Laminar Flow: Innovations in Pollution Control

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Evolution and Objectives

Laminar flow, a fundamental concept in fluid dynamics, has undergone significant evolution in its application to pollution control. The development of this technology can be traced back to the early 20th century when scientists first began to understand the principles of fluid mechanics. Over time, the potential of laminar flow in managing and mitigating pollution has become increasingly apparent, leading to a surge in research and innovation in this field.

The primary objective of laminar flow technology in pollution control is to create a stable, predictable flow pattern that can effectively capture and remove pollutants from air or water streams. This approach aims to minimize turbulence and maximize the efficiency of filtration and separation processes. By leveraging the properties of laminar flow, researchers and engineers seek to develop more effective and energy-efficient pollution control systems.

One of the key trends in the evolution of laminar flow technology has been the integration of advanced materials and design techniques. For instance, the development of microfluidic devices has allowed for precise control of fluid flow at microscopic scales, enabling more targeted and efficient pollution removal. Similarly, the use of computational fluid dynamics (CFD) has greatly enhanced our ability to model and optimize laminar flow systems for specific pollution control applications.

Another significant trend has been the expansion of laminar flow technology into new areas of pollution control. While initially focused primarily on air pollution, recent advancements have seen its application in water treatment, industrial emissions control, and even in the management of particulate matter in clean room environments. This broadening of scope has been driven by the increasing recognition of laminar flow's potential to address a wide range of environmental challenges.

The objectives of current research and development in laminar flow for pollution control are multifaceted. Researchers aim to improve the efficiency and effectiveness of existing systems, reduce energy consumption, and develop more compact and cost-effective solutions. There is also a growing focus on creating adaptive systems that can respond to changing pollution levels and environmental conditions in real-time.

Furthermore, there is an increasing emphasis on developing laminar flow technologies that can address emerging pollutants, such as microplastics and nanomaterials. These new challenges require innovative approaches that can leverage the principles of laminar flow to capture and remove increasingly small and complex contaminants from various media.

As we look to the future, the evolution of laminar flow in pollution control is likely to continue at a rapid pace. The integration of smart technologies, such as IoT sensors and artificial intelligence, promises to create more responsive and efficient pollution control systems. Additionally, the ongoing push for sustainability and environmental protection is expected to drive further innovation in this field, potentially leading to breakthrough technologies that could revolutionize our approach to pollution management.

The primary objective of laminar flow technology in pollution control is to create a stable, predictable flow pattern that can effectively capture and remove pollutants from air or water streams. This approach aims to minimize turbulence and maximize the efficiency of filtration and separation processes. By leveraging the properties of laminar flow, researchers and engineers seek to develop more effective and energy-efficient pollution control systems.

One of the key trends in the evolution of laminar flow technology has been the integration of advanced materials and design techniques. For instance, the development of microfluidic devices has allowed for precise control of fluid flow at microscopic scales, enabling more targeted and efficient pollution removal. Similarly, the use of computational fluid dynamics (CFD) has greatly enhanced our ability to model and optimize laminar flow systems for specific pollution control applications.

Another significant trend has been the expansion of laminar flow technology into new areas of pollution control. While initially focused primarily on air pollution, recent advancements have seen its application in water treatment, industrial emissions control, and even in the management of particulate matter in clean room environments. This broadening of scope has been driven by the increasing recognition of laminar flow's potential to address a wide range of environmental challenges.

The objectives of current research and development in laminar flow for pollution control are multifaceted. Researchers aim to improve the efficiency and effectiveness of existing systems, reduce energy consumption, and develop more compact and cost-effective solutions. There is also a growing focus on creating adaptive systems that can respond to changing pollution levels and environmental conditions in real-time.

Furthermore, there is an increasing emphasis on developing laminar flow technologies that can address emerging pollutants, such as microplastics and nanomaterials. These new challenges require innovative approaches that can leverage the principles of laminar flow to capture and remove increasingly small and complex contaminants from various media.

