Integrated Technological Systems Advanced by Laminar Flow

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Tech Evolution

Laminar flow technology has undergone significant evolution since its initial discovery and application. The development of this technology can be traced through several key stages, each marked by important advancements and breakthroughs.

In the early 20th century, scientists began to understand the fundamental principles of laminar flow, characterized by smooth, predictable fluid motion. This laid the groundwork for future applications in various fields. The 1930s and 1940s saw the first practical applications of laminar flow in aerodynamics, particularly in aircraft design, where it was used to reduce drag and improve fuel efficiency.

The 1950s and 1960s marked a period of rapid advancement in laminar flow control techniques. Researchers developed methods for maintaining laminar flow over larger surface areas, leading to improved performance in aerospace applications. Concurrently, the medical field began exploring laminar flow for creating sterile environments in operating rooms and laboratories.

The 1970s and 1980s witnessed the integration of laminar flow technology into industrial processes. Manufacturing sectors, particularly in electronics and pharmaceuticals, adopted laminar flow systems to create clean room environments, crucial for producing high-precision components and maintaining product purity.

In the 1990s and early 2000s, computational fluid dynamics (CFD) emerged as a powerful tool for studying and optimizing laminar flow systems. This led to more sophisticated designs and applications across various industries, including automotive, energy, and chemical processing.

The past two decades have seen a focus on miniaturization and integration of laminar flow systems. Microfluidics has become a key area of research, with applications in lab-on-a-chip devices, point-of-care diagnostics, and drug delivery systems. Additionally, advances in materials science have enabled the development of surfaces and coatings that can induce or maintain laminar flow more effectively.

Recent years have witnessed a growing interest in biomimetic approaches to laminar flow, inspired by natural phenomena such as the streamlined shapes of marine animals. This has led to innovative designs in fields ranging from underwater vehicles to pipeline systems.

Looking forward, the evolution of laminar flow technology is likely to continue in directions that emphasize energy efficiency, sustainability, and integration with smart systems. Emerging areas of research include adaptive laminar flow control systems, which can respond dynamically to changing conditions, and the application of artificial intelligence to optimize laminar flow in complex systems.

In the early 20th century, scientists began to understand the fundamental principles of laminar flow, characterized by smooth, predictable fluid motion. This laid the groundwork for future applications in various fields. The 1930s and 1940s saw the first practical applications of laminar flow in aerodynamics, particularly in aircraft design, where it was used to reduce drag and improve fuel efficiency.

The 1950s and 1960s marked a period of rapid advancement in laminar flow control techniques. Researchers developed methods for maintaining laminar flow over larger surface areas, leading to improved performance in aerospace applications. Concurrently, the medical field began exploring laminar flow for creating sterile environments in operating rooms and laboratories.

The 1970s and 1980s witnessed the integration of laminar flow technology into industrial processes. Manufacturing sectors, particularly in electronics and pharmaceuticals, adopted laminar flow systems to create clean room environments, crucial for producing high-precision components and maintaining product purity.

In the 1990s and early 2000s, computational fluid dynamics (CFD) emerged as a powerful tool for studying and optimizing laminar flow systems. This led to more sophisticated designs and applications across various industries, including automotive, energy, and chemical processing.

The past two decades have seen a focus on miniaturization and integration of laminar flow systems. Microfluidics has become a key area of research, with applications in lab-on-a-chip devices, point-of-care diagnostics, and drug delivery systems. Additionally, advances in materials science have enabled the development of surfaces and coatings that can induce or maintain laminar flow more effectively.

Recent years have witnessed a growing interest in biomimetic approaches to laminar flow, inspired by natural phenomena such as the streamlined shapes of marine animals. This has led to innovative designs in fields ranging from underwater vehicles to pipeline systems.

Looking forward, the evolution of laminar flow technology is likely to continue in directions that emphasize energy efficiency, sustainability, and integration with smart systems. Emerging areas of research include adaptive laminar flow control systems, which can respond dynamically to changing conditions, and the application of artificial intelligence to optimize laminar flow in complex systems.

