Laminar Flow Trends: Opportunities in the Energy Sector

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Evolution

Laminar flow, characterized by smooth and predictable fluid motion, has undergone significant evolution in the energy sector over the past decades. This progression has been driven by the increasing demand for energy efficiency and the need to optimize various processes within the industry.

In the early stages, laminar flow was primarily studied in the context of pipe flow and heat exchangers. The focus was on understanding the basic principles of fluid dynamics and heat transfer in laminar regimes. As research advanced, the application of laminar flow expanded to include more complex systems, such as oil and gas extraction, where precise control of fluid behavior became crucial for improving recovery rates.

The advent of computational fluid dynamics (CFD) in the 1970s and 1980s marked a significant milestone in laminar flow evolution. CFD simulations allowed engineers to model and predict laminar flow behavior with unprecedented accuracy, leading to more efficient designs in various energy applications. This technological leap facilitated the development of advanced heat exchangers, improved pipeline systems, and more effective cooling solutions for power plants.

In the renewable energy sector, laminar flow concepts have been instrumental in enhancing the performance of solar thermal systems. The design of solar collectors and heat transfer fluids has been optimized to maintain laminar flow conditions, maximizing energy capture and minimizing pumping power requirements. Similarly, in wind energy, understanding laminar flow around turbine blades has led to more aerodynamic designs, increasing overall energy output.

The oil and gas industry has seen significant advancements in laminar flow applications, particularly in enhanced oil recovery (EOR) techniques. The use of polymer flooding, which relies on maintaining laminar flow conditions in porous media, has become a key strategy for improving oil extraction efficiency. This approach has allowed for the recovery of previously inaccessible oil reserves, extending the lifespan of mature oil fields.

Recent years have witnessed a growing interest in microfluidics and nanofluidics, where laminar flow principles are applied at microscopic scales. These technologies have opened up new possibilities in areas such as fuel cells, micro-reactors for chemical processing, and advanced cooling systems for electronics in energy applications. The precise control of fluids at these scales has enabled more efficient energy conversion processes and novel approaches to energy storage.

As we look to the future, the evolution of laminar flow in the energy sector continues to be driven by the need for greater efficiency and sustainability. Emerging areas of research include the development of smart materials that can dynamically alter surface properties to maintain optimal laminar flow conditions, as well as the integration of artificial intelligence and machine learning to predict and control laminar flow in complex energy systems. These advancements promise to further optimize energy production, distribution, and utilization across various industries.

In the early stages, laminar flow was primarily studied in the context of pipe flow and heat exchangers. The focus was on understanding the basic principles of fluid dynamics and heat transfer in laminar regimes. As research advanced, the application of laminar flow expanded to include more complex systems, such as oil and gas extraction, where precise control of fluid behavior became crucial for improving recovery rates.

The advent of computational fluid dynamics (CFD) in the 1970s and 1980s marked a significant milestone in laminar flow evolution. CFD simulations allowed engineers to model and predict laminar flow behavior with unprecedented accuracy, leading to more efficient designs in various energy applications. This technological leap facilitated the development of advanced heat exchangers, improved pipeline systems, and more effective cooling solutions for power plants.

In the renewable energy sector, laminar flow concepts have been instrumental in enhancing the performance of solar thermal systems. The design of solar collectors and heat transfer fluids has been optimized to maintain laminar flow conditions, maximizing energy capture and minimizing pumping power requirements. Similarly, in wind energy, understanding laminar flow around turbine blades has led to more aerodynamic designs, increasing overall energy output.

The oil and gas industry has seen significant advancements in laminar flow applications, particularly in enhanced oil recovery (EOR) techniques. The use of polymer flooding, which relies on maintaining laminar flow conditions in porous media, has become a key strategy for improving oil extraction efficiency. This approach has allowed for the recovery of previously inaccessible oil reserves, extending the lifespan of mature oil fields.

Recent years have witnessed a growing interest in microfluidics and nanofluidics, where laminar flow principles are applied at microscopic scales. These technologies have opened up new possibilities in areas such as fuel cells, micro-reactors for chemical processing, and advanced cooling systems for electronics in energy applications. The precise control of fluids at these scales has enabled more efficient energy conversion processes and novel approaches to energy storage.

