Understanding Laminar Flow for Energy Efficiency

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Fundamentals and Objectives

Laminar flow, a fundamental concept in fluid dynamics, has been a subject of extensive research and application due to its significant implications for energy efficiency. The study of laminar flow dates back to the 19th century, with pioneering work by physicists such as George Stokes and Osborne Reynolds. Over time, our understanding of laminar flow has evolved, leading to numerous technological advancements across various industries.

The primary objective of studying laminar flow in the context of energy efficiency is to minimize energy losses in fluid systems. Laminar flow, characterized by smooth, predictable fluid motion with minimal mixing between adjacent layers, offers lower friction and reduced energy dissipation compared to turbulent flow. This makes it particularly attractive for applications where energy conservation is crucial.

In recent years, the focus on laminar flow has intensified due to growing concerns about energy consumption and environmental impact. Researchers and engineers are exploring ways to maintain laminar flow in systems where it would naturally transition to turbulent flow, thereby extending the benefits of laminar flow to a broader range of applications. This includes developing new materials and surface treatments that promote laminar flow, as well as innovative designs for fluid handling systems.

The evolution of computational fluid dynamics (CFD) has significantly contributed to our understanding of laminar flow. Advanced simulation tools now allow for precise modeling of fluid behavior, enabling researchers to optimize designs for laminar flow maintenance. This has led to breakthroughs in fields such as aerospace, where laminar flow control techniques have been developed to reduce drag on aircraft, potentially leading to substantial fuel savings.

Another key area of focus is the application of laminar flow principles in microfluidics. As miniaturization continues to drive technological progress, understanding and controlling laminar flow at microscopic scales has become crucial. This has implications for lab-on-a-chip devices, medical diagnostics, and advanced cooling systems for electronics.

The objectives of current laminar flow research extend beyond mere energy efficiency. Scientists and engineers are also exploring how laminar flow can be leveraged to enhance process control in manufacturing, improve heat transfer in thermal management systems, and even develop new medical treatments. The ultimate goal is to create a comprehensive framework for designing and implementing laminar flow systems that maximize energy efficiency while meeting the specific requirements of diverse applications.

The primary objective of studying laminar flow in the context of energy efficiency is to minimize energy losses in fluid systems. Laminar flow, characterized by smooth, predictable fluid motion with minimal mixing between adjacent layers, offers lower friction and reduced energy dissipation compared to turbulent flow. This makes it particularly attractive for applications where energy conservation is crucial.

In recent years, the focus on laminar flow has intensified due to growing concerns about energy consumption and environmental impact. Researchers and engineers are exploring ways to maintain laminar flow in systems where it would naturally transition to turbulent flow, thereby extending the benefits of laminar flow to a broader range of applications. This includes developing new materials and surface treatments that promote laminar flow, as well as innovative designs for fluid handling systems.

The evolution of computational fluid dynamics (CFD) has significantly contributed to our understanding of laminar flow. Advanced simulation tools now allow for precise modeling of fluid behavior, enabling researchers to optimize designs for laminar flow maintenance. This has led to breakthroughs in fields such as aerospace, where laminar flow control techniques have been developed to reduce drag on aircraft, potentially leading to substantial fuel savings.

Another key area of focus is the application of laminar flow principles in microfluidics. As miniaturization continues to drive technological progress, understanding and controlling laminar flow at microscopic scales has become crucial. This has implications for lab-on-a-chip devices, medical diagnostics, and advanced cooling systems for electronics.

The objectives of current laminar flow research extend beyond mere energy efficiency. Scientists and engineers are also exploring how laminar flow can be leveraged to enhance process control in manufacturing, improve heat transfer in thermal management systems, and even develop new medical treatments. The ultimate goal is to create a comprehensive framework for designing and implementing laminar flow systems that maximize energy efficiency while meeting the specific requirements of diverse applications.

Energy Efficiency Market Demand Analysis

The global energy efficiency market has been experiencing significant growth in recent years, driven by increasing awareness of environmental issues, rising energy costs, and stringent government regulations. The demand for energy-efficient solutions, particularly those involving laminar flow technology, has been on the rise across various sectors, including HVAC systems, industrial processes, and transportation.

In the HVAC industry, there is a growing demand for energy-efficient ventilation systems that utilize laminar flow principles to reduce energy consumption while maintaining optimal air quality. Building owners and facility managers are increasingly seeking solutions that can lower operational costs and meet sustainability goals. This trend is particularly evident in commercial and industrial buildings, where energy costs represent a significant portion of operational expenses.