Market Demand Analysis

The market demand for integrated technological systems advanced by laminar flow has been steadily increasing across various industries. This growth is primarily driven by the need for more efficient and precise fluid handling in sectors such as aerospace, automotive, healthcare, and manufacturing. Laminar flow technology offers significant advantages in terms of reduced turbulence, improved control over fluid dynamics, and enhanced overall system performance.

In the aerospace industry, there is a growing demand for laminar flow systems to optimize fuel efficiency and reduce drag on aircraft surfaces. Major airlines and aircraft manufacturers are investing heavily in research and development to incorporate these advanced systems into next-generation aircraft designs. The automotive sector is also showing increased interest in laminar flow technology, particularly for improving engine cooling systems and enhancing aerodynamics to boost fuel economy and vehicle performance.

The healthcare industry represents another significant market for laminar flow systems, especially in cleanroom environments and medical device manufacturing. The need for contamination control and precise fluid handling in pharmaceutical production and laboratory settings is driving the adoption of laminar flow technologies. Additionally, the semiconductor industry relies heavily on laminar flow systems for maintaining ultra-clean environments during chip manufacturing processes.

Market analysts project that the global market for laminar flow technologies will experience substantial growth over the next decade. This growth is attributed to the increasing emphasis on energy efficiency, environmental sustainability, and the need for more precise control in various industrial processes. The Asia-Pacific region is expected to emerge as a key market, driven by rapid industrialization and technological advancements in countries like China, Japan, and South Korea.

The demand for integrated technological systems advanced by laminar flow is also being fueled by stringent regulatory requirements in industries such as pharmaceuticals and food processing. These regulations mandate strict control over environmental conditions and contamination prevention, making laminar flow systems an essential component of quality assurance and compliance strategies.

As industries continue to prioritize automation and smart manufacturing concepts, the integration of laminar flow technologies with IoT and AI systems is becoming increasingly important. This trend is creating new market opportunities for advanced, interconnected laminar flow solutions that offer real-time monitoring, predictive maintenance, and optimized performance across entire production lines.

The market for laminar flow technologies is characterized by a growing demand for customized solutions tailored to specific industry needs. This trend is driving innovation among manufacturers and creating opportunities for specialized providers to capture niche market segments. As a result, the competitive landscape is becoming more diverse, with both established players and innovative startups vying for market share in this rapidly evolving technological domain.

In the aerospace industry, there is a growing demand for laminar flow systems to optimize fuel efficiency and reduce drag on aircraft surfaces. Major airlines and aircraft manufacturers are investing heavily in research and development to incorporate these advanced systems into next-generation aircraft designs. The automotive sector is also showing increased interest in laminar flow technology, particularly for improving engine cooling systems and enhancing aerodynamics to boost fuel economy and vehicle performance.

The healthcare industry represents another significant market for laminar flow systems, especially in cleanroom environments and medical device manufacturing. The need for contamination control and precise fluid handling in pharmaceutical production and laboratory settings is driving the adoption of laminar flow technologies. Additionally, the semiconductor industry relies heavily on laminar flow systems for maintaining ultra-clean environments during chip manufacturing processes.

Market analysts project that the global market for laminar flow technologies will experience substantial growth over the next decade. This growth is attributed to the increasing emphasis on energy efficiency, environmental sustainability, and the need for more precise control in various industrial processes. The Asia-Pacific region is expected to emerge as a key market, driven by rapid industrialization and technological advancements in countries like China, Japan, and South Korea.

The demand for integrated technological systems advanced by laminar flow is also being fueled by stringent regulatory requirements in industries such as pharmaceuticals and food processing. These regulations mandate strict control over environmental conditions and contamination prevention, making laminar flow systems an essential component of quality assurance and compliance strategies.

As industries continue to prioritize automation and smart manufacturing concepts, the integration of laminar flow technologies with IoT and AI systems is becoming increasingly important. This trend is creating new market opportunities for advanced, interconnected laminar flow solutions that offer real-time monitoring, predictive maintenance, and optimized performance across entire production lines.

