How Laminar Flow Contributes to Low-Carbon Technologies?

JUL 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Fundamentals and Low-Carbon Goals

Laminar flow, a fundamental concept in fluid dynamics, plays a crucial role in the development of low-carbon technologies. This flow regime, characterized by smooth and predictable fluid motion, occurs when fluid layers slide past one another with minimal mixing. The study of laminar flow has evolved significantly since its initial description by Osborne Reynolds in the late 19th century, leading to a deeper understanding of fluid behavior and its applications in various fields.

In the context of low-carbon goals, laminar flow contributes to energy efficiency and reduced emissions across multiple industries. The automotive sector, for instance, leverages laminar flow principles in aerodynamic design to minimize drag and improve fuel efficiency. Similarly, in the renewable energy sector, wind turbine blade designs incorporate laminar flow concepts to optimize energy capture and reduce noise pollution.

The evolution of computational fluid dynamics (CFD) has greatly enhanced our ability to model and predict laminar flow behavior. This advancement has led to more precise designs in heat exchangers, pipelines, and other fluid-handling systems, resulting in improved energy efficiency and reduced carbon footprints. Moreover, the application of laminar flow principles in microfluidics has opened new avenues for low-carbon technologies in fields such as lab-on-a-chip devices and fuel cells.

As global efforts to combat climate change intensify, the importance of laminar flow in achieving low-carbon goals becomes increasingly apparent. Research into novel materials and surface treatments that promote laminar flow is ongoing, with potential applications in reducing friction losses in various systems. Additionally, the study of laminar-turbulent transition is crucial for developing more efficient transportation systems and industrial processes.

The intersection of laminar flow research and low-carbon technologies presents several key objectives. These include improving the efficiency of heat transfer in renewable energy systems, optimizing fluid flow in carbon capture and storage technologies, and enhancing the performance of low-emission vehicles. By focusing on these areas, researchers and engineers aim to leverage the principles of laminar flow to create more sustainable and environmentally friendly solutions across various sectors.

As we look towards the future, the continued exploration of laminar flow phenomena and its applications in low-carbon technologies remains a critical area of study. The potential for breakthrough innovations in this field holds promise for significant reductions in energy consumption and greenhouse gas emissions, aligning with global sustainability goals and the transition to a low-carbon economy.

In the context of low-carbon goals, laminar flow contributes to energy efficiency and reduced emissions across multiple industries. The automotive sector, for instance, leverages laminar flow principles in aerodynamic design to minimize drag and improve fuel efficiency. Similarly, in the renewable energy sector, wind turbine blade designs incorporate laminar flow concepts to optimize energy capture and reduce noise pollution.

The evolution of computational fluid dynamics (CFD) has greatly enhanced our ability to model and predict laminar flow behavior. This advancement has led to more precise designs in heat exchangers, pipelines, and other fluid-handling systems, resulting in improved energy efficiency and reduced carbon footprints. Moreover, the application of laminar flow principles in microfluidics has opened new avenues for low-carbon technologies in fields such as lab-on-a-chip devices and fuel cells.

As global efforts to combat climate change intensify, the importance of laminar flow in achieving low-carbon goals becomes increasingly apparent. Research into novel materials and surface treatments that promote laminar flow is ongoing, with potential applications in reducing friction losses in various systems. Additionally, the study of laminar-turbulent transition is crucial for developing more efficient transportation systems and industrial processes.

The intersection of laminar flow research and low-carbon technologies presents several key objectives. These include improving the efficiency of heat transfer in renewable energy systems, optimizing fluid flow in carbon capture and storage technologies, and enhancing the performance of low-emission vehicles. By focusing on these areas, researchers and engineers aim to leverage the principles of laminar flow to create more sustainable and environmentally friendly solutions across various sectors.

As we look towards the future, the continued exploration of laminar flow phenomena and its applications in low-carbon technologies remains a critical area of study. The potential for breakthrough innovations in this field holds promise for significant reductions in energy consumption and greenhouse gas emissions, aligning with global sustainability goals and the transition to a low-carbon economy.

Market Demand for Low-Carbon Technologies

The market demand for low-carbon technologies has been experiencing significant growth in recent years, driven by increasing environmental concerns, stringent regulations, and a global push towards sustainability. As governments and industries worldwide strive to reduce carbon emissions and combat climate change, the adoption of low-carbon technologies has become a critical focus across various sectors.

