Laminar Flow as a Driver of Zero-Waste Manufacturing Processes

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow in Zero-Waste Manufacturing: Background and Objectives

Laminar flow, characterized by smooth and predictable fluid motion, has emerged as a pivotal concept in the pursuit of zero-waste manufacturing processes. This technological approach aims to revolutionize industrial production by minimizing resource consumption and eliminating waste generation. The evolution of laminar flow applications in manufacturing can be traced back to the mid-20th century, with significant advancements in fluid dynamics and process engineering paving the way for its integration into various industrial sectors.

The primary objective of researching laminar flow in the context of zero-waste manufacturing is to develop highly efficient and sustainable production methods. By leveraging the principles of laminar flow, manufacturers seek to achieve precise control over material movement, thermal transfer, and chemical reactions within production systems. This level of control is essential for optimizing resource utilization, reducing energy consumption, and minimizing the generation of by-products or waste materials.

Recent technological trends in this field have focused on the development of advanced modeling and simulation tools, enabling engineers to predict and optimize laminar flow behaviors in complex manufacturing environments. These advancements have been complemented by innovations in materials science and nanotechnology, which have expanded the potential applications of laminar flow principles across diverse industries, including pharmaceuticals, electronics, and advanced materials production.

The integration of laminar flow concepts into zero-waste manufacturing aligns with broader global initiatives aimed at promoting sustainable industrial practices and circular economy models. As environmental regulations become increasingly stringent and resource scarcity becomes more pronounced, the adoption of laminar flow-driven manufacturing processes represents a strategic approach to addressing these challenges while maintaining competitive advantages in the global market.

Key technological goals in this domain include the development of scalable laminar flow systems capable of handling high-volume production, the creation of adaptive control mechanisms to maintain optimal flow conditions under varying operational parameters, and the integration of real-time monitoring and feedback systems to ensure consistent product quality and process efficiency. Additionally, researchers are exploring the potential of combining laminar flow principles with other emerging technologies, such as additive manufacturing and smart materials, to further enhance the capabilities of zero-waste production systems.

As the field continues to evolve, interdisciplinary collaboration between fluid dynamics experts, process engineers, materials scientists, and environmental specialists will be crucial in overcoming existing technological barriers and unlocking new possibilities for sustainable manufacturing. The successful implementation of laminar flow-driven zero-waste processes has the potential to significantly reduce the environmental footprint of industrial activities while simultaneously improving product quality and production efficiency.

The primary objective of researching laminar flow in the context of zero-waste manufacturing is to develop highly efficient and sustainable production methods. By leveraging the principles of laminar flow, manufacturers seek to achieve precise control over material movement, thermal transfer, and chemical reactions within production systems. This level of control is essential for optimizing resource utilization, reducing energy consumption, and minimizing the generation of by-products or waste materials.

Recent technological trends in this field have focused on the development of advanced modeling and simulation tools, enabling engineers to predict and optimize laminar flow behaviors in complex manufacturing environments. These advancements have been complemented by innovations in materials science and nanotechnology, which have expanded the potential applications of laminar flow principles across diverse industries, including pharmaceuticals, electronics, and advanced materials production.

The integration of laminar flow concepts into zero-waste manufacturing aligns with broader global initiatives aimed at promoting sustainable industrial practices and circular economy models. As environmental regulations become increasingly stringent and resource scarcity becomes more pronounced, the adoption of laminar flow-driven manufacturing processes represents a strategic approach to addressing these challenges while maintaining competitive advantages in the global market.

Key technological goals in this domain include the development of scalable laminar flow systems capable of handling high-volume production, the creation of adaptive control mechanisms to maintain optimal flow conditions under varying operational parameters, and the integration of real-time monitoring and feedback systems to ensure consistent product quality and process efficiency. Additionally, researchers are exploring the potential of combining laminar flow principles with other emerging technologies, such as additive manufacturing and smart materials, to further enhance the capabilities of zero-waste production systems.