The market for laminar flow technologies is characterized by a growing demand for customized solutions tailored to specific industry needs. This trend is driving innovation among manufacturers and creating opportunities for specialized providers to capture niche market segments. As a result, the competitive landscape is becoming more diverse, with both established players and innovative startups vying for market share in this rapidly evolving technological domain.

Current Tech Challenges

The development of integrated technological systems advanced by laminar flow faces several significant challenges in the current landscape. One of the primary obstacles is the complexity of maintaining stable laminar flow conditions across diverse system components. Achieving and sustaining laminar flow in integrated systems requires precise control over fluid dynamics, which becomes increasingly difficult as system complexity grows.

Another major challenge lies in the integration of multiple technologies within a single system while preserving laminar flow characteristics. This integration often involves combining various materials, sensors, and actuators, each with its own impact on fluid behavior. Balancing these elements to maintain optimal laminar flow conditions presents a formidable engineering task.

The scalability of laminar flow systems poses yet another hurdle. While laminar flow principles can be effectively applied at smaller scales, translating these benefits to larger, more complex integrated systems remains problematic. Issues such as flow instability and increased turbulence tend to emerge as system size and complexity increase, limiting the practical applications of this technology in certain domains.

Energy efficiency is a critical concern in the development of laminar flow-based integrated systems. Although laminar flow can potentially reduce energy consumption in some applications, maintaining the necessary flow conditions often requires significant energy input. Striking a balance between the benefits of laminar flow and the energy required to sustain it remains a key challenge for researchers and engineers.

Material limitations also present obstacles in advancing these integrated systems. The surfaces and components used in laminar flow systems must meet stringent requirements for smoothness, durability, and chemical compatibility. Developing materials that can withstand the operational conditions while maintaining the necessary surface properties for laminar flow is an ongoing area of research and development.

Furthermore, the integration of sensing and control systems to monitor and maintain laminar flow conditions in real-time presents significant technical challenges. These systems must be capable of rapid response to changes in flow conditions, requiring advanced algorithms and high-speed data processing capabilities. The development of robust, reliable, and cost-effective sensing and control technologies remains a critical area for improvement.

Lastly, the interdisciplinary nature of laminar flow-based integrated systems poses challenges in terms of expertise and collaboration. Advancing this technology requires a deep understanding of fluid dynamics, materials science, control systems, and application-specific knowledge. Bridging these diverse fields and fostering effective collaboration among experts remains a significant challenge in pushing the boundaries of this technology.

Another major challenge lies in the integration of multiple technologies within a single system while preserving laminar flow characteristics. This integration often involves combining various materials, sensors, and actuators, each with its own impact on fluid behavior. Balancing these elements to maintain optimal laminar flow conditions presents a formidable engineering task.

The scalability of laminar flow systems poses yet another hurdle. While laminar flow principles can be effectively applied at smaller scales, translating these benefits to larger, more complex integrated systems remains problematic. Issues such as flow instability and increased turbulence tend to emerge as system size and complexity increase, limiting the practical applications of this technology in certain domains.

Energy efficiency is a critical concern in the development of laminar flow-based integrated systems. Although laminar flow can potentially reduce energy consumption in some applications, maintaining the necessary flow conditions often requires significant energy input. Striking a balance between the benefits of laminar flow and the energy required to sustain it remains a key challenge for researchers and engineers.

Material limitations also present obstacles in advancing these integrated systems. The surfaces and components used in laminar flow systems must meet stringent requirements for smoothness, durability, and chemical compatibility. Developing materials that can withstand the operational conditions while maintaining the necessary surface properties for laminar flow is an ongoing area of research and development.

Furthermore, the integration of sensing and control systems to monitor and maintain laminar flow conditions in real-time presents significant technical challenges. These systems must be capable of rapid response to changes in flow conditions, requiring advanced algorithms and high-speed data processing capabilities. The development of robust, reliable, and cost-effective sensing and control technologies remains a critical area for improvement.