The industrial sector has also shown a strong interest in laminar flow applications for energy efficiency. Manufacturing processes, chemical plants, and refineries are exploring ways to optimize fluid dynamics to reduce energy losses and improve overall efficiency. The potential for substantial cost savings and improved process control has been a key driver in this market segment.

In the transportation sector, the automotive and aerospace industries are investing heavily in research and development of laminar flow technologies to enhance fuel efficiency and reduce emissions. The demand for more aerodynamic designs in vehicles and aircraft has led to increased focus on understanding and applying laminar flow principles.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in the energy efficiency market, driven by rapid industrialization, urbanization, and government initiatives promoting sustainable development. North America and Europe continue to be significant markets, with a strong focus on retrofitting existing infrastructure with energy-efficient solutions.

The COVID-19 pandemic has further accelerated the demand for energy-efficient technologies, as businesses and organizations seek to reduce operational costs and improve indoor air quality. This has created new opportunities for laminar flow applications in ventilation systems and air purification technologies.

Key market drivers include government regulations and incentives promoting energy efficiency, rising energy prices, and increasing corporate sustainability initiatives. However, challenges such as high initial investment costs and lack of awareness about advanced energy-efficient technologies in some regions may hinder market growth.

Overall, the market demand for energy-efficient solutions leveraging laminar flow technology is expected to continue its upward trajectory. As research and development in this field progress, new applications and innovations are likely to emerge, further expanding the market potential and driving the adoption of laminar flow-based energy-efficient systems across various industries.

In the HVAC industry, there is a growing demand for energy-efficient ventilation systems that utilize laminar flow principles to reduce energy consumption while maintaining optimal air quality. Building owners and facility managers are increasingly seeking solutions that can lower operational costs and meet sustainability goals. This trend is particularly evident in commercial and industrial buildings, where energy costs represent a significant portion of operational expenses.

The industrial sector has also shown a strong interest in laminar flow applications for energy efficiency. Manufacturing processes, chemical plants, and refineries are exploring ways to optimize fluid dynamics to reduce energy losses and improve overall efficiency. The potential for substantial cost savings and improved process control has been a key driver in this market segment.

In the transportation sector, the automotive and aerospace industries are investing heavily in research and development of laminar flow technologies to enhance fuel efficiency and reduce emissions. The demand for more aerodynamic designs in vehicles and aircraft has led to increased focus on understanding and applying laminar flow principles.

Market analysis indicates that the Asia-Pacific region is expected to witness the highest growth rate in the energy efficiency market, driven by rapid industrialization, urbanization, and government initiatives promoting sustainable development. North America and Europe continue to be significant markets, with a strong focus on retrofitting existing infrastructure with energy-efficient solutions.

The COVID-19 pandemic has further accelerated the demand for energy-efficient technologies, as businesses and organizations seek to reduce operational costs and improve indoor air quality. This has created new opportunities for laminar flow applications in ventilation systems and air purification technologies.

Key market drivers include government regulations and incentives promoting energy efficiency, rising energy prices, and increasing corporate sustainability initiatives. However, challenges such as high initial investment costs and lack of awareness about advanced energy-efficient technologies in some regions may hinder market growth.

Overall, the market demand for energy-efficient solutions leveraging laminar flow technology is expected to continue its upward trajectory. As research and development in this field progress, new applications and innovations are likely to emerge, further expanding the market potential and driving the adoption of laminar flow-based energy-efficient systems across various industries.

Laminar Flow Technology: Current Status and Challenges

Laminar flow technology has made significant strides in recent years, particularly in the context of energy efficiency. However, the current state of this technology presents both promising advancements and notable challenges. At present, laminar flow systems are widely utilized in various industries, including aerospace, automotive, and HVAC, where they contribute to improved energy efficiency and reduced drag.

One of the primary challenges in laminar flow technology is maintaining stable laminar flow conditions in real-world applications. Environmental factors, such as turbulence, surface irregularities, and temperature fluctuations, can disrupt laminar flow, leading to decreased efficiency. Researchers and engineers are actively working on developing more robust laminar flow systems that can withstand these external disturbances.

Another significant hurdle is the scalability of laminar flow technology. While laminar flow principles have been successfully applied in small-scale systems, translating these benefits to larger, more complex systems remains a challenge. This is particularly evident in industries such as aviation, where achieving laminar flow over large surface areas of aircraft wings is crucial for fuel efficiency but technically demanding.

