Designing Flow-Optimized Infrastructure with Laminar Flow Insights

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Fundamentals and Objectives

Laminar flow, a fundamental concept in fluid dynamics, has been a subject of study for centuries. This type of flow, characterized by smooth and predictable fluid motion, occurs when fluid layers slide past one another with minimal mixing. The historical development of laminar flow understanding can be traced back to the pioneering work of Osborne Reynolds in the late 19th century, who introduced the concept of the Reynolds number, a dimensionless quantity that predicts flow patterns in different fluid flow situations.

The evolution of laminar flow research has been driven by its significant implications in various fields, including aerospace engineering, biomedical applications, and energy systems. As technology has advanced, so too has our ability to analyze and manipulate laminar flow conditions, leading to innovative designs in areas such as microfluidics and heat exchangers.

In the context of designing flow-optimized infrastructure, the primary objective is to leverage laminar flow insights to enhance system efficiency, reduce energy consumption, and improve overall performance. This involves a deep understanding of fluid behavior under different conditions and the ability to control flow characteristics to achieve desired outcomes.

Key technical goals in this domain include developing precise flow control mechanisms, optimizing channel geometries to maintain laminar conditions, and creating predictive models for complex flow scenarios. Additionally, there is a growing focus on integrating laminar flow principles with advanced materials and manufacturing techniques to create novel flow-optimized structures.

The current trajectory of laminar flow research points towards several emerging trends. These include the application of artificial intelligence and machine learning algorithms to predict and optimize flow patterns, the development of smart materials that can dynamically adjust to maintain laminar conditions, and the exploration of biomimetic designs inspired by natural laminar flow systems.

As we look to the future, the potential applications of laminar flow insights in infrastructure design are vast and promising. From more efficient HVAC systems in buildings to advanced drug delivery mechanisms in healthcare, the principles of laminar flow continue to shape our approach to solving complex engineering challenges. The ongoing pursuit of understanding and harnessing laminar flow phenomena remains crucial for advancing technology and addressing global issues such as energy efficiency and sustainable design.

The evolution of laminar flow research has been driven by its significant implications in various fields, including aerospace engineering, biomedical applications, and energy systems. As technology has advanced, so too has our ability to analyze and manipulate laminar flow conditions, leading to innovative designs in areas such as microfluidics and heat exchangers.

In the context of designing flow-optimized infrastructure, the primary objective is to leverage laminar flow insights to enhance system efficiency, reduce energy consumption, and improve overall performance. This involves a deep understanding of fluid behavior under different conditions and the ability to control flow characteristics to achieve desired outcomes.

Key technical goals in this domain include developing precise flow control mechanisms, optimizing channel geometries to maintain laminar conditions, and creating predictive models for complex flow scenarios. Additionally, there is a growing focus on integrating laminar flow principles with advanced materials and manufacturing techniques to create novel flow-optimized structures.

The current trajectory of laminar flow research points towards several emerging trends. These include the application of artificial intelligence and machine learning algorithms to predict and optimize flow patterns, the development of smart materials that can dynamically adjust to maintain laminar conditions, and the exploration of biomimetic designs inspired by natural laminar flow systems.

As we look to the future, the potential applications of laminar flow insights in infrastructure design are vast and promising. From more efficient HVAC systems in buildings to advanced drug delivery mechanisms in healthcare, the principles of laminar flow continue to shape our approach to solving complex engineering challenges. The ongoing pursuit of understanding and harnessing laminar flow phenomena remains crucial for advancing technology and addressing global issues such as energy efficiency and sustainable design.

Market Demand Analysis for Flow-Optimized Structures

The market demand for flow-optimized structures has been steadily increasing across various industries, driven by the growing need for energy efficiency, cost reduction, and environmental sustainability. In the automotive sector, manufacturers are increasingly focusing on aerodynamic designs to improve fuel efficiency and reduce emissions. This trend is particularly evident in the electric vehicle market, where optimized airflow can significantly extend battery range.

The aerospace industry continues to be a major driver of demand for flow-optimized structures. Airlines and aircraft manufacturers are constantly seeking ways to reduce drag and improve fuel efficiency, leading to increased investment in laminar flow technologies. The development of next-generation aircraft with more efficient wing designs and fuselage shapes is expected to further boost market demand in this sector.

In the renewable energy sector, wind turbine manufacturers are exploring flow-optimized blade designs to increase energy capture and reduce noise pollution. This has led to a surge in research and development activities focused on improving the aerodynamic performance of wind turbines, creating new opportunities for flow optimization technologies.