Lastly, the interdisciplinary nature of laminar flow-based integrated systems poses challenges in terms of expertise and collaboration. Advancing this technology requires a deep understanding of fluid dynamics, materials science, control systems, and application-specific knowledge. Bridging these diverse fields and fostering effective collaboration among experts remains a significant challenge in pushing the boundaries of this technology.

Existing Laminar Solutions

01 Laminar flow control systems in aircraft

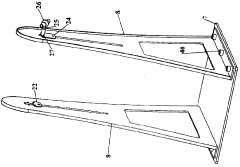

Integrated technological systems for laminar flow control in aircraft involve methods and devices to maintain smooth airflow over surfaces, reducing drag and improving fuel efficiency. These systems may include suction or blowing mechanisms, surface modifications, and sensors to monitor and adjust flow conditions in real-time.- Laminar flow control systems in aircraft: Integrated technological systems for laminar flow control in aircraft, including methods and devices for maintaining laminar airflow over wing surfaces. These systems may involve suction or blowing mechanisms, surface modifications, or active control systems to reduce drag and improve aerodynamic efficiency.

- Microfluidic devices with laminar flow: Development of integrated microfluidic systems that utilize laminar flow for various applications, such as chemical analysis, biological assays, and particle separation. These devices often incorporate precise channel geometries and flow control mechanisms to maintain laminar flow conditions at microscale levels.

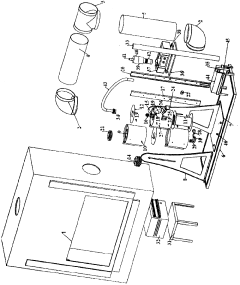

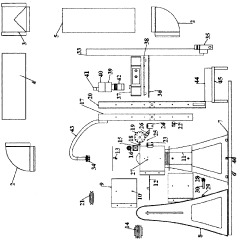

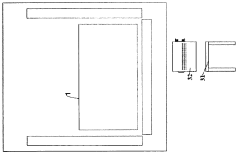

- Laminar flow hoods and clean room technologies: Integrated systems for creating and maintaining laminar airflow in controlled environments, such as clean rooms, laboratories, and manufacturing facilities. These technologies often include specialized filtration systems, air handling units, and precise control mechanisms to ensure consistent laminar flow patterns.

- Laminar flow measurement and analysis systems: Integrated technological systems for measuring, analyzing, and characterizing laminar flow in various applications. These may include advanced sensors, imaging technologies, and data processing algorithms to provide accurate and detailed information about flow characteristics and behavior.

- Laminar flow reactors and process equipment: Development of integrated systems that utilize laminar flow principles in chemical reactors, heat exchangers, and other process equipment. These technologies aim to improve mixing, heat transfer, and reaction efficiency while maintaining precise control over flow conditions.

02 Microfluidic devices with laminar flow

Integrated systems for controlling and manipulating laminar flow in microfluidic devices are used in various applications such as chemical analysis, biological assays, and drug delivery. These systems often incorporate precise flow control mechanisms, channel designs, and detection methods to achieve desired fluid behavior at microscale levels.Expand Specific Solutions03 Laminar flow hoods and clean room technology

Integrated technological systems for laminar flow in clean room environments and laboratory hoods ensure contamination-free workspaces. These systems incorporate air filtration, precise airflow control, and monitoring devices to maintain a unidirectional, particle-free airflow for sensitive operations in industries such as pharmaceuticals and electronics manufacturing.Expand Specific Solutions04 Laminar flow measurement and analysis systems

Advanced integrated systems for measuring and analyzing laminar flow characteristics in various applications, including fluid dynamics research and industrial processes. These systems may include sophisticated sensors, imaging technologies, and data processing algorithms to accurately capture and interpret flow patterns and properties.Expand Specific Solutions05 Laminar flow reactors and process equipment

Integrated technological systems for achieving and maintaining laminar flow conditions in chemical reactors and process equipment. These systems are designed to enhance mixing efficiency, heat transfer, and reaction control in various industrial applications, incorporating advanced flow distribution mechanisms and process control technologies.Expand Specific Solutions

Key Industry Players

The research on Integrated Technological Systems Advanced by Laminar Flow is in a nascent stage, with the market still developing and showing potential for significant growth. The technology's maturity varies across different applications, with some areas more advanced than others. Key players like Sony Group Corp., Siemens Healthcare Diagnostics, and Airbus are investing in research and development, indicating growing interest from major industries. Academic institutions such as Zhejiang University and the University of Washington are also contributing to the field, suggesting a strong focus on fundamental research. The involvement of diverse companies, from electronics to aerospace, highlights the technology's broad applicability and potential for cross-industry innovation.