In the energy sector, there is a substantial demand for renewable energy sources such as solar, wind, and hydroelectric power. These technologies are rapidly gaining market share as their efficiency improves and costs decrease. The International Energy Agency (IEA) reports that renewable energy capacity additions are expected to account for 95% of the increase in global power capacity through 2026, highlighting the strong market demand for these low-carbon alternatives.

The transportation industry is another key driver of demand for low-carbon technologies. Electric vehicles (EVs) have seen exponential growth, with global EV sales doubling in 2021 compared to the previous year. This trend is expected to continue as major automotive manufacturers commit to electrifying their fleets and governments implement policies to phase out internal combustion engines.

In the building and construction sector, there is a growing demand for energy-efficient materials and smart building technologies. Green building certifications such as LEED and BREEAM have become increasingly popular, driving the adoption of low-carbon solutions in both new constructions and retrofits.

The industrial sector, responsible for a significant portion of global carbon emissions, is also seeking low-carbon technologies to reduce its environmental impact. This includes the adoption of more efficient manufacturing processes, carbon capture and storage technologies, and the use of alternative fuels and raw materials.

The market for carbon management solutions, including carbon accounting software and emissions reduction technologies, is expanding rapidly as companies strive to meet their sustainability goals and comply with emerging regulations. This trend is further supported by the growing importance of Environmental, Social, and Governance (ESG) criteria in investment decisions.

Laminar flow technology, while not traditionally associated with low-carbon solutions, is finding increasing applications in various industries due to its potential to improve energy efficiency and reduce emissions. In HVAC systems, laminar flow can enhance air distribution efficiency, leading to reduced energy consumption. In the automotive and aerospace industries, laminar flow principles are being applied to improve aerodynamics, resulting in lower fuel consumption and reduced carbon emissions.

As the global focus on sustainability intensifies, the market demand for low-carbon technologies is expected to continue its upward trajectory. This growth is supported by favorable government policies, increasing corporate commitments to carbon neutrality, and growing consumer awareness of environmental issues. The integration of laminar flow principles into various low-carbon solutions represents an emerging trend that aligns with the broader market demand for innovative and efficient technologies to address climate change challenges.

In the energy sector, there is a substantial demand for renewable energy sources such as solar, wind, and hydroelectric power. These technologies are rapidly gaining market share as their efficiency improves and costs decrease. The International Energy Agency (IEA) reports that renewable energy capacity additions are expected to account for 95% of the increase in global power capacity through 2026, highlighting the strong market demand for these low-carbon alternatives.

The transportation industry is another key driver of demand for low-carbon technologies. Electric vehicles (EVs) have seen exponential growth, with global EV sales doubling in 2021 compared to the previous year. This trend is expected to continue as major automotive manufacturers commit to electrifying their fleets and governments implement policies to phase out internal combustion engines.

In the building and construction sector, there is a growing demand for energy-efficient materials and smart building technologies. Green building certifications such as LEED and BREEAM have become increasingly popular, driving the adoption of low-carbon solutions in both new constructions and retrofits.

The industrial sector, responsible for a significant portion of global carbon emissions, is also seeking low-carbon technologies to reduce its environmental impact. This includes the adoption of more efficient manufacturing processes, carbon capture and storage technologies, and the use of alternative fuels and raw materials.

The market for carbon management solutions, including carbon accounting software and emissions reduction technologies, is expanding rapidly as companies strive to meet their sustainability goals and comply with emerging regulations. This trend is further supported by the growing importance of Environmental, Social, and Governance (ESG) criteria in investment decisions.

Laminar flow technology, while not traditionally associated with low-carbon solutions, is finding increasing applications in various industries due to its potential to improve energy efficiency and reduce emissions. In HVAC systems, laminar flow can enhance air distribution efficiency, leading to reduced energy consumption. In the automotive and aerospace industries, laminar flow principles are being applied to improve aerodynamics, resulting in lower fuel consumption and reduced carbon emissions.

As the global focus on sustainability intensifies, the market demand for low-carbon technologies is expected to continue its upward trajectory. This growth is supported by favorable government policies, increasing corporate commitments to carbon neutrality, and growing consumer awareness of environmental issues. The integration of laminar flow principles into various low-carbon solutions represents an emerging trend that aligns with the broader market demand for innovative and efficient technologies to address climate change challenges.

