Laminar Flow's Influence on Next-Generation Material Science

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Fundamentals and Objectives

Laminar flow, a fundamental concept in fluid dynamics, has been a cornerstone of material science for decades. Its influence on next-generation material science is becoming increasingly significant as researchers explore new frontiers in material development and manufacturing processes. The study of laminar flow dates back to the 19th century, with early pioneers like Osborne Reynolds laying the groundwork for our understanding of fluid behavior.

In recent years, the field has experienced a renaissance, driven by advancements in computational modeling and experimental techniques. This resurgence has led to a deeper understanding of how laminar flow impacts material properties and behaviors at various scales, from nanomaterials to bulk substances. The evolution of this technology has been marked by key milestones, including the development of microfluidic devices and the application of laminar flow principles in 3D printing and advanced manufacturing processes.

The primary objective of current research in this area is to harness the unique properties of laminar flow to create novel materials with enhanced characteristics. This includes improving material strength, conductivity, and other physical properties by controlling the arrangement of molecules or particles during material synthesis. Additionally, researchers aim to develop more efficient and precise manufacturing techniques that leverage laminar flow principles to produce materials with unprecedented levels of structural control.

Another critical goal is to understand and exploit the interaction between laminar flow and various material types, including polymers, composites, and nanomaterials. This knowledge is essential for developing new materials with tailored properties for specific applications, such as aerospace, biomedical engineering, and energy storage. The potential for creating materials with gradient properties or hierarchical structures through controlled laminar flow processes is particularly exciting.

Furthermore, the integration of laminar flow concepts with other emerging technologies, such as artificial intelligence and machine learning, is opening up new avenues for material discovery and optimization. These interdisciplinary approaches are expected to accelerate the development of next-generation materials by enabling rapid experimentation and prediction of material properties based on flow conditions.

As we look to the future, the study of laminar flow's influence on material science is poised to play a crucial role in addressing global challenges. From developing more efficient energy storage materials to creating advanced biomaterials for medical applications, the potential applications are vast and diverse. The continued exploration of laminar flow phenomena promises to unlock new possibilities in material design and manufacturing, potentially revolutionizing industries and paving the way for innovative solutions to complex problems.

In recent years, the field has experienced a renaissance, driven by advancements in computational modeling and experimental techniques. This resurgence has led to a deeper understanding of how laminar flow impacts material properties and behaviors at various scales, from nanomaterials to bulk substances. The evolution of this technology has been marked by key milestones, including the development of microfluidic devices and the application of laminar flow principles in 3D printing and advanced manufacturing processes.

The primary objective of current research in this area is to harness the unique properties of laminar flow to create novel materials with enhanced characteristics. This includes improving material strength, conductivity, and other physical properties by controlling the arrangement of molecules or particles during material synthesis. Additionally, researchers aim to develop more efficient and precise manufacturing techniques that leverage laminar flow principles to produce materials with unprecedented levels of structural control.

Another critical goal is to understand and exploit the interaction between laminar flow and various material types, including polymers, composites, and nanomaterials. This knowledge is essential for developing new materials with tailored properties for specific applications, such as aerospace, biomedical engineering, and energy storage. The potential for creating materials with gradient properties or hierarchical structures through controlled laminar flow processes is particularly exciting.

Furthermore, the integration of laminar flow concepts with other emerging technologies, such as artificial intelligence and machine learning, is opening up new avenues for material discovery and optimization. These interdisciplinary approaches are expected to accelerate the development of next-generation materials by enabling rapid experimentation and prediction of material properties based on flow conditions.

As we look to the future, the study of laminar flow's influence on material science is poised to play a crucial role in addressing global challenges. From developing more efficient energy storage materials to creating advanced biomaterials for medical applications, the potential applications are vast and diverse. The continued exploration of laminar flow phenomena promises to unlock new possibilities in material design and manufacturing, potentially revolutionizing industries and paving the way for innovative solutions to complex problems.

Market Demand Analysis

The market demand for technologies and products related to laminar flow's influence on next-generation material science has been steadily growing in recent years. This growth is driven by the increasing need for advanced materials with enhanced properties and performance across various industries. The aerospace sector, in particular, has shown significant interest in leveraging laminar flow principles to develop materials that can improve fuel efficiency and reduce drag in aircraft design.