As we look to the future, the evolution of laminar flow in pollution control is likely to continue at a rapid pace. The integration of smart technologies, such as IoT sensors and artificial intelligence, promises to create more responsive and efficient pollution control systems. Additionally, the ongoing push for sustainability and environmental protection is expected to drive further innovation in this field, potentially leading to breakthrough technologies that could revolutionize our approach to pollution management.

Pollution Control Market Analysis

The pollution control market has experienced significant growth in recent years, driven by increasing environmental concerns and stringent regulations worldwide. The global market for pollution control technologies is projected to reach $98.2 billion by 2026, with a compound annual growth rate (CAGR) of 5.4% from 2021 to 2026. This growth is primarily attributed to the rising awareness of air and water pollution's adverse effects on human health and the environment.

In the context of laminar flow innovations, the market demand is particularly strong in industrial sectors such as manufacturing, chemical processing, and power generation. These industries are under pressure to reduce emissions and improve air quality, creating a substantial market for advanced pollution control solutions. The automotive industry is also a significant contributor to this market, as vehicle manufacturers seek to comply with increasingly strict emission standards.

Geographically, North America and Europe lead the pollution control market due to their well-established regulatory frameworks and high environmental standards. However, the Asia-Pacific region is expected to witness the fastest growth, with China and India at the forefront. This growth is fueled by rapid industrialization, urbanization, and the implementation of more stringent environmental policies in these countries.

The market for laminar flow-based pollution control technologies is characterized by a high degree of innovation and technological advancement. Companies are investing heavily in research and development to create more efficient and cost-effective solutions. The demand for these technologies is further boosted by government initiatives and subsidies aimed at promoting cleaner production methods and reducing industrial emissions.

One of the key trends in the pollution control market is the shift towards integrated solutions that combine multiple technologies to address various pollutants simultaneously. This approach is particularly relevant for laminar flow innovations, as they can be effectively combined with other pollution control methods to achieve superior results.

The market also shows a growing interest in smart pollution control systems that utilize IoT and AI technologies. These advanced systems offer real-time monitoring, predictive maintenance, and optimization of pollution control processes, making them increasingly attractive to industrial customers seeking to improve their environmental performance while minimizing operational costs.

Despite the positive outlook, the pollution control market faces challenges such as high initial investment costs and the need for skilled personnel to operate and maintain advanced systems. However, the long-term benefits of improved environmental compliance and potential cost savings through increased efficiency are expected to drive continued market growth and innovation in laminar flow and other pollution control technologies.

In the context of laminar flow innovations, the market demand is particularly strong in industrial sectors such as manufacturing, chemical processing, and power generation. These industries are under pressure to reduce emissions and improve air quality, creating a substantial market for advanced pollution control solutions. The automotive industry is also a significant contributor to this market, as vehicle manufacturers seek to comply with increasingly strict emission standards.

Geographically, North America and Europe lead the pollution control market due to their well-established regulatory frameworks and high environmental standards. However, the Asia-Pacific region is expected to witness the fastest growth, with China and India at the forefront. This growth is fueled by rapid industrialization, urbanization, and the implementation of more stringent environmental policies in these countries.

The market for laminar flow-based pollution control technologies is characterized by a high degree of innovation and technological advancement. Companies are investing heavily in research and development to create more efficient and cost-effective solutions. The demand for these technologies is further boosted by government initiatives and subsidies aimed at promoting cleaner production methods and reducing industrial emissions.

One of the key trends in the pollution control market is the shift towards integrated solutions that combine multiple technologies to address various pollutants simultaneously. This approach is particularly relevant for laminar flow innovations, as they can be effectively combined with other pollution control methods to achieve superior results.

The market also shows a growing interest in smart pollution control systems that utilize IoT and AI technologies. These advanced systems offer real-time monitoring, predictive maintenance, and optimization of pollution control processes, making them increasingly attractive to industrial customers seeking to improve their environmental performance while minimizing operational costs.

Despite the positive outlook, the pollution control market faces challenges such as high initial investment costs and the need for skilled personnel to operate and maintain advanced systems. However, the long-term benefits of improved environmental compliance and potential cost savings through increased efficiency are expected to drive continued market growth and innovation in laminar flow and other pollution control technologies.