The integration of advanced materials and surface treatments has emerged as a key focus area in addressing current challenges. Nano-engineered surfaces and smart materials that can dynamically adjust to maintain laminar flow conditions show promise in enhancing the technology's effectiveness and reliability. However, the cost and complexity of implementing these advanced materials on a large scale remain significant barriers.

In the field of computational fluid dynamics (CFD), substantial progress has been made in modeling and predicting laminar flow behavior. These advancements have greatly improved the design and optimization of laminar flow systems. Nevertheless, the accuracy of CFD models in complex, real-world scenarios still requires further refinement to bridge the gap between theoretical predictions and practical applications.

Energy efficiency remains a central driver for laminar flow technology development. Current research is focused on maximizing the energy-saving potential of laminar flow systems while minimizing the energy input required to maintain laminar conditions. This balance is crucial for the widespread adoption of the technology across various industries.

The intersection of laminar flow technology with other emerging fields, such as artificial intelligence and IoT, presents new opportunities and challenges. Smart, adaptive systems that can real-time monitor and adjust flow conditions show great potential but also introduce additional complexity in implementation and maintenance.

As the technology continues to evolve, addressing these challenges while capitalizing on recent advancements will be crucial for realizing the full potential of laminar flow in enhancing energy efficiency across diverse applications.

One of the primary challenges in laminar flow technology is maintaining stable laminar flow conditions in real-world applications. Environmental factors, such as turbulence, surface irregularities, and temperature fluctuations, can disrupt laminar flow, leading to decreased efficiency. Researchers and engineers are actively working on developing more robust laminar flow systems that can withstand these external disturbances.

Another significant hurdle is the scalability of laminar flow technology. While laminar flow principles have been successfully applied in small-scale systems, translating these benefits to larger, more complex systems remains a challenge. This is particularly evident in industries such as aviation, where achieving laminar flow over large surface areas of aircraft wings is crucial for fuel efficiency but technically demanding.

The integration of advanced materials and surface treatments has emerged as a key focus area in addressing current challenges. Nano-engineered surfaces and smart materials that can dynamically adjust to maintain laminar flow conditions show promise in enhancing the technology's effectiveness and reliability. However, the cost and complexity of implementing these advanced materials on a large scale remain significant barriers.

In the field of computational fluid dynamics (CFD), substantial progress has been made in modeling and predicting laminar flow behavior. These advancements have greatly improved the design and optimization of laminar flow systems. Nevertheless, the accuracy of CFD models in complex, real-world scenarios still requires further refinement to bridge the gap between theoretical predictions and practical applications.

Energy efficiency remains a central driver for laminar flow technology development. Current research is focused on maximizing the energy-saving potential of laminar flow systems while minimizing the energy input required to maintain laminar conditions. This balance is crucial for the widespread adoption of the technology across various industries.

The intersection of laminar flow technology with other emerging fields, such as artificial intelligence and IoT, presents new opportunities and challenges. Smart, adaptive systems that can real-time monitor and adjust flow conditions show great potential but also introduce additional complexity in implementation and maintenance.

As the technology continues to evolve, addressing these challenges while capitalizing on recent advancements will be crucial for realizing the full potential of laminar flow in enhancing energy efficiency across diverse applications.

Existing Laminar Flow Energy Efficiency Solutions

01 Laminar flow control in fluid systems

Implementing laminar flow control techniques in fluid systems can significantly improve energy efficiency. This involves designing components and systems that promote smooth, parallel fluid flow, reducing turbulence and energy losses. Techniques may include optimizing pipe geometries, using flow straighteners, and controlling fluid velocity to maintain laminar conditions.- Laminar flow control systems for aircraft: Laminar flow control systems are used in aircraft to reduce drag and improve energy efficiency. These systems maintain smooth airflow over the aircraft's surfaces, reducing turbulence and friction. Various techniques are employed, including suction systems, surface shaping, and active flow control mechanisms.

- Energy-efficient laminar flow in fluid handling systems: Fluid handling systems utilize laminar flow principles to enhance energy efficiency. This includes optimizing pipe designs, flow control devices, and pump systems to maintain laminar flow conditions. Such systems reduce energy losses due to turbulence and friction, leading to improved overall system efficiency.

- Laminar flow in HVAC and air purification systems: HVAC and air purification systems leverage laminar flow to improve energy efficiency and air quality. These systems use carefully designed air distribution methods to create uniform, low-turbulence airflow. This approach reduces energy consumption in air movement and enhances the effectiveness of filtration and purification processes.

