How Laminar Flow Solutions Can Strengthen Circular Economy Objectives?

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Fundamentals and Circular Economy Goals

Laminar flow, characterized by smooth and predictable fluid motion, plays a crucial role in various industrial processes and natural systems. This orderly flow regime occurs when fluid layers slide past one another with minimal mixing, typically at low Reynolds numbers. Understanding laminar flow principles is essential for optimizing fluid dynamics in applications ranging from microfluidics to large-scale industrial operations.

The circular economy, on the other hand, represents a paradigm shift in resource management and economic thinking. It aims to eliminate waste, maximize resource efficiency, and promote sustainable practices throughout product lifecycles. This model contrasts with the traditional linear economy of "take-make-dispose" by emphasizing regenerative design, reuse, and recycling.

The intersection of laminar flow solutions and circular economy objectives presents a compelling area for technological innovation and sustainable development. Laminar flow characteristics can be leveraged to enhance material separation processes, improve energy efficiency in fluid systems, and enable precise control in manufacturing processes – all of which align with circular economy goals.

In fluid separation technologies, laminar flow principles facilitate the efficient sorting of materials based on their physical properties. This capability is particularly valuable in recycling processes, where the separation of different materials is crucial for effective resource recovery. By utilizing laminar flow in separation systems, industries can achieve higher purity in recycled materials, thus increasing their value and potential for reuse.

Energy efficiency, a key tenet of the circular economy, can be significantly improved through the application of laminar flow principles. In piping systems and heat exchangers, maintaining laminar flow conditions can reduce friction losses and enhance heat transfer efficiency. This translates to lower energy consumption in industrial processes, contributing to the overall sustainability objectives of the circular economy.

Precision manufacturing, essential for producing durable and repairable products, benefits greatly from laminar flow control. In 3D printing and other additive manufacturing techniques, laminar flow ensures the accurate deposition of materials, enabling the creation of complex, high-quality components with minimal waste. This precision aligns with circular economy principles by facilitating the production of long-lasting products that can be easily repaired or upgraded, extending their lifecycle and reducing resource consumption.

Moreover, laminar flow solutions can enhance the efficiency of chemical processes integral to circular economy practices. In bio-based material production and waste treatment systems, controlled laminar flow conditions can optimize reaction kinetics and mass transfer, leading to more efficient and environmentally friendly processes.

The circular economy, on the other hand, represents a paradigm shift in resource management and economic thinking. It aims to eliminate waste, maximize resource efficiency, and promote sustainable practices throughout product lifecycles. This model contrasts with the traditional linear economy of "take-make-dispose" by emphasizing regenerative design, reuse, and recycling.

The intersection of laminar flow solutions and circular economy objectives presents a compelling area for technological innovation and sustainable development. Laminar flow characteristics can be leveraged to enhance material separation processes, improve energy efficiency in fluid systems, and enable precise control in manufacturing processes – all of which align with circular economy goals.

In fluid separation technologies, laminar flow principles facilitate the efficient sorting of materials based on their physical properties. This capability is particularly valuable in recycling processes, where the separation of different materials is crucial for effective resource recovery. By utilizing laminar flow in separation systems, industries can achieve higher purity in recycled materials, thus increasing their value and potential for reuse.

Energy efficiency, a key tenet of the circular economy, can be significantly improved through the application of laminar flow principles. In piping systems and heat exchangers, maintaining laminar flow conditions can reduce friction losses and enhance heat transfer efficiency. This translates to lower energy consumption in industrial processes, contributing to the overall sustainability objectives of the circular economy.

Precision manufacturing, essential for producing durable and repairable products, benefits greatly from laminar flow control. In 3D printing and other additive manufacturing techniques, laminar flow ensures the accurate deposition of materials, enabling the creation of complex, high-quality components with minimal waste. This precision aligns with circular economy principles by facilitating the production of long-lasting products that can be easily repaired or upgraded, extending their lifecycle and reducing resource consumption.