Laminar Flow Challenges in Pollution Control

Laminar flow technology has emerged as a promising solution for pollution control, offering significant advantages in various industrial applications. However, several challenges persist in its implementation and optimization. One of the primary obstacles is maintaining stable laminar flow conditions in real-world environments, where external factors such as temperature fluctuations, pressure changes, and turbulence can disrupt the desired flow patterns.

The scaling of laminar flow systems for large-scale industrial applications presents another significant challenge. As the size of the system increases, maintaining uniform flow characteristics becomes increasingly difficult, potentially compromising the efficiency of pollution control measures. This scaling issue is particularly pronounced in industries such as power generation and chemical processing, where large volumes of pollutants need to be treated.

Material limitations also pose a considerable challenge in laminar flow applications for pollution control. The selection of appropriate materials that can withstand harsh chemical environments while maintaining the necessary surface properties for laminar flow is crucial. Corrosion-resistant materials with low surface roughness are essential, but finding cost-effective solutions that meet these criteria remains a challenge for widespread adoption.

Energy efficiency is another critical concern in laminar flow systems for pollution control. While laminar flow can offer reduced energy consumption compared to turbulent flow systems, optimizing the energy requirements for maintaining laminar conditions in large-scale applications is an ongoing challenge. Balancing the energy input with pollution removal efficiency is essential for the economic viability of these systems.

The integration of laminar flow technology with existing pollution control infrastructure presents both technical and logistical challenges. Retrofitting existing systems to incorporate laminar flow principles often requires significant modifications and may face resistance due to high initial costs and potential disruptions to ongoing operations.

Monitoring and control systems for laminar flow in pollution control applications also face challenges. Developing accurate, real-time sensing technologies to detect flow disturbances and maintain optimal laminar conditions is crucial for system efficiency. Additionally, implementing adaptive control algorithms that can respond to changing environmental conditions and pollutant loads remains an area of active research and development.

Lastly, the regulatory landscape surrounding pollution control technologies adds another layer of complexity to the implementation of laminar flow solutions. Ensuring that these systems meet or exceed increasingly stringent environmental standards while remaining economically viable requires ongoing innovation and adaptation in both technology and regulatory frameworks.

The scaling of laminar flow systems for large-scale industrial applications presents another significant challenge. As the size of the system increases, maintaining uniform flow characteristics becomes increasingly difficult, potentially compromising the efficiency of pollution control measures. This scaling issue is particularly pronounced in industries such as power generation and chemical processing, where large volumes of pollutants need to be treated.

Material limitations also pose a considerable challenge in laminar flow applications for pollution control. The selection of appropriate materials that can withstand harsh chemical environments while maintaining the necessary surface properties for laminar flow is crucial. Corrosion-resistant materials with low surface roughness are essential, but finding cost-effective solutions that meet these criteria remains a challenge for widespread adoption.

Energy efficiency is another critical concern in laminar flow systems for pollution control. While laminar flow can offer reduced energy consumption compared to turbulent flow systems, optimizing the energy requirements for maintaining laminar conditions in large-scale applications is an ongoing challenge. Balancing the energy input with pollution removal efficiency is essential for the economic viability of these systems.

The integration of laminar flow technology with existing pollution control infrastructure presents both technical and logistical challenges. Retrofitting existing systems to incorporate laminar flow principles often requires significant modifications and may face resistance due to high initial costs and potential disruptions to ongoing operations.

Monitoring and control systems for laminar flow in pollution control applications also face challenges. Developing accurate, real-time sensing technologies to detect flow disturbances and maintain optimal laminar conditions is crucial for system efficiency. Additionally, implementing adaptive control algorithms that can respond to changing environmental conditions and pollutant loads remains an area of active research and development.

Lastly, the regulatory landscape surrounding pollution control technologies adds another layer of complexity to the implementation of laminar flow solutions. Ensuring that these systems meet or exceed increasingly stringent environmental standards while remaining economically viable requires ongoing innovation and adaptation in both technology and regulatory frameworks.