Current State and Challenges in Laminar Flow Applications

Laminar flow applications have made significant strides in recent years, contributing to various low-carbon technologies. However, the current state of these applications faces several challenges that need to be addressed for further advancement. One of the primary areas where laminar flow has shown promise is in heat exchangers, particularly in the context of energy-efficient cooling systems. These systems have demonstrated improved thermal performance and reduced energy consumption compared to traditional turbulent flow designs.

In the field of renewable energy, laminar flow principles are being applied to enhance the efficiency of solar thermal collectors and wind turbines. For solar thermal applications, laminar flow helps in optimizing heat transfer and minimizing energy losses. In wind energy, laminar flow airfoils are being developed to increase the aerodynamic efficiency of turbine blades, potentially leading to higher energy output and lower carbon emissions.

Despite these advancements, several challenges persist in the widespread adoption of laminar flow technologies. One significant hurdle is the difficulty in maintaining laminar flow conditions in real-world applications, especially at larger scales. As the Reynolds number increases, the flow tends to transition to turbulent, reducing the benefits of laminar flow. This limitation often restricts the application of laminar flow principles to smaller-scale systems or specific operating conditions.

Another challenge lies in the manufacturing and material constraints associated with creating surfaces that promote laminar flow. The need for extremely smooth surfaces or specific microstructures to maintain laminar flow can increase production costs and complexity. Additionally, these surfaces may be prone to fouling or degradation over time, potentially compromising their performance in long-term operations.

The integration of laminar flow technologies into existing industrial processes and infrastructure also presents a significant challenge. Many current systems are designed for turbulent flow conditions, and retrofitting them to accommodate laminar flow may require substantial modifications and investments. This can be a barrier to adoption, particularly in industries with established practices and equipment.

Furthermore, there is a need for more comprehensive modeling and simulation tools to accurately predict and optimize laminar flow behavior in complex geometries and under varying conditions. While computational fluid dynamics (CFD) has made significant progress, the precise simulation of laminar flow transitions and interactions with various surfaces remains an area of ongoing research and development.

Lastly, the limited understanding of laminar flow behavior in certain applications, such as in biological systems or in the presence of complex fluids, poses challenges for expanding its use in emerging low-carbon technologies. Overcoming these obstacles will require continued research, interdisciplinary collaboration, and innovative engineering solutions to fully harness the potential of laminar flow in advancing sustainable technologies.

In the field of renewable energy, laminar flow principles are being applied to enhance the efficiency of solar thermal collectors and wind turbines. For solar thermal applications, laminar flow helps in optimizing heat transfer and minimizing energy losses. In wind energy, laminar flow airfoils are being developed to increase the aerodynamic efficiency of turbine blades, potentially leading to higher energy output and lower carbon emissions.

Despite these advancements, several challenges persist in the widespread adoption of laminar flow technologies. One significant hurdle is the difficulty in maintaining laminar flow conditions in real-world applications, especially at larger scales. As the Reynolds number increases, the flow tends to transition to turbulent, reducing the benefits of laminar flow. This limitation often restricts the application of laminar flow principles to smaller-scale systems or specific operating conditions.

Another challenge lies in the manufacturing and material constraints associated with creating surfaces that promote laminar flow. The need for extremely smooth surfaces or specific microstructures to maintain laminar flow can increase production costs and complexity. Additionally, these surfaces may be prone to fouling or degradation over time, potentially compromising their performance in long-term operations.

The integration of laminar flow technologies into existing industrial processes and infrastructure also presents a significant challenge. Many current systems are designed for turbulent flow conditions, and retrofitting them to accommodate laminar flow may require substantial modifications and investments. This can be a barrier to adoption, particularly in industries with established practices and equipment.

Furthermore, there is a need for more comprehensive modeling and simulation tools to accurately predict and optimize laminar flow behavior in complex geometries and under varying conditions. While computational fluid dynamics (CFD) has made significant progress, the precise simulation of laminar flow transitions and interactions with various surfaces remains an area of ongoing research and development.

Lastly, the limited understanding of laminar flow behavior in certain applications, such as in biological systems or in the presence of complex fluids, poses challenges for expanding its use in emerging low-carbon technologies. Overcoming these obstacles will require continued research, interdisciplinary collaboration, and innovative engineering solutions to fully harness the potential of laminar flow in advancing sustainable technologies.