In the automotive industry, there is a rising demand for materials that can enhance aerodynamics and reduce energy consumption. Laminar flow-inspired materials are being explored for their potential to create smoother surfaces and reduce turbulence, leading to improved fuel economy and vehicle performance. This trend aligns with the global push towards more sustainable transportation solutions.

The renewable energy sector, especially wind power, has also identified potential applications for laminar flow-influenced materials. Wind turbine manufacturers are seeking ways to optimize blade designs and materials to increase energy capture efficiency. Materials that can maintain laminar flow characteristics under various environmental conditions are highly sought after in this market segment.

In the field of microfluidics and lab-on-a-chip technologies, there is a growing demand for materials that can precisely control fluid flow at microscopic scales. This is particularly relevant in the development of advanced diagnostic devices and drug delivery systems. The ability to manipulate laminar flow properties in materials can lead to more accurate and efficient microfluidic devices, driving innovation in healthcare and biotechnology.

The construction industry has shown interest in materials that can improve energy efficiency in buildings. Laminar flow-inspired materials are being investigated for their potential to enhance insulation properties and optimize air circulation within structures. This aligns with the increasing focus on sustainable building practices and energy conservation.

Furthermore, the sports and recreation industry has identified opportunities for laminar flow-influenced materials in the design of high-performance equipment. From swimwear to cycling gear, there is a demand for materials that can reduce drag and improve athletic performance through better fluid dynamics.

As environmental concerns continue to grow, there is an increasing market demand for materials that can contribute to pollution reduction and environmental remediation. Laminar flow principles are being explored in the development of filtration systems and materials that can more effectively remove contaminants from air and water.

Overall, the market for laminar flow-influenced materials in next-generation material science is diverse and expanding. Industries ranging from aerospace to healthcare are actively seeking innovative solutions that can leverage the principles of laminar flow to create materials with superior properties and performance characteristics.

In the automotive industry, there is a rising demand for materials that can enhance aerodynamics and reduce energy consumption. Laminar flow-inspired materials are being explored for their potential to create smoother surfaces and reduce turbulence, leading to improved fuel economy and vehicle performance. This trend aligns with the global push towards more sustainable transportation solutions.

The renewable energy sector, especially wind power, has also identified potential applications for laminar flow-influenced materials. Wind turbine manufacturers are seeking ways to optimize blade designs and materials to increase energy capture efficiency. Materials that can maintain laminar flow characteristics under various environmental conditions are highly sought after in this market segment.

In the field of microfluidics and lab-on-a-chip technologies, there is a growing demand for materials that can precisely control fluid flow at microscopic scales. This is particularly relevant in the development of advanced diagnostic devices and drug delivery systems. The ability to manipulate laminar flow properties in materials can lead to more accurate and efficient microfluidic devices, driving innovation in healthcare and biotechnology.

The construction industry has shown interest in materials that can improve energy efficiency in buildings. Laminar flow-inspired materials are being investigated for their potential to enhance insulation properties and optimize air circulation within structures. This aligns with the increasing focus on sustainable building practices and energy conservation.

Furthermore, the sports and recreation industry has identified opportunities for laminar flow-influenced materials in the design of high-performance equipment. From swimwear to cycling gear, there is a demand for materials that can reduce drag and improve athletic performance through better fluid dynamics.

As environmental concerns continue to grow, there is an increasing market demand for materials that can contribute to pollution reduction and environmental remediation. Laminar flow principles are being explored in the development of filtration systems and materials that can more effectively remove contaminants from air and water.

Overall, the market for laminar flow-influenced materials in next-generation material science is diverse and expanding. Industries ranging from aerospace to healthcare are actively seeking innovative solutions that can leverage the principles of laminar flow to create materials with superior properties and performance characteristics.

Current Challenges in Laminar Flow Applications

Despite the significant advancements in laminar flow applications, several challenges persist in harnessing its full potential for next-generation material science. One of the primary obstacles is achieving precise control over flow parameters in complex geometries. As materials become increasingly sophisticated, maintaining laminar flow conditions in intricate structures and at varying scales poses significant difficulties.

The integration of laminar flow principles with advanced manufacturing techniques, such as 3D printing and nanofabrication, presents another hurdle. Ensuring consistent laminar flow characteristics during the fabrication process of novel materials remains a challenge, particularly when dealing with multi-material systems or hierarchical structures.

Furthermore, the development of real-time monitoring and control systems for laminar flow in material processing applications is an ongoing challenge. Current sensor technologies and feedback mechanisms often struggle to provide the necessary resolution and response times required for precise manipulation of flow conditions during material synthesis or modification processes.