Current Laminar Flow Solutions for Pollution Control

01 Laminar flow systems for pollution control

Laminar flow systems are utilized in pollution control devices to enhance the efficiency of contaminant removal. These systems create a smooth, predictable flow of air or liquid, allowing for better separation and filtration of pollutants. The controlled flow reduces turbulence and improves the overall effectiveness of pollution control equipment.- Laminar flow systems for pollution control: Laminar flow systems are utilized in pollution control devices to manage and reduce emissions. These systems create a smooth, predictable flow of air or gas, which enhances the efficiency of pollutant capture and treatment. By maintaining a laminar flow, these systems can effectively separate and remove contaminants from exhaust streams, improving overall air quality.

- Fluid dynamics in pollution control equipment: Advanced fluid dynamics principles are applied in the design of pollution control equipment to optimize performance. This includes the use of computational fluid dynamics (CFD) modeling to predict and control flow patterns, ensuring efficient pollutant removal. By manipulating fluid behavior, these systems can enhance the interaction between contaminants and treatment mechanisms, leading to more effective pollution control.

- Laminar flow in exhaust gas treatment: Laminar flow techniques are specifically applied to exhaust gas treatment systems in various industries. These systems utilize laminar flow to ensure uniform distribution of exhaust gases across treatment surfaces or catalysts. This approach maximizes the contact between pollutants and treatment agents, enhancing the overall efficiency of exhaust gas purification processes.

- Sensor integration in laminar flow pollution control: Advanced sensor technologies are integrated into laminar flow pollution control systems to monitor and optimize performance. These sensors can detect flow rates, pollutant concentrations, and other critical parameters in real-time. The data collected allows for dynamic adjustments to the system, ensuring consistent and efficient pollution control under varying conditions.

- Innovative materials for laminar flow pollution control: Novel materials are being developed and utilized in laminar flow pollution control systems to enhance performance and durability. These materials may include advanced catalysts, nanostructured surfaces, or specialized coatings that improve pollutant capture or breakdown. The use of these innovative materials can significantly increase the efficiency and lifespan of pollution control equipment while maintaining laminar flow conditions.

02 Pollution control in fluid handling systems

Fluid handling systems incorporate pollution control measures to minimize environmental impact. These systems often use laminar flow principles to manage and treat contaminated fluids. Techniques such as precise flow control, filtration, and separation are employed to remove pollutants from liquids or gases before discharge.Expand Specific Solutions03 Laminar flow in air purification systems

Air purification systems leverage laminar flow to improve the removal of airborne pollutants. By creating a controlled airflow pattern, these systems can more effectively capture and filter out contaminants such as dust, allergens, and harmful gases. The laminar flow helps to prevent the re-circulation of pollutants and ensures a more thorough cleaning process.Expand Specific Solutions04 Pollution monitoring using laminar flow techniques

Laminar flow principles are applied in pollution monitoring devices to achieve more accurate measurements. These systems create a controlled environment for sampling and analyzing pollutants in air or water. The laminar flow helps to minimize interference and ensures consistent, reliable data collection for environmental monitoring purposes.Expand Specific Solutions05 Laminar flow in wastewater treatment

Wastewater treatment facilities utilize laminar flow concepts to enhance the efficiency of pollution removal processes. The controlled flow allows for better sedimentation, filtration, and chemical treatment of contaminated water. Laminar flow systems in wastewater treatment help to improve the overall quality of treated water before it is discharged into the environment.Expand Specific Solutions

Key Industry Players and Competitors

The laminar flow technology for pollution control is in a growth phase, with increasing market size and evolving technical maturity. The global market for this technology is expanding as environmental regulations become stricter worldwide. Companies like China City Environment Protection Engineering and Powerchina Huadong Engineering are leading players in developing large-scale laminar flow systems for industrial applications. Meanwhile, research institutions such as Tongji University and Carnegie Mellon University are advancing the fundamental science. Smaller firms like Aerosol Dynamics are innovating in niche areas like airborne particle measurement. The involvement of major corporations like Toshiba and Boeing indicates the technology's growing importance across various sectors.

China City Environment Protection Engineering Ltd. Co.