Moreover, laminar flow solutions can enhance the efficiency of chemical processes integral to circular economy practices. In bio-based material production and waste treatment systems, controlled laminar flow conditions can optimize reaction kinetics and mass transfer, leading to more efficient and environmentally friendly processes.

Market Demand for Sustainable Flow Solutions

The market demand for sustainable flow solutions has been steadily increasing in recent years, driven by the growing emphasis on circular economy principles and environmental sustainability. Industries across various sectors are recognizing the need for more efficient and eco-friendly fluid management systems to reduce waste, conserve resources, and minimize environmental impact.

In the manufacturing sector, there is a significant demand for laminar flow solutions that can optimize production processes while reducing energy consumption and material waste. Companies are seeking technologies that can improve product quality, increase yield, and lower operational costs simultaneously. This demand is particularly strong in industries such as pharmaceuticals, food and beverage, and electronics manufacturing, where precise control of fluid dynamics is crucial.

The water treatment industry is another key driver of market demand for sustainable flow solutions. As water scarcity becomes a global concern, there is an increasing need for advanced laminar flow technologies that can enhance water purification processes, improve filtration efficiency, and enable water reuse. Municipalities and industrial facilities are investing in innovative flow solutions to meet stringent environmental regulations and reduce their water footprint.

In the energy sector, the transition towards renewable energy sources has created new opportunities for laminar flow solutions. Wind turbine manufacturers are exploring advanced flow control technologies to improve the efficiency and lifespan of their products. Similarly, the growing hydrogen economy is driving demand for flow solutions that can optimize electrolysis processes and enhance the production and distribution of green hydrogen.

The automotive industry is also contributing to the market demand for sustainable flow solutions. As electric vehicles gain popularity, there is a need for improved thermal management systems that can efficiently regulate battery temperatures and extend driving range. Laminar flow technologies are being explored to develop more effective cooling solutions for electric vehicle powertrains.

The construction sector is increasingly adopting sustainable building practices, creating a demand for flow solutions that can improve energy efficiency in HVAC systems and reduce overall building energy consumption. Laminar flow technologies are being integrated into smart building designs to optimize air circulation, enhance indoor air quality, and minimize energy waste.

As circular economy objectives gain traction globally, the market for sustainable flow solutions is expected to expand further. Companies are recognizing the potential of laminar flow technologies to not only improve their operational efficiency but also to contribute to their sustainability goals and corporate social responsibility initiatives. This growing awareness is driving investment in research and development of innovative flow solutions that align with circular economy principles.

In the manufacturing sector, there is a significant demand for laminar flow solutions that can optimize production processes while reducing energy consumption and material waste. Companies are seeking technologies that can improve product quality, increase yield, and lower operational costs simultaneously. This demand is particularly strong in industries such as pharmaceuticals, food and beverage, and electronics manufacturing, where precise control of fluid dynamics is crucial.

The water treatment industry is another key driver of market demand for sustainable flow solutions. As water scarcity becomes a global concern, there is an increasing need for advanced laminar flow technologies that can enhance water purification processes, improve filtration efficiency, and enable water reuse. Municipalities and industrial facilities are investing in innovative flow solutions to meet stringent environmental regulations and reduce their water footprint.

In the energy sector, the transition towards renewable energy sources has created new opportunities for laminar flow solutions. Wind turbine manufacturers are exploring advanced flow control technologies to improve the efficiency and lifespan of their products. Similarly, the growing hydrogen economy is driving demand for flow solutions that can optimize electrolysis processes and enhance the production and distribution of green hydrogen.

The automotive industry is also contributing to the market demand for sustainable flow solutions. As electric vehicles gain popularity, there is a need for improved thermal management systems that can efficiently regulate battery temperatures and extend driving range. Laminar flow technologies are being explored to develop more effective cooling solutions for electric vehicle powertrains.

The construction sector is increasingly adopting sustainable building practices, creating a demand for flow solutions that can improve energy efficiency in HVAC systems and reduce overall building energy consumption. Laminar flow technologies are being integrated into smart building designs to optimize air circulation, enhance indoor air quality, and minimize energy waste.