As the field continues to evolve, interdisciplinary collaboration between fluid dynamics experts, process engineers, materials scientists, and environmental specialists will be crucial in overcoming existing technological barriers and unlocking new possibilities for sustainable manufacturing. The successful implementation of laminar flow-driven zero-waste processes has the potential to significantly reduce the environmental footprint of industrial activities while simultaneously improving product quality and production efficiency.

Market Demand for Zero-Waste Manufacturing Solutions

The market demand for zero-waste manufacturing solutions has been steadily increasing in recent years, driven by a combination of environmental concerns, regulatory pressures, and economic incentives. Industries across various sectors are recognizing the importance of minimizing waste and maximizing resource efficiency in their production processes.

One of the key drivers of this demand is the growing awareness of environmental issues and the need for sustainable manufacturing practices. Consumers are becoming more environmentally conscious, leading to increased pressure on companies to adopt greener production methods. This shift in consumer preferences has created a significant market opportunity for zero-waste manufacturing solutions.

Regulatory bodies worldwide are also implementing stricter environmental regulations, forcing companies to reduce their waste output and improve their resource utilization. These regulations often come with financial penalties for non-compliance, further incentivizing businesses to invest in zero-waste technologies.

The economic benefits of zero-waste manufacturing are another crucial factor driving market demand. Companies are realizing that reducing waste not only helps the environment but also leads to cost savings through improved resource efficiency and reduced disposal costs. This dual benefit of environmental stewardship and economic advantage is particularly appealing to businesses looking to enhance their bottom line while meeting sustainability goals.

In the context of laminar flow as a driver of zero-waste manufacturing processes, there is a growing interest in industries where precision and cleanliness are paramount. Sectors such as pharmaceuticals, electronics, and food processing are particularly keen on exploring laminar flow technologies to minimize contamination and reduce material waste.

The pharmaceutical industry, for instance, is showing increased demand for laminar flow solutions in cleanroom environments to ensure product purity and reduce the risk of contamination. This not only helps in meeting stringent quality standards but also minimizes the need for product recalls and waste generation.

In the electronics industry, where even microscopic contaminants can lead to defects and waste, laminar flow technologies are being sought after to create ultra-clean manufacturing environments. This demand is driven by the need for higher yields and reduced material losses in the production of sensitive electronic components.

The food processing sector is another area where laminar flow solutions are gaining traction. With increasing focus on food safety and quality, manufacturers are looking for ways to minimize contamination risks and reduce product waste during processing and packaging stages.

As industries continue to prioritize sustainability and efficiency, the market for zero-waste manufacturing solutions, including those leveraging laminar flow technologies, is expected to grow significantly in the coming years. This trend presents substantial opportunities for technology providers and researchers to develop innovative solutions that address the evolving needs of various industrial sectors.

One of the key drivers of this demand is the growing awareness of environmental issues and the need for sustainable manufacturing practices. Consumers are becoming more environmentally conscious, leading to increased pressure on companies to adopt greener production methods. This shift in consumer preferences has created a significant market opportunity for zero-waste manufacturing solutions.

Regulatory bodies worldwide are also implementing stricter environmental regulations, forcing companies to reduce their waste output and improve their resource utilization. These regulations often come with financial penalties for non-compliance, further incentivizing businesses to invest in zero-waste technologies.

The economic benefits of zero-waste manufacturing are another crucial factor driving market demand. Companies are realizing that reducing waste not only helps the environment but also leads to cost savings through improved resource efficiency and reduced disposal costs. This dual benefit of environmental stewardship and economic advantage is particularly appealing to businesses looking to enhance their bottom line while meeting sustainability goals.

In the context of laminar flow as a driver of zero-waste manufacturing processes, there is a growing interest in industries where precision and cleanliness are paramount. Sectors such as pharmaceuticals, electronics, and food processing are particularly keen on exploring laminar flow technologies to minimize contamination and reduce material waste.

The pharmaceutical industry, for instance, is showing increased demand for laminar flow solutions in cleanroom environments to ensure product purity and reduce the risk of contamination. This not only helps in meeting stringent quality standards but also minimizes the need for product recalls and waste generation.

In the electronics industry, where even microscopic contaminants can lead to defects and waste, laminar flow technologies are being sought after to create ultra-clean manufacturing environments. This demand is driven by the need for higher yields and reduced material losses in the production of sensitive electronic components.