Technical Solution: China City Environment Protection Engineering Ltd. Co. has developed an innovative laminar flow system for pollution control in urban environments. Their technology utilizes a network of strategically placed laminar flow devices throughout city streets and industrial areas. These devices create controlled air currents that effectively channel and filter pollutants, significantly reducing particulate matter and harmful gases in the air. The system incorporates advanced sensors and AI-driven control mechanisms to adjust flow patterns based on real-time pollution levels and weather conditions[1][3]. Additionally, the company has integrated green infrastructure elements, such as specially designed vegetation barriers, to enhance the natural filtration process and improve overall air quality[5].

Strengths: Comprehensive urban-scale solution, adaptable to various city layouts, and integration with existing infrastructure. Weaknesses: High initial implementation cost and potential disruption to urban traffic during installation.

Powerchina Huadong Engineering Corp. Ltd.

Technical Solution: Powerchina Huadong Engineering Corp. Ltd. has pioneered a laminar flow-based pollution control system for large-scale industrial applications. Their technology focuses on creating laminar airflow patterns within industrial facilities to effectively manage and contain pollutants. The system employs a combination of precisely engineered air intake and exhaust structures, coupled with advanced filtration technologies. By maintaining laminar flow conditions, the system significantly reduces turbulence and prevents the spread of pollutants throughout the facility. The company has also developed a proprietary software that optimizes the flow patterns based on the specific layout and processes of each industrial site, ensuring maximum efficiency in pollutant capture and removal[2][4]. Recent implementations have shown a reduction in airborne pollutants by up to 85% in some industrial settings[6].

Strengths: Highly effective for large industrial spaces, customizable to specific industry needs, and significant reduction in workplace pollutant exposure. Weaknesses: Complex installation process and potentially high energy consumption for maintaining laminar flow in large spaces.

Breakthrough Laminar Flow Innovations

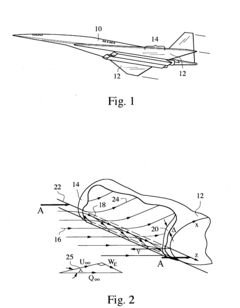

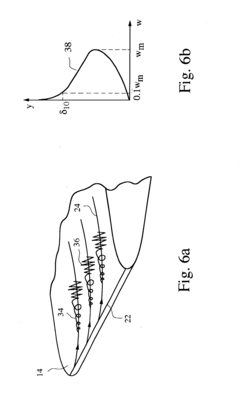

Surface plasma discharge for controlling leading edge contamination and crossflow instabilities for laminar flow

PatentInactiveUS20040195462A1

Innovation

- A lightweight, low-power system using plasma surface discharges with a closed-loop feedback control system, incorporating heat-flow sensors and PID controllers to provide volumetric heating of the boundary layer, reducing the Poll Reynolds and cross flow Reynolds numbers and delaying transition to turbulent flow.

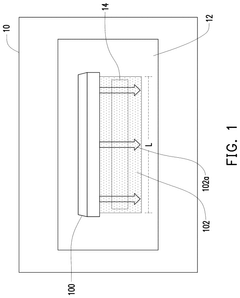

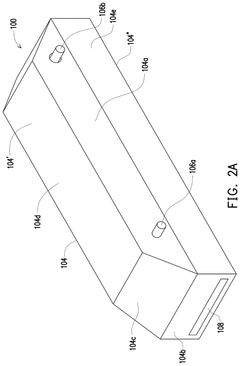

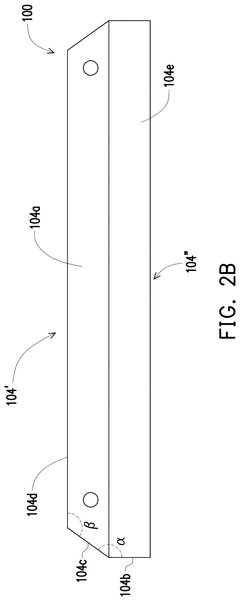

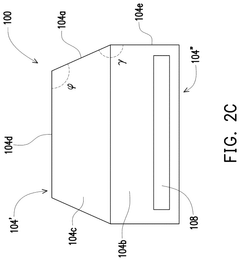

Laminar Gas Flow Filter

PatentPendingUS20250065254A1

Innovation

- A laminar gas flow filter and apparatus are designed to produce a laminar flow of gas, or air curtain, that covers the opening to a semiconductor FAB space or equipment chamber. This is achieved through a pair of diffuser tubes with gas inlets at opposite ends, which create a uniform gas flow velocity across the length of the filter, and an air filter module that can be selectively replaced.