The construction industry is also showing increased interest in flow-optimized structures, particularly in the design of tall buildings and bridges. Architects and engineers are incorporating computational fluid dynamics (CFD) simulations into their design processes to minimize wind loads and improve the overall stability and efficiency of structures. This trend is expected to grow as urbanization continues and the need for resilient infrastructure increases.

In the HVAC (Heating, Ventilation, and Air Conditioning) industry, there is a rising demand for flow-optimized systems that can improve energy efficiency and indoor air quality. Building owners and facility managers are increasingly investing in smart HVAC solutions that utilize laminar flow principles to optimize airflow distribution and reduce energy consumption.

The water management sector is another area where flow-optimized structures are gaining traction. Municipal water authorities and industrial users are seeking more efficient pipeline designs and pump systems to reduce energy consumption and minimize water losses. This has led to increased demand for flow optimization technologies in water distribution networks and wastewater treatment facilities.

As environmental regulations become more stringent worldwide, industries are increasingly turning to flow-optimized designs to meet emissions targets and improve overall sustainability. This trend is expected to drive further growth in the market for flow optimization technologies across multiple sectors, including manufacturing, chemical processing, and power generation.

The aerospace industry continues to be a major driver of demand for flow-optimized structures. Airlines and aircraft manufacturers are constantly seeking ways to reduce drag and improve fuel efficiency, leading to increased investment in laminar flow technologies. The development of next-generation aircraft with more efficient wing designs and fuselage shapes is expected to further boost market demand in this sector.

In the renewable energy sector, wind turbine manufacturers are exploring flow-optimized blade designs to increase energy capture and reduce noise pollution. This has led to a surge in research and development activities focused on improving the aerodynamic performance of wind turbines, creating new opportunities for flow optimization technologies.

The construction industry is also showing increased interest in flow-optimized structures, particularly in the design of tall buildings and bridges. Architects and engineers are incorporating computational fluid dynamics (CFD) simulations into their design processes to minimize wind loads and improve the overall stability and efficiency of structures. This trend is expected to grow as urbanization continues and the need for resilient infrastructure increases.

In the HVAC (Heating, Ventilation, and Air Conditioning) industry, there is a rising demand for flow-optimized systems that can improve energy efficiency and indoor air quality. Building owners and facility managers are increasingly investing in smart HVAC solutions that utilize laminar flow principles to optimize airflow distribution and reduce energy consumption.

The water management sector is another area where flow-optimized structures are gaining traction. Municipal water authorities and industrial users are seeking more efficient pipeline designs and pump systems to reduce energy consumption and minimize water losses. This has led to increased demand for flow optimization technologies in water distribution networks and wastewater treatment facilities.

As environmental regulations become more stringent worldwide, industries are increasingly turning to flow-optimized designs to meet emissions targets and improve overall sustainability. This trend is expected to drive further growth in the market for flow optimization technologies across multiple sectors, including manufacturing, chemical processing, and power generation.

Current Challenges in Laminar Flow Infrastructure Design

The design of laminar flow infrastructure faces several significant challenges that hinder its widespread implementation and optimization. One of the primary obstacles is the complexity of maintaining laminar flow conditions in real-world environments. Laminar flow, characterized by smooth and predictable fluid motion, is highly sensitive to external disturbances and geometric irregularities. This sensitivity makes it difficult to sustain laminar flow over extended distances or in complex infrastructure configurations.

Another major challenge lies in the scalability of laminar flow systems. While laminar flow principles can be effectively applied in small-scale laboratory settings or specialized industrial applications, translating these benefits to large-scale infrastructure projects presents considerable engineering hurdles. The transition from small to large scales often introduces unforeseen turbulence and flow instabilities, compromising the intended laminar flow characteristics.

Material selection and surface engineering pose additional challenges in laminar flow infrastructure design. The interaction between the fluid and the surface of the infrastructure plays a crucial role in maintaining laminar flow. Developing materials and surface treatments that can consistently promote laminar flow while withstanding operational wear and environmental factors remains a significant area of research and development.

The integration of laminar flow principles with existing infrastructure designs presents compatibility issues. Many current infrastructure systems are not optimized for laminar flow, and retrofitting them to accommodate these principles can be costly and technically challenging. This integration challenge extends to the interface between laminar flow sections and other parts of the infrastructure where turbulent flow may be unavoidable or even desirable.