Siemens Healthcare Diagnostics, Inc.

Technical Solution: Siemens Healthcare Diagnostics, Inc. has integrated laminar flow principles into their advanced diagnostic systems, particularly in the development of automated clinical analyzers and point-of-care testing devices. Their approach focuses on utilizing laminar flow for precise sample handling, reagent mixing, and analysis in compact, high-throughput systems. Siemens has developed microfluidic cartridges that leverage laminar flow for blood separation and analysis, enabling rapid and accurate diagnostics. Their research extends to the application of laminar flow in immunoassay platforms, enhancing sensitivity and reducing sample volume requirements. Siemens has also explored the use of laminar flow in the design of continuous flow chemistry systems for on-demand reagent production in clinical settings[9][10]. These advancements have contributed to faster, more efficient, and more reliable diagnostic processes in healthcare facilities worldwide.

Strengths: Extensive experience in clinical diagnostics, strong integration capabilities with existing healthcare infrastructure. Weaknesses: Regulatory challenges in implementing new technologies in healthcare settings.

University of Washington

Technical Solution: The University of Washington has conducted significant research on integrated technological systems advanced by laminar flow, particularly in the fields of microfluidics and bioengineering. Their approach focuses on developing novel microfluidic devices that utilize laminar flow for cell sorting, drug screening, and tissue engineering applications. The university has pioneered the development of organ-on-a-chip systems that replicate human physiological conditions using laminar flow to control the microenvironment. Their research also extends to the creation of 3D-printed microfluidic devices that leverage laminar flow for point-of-care diagnostics. The University of Washington has explored the use of laminar flow in the design of artificial lymph nodes and vascularized tissue constructs, advancing the field of regenerative medicine[7][8]. These innovations have led to more accurate in vitro models for drug testing and personalized medicine applications.

Strengths: Strong interdisciplinary approach, cutting-edge research in biomedical applications of laminar flow. Weaknesses: Potential challenges in translating academic research into commercial products.

Core Laminar Innovations

Device for generating laminar flow implemented in a tubular furnace.

PatentActiveMX2017015541A

Innovation

- A laminar flow emitter device is integrated into a tubular oven with a piezoelectric system operating at 0.8 MHz to generate aerosols, surrounded by four cylindrical ducts that maintain laminar flow and prevent turbulence, allowing for both horizontal and vertical orientations, with independently controlled gas flows to enhance aerosol delivery.

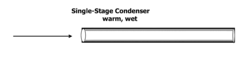

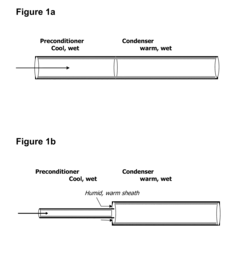

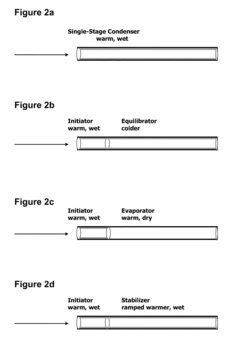

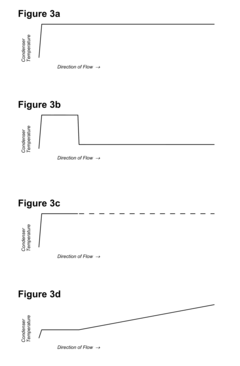

Advanced laminar flow water condensation technology for ultrafine particles

PatentActiveUS20150075372A1

Innovation

- The development of laminar flow water condensation systems with narrower dimensions and double-stage condenser designs, such as the initiator-equilibrator configuration, to create controlled vapor supersaturation and uniform droplet growth, allowing for consistent particle activation and growth across a wide range of concentrations.