As circular economy objectives gain traction globally, the market for sustainable flow solutions is expected to expand further. Companies are recognizing the potential of laminar flow technologies to not only improve their operational efficiency but also to contribute to their sustainability goals and corporate social responsibility initiatives. This growing awareness is driving investment in research and development of innovative flow solutions that align with circular economy principles.

Current Challenges in Laminar Flow Technology

Laminar flow technology, while offering significant benefits in various applications, faces several challenges that hinder its widespread adoption and effectiveness in supporting circular economy objectives. One of the primary obstacles is the difficulty in maintaining laminar flow conditions in complex geometries and at larger scales. As systems increase in size or complexity, the likelihood of turbulence and flow instabilities rises, compromising the efficiency and predictability of laminar flow solutions.

Another significant challenge is the energy consumption associated with maintaining laminar flow conditions. In many industrial processes, achieving and sustaining laminar flow often requires substantial energy input, which can offset the potential environmental benefits and circular economy gains. This energy-intensive nature poses a dilemma for organizations striving to balance operational efficiency with sustainability goals.

The sensitivity of laminar flow to external disturbances presents an additional hurdle. Vibrations, temperature fluctuations, and minor imperfections in system components can disrupt laminar flow, leading to reduced performance and increased resource consumption. This sensitivity necessitates precise control systems and high-quality manufacturing processes, which can be costly and resource-intensive.

Furthermore, the limited applicability of laminar flow solutions across diverse industrial sectors poses a challenge to their integration into circular economy strategies. While laminar flow principles are well-established in certain fields like microfluidics and aerospace, their adaptation to other industries, such as waste management or recycling, requires significant research and development efforts.

The lack of standardized design methodologies and simulation tools specifically tailored for laminar flow applications in circular economy contexts is another obstacle. This gap in knowledge and resources makes it difficult for engineers and designers to effectively implement laminar flow solutions in new or existing circular economy systems.

Additionally, the high initial costs associated with implementing laminar flow technologies can deter adoption, particularly for small and medium-sized enterprises. The investment required for specialized equipment, precise manufacturing, and advanced control systems may outweigh the perceived benefits, especially when the long-term advantages for circular economy objectives are not immediately apparent.

Lastly, there is a challenge in quantifying and communicating the direct impact of laminar flow solutions on circular economy metrics. The complex interplay between fluid dynamics, energy efficiency, and material conservation makes it difficult to establish clear, measurable links between laminar flow implementations and circular economy outcomes. This lack of tangible evidence can hinder decision-making processes and limit investment in laminar flow technologies for circular economy applications.

Another significant challenge is the energy consumption associated with maintaining laminar flow conditions. In many industrial processes, achieving and sustaining laminar flow often requires substantial energy input, which can offset the potential environmental benefits and circular economy gains. This energy-intensive nature poses a dilemma for organizations striving to balance operational efficiency with sustainability goals.

The sensitivity of laminar flow to external disturbances presents an additional hurdle. Vibrations, temperature fluctuations, and minor imperfections in system components can disrupt laminar flow, leading to reduced performance and increased resource consumption. This sensitivity necessitates precise control systems and high-quality manufacturing processes, which can be costly and resource-intensive.

Furthermore, the limited applicability of laminar flow solutions across diverse industrial sectors poses a challenge to their integration into circular economy strategies. While laminar flow principles are well-established in certain fields like microfluidics and aerospace, their adaptation to other industries, such as waste management or recycling, requires significant research and development efforts.

The lack of standardized design methodologies and simulation tools specifically tailored for laminar flow applications in circular economy contexts is another obstacle. This gap in knowledge and resources makes it difficult for engineers and designers to effectively implement laminar flow solutions in new or existing circular economy systems.