Another significant challenge lies in scaling up laminar flow applications from laboratory settings to industrial-scale production. Maintaining laminar flow characteristics across larger volumes and longer durations while ensuring cost-effectiveness and energy efficiency is a complex task that requires innovative engineering solutions.

The interaction between laminar flow and emerging smart materials or stimuli-responsive systems presents yet another frontier of challenges. Understanding and controlling the dynamic interplay between flow behavior and material properties that can change in response to external stimuli is crucial for developing advanced functional materials.

Moreover, the computational modeling and simulation of laminar flow in complex material systems remain computationally intensive and often require simplifications that may not fully capture real-world behaviors. Developing more accurate and efficient simulation tools is essential for predicting and optimizing laminar flow effects on material properties and performance.

Lastly, the interdisciplinary nature of laminar flow applications in material science necessitates collaboration between fluid dynamicists, materials scientists, and process engineers. Bridging the knowledge gaps between these disciplines and developing a common language for addressing laminar flow challenges in material development is an ongoing process that requires continued effort and innovation.

The integration of laminar flow principles with advanced manufacturing techniques, such as 3D printing and nanofabrication, presents another hurdle. Ensuring consistent laminar flow characteristics during the fabrication process of novel materials remains a challenge, particularly when dealing with multi-material systems or hierarchical structures.

Furthermore, the development of real-time monitoring and control systems for laminar flow in material processing applications is an ongoing challenge. Current sensor technologies and feedback mechanisms often struggle to provide the necessary resolution and response times required for precise manipulation of flow conditions during material synthesis or modification processes.

Another significant challenge lies in scaling up laminar flow applications from laboratory settings to industrial-scale production. Maintaining laminar flow characteristics across larger volumes and longer durations while ensuring cost-effectiveness and energy efficiency is a complex task that requires innovative engineering solutions.

The interaction between laminar flow and emerging smart materials or stimuli-responsive systems presents yet another frontier of challenges. Understanding and controlling the dynamic interplay between flow behavior and material properties that can change in response to external stimuli is crucial for developing advanced functional materials.

Moreover, the computational modeling and simulation of laminar flow in complex material systems remain computationally intensive and often require simplifications that may not fully capture real-world behaviors. Developing more accurate and efficient simulation tools is essential for predicting and optimizing laminar flow effects on material properties and performance.

Lastly, the interdisciplinary nature of laminar flow applications in material science necessitates collaboration between fluid dynamicists, materials scientists, and process engineers. Bridging the knowledge gaps between these disciplines and developing a common language for addressing laminar flow challenges in material development is an ongoing process that requires continued effort and innovation.

Existing Laminar Flow Solutions

01 Laminar flow measurement and control systems

Various systems and methods for measuring and controlling laminar flow in different applications. These include optical systems for detecting flow characteristics, flow meters for precise measurements, and control mechanisms to maintain laminar flow conditions in fluid systems.- Laminar flow measurement and control systems: Various systems and methods for measuring and controlling laminar flow in different applications. These include optical systems for detecting flow characteristics, flow meters for precise measurements, and control mechanisms to maintain laminar flow conditions in fluid systems.

- Laminar flow in air distribution and ventilation: Techniques for creating and maintaining laminar airflow in ventilation systems, clean rooms, and air distribution devices. This includes designs for air outlets, diffusers, and flow straighteners to ensure smooth, non-turbulent air movement in controlled environments.

- Laminar flow in fluid handling and processing: Applications of laminar flow principles in fluid handling equipment, including filtration systems, separators, and fluid processing devices. These designs optimize fluid movement to enhance efficiency and performance in various industrial processes.

- Laminar flow nozzles and spray systems: Specialized nozzle designs and spray systems that utilize laminar flow principles to improve spray patterns, droplet formation, and overall efficiency in applications such as coating, cleaning, and agricultural spraying.

- Laminar flow in microfluidic and analytical devices: Implementation of laminar flow concepts in microfluidic devices and analytical instruments. This includes designs for lab-on-a-chip systems, flow cytometers, and other miniaturized fluid handling devices that rely on precise control of small fluid volumes.