Environmental Impact

The integration of laminar flow technology into advanced technological systems has significant environmental implications that warrant careful consideration. This approach to system design and operation can lead to substantial improvements in energy efficiency and resource utilization, thereby reducing the overall environmental footprint of various industrial processes and applications.

One of the primary environmental benefits of laminar flow-based systems is their potential for energy conservation. By minimizing turbulence and optimizing fluid dynamics, these systems can significantly reduce energy consumption in processes involving fluid transport, heat exchange, and material handling. This reduction in energy usage translates directly to lower greenhouse gas emissions and a decreased reliance on fossil fuels, contributing to global efforts to mitigate climate change.

Furthermore, the precise control afforded by laminar flow systems can lead to more efficient use of resources in manufacturing and processing industries. By enhancing the accuracy of material deposition, mixing, and separation processes, these systems can minimize waste production and improve product quality. This efficiency not only reduces the consumption of raw materials but also decreases the volume of waste that needs to be treated or disposed of, thereby lessening the environmental burden associated with industrial activities.

In the context of environmental remediation and pollution control, laminar flow technologies offer promising solutions. For instance, in air and water purification systems, the application of laminar flow principles can enhance the effectiveness of filtration and separation processes, leading to more thorough removal of contaminants and pollutants. This capability is particularly valuable in addressing challenges related to air quality in urban environments and water treatment in industrial settings.

The integration of laminar flow concepts into cooling systems for electronic devices and data centers presents another avenue for environmental improvement. By optimizing heat dissipation and reducing the energy required for cooling, these advanced systems can contribute to the reduction of the carbon footprint associated with the rapidly growing information technology sector.

However, it is important to note that the environmental benefits of laminar flow-based systems must be balanced against potential drawbacks. The manufacturing and implementation of these advanced systems may require specialized materials and components, which could have their own environmental impacts in terms of resource extraction and production processes. Additionally, the disposal or recycling of these systems at the end of their lifecycle needs to be carefully managed to prevent negative environmental consequences.

In conclusion, the environmental impact of integrated technological systems advanced by laminar flow is largely positive, offering significant potential for energy savings, resource efficiency, and pollution reduction. As research in this field progresses, it will be crucial to continue evaluating and optimizing these systems to maximize their environmental benefits while minimizing any associated negative impacts.

One of the primary environmental benefits of laminar flow-based systems is their potential for energy conservation. By minimizing turbulence and optimizing fluid dynamics, these systems can significantly reduce energy consumption in processes involving fluid transport, heat exchange, and material handling. This reduction in energy usage translates directly to lower greenhouse gas emissions and a decreased reliance on fossil fuels, contributing to global efforts to mitigate climate change.

Furthermore, the precise control afforded by laminar flow systems can lead to more efficient use of resources in manufacturing and processing industries. By enhancing the accuracy of material deposition, mixing, and separation processes, these systems can minimize waste production and improve product quality. This efficiency not only reduces the consumption of raw materials but also decreases the volume of waste that needs to be treated or disposed of, thereby lessening the environmental burden associated with industrial activities.

In the context of environmental remediation and pollution control, laminar flow technologies offer promising solutions. For instance, in air and water purification systems, the application of laminar flow principles can enhance the effectiveness of filtration and separation processes, leading to more thorough removal of contaminants and pollutants. This capability is particularly valuable in addressing challenges related to air quality in urban environments and water treatment in industrial settings.

The integration of laminar flow concepts into cooling systems for electronic devices and data centers presents another avenue for environmental improvement. By optimizing heat dissipation and reducing the energy required for cooling, these advanced systems can contribute to the reduction of the carbon footprint associated with the rapidly growing information technology sector.

However, it is important to note that the environmental benefits of laminar flow-based systems must be balanced against potential drawbacks. The manufacturing and implementation of these advanced systems may require specialized materials and components, which could have their own environmental impacts in terms of resource extraction and production processes. Additionally, the disposal or recycling of these systems at the end of their lifecycle needs to be carefully managed to prevent negative environmental consequences.