- Measurement and analysis of laminar flow for efficiency optimization: Advanced measurement and analysis techniques are employed to study and optimize laminar flow in various applications. This includes the use of sensors, imaging systems, and computational fluid dynamics to accurately characterize flow patterns. The data obtained is used to fine-tune systems for maximum energy efficiency.

- Energy-efficient laminar flow in industrial processes: Industrial processes utilize laminar flow principles to enhance energy efficiency in various applications such as chemical processing, material handling, and manufacturing. This involves designing equipment and processes that maintain laminar flow conditions, reducing energy consumption and improving product quality.

02 Energy-efficient laminar flow in HVAC systems

Applying laminar flow principles to heating, ventilation, and air conditioning (HVAC) systems can enhance energy efficiency. This includes designing air distribution systems with smooth transitions, optimizing duct sizes, and using low-velocity airflow to reduce friction losses and improve overall system performance.Expand Specific Solutions03 Laminar flow in renewable energy applications

Utilizing laminar flow concepts in renewable energy technologies can improve their efficiency. This includes optimizing the design of wind turbine blades, solar thermal collectors, and hydroelectric systems to maintain laminar flow conditions, reducing drag and increasing energy capture.Expand Specific Solutions04 Measurement and monitoring of laminar flow efficiency

Developing advanced measurement and monitoring techniques for laminar flow systems can help optimize energy efficiency. This involves using sensors, flow meters, and data analysis tools to assess flow characteristics, identify inefficiencies, and make real-time adjustments to maintain optimal laminar flow conditions.Expand Specific Solutions05 Laminar flow in industrial processes

Implementing laminar flow principles in industrial processes can lead to significant energy savings. This includes designing efficient fluid handling systems, optimizing chemical reactors, and improving heat exchangers to maintain laminar flow conditions, reducing energy consumption and improving process efficiency.Expand Specific Solutions

Key Players in Laminar Flow Research and Implementation

The laminar flow technology for energy efficiency is in a growth phase, with increasing market size driven by the global push for sustainable energy solutions. The market is characterized by a mix of established players and innovative startups, indicating a maturing but still evolving landscape. Companies like State Grid Corp. of China, Sony Group Corp., and ASML Holding NV are leveraging their technological expertise to advance laminar flow applications. Academic institutions such as Tsinghua University and Zhejiang University are contributing to research and development, while specialized firms like Efficient Energy GmbH and H2scan Corp. are focusing on niche applications. The technology's maturity varies across sectors, with some areas like HVAC and industrial processes showing higher adoption rates, while others are still in experimental stages.

ebm-papst Landshut GmbH

Technical Solution: ebm-papst Landshut GmbH has developed advanced laminar flow technologies for energy-efficient fan and motor systems. Their approach involves computational fluid dynamics (CFD) simulations to optimize airflow patterns, reducing turbulence and energy loss. They have implemented biomimetic designs inspired by nature, such as owl wing-inspired fan blades that minimize noise while maintaining laminar flow[1]. The company has also developed innovative air inlet geometries and guide vanes to ensure smooth, laminar airflow across heat exchangers and other components[2]. Their EC (electronically commutated) motors are designed to maintain optimal laminar flow conditions across a wide range of operating speeds, further enhancing energy efficiency[3].

Strengths: Expertise in fan and motor systems, advanced CFD capabilities, biomimetic design approach. Weaknesses: Primarily focused on HVAC and automotive applications, may have limited experience in other industries.

Efficient Energy GmbH

Technical Solution: Efficient Energy GmbH has developed the eChiller, a revolutionary cooling system that utilizes water as a refrigerant and leverages laminar flow principles for enhanced energy efficiency. Their technology employs a unique centrifugal compressor design that maintains laminar flow conditions within the refrigerant circuit, reducing turbulence and minimizing energy losses[1]. The eChiller's evaporator and condenser use specially designed plate heat exchangers that promote laminar flow of both water and refrigerant, maximizing heat transfer efficiency[2]. The company has also implemented advanced control algorithms that optimize system operation to maintain laminar flow conditions across a wide range of cooling loads, resulting in consistent high efficiency[3]. Efficient Energy's approach has achieved energy efficiency ratios (EERs) up to 20, significantly higher than conventional cooling systems[4].

