines for water quality testing methods, which may include microfluidic-based technologies. Similarly, in the food and beverage industry, microfluidic devices used for quality control and safety testing must comply with regulations set by food safety authorities, such as the FDA in the US or the European Food Safety Authority (EFSA) in the EU.

Regulatory considerations also extend to the materials used in microfluidic devices. Many applications require biocompatible materials that meet standards set by organizations like the International Organization for Standardization (ISO) or the United States Pharmacopeia (USP). For instance, ISO 10993 provides a framework for evaluating the biocompatibility of medical devices, including those incorporating microfluidic technology.

As microfluidic devices increasingly incorporate data processing and connectivity features, cybersecurity regulations become relevant. In the healthcare sector, compliance with the Health Insurance Portability and Accountability Act (HIPAA) in the US or similar data protection laws in other jurisdictions is crucial for devices handling patient information.

Standardization efforts are ongoing to harmonize regulations and facilitate the development and commercialization of microfluidic technologies. Organizations such as the International Electrotechnical Commission (IEC) and the American Society for Testing and Materials (ASTM) are working on developing standards specific to microfluidic devices, which will likely influence future regulatory frameworks.

In the European Union, microfluidic devices fall under the In Vitro Diagnostic Medical Devices Regulation (IVDR), which came into full effect in May 2022. This regulation introduces a new risk-based classification system and more stringent requirements for clinical evidence and post-market surveillance. Manufacturers must also comply with the General Data Protection Regulation (GDPR) when handling patient data in microfluidic diagnostic applications.

For environmental monitoring applications, microfluidic devices must adhere to standards set by environmental protection agencies. In the United States, the Environmental Protection Agency (EPA) provides guidelines for water quality testing methods, which may include microfluidic-based technologies. Similarly, in the food and beverage industry, microfluidic devices used for quality control and safety testing must comply with regulations set by food safety authorities, such as the FDA in the US or the European Food Safety Authority (EFSA) in the EU.

Regulatory considerations also extend to the materials used in microfluidic devices. Many applications require biocompatible materials that meet standards set by organizations like the International Organization for Standardization (ISO) or the United States Pharmacopeia (USP). For instance, ISO 10993 provides a framework for evaluating the biocompatibility of medical devices, including those incorporating microfluidic technology.

As microfluidic devices increasingly incorporate data processing and connectivity features, cybersecurity regulations become relevant. In the healthcare sector, compliance with the Health Insurance Portability and Accountability Act (HIPAA) in the US or similar data protection laws in other jurisdictions is crucial for devices handling patient information.

Standardization efforts are ongoing to harmonize regulations and facilitate the development and commercialization of microfluidic technologies. Organizations such as the International Electrotechnical Commission (IEC) and the American Society for Testing and Materials (ASTM) are working on developing standards specific to microfluidic devices, which will likely influence future regulatory frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!