In conclusion, the environmental impact of integrated technological systems advanced by laminar flow is largely positive, offering significant potential for energy savings, resource efficiency, and pollution reduction. As research in this field progresses, it will be crucial to continue evaluating and optimizing these systems to maximize their environmental benefits while minimizing any associated negative impacts.

Regulatory Considerations

The regulatory landscape surrounding integrated technological systems advanced by laminar flow is complex and multifaceted, requiring careful consideration from developers and implementers. These systems, which leverage the principles of laminar flow to enhance efficiency and performance, are subject to various regulations across different sectors and jurisdictions.

In the aerospace industry, regulatory bodies such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) have established stringent guidelines for the implementation of laminar flow technologies in aircraft design. These regulations focus on ensuring the safety and reliability of laminar flow systems, particularly in critical areas such as wing surfaces and engine nacelles. Compliance with these regulations often involves extensive testing and certification processes to demonstrate the long-term stability and performance of laminar flow systems under various operational conditions.

In the field of medical devices, regulatory agencies like the Food and Drug Administration (FDA) in the United States and the European Medicines Agency (EMA) have specific requirements for devices that utilize laminar flow principles. These regulations primarily address issues of sterility, contamination control, and overall patient safety. Manufacturers must demonstrate that their laminar flow-based systems meet strict standards for air quality, particulate control, and microbial contamination prevention.

Environmental regulations also play a significant role in the development and deployment of integrated technological systems advanced by laminar flow. Many countries have implemented energy efficiency standards that indirectly impact the design and operation of these systems. For instance, regulations aimed at reducing carbon emissions in industrial processes may incentivize the adoption of laminar flow technologies that can improve energy efficiency and reduce waste.

In the context of manufacturing and industrial applications, occupational health and safety regulations often intersect with the implementation of laminar flow systems. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States have established guidelines for maintaining safe working environments, which can influence the design and operation of laminar flow-based technologies in industrial settings.

As the technology continues to evolve, regulatory frameworks are likely to adapt and expand. Developers and manufacturers must stay abreast of these changes and engage proactively with regulatory bodies to ensure compliance and facilitate innovation. This may involve participating in standards development processes, contributing to industry working groups, and collaborating with regulatory agencies to establish appropriate guidelines for emerging applications of laminar flow technologies.

In the aerospace industry, regulatory bodies such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) have established stringent guidelines for the implementation of laminar flow technologies in aircraft design. These regulations focus on ensuring the safety and reliability of laminar flow systems, particularly in critical areas such as wing surfaces and engine nacelles. Compliance with these regulations often involves extensive testing and certification processes to demonstrate the long-term stability and performance of laminar flow systems under various operational conditions.

In the field of medical devices, regulatory agencies like the Food and Drug Administration (FDA) in the United States and the European Medicines Agency (EMA) have specific requirements for devices that utilize laminar flow principles. These regulations primarily address issues of sterility, contamination control, and overall patient safety. Manufacturers must demonstrate that their laminar flow-based systems meet strict standards for air quality, particulate control, and microbial contamination prevention.

Environmental regulations also play a significant role in the development and deployment of integrated technological systems advanced by laminar flow. Many countries have implemented energy efficiency standards that indirectly impact the design and operation of these systems. For instance, regulations aimed at reducing carbon emissions in industrial processes may incentivize the adoption of laminar flow technologies that can improve energy efficiency and reduce waste.

In the context of manufacturing and industrial applications, occupational health and safety regulations often intersect with the implementation of laminar flow systems. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) in the United States have established guidelines for maintaining safe working environments, which can influence the design and operation of laminar flow-based technologies in industrial settings.

As the technology continues to evolve, regulatory frameworks are likely to adapt and expand. Developers and manufacturers must stay abreast of these changes and engage proactively with regulatory bodies to ensure compliance and facilitate innovation. This may involve participating in standards development processes, contributing to industry working groups, and collaborating with regulatory agencies to establish appropriate guidelines for emerging applications of laminar flow technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!