Additionally, the high initial costs associated with implementing laminar flow technologies can deter adoption, particularly for small and medium-sized enterprises. The investment required for specialized equipment, precise manufacturing, and advanced control systems may outweigh the perceived benefits, especially when the long-term advantages for circular economy objectives are not immediately apparent.

Lastly, there is a challenge in quantifying and communicating the direct impact of laminar flow solutions on circular economy metrics. The complex interplay between fluid dynamics, energy efficiency, and material conservation makes it difficult to establish clear, measurable links between laminar flow implementations and circular economy outcomes. This lack of tangible evidence can hinder decision-making processes and limit investment in laminar flow technologies for circular economy applications.

Existing Laminar Flow Circular Economy Solutions

01 Laminar flow measurement and control systems

Various systems and methods for measuring and controlling laminar flow in different applications. These include optical measurement techniques, flow sensors, and control mechanisms to maintain stable laminar flow conditions in diverse settings such as industrial processes, scientific instruments, and fluid handling systems.- Laminar flow measurement and control systems: Advanced systems for measuring and controlling laminar flow in various applications. These systems utilize sensors, flow meters, and control algorithms to maintain stable laminar flow conditions, enhancing efficiency and precision in fluid dynamics experiments and industrial processes.

- Laminar flow devices for fluid handling: Specialized devices designed to create and maintain laminar flow in fluid handling applications. These include nozzles, diffusers, and flow channels engineered to minimize turbulence and ensure smooth, predictable fluid movement in various industrial and scientific settings.

- Laminar flow solutions in aerodynamics: Innovations in aerodynamic design to promote laminar flow over surfaces, reducing drag and improving efficiency. These solutions encompass wing designs, fuselage modifications, and surface treatments that delay the transition from laminar to turbulent flow in aviation and automotive applications.

- Laminar flow in environmental control systems: Applications of laminar flow principles in environmental control systems, such as clean rooms, HVAC systems, and air purification units. These solutions ensure precise control of air movement, minimizing contaminants and maintaining stable atmospheric conditions in sensitive environments.

- Laminar flow solutions for fluid separation and filtration: Utilization of laminar flow characteristics in fluid separation and filtration processes. These solutions involve the design of specialized membranes, filters, and separation chambers that leverage laminar flow to enhance the efficiency and precision of particle removal and fluid purification in various industries.

02 Laminar flow devices for fluid distribution

Devices and apparatus designed to create and maintain laminar flow for efficient fluid distribution. These solutions are applied in areas such as irrigation systems, spray nozzles, and liquid dispensing equipment to ensure uniform and controlled fluid delivery.Expand Specific Solutions03 Laminar flow in aerodynamic applications

Innovations focused on achieving and maintaining laminar flow in aerodynamic contexts. This includes designs for aircraft components, wind tunnel testing equipment, and other applications where smooth airflow is critical for performance and efficiency.Expand Specific Solutions04 Laminar flow solutions for medical and laboratory equipment

Specialized laminar flow technologies developed for medical and laboratory environments. These include clean room systems, biosafety cabinets, and precision fluid handling devices that require controlled, contamination-free airflow or liquid flow.Expand Specific Solutions05 Industrial processes utilizing laminar flow principles

Applications of laminar flow in various industrial processes, including manufacturing, chemical processing, and material handling. These solutions aim to improve efficiency, product quality, and process control by leveraging the predictable characteristics of laminar flow.Expand Specific Solutions

Key Players in Laminar Flow Industry

The laminar flow solutions market is in a growth phase, driven by increasing focus on circular economy objectives across industries. The market size is expanding as more companies adopt these technologies to improve resource efficiency and reduce environmental impact. Technologically, laminar flow solutions are maturing, with leading players like Commissariat à l´énergie atomique et aux énergies Alternatives, Hayward Industries, and Lenzing AG advancing innovations in fluid dynamics and process optimization. While established firms dominate, emerging players are introducing novel applications, indicating a dynamic competitive landscape with potential for further technological breakthroughs and market expansion.