The food processing sector is another area where laminar flow solutions are gaining traction. With increasing focus on food safety and quality, manufacturers are looking for ways to minimize contamination risks and reduce product waste during processing and packaging stages.

As industries continue to prioritize sustainability and efficiency, the market for zero-waste manufacturing solutions, including those leveraging laminar flow technologies, is expected to grow significantly in the coming years. This trend presents substantial opportunities for technology providers and researchers to develop innovative solutions that address the evolving needs of various industrial sectors.

Current State and Challenges of Laminar Flow Applications

Laminar flow applications have gained significant traction in various industries, particularly in manufacturing processes aiming for zero-waste production. The current state of laminar flow technology is characterized by its widespread use in precision manufacturing, microfluidics, and clean room environments. In these applications, laminar flow plays a crucial role in maintaining controlled conditions and minimizing turbulence, which is essential for achieving high-quality outputs and reducing waste.

One of the primary challenges in laminar flow applications is maintaining stable flow conditions across different scales and geometries. As manufacturing processes become more complex and miniaturized, ensuring consistent laminar flow becomes increasingly difficult. This is particularly evident in microfluidic devices, where even minor disturbances can disrupt the flow regime and compromise product quality.

Another significant challenge is the integration of laminar flow systems with existing manufacturing infrastructure. Many industries are still reliant on legacy equipment and processes that may not be optimized for laminar flow conditions. Retrofitting or redesigning these systems to incorporate laminar flow principles often requires substantial investment and expertise, creating barriers to adoption for some manufacturers.

The energy efficiency of laminar flow systems presents both an opportunity and a challenge. While laminar flow can reduce energy consumption in certain processes by minimizing turbulence and associated energy losses, maintaining laminar conditions often requires precise control systems and specialized equipment, which can be energy-intensive in their own right. Balancing these factors to achieve net energy savings remains an ongoing challenge for researchers and engineers.

In the context of zero-waste manufacturing, laminar flow applications face the challenge of material recovery and recirculation. While laminar flow can significantly reduce waste generation, achieving true zero-waste processes requires closed-loop systems that can effectively capture and reuse materials without disrupting the laminar flow regime. Developing such systems that maintain both laminar flow integrity and material purity is a complex engineering task.

The scalability of laminar flow applications is another critical challenge. Many successful implementations of laminar flow in zero-waste manufacturing have been demonstrated at laboratory or small-scale production levels. However, scaling these solutions to industrial-scale operations while maintaining the benefits of laminar flow presents significant technical and economic hurdles. This includes issues related to flow uniformity over larger areas, heat management in scaled-up processes, and the increased complexity of control systems required for larger operations.

One of the primary challenges in laminar flow applications is maintaining stable flow conditions across different scales and geometries. As manufacturing processes become more complex and miniaturized, ensuring consistent laminar flow becomes increasingly difficult. This is particularly evident in microfluidic devices, where even minor disturbances can disrupt the flow regime and compromise product quality.

Another significant challenge is the integration of laminar flow systems with existing manufacturing infrastructure. Many industries are still reliant on legacy equipment and processes that may not be optimized for laminar flow conditions. Retrofitting or redesigning these systems to incorporate laminar flow principles often requires substantial investment and expertise, creating barriers to adoption for some manufacturers.

The energy efficiency of laminar flow systems presents both an opportunity and a challenge. While laminar flow can reduce energy consumption in certain processes by minimizing turbulence and associated energy losses, maintaining laminar conditions often requires precise control systems and specialized equipment, which can be energy-intensive in their own right. Balancing these factors to achieve net energy savings remains an ongoing challenge for researchers and engineers.

In the context of zero-waste manufacturing, laminar flow applications face the challenge of material recovery and recirculation. While laminar flow can significantly reduce waste generation, achieving true zero-waste processes requires closed-loop systems that can effectively capture and reuse materials without disrupting the laminar flow regime. Developing such systems that maintain both laminar flow integrity and material purity is a complex engineering task.