Strengths: Innovative water-based refrigeration technology, high energy efficiency, environmentally friendly solution. Weaknesses: Relatively new technology with limited track record, may have limitations in very high-capacity applications.

Core Innovations in Laminar Flow Control

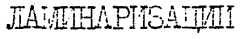

Method and device for laminarization of turbulent flow of continuous medium

PatentWO1993013321A1

Innovation

- A method involving a conical channel with a longitudinal axis of symmetry, where the cross-sectional area is reduced to achieve laminarization by controlling the flow's linear scores and coordinates, allowing for universal application across different scenarios by optimizing the channel's geometry and flow parameters.

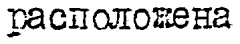

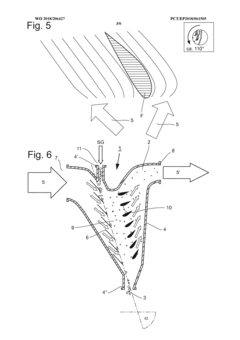

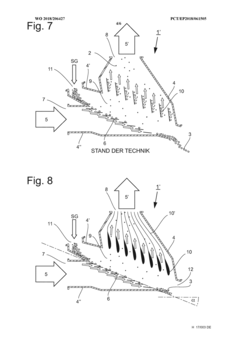

Separator having separating slats with wing profile

PatentWO2018206427A1

Innovation

- Designing the sifting streams with a wing profile to promote laminar flow, preventing the formation of turbulent zones and ensuring that smaller granules remain suspended in the classifying gas, thereby reducing energy consumption and wear on the classifier.

Environmental Impact of Laminar Flow Technologies

Laminar flow technologies have significant environmental implications, particularly in terms of energy efficiency and resource conservation. The implementation of laminar flow principles in various industries has led to substantial reductions in energy consumption and associated greenhouse gas emissions. In the automotive sector, for instance, the application of laminar flow concepts in vehicle design has resulted in improved aerodynamics, leading to decreased fuel consumption and lower carbon dioxide emissions. This not only contributes to meeting stringent environmental regulations but also aligns with global efforts to combat climate change.

In the field of heating, ventilation, and air conditioning (HVAC), laminar flow systems have demonstrated remarkable energy savings. By minimizing turbulence and optimizing air distribution, these systems require less power to maintain desired indoor environmental conditions. This reduction in energy demand translates directly to decreased reliance on fossil fuels for electricity generation, thereby mitigating the environmental impact of building operations.

The environmental benefits of laminar flow technologies extend to water conservation as well. In water treatment facilities, laminar flow principles are applied to enhance the efficiency of filtration and purification processes. This results in reduced energy requirements for pumping and treatment, as well as improved water quality. Consequently, the overall environmental footprint of water management systems is significantly diminished.

In industrial manufacturing, the adoption of laminar flow technologies in production processes has led to more precise control over material flows and reduced waste generation. This not only improves resource utilization but also minimizes the environmental impact associated with raw material extraction and disposal of manufacturing byproducts.

Furthermore, the application of laminar flow concepts in renewable energy technologies, such as wind turbines and hydroelectric systems, has enhanced their efficiency and power output. This improvement in renewable energy generation contributes to the global transition towards cleaner energy sources, reducing dependence on fossil fuels and mitigating climate change impacts.

However, it is important to note that the production and implementation of laminar flow technologies may have their own environmental considerations. The manufacturing of specialized equipment and materials required for these systems can involve energy-intensive processes and the use of potentially harmful substances. Therefore, a comprehensive life cycle assessment is crucial to fully understand the net environmental impact of laminar flow technologies across various applications.

In the field of heating, ventilation, and air conditioning (HVAC), laminar flow systems have demonstrated remarkable energy savings. By minimizing turbulence and optimizing air distribution, these systems require less power to maintain desired indoor environmental conditions. This reduction in energy demand translates directly to decreased reliance on fossil fuels for electricity generation, thereby mitigating the environmental impact of building operations.

The environmental benefits of laminar flow technologies extend to water conservation as well. In water treatment facilities, laminar flow principles are applied to enhance the efficiency of filtration and purification processes. This results in reduced energy requirements for pumping and treatment, as well as improved water quality. Consequently, the overall environmental footprint of water management systems is significantly diminished.

In industrial manufacturing, the adoption of laminar flow technologies in production processes has led to more precise control over material flows and reduced waste generation. This not only improves resource utilization but also minimizes the environmental impact associated with raw material extraction and disposal of manufacturing byproducts.