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has integrated laminar flow solutions into their circular economy initiatives, particularly in manufacturing processes and product design. Their approach focuses on optimizing fluid dynamics in production lines and developing products that utilize laminar flow principles for improved efficiency. In automotive applications, Bosch has developed fuel injection systems that leverage laminar flow to enhance fuel atomization, resulting in more complete combustion and reduced emissions[4]. This technology has shown to improve fuel efficiency by up to 15% in certain engine types. In their home appliance division, Bosch has incorporated laminar flow concepts into dishwasher and washing machine designs, reducing water consumption by up to 20% while maintaining cleaning effectiveness[5]. Additionally, Bosch's industrial technology sector has developed laminar flow-based cooling systems for manufacturing equipment, significantly reducing energy consumption and extending machine lifespans[6].

Strengths: Wide range of applications across multiple sectors, strong focus on energy and resource efficiency. Weaknesses: Implementation may require significant changes to existing manufacturing processes, potential for increased complexity in product design.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has developed advanced laminar flow solutions to strengthen circular economy objectives. Their technology focuses on heat transfer, separation, and fluid handling processes. In the context of circular economy, Alfa Laval's laminar flow solutions are applied in various industries to improve resource efficiency and reduce waste. For example, their plate heat exchangers utilize laminar flow principles to maximize heat transfer efficiency, reducing energy consumption by up to 30% compared to traditional methods[1]. In wastewater treatment, Alfa Laval's membrane filtration systems employ laminar flow to separate contaminants from water, enabling water reuse and reducing freshwater demand[2]. The company has also developed laminar flow-based separation technologies for oil and gas industries, allowing for more efficient resource recovery and minimizing environmental impact[3].

Strengths: High energy efficiency, versatile applications across industries, proven track record in circular economy solutions. Weaknesses: Initial investment costs may be high, requires specialized knowledge for optimal implementation.

Innovative Laminar Flow Recycling Techniques

Microparticle separation and cleaning method using combinational laminar flow of viscoelastic fluid and viscous fluid

PatentWO2017126755A1

Innovation

- The method employs parallel laminar flow of viscoelastic and viscous fluids in a fluid channel to separate and clean microparticles by balancing forces, using a fluid chip with specific design features like angled inlets and outlets, and adjustable flow rates to move target particles from viscoelastic fluids into viscous fluids for cleaning, without the need for centrifugation or sample dilution.

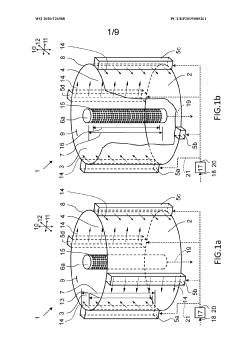

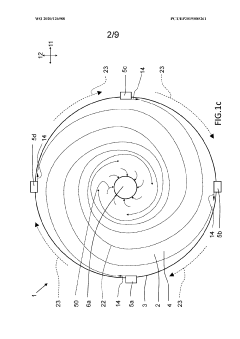

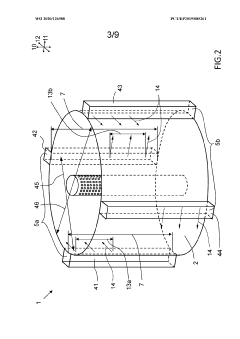

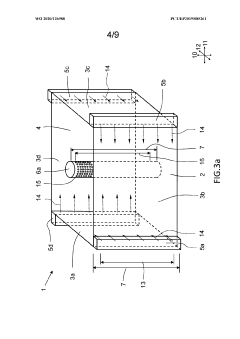

Fish farming tank for cultivating living fish

PatentWO2020126988A1

Innovation

- A fish farming tank design with an active flow control system featuring a wide water inlet arrangement that injects water over more than 50% of the maximal depth and a corresponding wide water outlet arrangement that sucks water over a similar span, ensuring a uniform and laminar circulating flow throughout the tank, reducing turbulence and improving water quality.