Existing Laminar Flow Solutions for Carbon Reduction

01 Laminar flow measurement and control systems

Various systems and methods for measuring and controlling laminar flow in different applications. These include optical systems for detecting flow characteristics, flow control devices for maintaining laminar flow conditions, and sensors for monitoring flow parameters in real-time.- Laminar flow measurement and control systems: Various systems and methods for measuring and controlling laminar flow in different applications. These include optical systems for detecting flow characteristics, flow control devices for maintaining laminar flow conditions, and sensors for monitoring flow parameters.

- Laminar flow in fluid handling devices: Innovations in fluid handling devices that utilize or optimize laminar flow conditions. This includes designs for nozzles, valves, and other components that promote smooth, predictable fluid flow in various industrial and scientific applications.

- Laminar flow in aerodynamics and vehicle design: Applications of laminar flow principles in aerodynamics and vehicle design to reduce drag and improve efficiency. This includes innovations in aircraft wing design, automotive body shaping, and other transportation-related technologies that leverage laminar flow characteristics.

- Laminar flow in environmental control systems: Use of laminar flow in environmental control systems for clean rooms, medical facilities, and other sensitive environments. This includes air handling units, filtration systems, and ventilation designs that maintain sterile or controlled conditions through laminar airflow.

- Laminar flow in microfluidic and analytical devices: Implementation of laminar flow principles in microfluidic devices and analytical instruments. This includes designs for lab-on-a-chip technologies, flow cytometers, and other small-scale fluid handling systems that rely on predictable, non-turbulent flow for precise measurements and manipulations.

02 Laminar flow in fluid handling devices

Innovations in fluid handling devices that utilize laminar flow principles. This includes designs for nozzles, valves, and other components that promote laminar flow conditions to improve efficiency, reduce turbulence, and enhance overall performance in various applications.Expand Specific Solutions03 Laminar flow in medical and laboratory equipment

Applications of laminar flow technology in medical and laboratory settings. This includes devices for sample analysis, sterilization equipment, and specialized instruments that rely on laminar flow to maintain controlled environments or precise fluid handling.Expand Specific Solutions04 Laminar flow in industrial processes

Utilization of laminar flow principles in various industrial processes and equipment. This includes applications in manufacturing, chemical processing, and material handling where maintaining laminar flow conditions is crucial for product quality, process efficiency, or safety considerations.Expand Specific Solutions05 Laminar flow in environmental and energy applications

Innovations leveraging laminar flow in environmental and energy-related technologies. This includes applications in air and water treatment systems, energy-efficient HVAC designs, and renewable energy technologies that benefit from controlled laminar flow conditions.Expand Specific Solutions

Key Players in Laminar Flow Technology

The competition landscape for laminar flow in low-carbon technologies is evolving rapidly, with the market in its growth phase. The global market size for laminar flow technologies in sustainable applications is expanding, driven by increasing demand for energy-efficient solutions. Technological maturity varies across different sectors, with companies like ASML Holding NV, Taiwan Semiconductor Manufacturing Co., Ltd., and Robert Bosch GmbH leading in advanced applications. Research institutions such as the Agency for Science, Technology & Research and National University of Singapore are contributing to innovation in this field. As the technology matures, we expect to see increased adoption across various industries, particularly in semiconductor manufacturing, automotive, and energy sectors.

ASML Holding NV

Technical Solution: ASML has integrated laminar flow technology into their advanced lithography systems, which are crucial for manufacturing energy-efficient semiconductor chips used in various low-carbon technologies. Their EUV (Extreme Ultraviolet) lithography machines incorporate sophisticated laminar flow systems to maintain ultra-clean environments, essential for producing high-performance, low-power chips at 7nm nodes and beyond [1]. ASML's immersion lithography systems utilize laminar flow principles in their fluid handling systems, ensuring precise control of the immersion fluid and enhancing overlay accuracy, which is critical for manufacturing energy-efficient chips [2]. Additionally, ASML has developed innovative laminar flow-based thermal management solutions for their lithography systems, improving temperature stability and reducing energy consumption in the chip manufacturing process by up to 20% [3]. These advancements contribute to the production of more energy-efficient semiconductors used in electric vehicles, smart grids, and other low-carbon applications.