Energy efficiency considerations also present a paradox in laminar flow infrastructure design. While laminar flow can reduce friction and energy losses in some scenarios, maintaining laminar conditions over large scales may require additional energy input, potentially offsetting the efficiency gains. Balancing these energy trade-offs is a complex optimization problem that designers must address.

Lastly, the measurement and monitoring of laminar flow conditions in operational infrastructure present significant technical challenges. Developing robust, non-intrusive sensing technologies that can accurately detect and characterize flow regimes in real-time is crucial for the effective management and optimization of laminar flow systems. These measurement challenges are compounded by the need for data interpretation and control systems that can respond to changing flow conditions dynamically.

Another major challenge lies in the scalability of laminar flow systems. While laminar flow principles can be effectively applied in small-scale laboratory settings or specialized industrial applications, translating these benefits to large-scale infrastructure projects presents considerable engineering hurdles. The transition from small to large scales often introduces unforeseen turbulence and flow instabilities, compromising the intended laminar flow characteristics.

Material selection and surface engineering pose additional challenges in laminar flow infrastructure design. The interaction between the fluid and the surface of the infrastructure plays a crucial role in maintaining laminar flow. Developing materials and surface treatments that can consistently promote laminar flow while withstanding operational wear and environmental factors remains a significant area of research and development.

The integration of laminar flow principles with existing infrastructure designs presents compatibility issues. Many current infrastructure systems are not optimized for laminar flow, and retrofitting them to accommodate these principles can be costly and technically challenging. This integration challenge extends to the interface between laminar flow sections and other parts of the infrastructure where turbulent flow may be unavoidable or even desirable.

Energy efficiency considerations also present a paradox in laminar flow infrastructure design. While laminar flow can reduce friction and energy losses in some scenarios, maintaining laminar conditions over large scales may require additional energy input, potentially offsetting the efficiency gains. Balancing these energy trade-offs is a complex optimization problem that designers must address.

Lastly, the measurement and monitoring of laminar flow conditions in operational infrastructure present significant technical challenges. Developing robust, non-intrusive sensing technologies that can accurately detect and characterize flow regimes in real-time is crucial for the effective management and optimization of laminar flow systems. These measurement challenges are compounded by the need for data interpretation and control systems that can respond to changing flow conditions dynamically.

Existing Laminar Flow Design Solutions

01 Flow control devices for laminar flow optimization

Various flow control devices are used to optimize laminar flow in different applications. These devices include specialized nozzles, valves, and flow regulators that help maintain smooth, predictable fluid movement. By carefully designing and implementing these components, engineers can reduce turbulence and improve overall system efficiency in applications ranging from aerospace to industrial processes.- Flow control devices for laminar flow optimization: Various flow control devices are used to optimize laminar flow in different applications. These devices include specialized nozzles, valves, and flow regulators that help maintain smooth, predictable fluid movement. By carefully designing and implementing these components, engineers can reduce turbulence and improve overall system efficiency in areas such as aerodynamics, fluid dynamics, and process control.

- Measurement and analysis techniques for laminar flow: Advanced measurement and analysis techniques are crucial for optimizing laminar flow. These methods include the use of sensors, flow meters, and imaging systems to accurately assess fluid behavior. Data collected from these instruments is then analyzed using specialized software and algorithms to identify areas for improvement and fine-tune flow parameters.

- Surface modifications for enhancing laminar flow: Modifying surface characteristics plays a significant role in optimizing laminar flow. Techniques such as applying specialized coatings, creating micro-textures, or altering surface geometries can reduce friction and promote smoother fluid movement. These modifications are particularly important in applications like aerospace, where even small improvements in laminar flow can lead to substantial gains in efficiency.

- Computational fluid dynamics for laminar flow optimization: Computational fluid dynamics (CFD) is a powerful tool for optimizing laminar flow. Advanced simulation software allows engineers to model and predict fluid behavior under various conditions, enabling them to test and refine designs virtually before physical implementation. This approach significantly reduces development time and costs while improving the overall effectiveness of laminar flow systems.

- Adaptive control systems for maintaining laminar flow: Adaptive control systems are increasingly used to maintain optimal laminar flow conditions in dynamic environments. These systems employ real-time monitoring and adjustment of flow parameters based on changing conditions. By continuously optimizing flow characteristics, these adaptive systems can ensure consistent performance and efficiency across a wide range of operating conditions.