Environmental Impact Assessment

Laminar flow solutions have the potential to significantly contribute to circular economy objectives by minimizing waste, optimizing resource utilization, and reducing environmental impact. The environmental impact assessment of laminar flow technologies reveals several key benefits and considerations.

Firstly, laminar flow systems can substantially reduce energy consumption in various industrial processes. By maintaining a smooth, predictable flow of fluids or gases, these systems minimize turbulence and energy loss, leading to improved efficiency in heat transfer, mixing, and separation processes. This reduction in energy usage directly translates to lower greenhouse gas emissions and a decreased carbon footprint for industrial operations.

Furthermore, laminar flow solutions can enhance the efficiency of water treatment and purification processes. By facilitating more precise control over fluid dynamics, these systems can improve the removal of contaminants and pollutants from water sources. This not only contributes to water conservation efforts but also reduces the need for chemical treatments, aligning with circular economy principles of minimizing resource consumption and environmental impact.

In the context of manufacturing and production, laminar flow technologies can lead to significant reductions in material waste. By providing more precise control over fluid flows in processes such as coating, printing, and material deposition, these systems can minimize overspray, reduce material loss, and improve product quality. This aligns with circular economy goals of maximizing resource efficiency and minimizing waste generation throughout the production cycle.

Additionally, laminar flow solutions can play a crucial role in improving air quality in various settings. In clean room environments, laminar airflow systems effectively remove particulates and contaminants, ensuring a sterile environment for sensitive manufacturing processes or healthcare applications. This not only enhances product quality and safety but also reduces the need for extensive cleaning and decontamination procedures, further supporting resource conservation efforts.

The implementation of laminar flow technologies in transportation systems, particularly in aerodynamics, can lead to significant improvements in fuel efficiency. By reducing drag and optimizing airflow around vehicles, these solutions can decrease fuel consumption and emissions in both ground and air transportation. This contributes to the overall reduction of the transportation sector's environmental footprint, a key objective in circular economy strategies.

However, it is important to note that the environmental benefits of laminar flow solutions must be balanced against the potential impacts of their implementation. The production and installation of specialized equipment may have initial environmental costs, which should be considered in a comprehensive life cycle assessment. Additionally, the use of certain materials or chemicals in maintaining laminar flow conditions should be carefully evaluated to ensure they do not introduce new environmental risks.

Firstly, laminar flow systems can substantially reduce energy consumption in various industrial processes. By maintaining a smooth, predictable flow of fluids or gases, these systems minimize turbulence and energy loss, leading to improved efficiency in heat transfer, mixing, and separation processes. This reduction in energy usage directly translates to lower greenhouse gas emissions and a decreased carbon footprint for industrial operations.

Furthermore, laminar flow solutions can enhance the efficiency of water treatment and purification processes. By facilitating more precise control over fluid dynamics, these systems can improve the removal of contaminants and pollutants from water sources. This not only contributes to water conservation efforts but also reduces the need for chemical treatments, aligning with circular economy principles of minimizing resource consumption and environmental impact.

In the context of manufacturing and production, laminar flow technologies can lead to significant reductions in material waste. By providing more precise control over fluid flows in processes such as coating, printing, and material deposition, these systems can minimize overspray, reduce material loss, and improve product quality. This aligns with circular economy goals of maximizing resource efficiency and minimizing waste generation throughout the production cycle.

Additionally, laminar flow solutions can play a crucial role in improving air quality in various settings. In clean room environments, laminar airflow systems effectively remove particulates and contaminants, ensuring a sterile environment for sensitive manufacturing processes or healthcare applications. This not only enhances product quality and safety but also reduces the need for extensive cleaning and decontamination procedures, further supporting resource conservation efforts.

The implementation of laminar flow technologies in transportation systems, particularly in aerodynamics, can lead to significant improvements in fuel efficiency. By reducing drag and optimizing airflow around vehicles, these solutions can decrease fuel consumption and emissions in both ground and air transportation. This contributes to the overall reduction of the transportation sector's environmental footprint, a key objective in circular economy strategies.