02 Laminar flow in air distribution and ventilation

Techniques for creating and maintaining laminar airflow in ventilation systems, clean rooms, and air distribution units. This includes designs for air outlets, flow straighteners, and systems to reduce turbulence in air handling equipment.Expand Specific Solutions03 Laminar flow in fluid handling and processing

Applications of laminar flow principles in fluid handling equipment, including pumps, valves, and fluid processing systems. These innovations focus on maintaining laminar flow conditions to improve efficiency and reduce turbulence in fluid transport and processing.Expand Specific Solutions04 Laminar flow in manufacturing and material processing

Utilization of laminar flow techniques in manufacturing processes and material handling. This includes applications in coating systems, material deposition, and process control where maintaining laminar flow is critical for product quality and process efficiency.Expand Specific Solutions05 Laminar flow in microfluidic and analytical devices

Implementation of laminar flow principles in microfluidic devices and analytical instruments. These innovations focus on creating controlled laminar flow conditions in small-scale systems for applications in chemical analysis, biological research, and medical diagnostics.Expand Specific Solutions

Key Industry Players

The field of laminar flow's influence on next-generation material science is in a nascent stage of development, with significant potential for growth. The market size is expanding as industries recognize the importance of laminar flow in material design and manufacturing processes. While the technology is still evolving, several key players are driving innovation. Shanghai University and Xi'an Jiaotong University are conducting fundamental research, while companies like ASML Netherlands BV and Corning, Inc. are applying laminar flow principles to semiconductor and glass manufacturing. Government agencies such as the Naval Research Laboratory and the Agency for Science, Technology & Research are investing in research to advance the field. The technology's maturity varies across applications, with some areas showing promising results and others still in early experimental stages.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory (NRL) has been at the forefront of laminar flow research for next-generation material science. Their approach focuses on developing advanced materials with controlled surface properties to enhance laminar flow characteristics. NRL utilizes computational fluid dynamics (CFD) simulations to design and optimize surface structures at the micro and nanoscale[1]. They have successfully created hydrophobic coatings that reduce drag by up to 30% in marine environments[2]. Additionally, NRL is exploring the use of active flow control techniques, such as micro-electromechanical systems (MEMS), to dynamically adjust surface properties in response to changing flow conditions[3]. This adaptive approach allows for real-time optimization of laminar flow across various operational scenarios.

Strengths: Advanced simulation capabilities, expertise in surface engineering, and integration of active flow control. Weaknesses: High development costs and potential scalability issues for large-scale applications.

ASML Netherlands BV

Technical Solution: ASML, a leader in semiconductor lithography equipment, has been leveraging laminar flow principles in their next-generation material science applications. Their focus is on ultra-clean environments for semiconductor manufacturing. ASML has developed advanced laminar flow systems that maintain particle-free conditions in their lithography machines[4]. These systems use precisely controlled airflow to create a "curtain" of clean air around the wafer and optical components. ASML's latest EUV (Extreme Ultraviolet) lithography systems incorporate multi-zone laminar flow control, allowing for nanometer-scale precision in chip manufacturing[5]. They have also pioneered the use of computational fluid dynamics to optimize gas flow within the vacuum environment of EUV systems, ensuring stable thermal conditions and minimizing molecular contamination[6].

Strengths: Unparalleled expertise in clean room technology and nanoscale manufacturing environments. Weaknesses: Highly specialized applications may limit broader material science impact.

Core Innovations in Laminar Flow Research

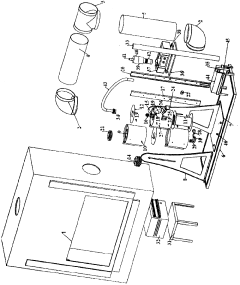

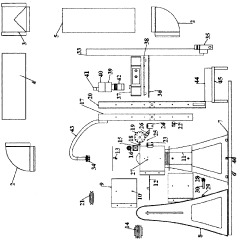

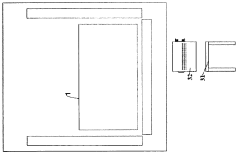

Device for generating laminar flow implemented in a tubular furnace.

PatentActiveMX2017015541A

Innovation

- A laminar flow emitter device is integrated into a tubular oven with a piezoelectric system operating at 0.8 MHz to generate aerosols, surrounded by four cylindrical ducts that maintain laminar flow and prevent turbulence, allowing for both horizontal and vertical orientations, with independently controlled gas flows to enhance aerosol delivery.