02 Measurement and analysis techniques for laminar flow

Advanced measurement and analysis techniques are crucial for optimizing laminar flow. These methods include the use of sensors, flow meters, and imaging systems to accurately assess fluid behavior. By gathering precise data on flow characteristics, researchers and engineers can fine-tune system parameters to achieve optimal laminar flow conditions in various applications, such as microfluidics and aerodynamics.Expand Specific Solutions03 Surface modification for laminar flow enhancement

Modifying surface properties is an effective approach to optimize laminar flow. Techniques such as applying specialized coatings, creating micro-textures, or altering surface geometry can significantly reduce friction and promote smoother fluid movement. These modifications are particularly useful in applications like pipeline transport, heat exchangers, and aircraft design, where maintaining laminar flow is critical for efficiency and performance.Expand Specific Solutions04 Computational modeling and simulation for laminar flow optimization

Advanced computational modeling and simulation tools play a crucial role in optimizing laminar flow. These techniques allow engineers to predict fluid behavior, test various design configurations, and identify optimal parameters without the need for extensive physical prototyping. By leveraging computational fluid dynamics (CFD) and other simulation methods, researchers can develop more efficient and effective laminar flow systems for a wide range of applications.Expand Specific Solutions05 Adaptive control systems for maintaining laminar flow

Adaptive control systems are increasingly used to maintain optimal laminar flow conditions in dynamic environments. These systems employ sensors, actuators, and advanced algorithms to continuously monitor and adjust flow parameters in real-time. By responding to changing conditions, such as variations in fluid properties or external disturbances, adaptive control systems can ensure consistent laminar flow performance in applications ranging from manufacturing processes to environmental control systems.Expand Specific Solutions

Key Players in Flow Optimization Industry

The field of flow-optimized infrastructure design using laminar flow insights is in its early development stage, with significant potential for growth. The market size is expanding as industries recognize the importance of efficient fluid dynamics in various applications. While the technology is still evolving, several key players are driving innovation. Companies like Huawei Technologies and Sony Group are leveraging their expertise in advanced engineering to develop solutions. Research institutions such as Yeda Research & Development and universities like South China University of Technology are contributing to fundamental advancements. Specialized firms like Aerosol Dynamics and Silixa Ltd. are focusing on niche applications, indicating a diverse and competitive landscape with opportunities for both established corporations and innovative startups.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed an innovative approach to designing flow-optimized infrastructure using laminar flow insights. Their solution incorporates advanced computational fluid dynamics (CFD) simulations to model and optimize airflow in data centers and telecommunications equipment. By leveraging machine learning algorithms, Huawei's system can predict airflow patterns and thermal distributions with high accuracy[1]. This allows for real-time adjustments to cooling systems, reducing energy consumption by up to 30% compared to traditional cooling methods[2]. Additionally, Huawei has implemented a modular design approach that allows for easy scalability and customization of their flow-optimized infrastructure solutions[3].

Strengths: Advanced CFD simulations, machine learning integration, and modular design approach. Weaknesses: High initial implementation costs and potential complexity in retrofitting existing infrastructure.

ASML Netherlands BV

Technical Solution: ASML has developed a cutting-edge flow-optimized infrastructure design for their lithography systems, crucial in semiconductor manufacturing. Their approach utilizes laminar flow insights to create ultra-clean environments necessary for nanoscale chip production. ASML's system incorporates advanced airflow management techniques, including precision-controlled laminar airflow hoods and innovative filtration systems[1]. These technologies maintain a particle-free environment, with contamination levels as low as 10 particles per cubic meter for particles sized 0.1 microns or larger[2]. The company has also implemented adaptive flow control systems that adjust in real-time to maintain optimal laminar flow conditions, even as operators move within the space[3].

Strengths: Ultra-clean environment creation, adaptive flow control, and integration with high-precision manufacturing processes. Weaknesses: High costs associated with implementation and maintenance, limited applicability outside of specialized manufacturing environments.