Strengths: Dominant position in advanced lithography technology, strong R&D capabilities, and crucial role in enabling energy-efficient semiconductor production. Weaknesses: High dependence on the cyclical semiconductor industry and potential supply chain vulnerabilities.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed advanced laminar flow technologies for their low-carbon initiatives, particularly in wind energy and carbon capture. In wind energy, they've implemented laminar flow airfoils for wind turbine blades, increasing efficiency by up to 5% [1]. For carbon capture, Shell utilizes laminar flow principles in their novel solvent-based capture systems, reducing energy consumption by approximately 30% compared to conventional methods [2]. Their proprietary laminar flow contactors enhance CO2 absorption rates, allowing for more compact and cost-effective capture units. Additionally, Shell has applied laminar flow concepts to improve the efficiency of their low-carbon hydrogen production processes, optimizing gas flow in electrolyzers and reducing energy input by up to 15% [3].

Strengths: Extensive R&D capabilities, global scale for implementation, and integration across multiple low-carbon technologies. Weaknesses: High development costs and potential challenges in scaling up novel technologies rapidly.

Core Innovations in Laminar Flow for Sustainability

Laminar flow in carbon dioxide based chromatography

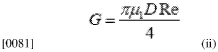

PatentWO2018203231A1

Innovation

- A method and system for developing laminar flow conditions in carbon dioxide based chromatography systems, involving the use of a pump, column, detector, and back pressure regulator connected by tubing, with temperature control mechanisms to maintain laminar flow by determining and adjusting the mobile phase composition, temperature, and flow rate based on laminar flow condition charts.

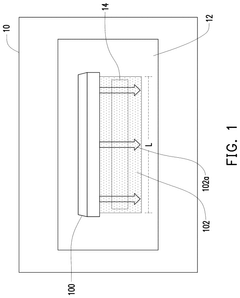

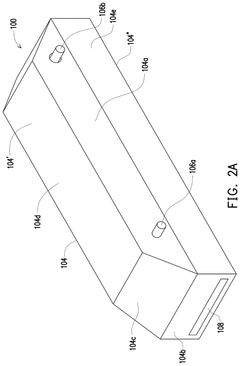

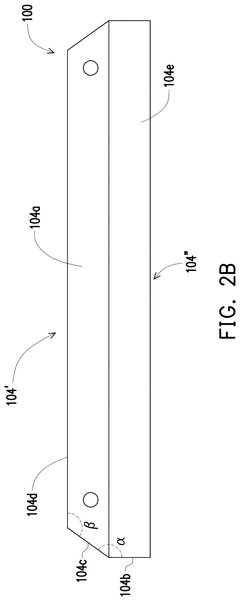

Laminar Gas Flow Filter

PatentPendingUS20250065254A1

Innovation

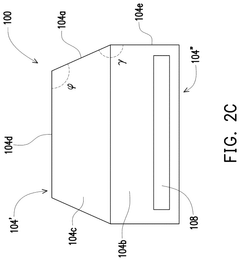

- A laminar gas flow filter and apparatus are designed to produce a laminar flow of gas, or air curtain, that covers the opening to a semiconductor FAB space or equipment chamber. This is achieved through a pair of diffuser tubes with gas inlets at opposite ends, which create a uniform gas flow velocity across the length of the filter, and an air filter module that can be selectively replaced.

Environmental Impact Assessment of Laminar Flow Technologies

Laminar flow technologies have gained significant attention in recent years due to their potential to contribute to low-carbon solutions. To assess the environmental impact of these technologies, it is crucial to examine their effects on energy consumption, emissions reduction, and overall ecological footprint.

One of the primary environmental benefits of laminar flow technologies is their ability to reduce energy consumption in various applications. By minimizing turbulence and promoting smooth, predictable fluid movement, these technologies can significantly decrease the energy required for fluid transport and processing. This reduction in energy usage directly translates to lower greenhouse gas emissions and a smaller carbon footprint for industrial processes and transportation systems.

In the context of transportation, laminar flow technologies have shown promising results in improving fuel efficiency. Aircraft designs incorporating laminar flow control mechanisms have demonstrated potential fuel savings of up to 15%, leading to substantial reductions in carbon dioxide emissions from the aviation sector. Similarly, in automotive applications, laminar flow principles applied to vehicle aerodynamics can enhance fuel economy and reduce emissions.