The scalability of laminar flow applications is another critical challenge. Many successful implementations of laminar flow in zero-waste manufacturing have been demonstrated at laboratory or small-scale production levels. However, scaling these solutions to industrial-scale operations while maintaining the benefits of laminar flow presents significant technical and economic hurdles. This includes issues related to flow uniformity over larger areas, heat management in scaled-up processes, and the increased complexity of control systems required for larger operations.

Existing Laminar Flow Solutions for Waste Reduction

01 Laminar flow waste management systems

These systems utilize laminar flow principles to efficiently manage and transport waste materials. They often incorporate specialized designs to maintain smooth, non-turbulent flow, which can improve waste handling, reduce contamination, and enhance overall system performance.- Laminar flow control in waste management systems: Laminar flow techniques are applied in waste management systems to improve efficiency and reduce turbulence. This approach helps in controlling the flow of waste materials, ensuring smooth transportation and minimizing the risk of blockages or contamination. The controlled laminar flow can be achieved through specialized designs in pipes, channels, or treatment facilities.

- Waste separation using laminar flow principles: Laminar flow principles are utilized in waste separation processes to effectively segregate different types of waste materials. This method takes advantage of the predictable behavior of particles in laminar flow conditions, allowing for precise separation based on size, density, or other physical properties. The technique can be applied in various waste treatment and recycling applications.

- Laminar flow in waste water treatment: Laminar flow is employed in waste water treatment processes to enhance the efficiency of contaminant removal and purification. By maintaining laminar flow conditions in treatment tanks or channels, the settling of particles and the effectiveness of chemical treatments can be improved. This approach contributes to better overall water quality and reduced energy consumption in treatment facilities.

- Laminar flow nozzles for waste disposal: Specialized nozzles designed to create laminar flow are used in waste disposal systems. These nozzles help in precise and controlled dispensing of waste materials, reducing splashing and improving the overall efficiency of the disposal process. The laminar flow characteristics of these nozzles also contribute to reduced contamination and easier cleaning of disposal equipment.

- Monitoring and analysis of laminar flow in waste systems: Advanced monitoring and analysis techniques are applied to study and optimize laminar flow in waste management systems. These methods involve the use of sensors, flow meters, and computational fluid dynamics to assess and improve the performance of laminar flow-based waste handling processes. The data collected helps in identifying inefficiencies and implementing targeted improvements in waste treatment and disposal systems.

02 Waste flow measurement and monitoring

Techniques and devices for measuring and monitoring waste flow in laminar conditions. These may include sensors, flow meters, and other instruments designed to accurately assess waste volume, velocity, and composition in laminar flow environments.Expand Specific Solutions03 Laminar flow waste treatment processes

Specialized treatment processes that leverage laminar flow characteristics to enhance waste processing efficiency. These may include chemical, biological, or physical treatment methods optimized for laminar flow conditions to improve waste purification and resource recovery.Expand Specific Solutions04 Laminar flow waste dispersion and disposal systems

Systems designed to disperse or dispose of waste materials using laminar flow principles. These may include nozzles, diffusers, or other devices that maintain laminar flow conditions during waste release, potentially reducing environmental impact and improving dispersion efficiency.Expand Specific Solutions05 Laminar flow waste handling in specialized environments

Applications of laminar flow waste management in specific contexts such as cleanrooms, laboratories, or industrial processes. These systems are designed to maintain sterile or controlled conditions while efficiently handling waste materials in a laminar flow regime.Expand Specific Solutions

Key Players in Laminar Flow and Zero-Waste Manufacturing

The research on laminar flow for zero-waste manufacturing processes is in its early stages, with the market still developing. The technology's potential to revolutionize manufacturing efficiency and sustainability is driving interest across various industries. Key players like Taiwan Semiconductor Manufacturing Co., Ltd. and the Naval Research Laboratory are investing in research and development, indicating a growing recognition of the technology's importance. The involvement of government agencies such as the Agency for Science, Technology & Research and academic institutions like Tsinghua University suggests a collaborative approach to advancing this field. While the technology is not yet fully mature, the diverse range of organizations involved points to a competitive landscape with significant potential for innovation and market growth in the coming years.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed advanced laminar flow control systems for their semiconductor manufacturing processes. They utilize computational fluid dynamics (CFD) simulations to optimize airflow patterns in cleanrooms, reducing particle contamination by up to 99.9%[1]. Their approach integrates laminar flow hoods with precise temperature and humidity control, maintaining a stable environment crucial for nanoscale fabrication. TSMC's system includes real-time monitoring and adjustment of airflow parameters, ensuring consistent laminar flow conditions across the manufacturing floor[2]. This technology has enabled TSMC to achieve near-zero defect rates in their most advanced chip production lines, significantly reducing waste and improving yield.