Core Innovations in Laminar Flow Modeling

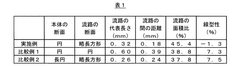

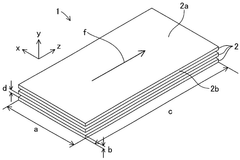

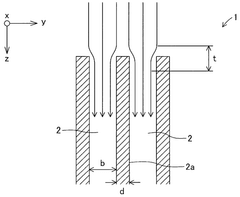

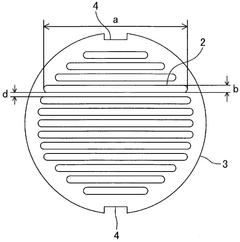

Laminar flow element, flow rate sensor, and mass flow controller

PatentWO2024162194A1

Innovation

- A laminar flow element with a rectangular cross-sectional shape and an aspect ratio of 5.0 or more, where the long side is significantly longer than the short side, and a configuration that minimizes the number of dividing walls, allowing for increased flow path area and reduced turbulence, enhancing flow rate and linearity of measurement.

Vortical Thin Film Reactor

PatentInactiveUS20180252686A1

Innovation

- The development of a centrifugally rotating spiral channel system that enables vortical flow of fluids into discrete radial lamellae based on density, allowing for stable, scalable, thin-film reactors with exogenous energy supplies and dynamic control, enabling serial and parallel reactions and efficient mass and heat transfer.

Environmental Impact Assessment

The environmental impact assessment of designing flow-optimized infrastructure with laminar flow insights reveals both positive and negative implications. On the positive side, laminar flow-based designs can significantly reduce energy consumption in various applications. By minimizing turbulence and optimizing fluid dynamics, these systems require less power to operate, leading to decreased greenhouse gas emissions and a smaller carbon footprint. This is particularly relevant in industries such as HVAC, water treatment, and manufacturing processes where fluid flow is a critical component.

Furthermore, the implementation of laminar flow principles in infrastructure design can lead to more efficient use of resources. For example, in water distribution systems, laminar flow can reduce friction losses, allowing for smaller pipe diameters and less material usage. This not only conserves resources but also minimizes the environmental impact associated with material production and transportation.

However, the environmental benefits of laminar flow-optimized infrastructure must be balanced against potential drawbacks. The production of highly specialized components required for laminar flow systems may involve energy-intensive manufacturing processes or the use of advanced materials with their own environmental considerations. Additionally, the installation and maintenance of these systems might require specialized skills and equipment, potentially increasing the overall environmental footprint during the lifecycle of the infrastructure.

In terms of ecosystem impact, laminar flow designs in water management systems can have mixed effects. While they can reduce erosion and sediment transport in some cases, they may also alter natural flow patterns in aquatic environments. This could potentially disrupt habitats and affect local biodiversity, necessitating careful environmental monitoring and mitigation strategies.

The long-term environmental implications of widespread adoption of laminar flow-optimized infrastructure are also worth considering. As these systems become more prevalent, there may be a shift in industrial practices and urban planning approaches. This could lead to broader changes in land use, resource allocation, and energy consumption patterns, with cascading effects on local and global ecosystems.

In conclusion, while laminar flow-optimized infrastructure offers promising environmental benefits, particularly in terms of energy efficiency and resource conservation, a comprehensive assessment must account for the full lifecycle impact of these systems. Balancing the advantages against potential drawbacks and considering long-term ecological effects will be crucial in determining the overall environmental sustainability of this approach to infrastructure design.

Furthermore, the implementation of laminar flow principles in infrastructure design can lead to more efficient use of resources. For example, in water distribution systems, laminar flow can reduce friction losses, allowing for smaller pipe diameters and less material usage. This not only conserves resources but also minimizes the environmental impact associated with material production and transportation.

However, the environmental benefits of laminar flow-optimized infrastructure must be balanced against potential drawbacks. The production of highly specialized components required for laminar flow systems may involve energy-intensive manufacturing processes or the use of advanced materials with their own environmental considerations. Additionally, the installation and maintenance of these systems might require specialized skills and equipment, potentially increasing the overall environmental footprint during the lifecycle of the infrastructure.

In terms of ecosystem impact, laminar flow designs in water management systems can have mixed effects. While they can reduce erosion and sediment transport in some cases, they may also alter natural flow patterns in aquatic environments. This could potentially disrupt habitats and affect local biodiversity, necessitating careful environmental monitoring and mitigation strategies.

The long-term environmental implications of widespread adoption of laminar flow-optimized infrastructure are also worth considering. As these systems become more prevalent, there may be a shift in industrial practices and urban planning approaches. This could lead to broader changes in land use, resource allocation, and energy consumption patterns, with cascading effects on local and global ecosystems.

In conclusion, while laminar flow-optimized infrastructure offers promising environmental benefits, particularly in terms of energy efficiency and resource conservation, a comprehensive assessment must account for the full lifecycle impact of these systems. Balancing the advantages against potential drawbacks and considering long-term ecological effects will be crucial in determining the overall environmental sustainability of this approach to infrastructure design.