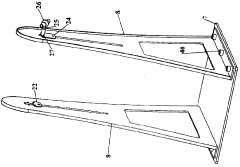

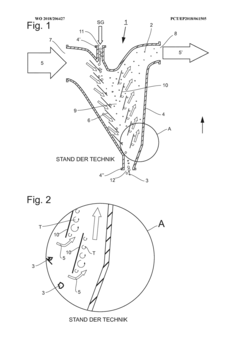

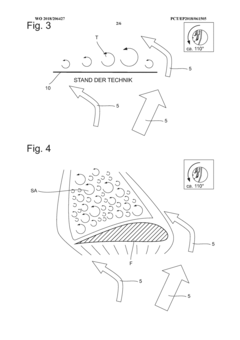

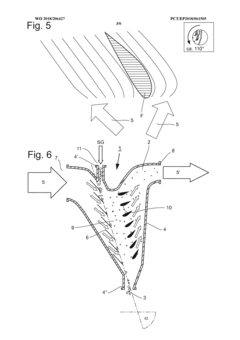

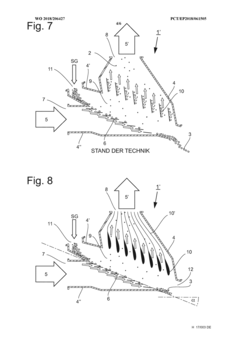

Separator having separating slats with wing profile

PatentWO2018206427A1

Innovation

- Designing the sifting streams with a wing profile to promote laminar flow, preventing the formation of turbulent zones and ensuring that smaller granules remain suspended in the classifying gas, thereby reducing energy consumption and wear on the classifier.

Environmental Impact Assessment

The environmental impact of laminar flow in next-generation material science is a critical consideration as this technology advances. Laminar flow, characterized by smooth and predictable fluid motion, has the potential to significantly reduce energy consumption in various industrial processes. This reduction in energy usage translates to lower greenhouse gas emissions, contributing to global efforts to combat climate change.

In material synthesis, laminar flow enables more precise control over reaction conditions, potentially leading to the development of more environmentally friendly materials. For instance, it can facilitate the creation of advanced composites with enhanced durability and lighter weight, which could find applications in automotive and aerospace industries, ultimately reducing fuel consumption and emissions.

However, the implementation of laminar flow technologies may require specialized equipment and infrastructure, which could initially increase resource consumption and waste generation during the transition phase. It is crucial to conduct comprehensive life cycle assessments to ensure that the long-term environmental benefits outweigh the short-term impacts of adoption.

Water conservation is another area where laminar flow can make a positive environmental impact. In water treatment processes, laminar flow can enhance the efficiency of filtration and separation techniques, potentially reducing the amount of chemicals needed and improving water quality. This has implications for both industrial wastewater treatment and potable water production, contributing to the preservation of water resources.

The influence of laminar flow on material science also extends to the development of novel surface coatings and treatments. These advancements can lead to the creation of self-cleaning surfaces or anti-fouling materials, reducing the need for harsh cleaning chemicals and extending the lifespan of various products. This, in turn, can decrease waste generation and the environmental footprint of maintenance activities.

In the realm of renewable energy, laminar flow principles are being applied to improve the efficiency of solar panels and wind turbines. By optimizing fluid dynamics around these structures, researchers aim to enhance energy capture and reduce wear, potentially increasing the viability and adoption of clean energy technologies.

As research in this field progresses, it is essential to consider potential negative environmental impacts, such as the use of rare or toxic materials in specialized equipment. Ongoing studies should focus on developing sustainable alternatives and ensuring that the benefits of laminar flow applications in material science do not come at the cost of environmental degradation in other areas.

In material synthesis, laminar flow enables more precise control over reaction conditions, potentially leading to the development of more environmentally friendly materials. For instance, it can facilitate the creation of advanced composites with enhanced durability and lighter weight, which could find applications in automotive and aerospace industries, ultimately reducing fuel consumption and emissions.

However, the implementation of laminar flow technologies may require specialized equipment and infrastructure, which could initially increase resource consumption and waste generation during the transition phase. It is crucial to conduct comprehensive life cycle assessments to ensure that the long-term environmental benefits outweigh the short-term impacts of adoption.

Water conservation is another area where laminar flow can make a positive environmental impact. In water treatment processes, laminar flow can enhance the efficiency of filtration and separation techniques, potentially reducing the amount of chemicals needed and improving water quality. This has implications for both industrial wastewater treatment and potable water production, contributing to the preservation of water resources.