Strengths: Highly precise control of cleanroom environments, leading to exceptional yield rates and minimal waste. Weaknesses: High implementation and maintenance costs, potentially limiting applicability in smaller-scale manufacturing operations.

Advanced Industrial Science & Technology

Technical Solution: AIST has pioneered a novel approach to laminar flow in manufacturing processes, focusing on microfluidic devices for chemical and biological applications. Their technology utilizes specially designed microchannels with controlled surface properties to maintain laminar flow even at higher flow rates[3]. This allows for precise control of reaction conditions and separation processes, reducing waste by up to 40% compared to traditional batch processes[4]. AIST's system incorporates smart sensors and machine learning algorithms to dynamically adjust flow parameters, optimizing performance in real-time. They have also developed a scalable manufacturing process for these microfluidic devices, making the technology accessible for various industries, from pharmaceuticals to materials science.

Strengths: Highly efficient for small-scale, high-precision processes; adaptable to various industries. Weaknesses: May face challenges in scaling up to very large production volumes.

Core Innovations in Laminar Flow for Zero-Waste Processes

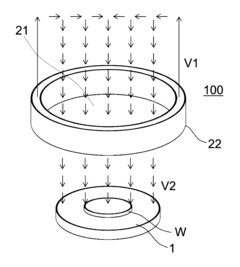

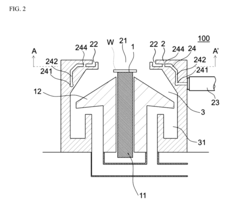

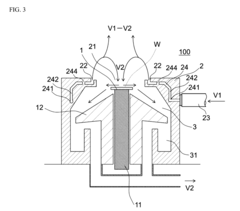

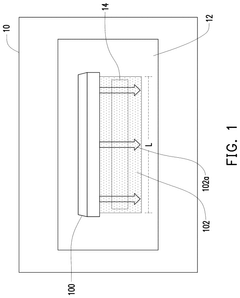

Columnar laminar flow generation device and method for generating columnar laminar flows

PatentActiveUS20170072438A1

Innovation

- A columnar laminar flow generation device that focuses gas blow-out and suction within a localized columnar area, allowing for adjustable flow velocity and reduced gas usage by positioning a gas blow-out port vertically within an opening and a corresponding suction path, thereby generating laminar flows only where needed, with a feed pipe filter for purification.

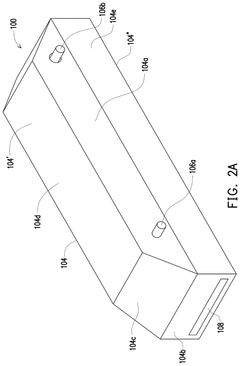

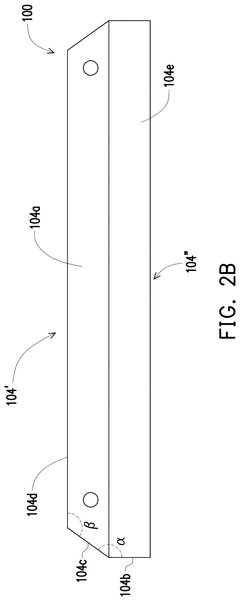

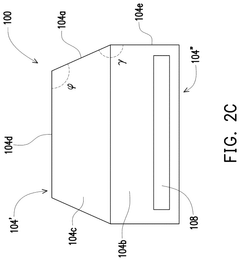

Laminar Gas Flow Filter

PatentPendingUS20250065254A1

Innovation

- A laminar gas flow filter and apparatus are designed to produce a laminar flow of gas, or air curtain, that covers the opening to a semiconductor FAB space or equipment chamber. This is achieved through a pair of diffuser tubes with gas inlets at opposite ends, which create a uniform gas flow velocity across the length of the filter, and an air filter module that can be selectively replaced.