Furthermore, the application of laminar flow concepts in renewable energy technologies, such as wind turbines and hydroelectric systems, has enhanced their efficiency and power output. This improvement in renewable energy generation contributes to the global transition towards cleaner energy sources, reducing dependence on fossil fuels and mitigating climate change impacts.

However, it is important to note that the production and implementation of laminar flow technologies may have their own environmental considerations. The manufacturing of specialized equipment and materials required for these systems can involve energy-intensive processes and the use of potentially harmful substances. Therefore, a comprehensive life cycle assessment is crucial to fully understand the net environmental impact of laminar flow technologies across various applications.

Laminar Flow Simulation and Modeling Advancements

Recent advancements in laminar flow simulation and modeling have significantly enhanced our understanding and application of this critical fluid dynamics concept. Computational Fluid Dynamics (CFD) techniques have evolved to provide more accurate and detailed representations of laminar flow behavior, enabling engineers to optimize designs for improved energy efficiency.

One of the key developments in this field is the refinement of mesh generation algorithms. These improvements allow for more precise discretization of complex geometries, resulting in higher-fidelity simulations of laminar flow in intricate systems. Adaptive mesh refinement techniques have become increasingly sophisticated, automatically adjusting mesh density in regions of high gradients or complex flow patterns.

Parallel computing and GPU acceleration have dramatically reduced computation times for laminar flow simulations. This has enabled the analysis of larger, more complex systems and facilitated the use of higher-order numerical schemes. As a result, researchers and engineers can now explore a wider range of design parameters and conduct more comprehensive optimization studies.

Machine learning and artificial intelligence have begun to play a significant role in laminar flow modeling. These techniques are being used to develop surrogate models that can rapidly predict flow behavior, reducing the need for time-consuming full-scale simulations. Additionally, AI-assisted parameter tuning has improved the accuracy of turbulence models in transitional regimes, enhancing our ability to predict the onset of turbulence in near-laminar conditions.

Multi-physics coupling has become more prevalent in laminar flow simulations. Integration of heat transfer, chemical reactions, and structural mechanics into CFD models provides a more holistic understanding of system behavior. This is particularly valuable in applications such as heat exchangers, microfluidic devices, and biomedical systems where laminar flow interacts with other physical phenomena.

Uncertainty quantification methods have been incorporated into laminar flow modeling workflows. These techniques allow engineers to assess the impact of manufacturing tolerances, material properties, and operating conditions on flow behavior, leading to more robust designs and improved reliability predictions.

Visualization techniques for laminar flow simulation results have also seen significant advancements. Virtual and augmented reality tools now enable immersive exploration of flow fields, enhancing intuition and facilitating collaborative analysis among engineering teams.

One of the key developments in this field is the refinement of mesh generation algorithms. These improvements allow for more precise discretization of complex geometries, resulting in higher-fidelity simulations of laminar flow in intricate systems. Adaptive mesh refinement techniques have become increasingly sophisticated, automatically adjusting mesh density in regions of high gradients or complex flow patterns.

Parallel computing and GPU acceleration have dramatically reduced computation times for laminar flow simulations. This has enabled the analysis of larger, more complex systems and facilitated the use of higher-order numerical schemes. As a result, researchers and engineers can now explore a wider range of design parameters and conduct more comprehensive optimization studies.

Machine learning and artificial intelligence have begun to play a significant role in laminar flow modeling. These techniques are being used to develop surrogate models that can rapidly predict flow behavior, reducing the need for time-consuming full-scale simulations. Additionally, AI-assisted parameter tuning has improved the accuracy of turbulence models in transitional regimes, enhancing our ability to predict the onset of turbulence in near-laminar conditions.

Multi-physics coupling has become more prevalent in laminar flow simulations. Integration of heat transfer, chemical reactions, and structural mechanics into CFD models provides a more holistic understanding of system behavior. This is particularly valuable in applications such as heat exchangers, microfluidic devices, and biomedical systems where laminar flow interacts with other physical phenomena.

Uncertainty quantification methods have been incorporated into laminar flow modeling workflows. These techniques allow engineers to assess the impact of manufacturing tolerances, material properties, and operating conditions on flow behavior, leading to more robust designs and improved reliability predictions.

Visualization techniques for laminar flow simulation results have also seen significant advancements. Virtual and augmented reality tools now enable immersive exploration of flow fields, enhancing intuition and facilitating collaborative analysis among engineering teams.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!