Environmental Regulations and Compliance

Environmental regulations and compliance play a crucial role in shaping the development and implementation of laminar flow technologies for pollution control. As governments worldwide increasingly prioritize environmental protection, industries face stricter regulations and emission standards. These regulations often mandate the use of advanced pollution control technologies, including laminar flow systems, to minimize environmental impact.

In the United States, the Clean Air Act and Clean Water Act set the foundation for air and water quality standards. The Environmental Protection Agency (EPA) enforces these regulations, continually updating them to reflect advancements in pollution control technologies. For instance, the National Emission Standards for Hazardous Air Pollutants (NESHAP) require industries to implement Maximum Achievable Control Technology (MACT), which often includes laminar flow systems for efficient pollutant capture.

The European Union's Industrial Emissions Directive (IED) similarly emphasizes the use of Best Available Techniques (BAT) for pollution control. This directive encourages the adoption of innovative technologies like laminar flow systems to achieve emission reduction targets. The EU's REACH regulation (Registration, Evaluation, Authorization, and Restriction of Chemicals) further influences the design of pollution control systems by regulating the use of certain chemicals in industrial processes.

In Asia, countries like China and India have also strengthened their environmental regulations. China's Air Pollution Prevention and Control Law and Water Pollution Prevention and Control Law have been amended to include more stringent emission standards, driving the adoption of advanced pollution control technologies. India's National Clean Air Programme (NCAP) aims to reduce particulate matter concentrations by 20-30% by 2024, necessitating the implementation of effective air pollution control measures.

Compliance with these regulations often requires industries to invest in state-of-the-art pollution control systems. Laminar flow technologies, with their ability to efficiently capture and remove pollutants, have become increasingly important in meeting these regulatory requirements. Industries are incentivized to adopt these technologies not only to avoid penalties but also to maintain their social license to operate and enhance their environmental reputation.

The regulatory landscape also influences research and development in laminar flow technologies. As emission standards become more stringent, there is a growing demand for more efficient and cost-effective pollution control solutions. This has led to increased investment in R&D, focusing on improving the performance and versatility of laminar flow systems across various industrial applications.

In the United States, the Clean Air Act and Clean Water Act set the foundation for air and water quality standards. The Environmental Protection Agency (EPA) enforces these regulations, continually updating them to reflect advancements in pollution control technologies. For instance, the National Emission Standards for Hazardous Air Pollutants (NESHAP) require industries to implement Maximum Achievable Control Technology (MACT), which often includes laminar flow systems for efficient pollutant capture.

The European Union's Industrial Emissions Directive (IED) similarly emphasizes the use of Best Available Techniques (BAT) for pollution control. This directive encourages the adoption of innovative technologies like laminar flow systems to achieve emission reduction targets. The EU's REACH regulation (Registration, Evaluation, Authorization, and Restriction of Chemicals) further influences the design of pollution control systems by regulating the use of certain chemicals in industrial processes.

In Asia, countries like China and India have also strengthened their environmental regulations. China's Air Pollution Prevention and Control Law and Water Pollution Prevention and Control Law have been amended to include more stringent emission standards, driving the adoption of advanced pollution control technologies. India's National Clean Air Programme (NCAP) aims to reduce particulate matter concentrations by 20-30% by 2024, necessitating the implementation of effective air pollution control measures.

Compliance with these regulations often requires industries to invest in state-of-the-art pollution control systems. Laminar flow technologies, with their ability to efficiently capture and remove pollutants, have become increasingly important in meeting these regulatory requirements. Industries are incentivized to adopt these technologies not only to avoid penalties but also to maintain their social license to operate and enhance their environmental reputation.