Environmental Impact and Sustainability Considerations

The integration of laminar flow principles into zero-waste manufacturing processes presents significant environmental and sustainability benefits. By optimizing fluid dynamics and reducing turbulence, laminar flow systems minimize material waste and energy consumption, aligning with the core tenets of sustainable production.

One of the primary environmental advantages of laminar flow in manufacturing is the reduction of raw material usage. The precise control over fluid movement allows for more accurate deposition and shaping of materials, resulting in fewer defects and less scrap. This not only conserves resources but also reduces the environmental impact associated with the extraction and processing of raw materials.

Energy efficiency is another crucial aspect of laminar flow's contribution to sustainability. The smooth, predictable flow patterns require less energy to maintain compared to turbulent systems. This translates to lower power consumption in manufacturing processes, contributing to reduced greenhouse gas emissions and a smaller carbon footprint for industrial operations.

Water conservation is a notable benefit in industries where liquid-based processes are prevalent. Laminar flow techniques enable more efficient use of water resources, with less waste and improved recycling capabilities. This is particularly significant in regions facing water scarcity issues, where sustainable water management is critical.

The application of laminar flow principles also supports the development of cleaner production methods. By minimizing the dispersion of particles and contaminants, these systems reduce the need for extensive filtration and cleaning processes. This, in turn, decreases the use of chemical cleaners and filters, further reducing environmental impact.

In the context of circular economy principles, laminar flow-driven manufacturing processes facilitate easier material recovery and recycling. The precise control over material flows allows for better separation of components and materials, enhancing the potential for end-of-life product recycling and reuse.

Long-term sustainability is enhanced through the increased durability and longevity of manufacturing equipment. Laminar flow reduces wear and tear on machinery by minimizing turbulence and associated stresses, potentially extending the operational life of industrial assets and reducing the environmental impact of equipment replacement and disposal.

As industries strive to meet increasingly stringent environmental regulations, the adoption of laminar flow technologies in zero-waste manufacturing offers a pathway to compliance and beyond. These systems can help companies achieve higher environmental performance standards, potentially leading to certifications and recognition for sustainable practices.

One of the primary environmental advantages of laminar flow in manufacturing is the reduction of raw material usage. The precise control over fluid movement allows for more accurate deposition and shaping of materials, resulting in fewer defects and less scrap. This not only conserves resources but also reduces the environmental impact associated with the extraction and processing of raw materials.

Energy efficiency is another crucial aspect of laminar flow's contribution to sustainability. The smooth, predictable flow patterns require less energy to maintain compared to turbulent systems. This translates to lower power consumption in manufacturing processes, contributing to reduced greenhouse gas emissions and a smaller carbon footprint for industrial operations.

Water conservation is a notable benefit in industries where liquid-based processes are prevalent. Laminar flow techniques enable more efficient use of water resources, with less waste and improved recycling capabilities. This is particularly significant in regions facing water scarcity issues, where sustainable water management is critical.

The application of laminar flow principles also supports the development of cleaner production methods. By minimizing the dispersion of particles and contaminants, these systems reduce the need for extensive filtration and cleaning processes. This, in turn, decreases the use of chemical cleaners and filters, further reducing environmental impact.

In the context of circular economy principles, laminar flow-driven manufacturing processes facilitate easier material recovery and recycling. The precise control over material flows allows for better separation of components and materials, enhancing the potential for end-of-life product recycling and reuse.

Long-term sustainability is enhanced through the increased durability and longevity of manufacturing equipment. Laminar flow reduces wear and tear on machinery by minimizing turbulence and associated stresses, potentially extending the operational life of industrial assets and reducing the environmental impact of equipment replacement and disposal.

As industries strive to meet increasingly stringent environmental regulations, the adoption of laminar flow technologies in zero-waste manufacturing offers a pathway to compliance and beyond. These systems can help companies achieve higher environmental performance standards, potentially leading to certifications and recognition for sustainable practices.