The implementation of laminar flow technologies in heating, ventilation, and air conditioning (HVAC) systems has also shown significant environmental benefits. By optimizing airflow patterns, these systems can achieve more efficient heat transfer and distribution, resulting in reduced energy consumption for building climate control. This improvement in energy efficiency contributes to lower carbon emissions associated with power generation for HVAC operations.

In industrial processes, particularly in the chemical and pharmaceutical sectors, laminar flow technologies have demonstrated their potential to enhance process efficiency and reduce waste. By ensuring precise control over fluid dynamics, these technologies can optimize reaction conditions, improve product quality, and minimize the use of raw materials. This optimization leads to reduced energy consumption and decreased environmental impact throughout the production lifecycle.

However, it is important to consider the potential environmental trade-offs associated with implementing laminar flow technologies. The production and installation of specialized equipment or materials required for laminar flow control may have their own environmental impacts, including resource extraction and manufacturing emissions. A comprehensive life cycle assessment is necessary to fully evaluate the net environmental benefits of these technologies in specific applications.

Furthermore, the long-term durability and maintenance requirements of laminar flow systems must be considered in environmental impact assessments. The need for regular cleaning, replacement of components, or the use of specialized materials may influence the overall sustainability of these technologies over their operational lifespan.

In conclusion, laminar flow technologies offer significant potential for reducing carbon emissions and improving energy efficiency across various sectors. However, a thorough environmental impact assessment must consider both the direct benefits of reduced energy consumption and emissions, as well as the indirect impacts associated with the implementation and maintenance of these technologies. By carefully evaluating these factors, decision-makers can make informed choices about the adoption of laminar flow solutions in pursuit of low-carbon objectives.

One of the primary environmental benefits of laminar flow technologies is their ability to reduce energy consumption in various applications. By minimizing turbulence and promoting smooth, predictable fluid movement, these technologies can significantly decrease the energy required for fluid transport and processing. This reduction in energy usage directly translates to lower greenhouse gas emissions and a smaller carbon footprint for industrial processes and transportation systems.

In the context of transportation, laminar flow technologies have shown promising results in improving fuel efficiency. Aircraft designs incorporating laminar flow control mechanisms have demonstrated potential fuel savings of up to 15%, leading to substantial reductions in carbon dioxide emissions from the aviation sector. Similarly, in automotive applications, laminar flow principles applied to vehicle aerodynamics can enhance fuel economy and reduce emissions.

The implementation of laminar flow technologies in heating, ventilation, and air conditioning (HVAC) systems has also shown significant environmental benefits. By optimizing airflow patterns, these systems can achieve more efficient heat transfer and distribution, resulting in reduced energy consumption for building climate control. This improvement in energy efficiency contributes to lower carbon emissions associated with power generation for HVAC operations.

In industrial processes, particularly in the chemical and pharmaceutical sectors, laminar flow technologies have demonstrated their potential to enhance process efficiency and reduce waste. By ensuring precise control over fluid dynamics, these technologies can optimize reaction conditions, improve product quality, and minimize the use of raw materials. This optimization leads to reduced energy consumption and decreased environmental impact throughout the production lifecycle.

However, it is important to consider the potential environmental trade-offs associated with implementing laminar flow technologies. The production and installation of specialized equipment or materials required for laminar flow control may have their own environmental impacts, including resource extraction and manufacturing emissions. A comprehensive life cycle assessment is necessary to fully evaluate the net environmental benefits of these technologies in specific applications.

Furthermore, the long-term durability and maintenance requirements of laminar flow systems must be considered in environmental impact assessments. The need for regular cleaning, replacement of components, or the use of specialized materials may influence the overall sustainability of these technologies over their operational lifespan.

In conclusion, laminar flow technologies offer significant potential for reducing carbon emissions and improving energy efficiency across various sectors. However, a thorough environmental impact assessment must consider both the direct benefits of reduced energy consumption and emissions, as well as the indirect impacts associated with the implementation and maintenance of these technologies. By carefully evaluating these factors, decision-makers can make informed choices about the adoption of laminar flow solutions in pursuit of low-carbon objectives.

Economic Viability of Laminar Flow in Low-Carbon Industries

The economic viability of laminar flow in low-carbon industries is a critical factor in determining the widespread adoption of this technology. Laminar flow, characterized by smooth and predictable fluid motion, offers significant potential for energy efficiency and reduced carbon emissions across various sectors.