The regulatory landscape also influences research and development in laminar flow technologies. As emission standards become more stringent, there is a growing demand for more efficient and cost-effective pollution control solutions. This has led to increased investment in R&D, focusing on improving the performance and versatility of laminar flow systems across various industrial applications.

Cost-Benefit Analysis of Laminar Flow Systems

The implementation of laminar flow systems for pollution control requires a comprehensive cost-benefit analysis to determine their economic viability and environmental impact. Initial investment costs for laminar flow systems can be substantial, including equipment procurement, installation, and facility modifications. However, these upfront expenses must be weighed against long-term operational benefits and potential savings.

Operational costs of laminar flow systems typically include energy consumption, maintenance, and periodic system upgrades. These ongoing expenses are often offset by improved efficiency in pollution control processes, resulting in reduced waste treatment costs and lower emissions-related penalties. Additionally, the enhanced air quality achieved through laminar flow systems can lead to improved worker health and productivity, potentially decreasing healthcare costs and absenteeism.

Environmental benefits of laminar flow systems are significant, contributing to cleaner air and reduced pollutant emissions. This can result in compliance with stricter environmental regulations, avoiding costly fines and legal issues. Furthermore, the adoption of advanced pollution control technologies can enhance a company's reputation, potentially leading to increased market share and customer loyalty.

The cost-effectiveness of laminar flow systems varies depending on the scale of implementation and specific industry requirements. Large-scale industrial applications often demonstrate more favorable cost-benefit ratios due to economies of scale. Smaller operations may face longer payback periods but can still benefit from improved environmental performance and regulatory compliance.

Long-term financial benefits of laminar flow systems include reduced energy consumption through more efficient air handling and filtration processes. These systems can also extend the lifespan of equipment by minimizing exposure to harmful pollutants, thereby reducing replacement and maintenance costs over time.

Government incentives and tax benefits for implementing advanced pollution control technologies can significantly impact the cost-benefit analysis. These financial incentives can help offset initial investment costs and improve the overall economic viability of laminar flow systems.

In conclusion, while the initial costs of laminar flow systems for pollution control can be substantial, the long-term benefits often outweigh the expenses. Improved environmental performance, regulatory compliance, operational efficiency, and potential cost savings contribute to a favorable cost-benefit ratio for many industries considering the implementation of these innovative pollution control solutions.

Operational costs of laminar flow systems typically include energy consumption, maintenance, and periodic system upgrades. These ongoing expenses are often offset by improved efficiency in pollution control processes, resulting in reduced waste treatment costs and lower emissions-related penalties. Additionally, the enhanced air quality achieved through laminar flow systems can lead to improved worker health and productivity, potentially decreasing healthcare costs and absenteeism.

Environmental benefits of laminar flow systems are significant, contributing to cleaner air and reduced pollutant emissions. This can result in compliance with stricter environmental regulations, avoiding costly fines and legal issues. Furthermore, the adoption of advanced pollution control technologies can enhance a company's reputation, potentially leading to increased market share and customer loyalty.

The cost-effectiveness of laminar flow systems varies depending on the scale of implementation and specific industry requirements. Large-scale industrial applications often demonstrate more favorable cost-benefit ratios due to economies of scale. Smaller operations may face longer payback periods but can still benefit from improved environmental performance and regulatory compliance.

Long-term financial benefits of laminar flow systems include reduced energy consumption through more efficient air handling and filtration processes. These systems can also extend the lifespan of equipment by minimizing exposure to harmful pollutants, thereby reducing replacement and maintenance costs over time.

Government incentives and tax benefits for implementing advanced pollution control technologies can significantly impact the cost-benefit analysis. These financial incentives can help offset initial investment costs and improve the overall economic viability of laminar flow systems.

In conclusion, while the initial costs of laminar flow systems for pollution control can be substantial, the long-term benefits often outweigh the expenses. Improved environmental performance, regulatory compliance, operational efficiency, and potential cost savings contribute to a favorable cost-benefit ratio for many industries considering the implementation of these innovative pollution control solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!