However, it is important to note that the environmental benefits of laminar flow solutions must be balanced against the potential impacts of their implementation. The production and installation of specialized equipment may have initial environmental costs, which should be considered in a comprehensive life cycle assessment. Additionally, the use of certain materials or chemicals in maintaining laminar flow conditions should be carefully evaluated to ensure they do not introduce new environmental risks.

Policy Framework for Circular Economy

The policy framework for circular economy plays a crucial role in promoting and facilitating the integration of laminar flow solutions to strengthen circular economy objectives. Governments and regulatory bodies are increasingly recognizing the importance of creating supportive policies that encourage the adoption of innovative technologies and practices that align with circular economy principles.

One key aspect of the policy framework is the development of incentives and regulations that promote the use of laminar flow solutions in various industries. These policies may include tax breaks, grants, or subsidies for businesses that implement laminar flow technologies to reduce waste, improve resource efficiency, and minimize environmental impact. By providing financial incentives, policymakers can accelerate the adoption of these solutions and drive the transition towards a more circular economy.

Additionally, the policy framework should address the need for standardization and certification of laminar flow technologies. Establishing clear standards and certification processes can help ensure the quality and effectiveness of these solutions, while also providing a level playing field for businesses operating in this space. This approach can foster innovation and competition while maintaining high environmental and performance standards.

Another important element of the policy framework is the promotion of research and development in laminar flow technologies. Governments can allocate funding for academic institutions and private sector collaborations to advance the understanding and application of laminar flow principles in circular economy contexts. This investment in R&D can lead to breakthrough innovations that further enhance the effectiveness of laminar flow solutions in supporting circular economy objectives.

The policy framework should also focus on education and awareness initiatives. By incorporating circular economy principles and laminar flow concepts into educational curricula and professional training programs, policymakers can cultivate a workforce that is equipped to implement and optimize these solutions across various sectors. This approach can help create a culture of sustainability and innovation that supports the long-term goals of a circular economy.

Furthermore, the policy framework should address the need for cross-sector collaboration and knowledge sharing. Governments can facilitate partnerships between industries, research institutions, and environmental organizations to promote the exchange of best practices and lessons learned in implementing laminar flow solutions for circular economy objectives. This collaborative approach can accelerate the adoption of effective strategies and drive continuous improvement in the field.

One key aspect of the policy framework is the development of incentives and regulations that promote the use of laminar flow solutions in various industries. These policies may include tax breaks, grants, or subsidies for businesses that implement laminar flow technologies to reduce waste, improve resource efficiency, and minimize environmental impact. By providing financial incentives, policymakers can accelerate the adoption of these solutions and drive the transition towards a more circular economy.

Additionally, the policy framework should address the need for standardization and certification of laminar flow technologies. Establishing clear standards and certification processes can help ensure the quality and effectiveness of these solutions, while also providing a level playing field for businesses operating in this space. This approach can foster innovation and competition while maintaining high environmental and performance standards.

Another important element of the policy framework is the promotion of research and development in laminar flow technologies. Governments can allocate funding for academic institutions and private sector collaborations to advance the understanding and application of laminar flow principles in circular economy contexts. This investment in R&D can lead to breakthrough innovations that further enhance the effectiveness of laminar flow solutions in supporting circular economy objectives.

The policy framework should also focus on education and awareness initiatives. By incorporating circular economy principles and laminar flow concepts into educational curricula and professional training programs, policymakers can cultivate a workforce that is equipped to implement and optimize these solutions across various sectors. This approach can help create a culture of sustainability and innovation that supports the long-term goals of a circular economy.

Furthermore, the policy framework should address the need for cross-sector collaboration and knowledge sharing. Governments can facilitate partnerships between industries, research institutions, and environmental organizations to promote the exchange of best practices and lessons learned in implementing laminar flow solutions for circular economy objectives. This collaborative approach can accelerate the adoption of effective strategies and drive continuous improvement in the field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!