The influence of laminar flow on material science also extends to the development of novel surface coatings and treatments. These advancements can lead to the creation of self-cleaning surfaces or anti-fouling materials, reducing the need for harsh cleaning chemicals and extending the lifespan of various products. This, in turn, can decrease waste generation and the environmental footprint of maintenance activities.

In the realm of renewable energy, laminar flow principles are being applied to improve the efficiency of solar panels and wind turbines. By optimizing fluid dynamics around these structures, researchers aim to enhance energy capture and reduce wear, potentially increasing the viability and adoption of clean energy technologies.

As research in this field progresses, it is essential to consider potential negative environmental impacts, such as the use of rare or toxic materials in specialized equipment. Ongoing studies should focus on developing sustainable alternatives and ensuring that the benefits of laminar flow applications in material science do not come at the cost of environmental degradation in other areas.

Regulatory Framework for Advanced Materials

The regulatory framework for advanced materials in the context of laminar flow's influence on next-generation material science is a complex and evolving landscape. As new materials and manufacturing processes emerge, regulatory bodies must adapt to ensure safety, quality, and environmental protection while fostering innovation.

At the international level, organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) play crucial roles in developing standards for advanced materials. These standards often incorporate considerations for laminar flow properties, as they can significantly impact material performance and safety.

National regulatory agencies, such as the U.S. Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA), have established frameworks for assessing and regulating new materials. The EPA's Toxic Substances Control Act (TSCA) and the EU's Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation are key examples. These frameworks often require manufacturers to provide detailed information on material properties, including those influenced by laminar flow, before market approval.

In the aerospace and automotive industries, where laminar flow characteristics are particularly critical, regulatory bodies like the Federal Aviation Administration (FAA) and the National Highway Traffic Safety Administration (NHTSA) have specific guidelines for material testing and certification. These guidelines often include requirements for assessing material behavior under various flow conditions.

The medical device industry also faces stringent regulations for advanced materials, with agencies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) overseeing approval processes. These agencies often require extensive testing of material properties, including those affected by laminar flow, to ensure patient safety.

As research in laminar flow's influence on material science progresses, regulatory frameworks are likely to evolve. There is a growing trend towards performance-based regulations, which focus on the end-result rather than prescriptive requirements. This approach allows for greater flexibility in material innovation while maintaining safety standards.

Regulatory bodies are also increasingly considering the entire lifecycle of advanced materials, from production to disposal. This holistic approach aims to address potential environmental and health impacts throughout the material's lifespan, including those related to laminar flow properties during use and degradation.

Collaboration between industry, academia, and regulatory agencies is becoming more common in developing appropriate frameworks for advanced materials. This collaborative approach helps ensure that regulations keep pace with technological advancements while addressing potential risks effectively.

At the international level, organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM) play crucial roles in developing standards for advanced materials. These standards often incorporate considerations for laminar flow properties, as they can significantly impact material performance and safety.

National regulatory agencies, such as the U.S. Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA), have established frameworks for assessing and regulating new materials. The EPA's Toxic Substances Control Act (TSCA) and the EU's Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation are key examples. These frameworks often require manufacturers to provide detailed information on material properties, including those influenced by laminar flow, before market approval.

In the aerospace and automotive industries, where laminar flow characteristics are particularly critical, regulatory bodies like the Federal Aviation Administration (FAA) and the National Highway Traffic Safety Administration (NHTSA) have specific guidelines for material testing and certification. These guidelines often include requirements for assessing material behavior under various flow conditions.

The medical device industry also faces stringent regulations for advanced materials, with agencies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) overseeing approval processes. These agencies often require extensive testing of material properties, including those affected by laminar flow, to ensure patient safety.

As research in laminar flow's influence on material science progresses, regulatory frameworks are likely to evolve. There is a growing trend towards performance-based regulations, which focus on the end-result rather than prescriptive requirements. This approach allows for greater flexibility in material innovation while maintaining safety standards.

Regulatory bodies are also increasingly considering the entire lifecycle of advanced materials, from production to disposal. This holistic approach aims to address potential environmental and health impacts throughout the material's lifespan, including those related to laminar flow properties during use and degradation.

Collaboration between industry, academia, and regulatory agencies is becoming more common in developing appropriate frameworks for advanced materials. This collaborative approach helps ensure that regulations keep pace with technological advancements while addressing potential risks effectively.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!