Computational Fluid Dynamics Integration

Computational Fluid Dynamics (CFD) integration plays a crucial role in designing flow-optimized infrastructure with laminar flow insights. This advanced simulation technique allows engineers and researchers to model and analyze complex fluid flow behaviors within various systems and structures. By leveraging CFD, designers can gain valuable insights into the intricate dynamics of laminar flow, enabling them to optimize infrastructure designs for enhanced performance and efficiency.

The integration of CFD in flow-optimized infrastructure design involves several key components. Firstly, accurate geometric modeling of the infrastructure is essential to capture the precise physical dimensions and features that influence fluid flow. This includes creating detailed 3D representations of pipes, channels, or other flow-conducting elements within the system.

Once the geometry is established, the next step is to define the fluid properties and boundary conditions. This involves specifying parameters such as fluid viscosity, density, temperature, and pressure, as well as setting appropriate inlet and outlet conditions. These inputs are critical for accurately simulating the behavior of laminar flow within the infrastructure.

The CFD solver then employs advanced numerical methods to solve the governing equations of fluid dynamics, typically the Navier-Stokes equations for laminar flow. These equations describe the conservation of mass, momentum, and energy within the fluid system. By discretizing the computational domain and applying finite volume or finite element methods, the solver can predict fluid velocities, pressures, and other relevant flow characteristics throughout the infrastructure.

Post-processing and visualization tools are integral to CFD integration, allowing designers to interpret and analyze the simulation results effectively. These tools enable the generation of detailed flow field visualizations, including streamlines, velocity contours, and pressure distributions. Such visual representations provide invaluable insights into the laminar flow behavior, helping identify areas of potential improvement or optimization within the infrastructure design.

Furthermore, CFD integration facilitates parametric studies and design iterations. By systematically varying design parameters and running multiple simulations, engineers can explore a wide range of design options and evaluate their impact on laminar flow characteristics. This iterative process enables the identification of optimal design configurations that maximize flow efficiency, minimize pressure losses, and enhance overall system performance.

The integration of CFD in flow-optimized infrastructure design also extends to multiphysics simulations. This approach allows for the consideration of additional physical phenomena, such as heat transfer or structural mechanics, alongside fluid dynamics. By coupling these different physics models, designers can gain a more comprehensive understanding of the infrastructure's behavior under various operating conditions, leading to more robust and efficient designs.

The integration of CFD in flow-optimized infrastructure design involves several key components. Firstly, accurate geometric modeling of the infrastructure is essential to capture the precise physical dimensions and features that influence fluid flow. This includes creating detailed 3D representations of pipes, channels, or other flow-conducting elements within the system.

Once the geometry is established, the next step is to define the fluid properties and boundary conditions. This involves specifying parameters such as fluid viscosity, density, temperature, and pressure, as well as setting appropriate inlet and outlet conditions. These inputs are critical for accurately simulating the behavior of laminar flow within the infrastructure.

The CFD solver then employs advanced numerical methods to solve the governing equations of fluid dynamics, typically the Navier-Stokes equations for laminar flow. These equations describe the conservation of mass, momentum, and energy within the fluid system. By discretizing the computational domain and applying finite volume or finite element methods, the solver can predict fluid velocities, pressures, and other relevant flow characteristics throughout the infrastructure.

Post-processing and visualization tools are integral to CFD integration, allowing designers to interpret and analyze the simulation results effectively. These tools enable the generation of detailed flow field visualizations, including streamlines, velocity contours, and pressure distributions. Such visual representations provide invaluable insights into the laminar flow behavior, helping identify areas of potential improvement or optimization within the infrastructure design.

Furthermore, CFD integration facilitates parametric studies and design iterations. By systematically varying design parameters and running multiple simulations, engineers can explore a wide range of design options and evaluate their impact on laminar flow characteristics. This iterative process enables the identification of optimal design configurations that maximize flow efficiency, minimize pressure losses, and enhance overall system performance.

The integration of CFD in flow-optimized infrastructure design also extends to multiphysics simulations. This approach allows for the consideration of additional physical phenomena, such as heat transfer or structural mechanics, alongside fluid dynamics. By coupling these different physics models, designers can gain a more comprehensive understanding of the infrastructure's behavior under various operating conditions, leading to more robust and efficient designs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!