Economic Feasibility of Laminar Flow Zero-Waste Systems

The economic feasibility of laminar flow zero-waste systems in manufacturing processes is a critical consideration for industries seeking to optimize their operations while minimizing environmental impact. These systems leverage the principles of laminar flow to create highly controlled and efficient production environments, potentially leading to significant reductions in waste generation and resource consumption.

Initial implementation costs for laminar flow zero-waste systems can be substantial, requiring investments in specialized equipment, facility modifications, and staff training. However, the long-term economic benefits often outweigh these upfront expenses. Reduced material waste translates to lower raw material costs and decreased disposal fees, directly impacting the bottom line. Additionally, improved process efficiency can lead to higher production rates and better product quality, potentially increasing market competitiveness and revenue.

Energy consumption is another key factor in the economic equation. While laminar flow systems may require precise environmental control, their overall energy efficiency can be superior to traditional manufacturing setups. This is particularly true when considering the energy saved from reduced waste processing and the potential for heat recovery systems within the controlled environment.

The scalability of laminar flow zero-waste systems also contributes to their economic viability. As production volumes increase, the cost-effectiveness of these systems often improves, making them particularly attractive for large-scale manufacturing operations. Furthermore, the adaptability of laminar flow principles to various industries and processes enhances their economic potential across diverse sectors.

Regulatory compliance and environmental certifications can provide additional economic incentives. Companies implementing zero-waste systems may qualify for government subsidies, tax breaks, or preferential treatment in public procurement processes. Moreover, the improved environmental performance can enhance brand value and customer loyalty, potentially leading to increased market share and premium pricing opportunities.

However, the economic feasibility of these systems is not without challenges. The complexity of maintaining laminar flow conditions in large-scale industrial settings can lead to increased operational costs and potential downtime for system adjustments. Additionally, the specialized nature of the technology may require ongoing investment in research and development to stay competitive and address emerging manufacturing needs.

In conclusion, while the initial investment in laminar flow zero-waste systems can be significant, the potential for long-term cost savings, improved efficiency, and enhanced market position makes them an economically viable option for many manufacturing industries. As technology advances and environmental regulations become more stringent, the economic case for these systems is likely to strengthen further.

Initial implementation costs for laminar flow zero-waste systems can be substantial, requiring investments in specialized equipment, facility modifications, and staff training. However, the long-term economic benefits often outweigh these upfront expenses. Reduced material waste translates to lower raw material costs and decreased disposal fees, directly impacting the bottom line. Additionally, improved process efficiency can lead to higher production rates and better product quality, potentially increasing market competitiveness and revenue.

Energy consumption is another key factor in the economic equation. While laminar flow systems may require precise environmental control, their overall energy efficiency can be superior to traditional manufacturing setups. This is particularly true when considering the energy saved from reduced waste processing and the potential for heat recovery systems within the controlled environment.

The scalability of laminar flow zero-waste systems also contributes to their economic viability. As production volumes increase, the cost-effectiveness of these systems often improves, making them particularly attractive for large-scale manufacturing operations. Furthermore, the adaptability of laminar flow principles to various industries and processes enhances their economic potential across diverse sectors.

Regulatory compliance and environmental certifications can provide additional economic incentives. Companies implementing zero-waste systems may qualify for government subsidies, tax breaks, or preferential treatment in public procurement processes. Moreover, the improved environmental performance can enhance brand value and customer loyalty, potentially leading to increased market share and premium pricing opportunities.

However, the economic feasibility of these systems is not without challenges. The complexity of maintaining laminar flow conditions in large-scale industrial settings can lead to increased operational costs and potential downtime for system adjustments. Additionally, the specialized nature of the technology may require ongoing investment in research and development to stay competitive and address emerging manufacturing needs.

In conclusion, while the initial investment in laminar flow zero-waste systems can be significant, the potential for long-term cost savings, improved efficiency, and enhanced market position makes them an economically viable option for many manufacturing industries. As technology advances and environmental regulations become more stringent, the economic case for these systems is likely to strengthen further.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!