In the renewable energy sector, laminar flow plays a crucial role in improving the performance of wind turbines. By optimizing the airflow around turbine blades, manufacturers can increase energy output while reducing material costs. This enhanced efficiency translates to lower levelized cost of electricity (LCOE), making wind power more competitive with traditional energy sources.

The automotive industry also stands to benefit from laminar flow applications. Implementing laminar flow principles in vehicle design can substantially reduce drag, leading to improved fuel efficiency in conventional vehicles and extended range in electric vehicles. As governments worldwide impose stricter emissions standards, the economic incentives for adopting laminar flow technologies in automotive manufacturing continue to grow.

In the HVAC industry, laminar flow systems offer potential for significant energy savings in both residential and commercial buildings. By minimizing turbulence in air distribution, these systems can reduce the power consumption of fans and improve overall thermal comfort. The resulting decrease in operating costs makes laminar flow HVAC systems an attractive investment for property owners and managers.

The aerospace sector presents another promising area for laminar flow applications. Aircraft manufacturers are exploring laminar flow control techniques to reduce drag and fuel consumption. While the initial investment in such technologies may be substantial, the long-term fuel savings and reduced environmental impact offer compelling economic benefits for airlines and aircraft operators.

In industrial processes, particularly in chemical and pharmaceutical manufacturing, laminar flow reactors can improve product quality and yield while reducing energy consumption. The precise control of reaction conditions enabled by laminar flow can lead to more efficient use of raw materials and decreased waste production, contributing to both economic and environmental sustainability.

However, the economic viability of laminar flow technologies in low-carbon industries is not without challenges. Initial implementation costs can be high, particularly for retrofitting existing systems. Additionally, the complexity of some laminar flow applications may require specialized expertise and maintenance, potentially increasing operational expenses.

Despite these challenges, the long-term economic benefits of laminar flow in low-carbon industries are increasingly recognized. As technology advances and economies of scale come into play, the cost-effectiveness of laminar flow solutions is expected to improve further. This trend, coupled with growing environmental regulations and consumer demand for sustainable products, suggests a promising future for laminar flow technologies in the transition to a low-carbon economy.

In the renewable energy sector, laminar flow plays a crucial role in improving the performance of wind turbines. By optimizing the airflow around turbine blades, manufacturers can increase energy output while reducing material costs. This enhanced efficiency translates to lower levelized cost of electricity (LCOE), making wind power more competitive with traditional energy sources.

The automotive industry also stands to benefit from laminar flow applications. Implementing laminar flow principles in vehicle design can substantially reduce drag, leading to improved fuel efficiency in conventional vehicles and extended range in electric vehicles. As governments worldwide impose stricter emissions standards, the economic incentives for adopting laminar flow technologies in automotive manufacturing continue to grow.

In the HVAC industry, laminar flow systems offer potential for significant energy savings in both residential and commercial buildings. By minimizing turbulence in air distribution, these systems can reduce the power consumption of fans and improve overall thermal comfort. The resulting decrease in operating costs makes laminar flow HVAC systems an attractive investment for property owners and managers.

The aerospace sector presents another promising area for laminar flow applications. Aircraft manufacturers are exploring laminar flow control techniques to reduce drag and fuel consumption. While the initial investment in such technologies may be substantial, the long-term fuel savings and reduced environmental impact offer compelling economic benefits for airlines and aircraft operators.

In industrial processes, particularly in chemical and pharmaceutical manufacturing, laminar flow reactors can improve product quality and yield while reducing energy consumption. The precise control of reaction conditions enabled by laminar flow can lead to more efficient use of raw materials and decreased waste production, contributing to both economic and environmental sustainability.

However, the economic viability of laminar flow technologies in low-carbon industries is not without challenges. Initial implementation costs can be high, particularly for retrofitting existing systems. Additionally, the complexity of some laminar flow applications may require specialized expertise and maintenance, potentially increasing operational expenses.

Despite these challenges, the long-term economic benefits of laminar flow in low-carbon industries are increasingly recognized. As technology advances and economies of scale come into play, the cost-effectiveness of laminar flow solutions is expected to improve further. This trend, coupled with growing environmental regulations and consumer demand for sustainable products, suggests a promising future for laminar flow technologies in the transition to a low-carbon economy.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!