As we look to the future, the evolution of laminar flow in the energy sector continues to be driven by the need for greater efficiency and sustainability. Emerging areas of research include the development of smart materials that can dynamically alter surface properties to maintain optimal laminar flow conditions, as well as the integration of artificial intelligence and machine learning to predict and control laminar flow in complex energy systems. These advancements promise to further optimize energy production, distribution, and utilization across various industries.

Energy Sector Demand

The energy sector's demand for laminar flow technologies has been steadily increasing, driven by the need for more efficient and sustainable energy production and distribution systems. This growing interest stems from the potential of laminar flow to enhance various processes within the energy industry, particularly in areas such as oil and gas extraction, renewable energy generation, and energy storage systems.

In the oil and gas sector, laminar flow technologies are becoming increasingly crucial for improving extraction efficiency and reducing environmental impact. The industry is facing pressure to optimize production while minimizing resource waste and environmental footprint. Laminar flow applications in enhanced oil recovery techniques, such as polymer flooding and low-salinity water injection, have shown promising results in increasing oil recovery rates and extending the life of mature oil fields.

Renewable energy sectors, particularly wind and hydroelectric power generation, are also experiencing a surge in demand for laminar flow technologies. Wind turbine manufacturers are exploring laminar flow control techniques to enhance blade aerodynamics, potentially increasing energy output and reducing noise pollution. In hydroelectric power plants, optimizing water flow through turbines using laminar flow principles can lead to significant improvements in energy conversion efficiency.

The growing focus on energy storage solutions, especially in the context of grid stabilization for renewable energy integration, has created new opportunities for laminar flow applications. Flow batteries, which rely on the controlled movement of electrolytes, benefit from laminar flow designs to improve energy density and overall system efficiency. As the demand for large-scale energy storage continues to rise, the market for laminar flow technologies in this sector is expected to expand significantly.

Moreover, the increasing adoption of district heating and cooling systems in urban areas has opened up new avenues for laminar flow technologies. These systems require efficient heat transfer and fluid distribution, where laminar flow principles can be applied to optimize energy delivery and reduce losses in the distribution network.

The demand for laminar flow technologies in the energy sector is also being driven by stringent environmental regulations and the global push towards decarbonization. As energy companies strive to reduce their carbon footprint and improve overall operational efficiency, laminar flow solutions offer a pathway to achieve these goals by minimizing energy losses and optimizing resource utilization across various processes.

In conclusion, the energy sector's demand for laminar flow technologies is multifaceted and growing, spanning across traditional fossil fuel industries, renewable energy generation, energy storage, and distribution systems. This trend is expected to continue as the industry seeks innovative solutions to address the challenges of energy efficiency, sustainability, and environmental compliance.

In the oil and gas sector, laminar flow technologies are becoming increasingly crucial for improving extraction efficiency and reducing environmental impact. The industry is facing pressure to optimize production while minimizing resource waste and environmental footprint. Laminar flow applications in enhanced oil recovery techniques, such as polymer flooding and low-salinity water injection, have shown promising results in increasing oil recovery rates and extending the life of mature oil fields.

Renewable energy sectors, particularly wind and hydroelectric power generation, are also experiencing a surge in demand for laminar flow technologies. Wind turbine manufacturers are exploring laminar flow control techniques to enhance blade aerodynamics, potentially increasing energy output and reducing noise pollution. In hydroelectric power plants, optimizing water flow through turbines using laminar flow principles can lead to significant improvements in energy conversion efficiency.

The growing focus on energy storage solutions, especially in the context of grid stabilization for renewable energy integration, has created new opportunities for laminar flow applications. Flow batteries, which rely on the controlled movement of electrolytes, benefit from laminar flow designs to improve energy density and overall system efficiency. As the demand for large-scale energy storage continues to rise, the market for laminar flow technologies in this sector is expected to expand significantly.

Moreover, the increasing adoption of district heating and cooling systems in urban areas has opened up new avenues for laminar flow technologies. These systems require efficient heat transfer and fluid distribution, where laminar flow principles can be applied to optimize energy delivery and reduce losses in the distribution network.

The demand for laminar flow technologies in the energy sector is also being driven by stringent environmental regulations and the global push towards decarbonization. As energy companies strive to reduce their carbon footprint and improve overall operational efficiency, laminar flow solutions offer a pathway to achieve these goals by minimizing energy losses and optimizing resource utilization across various processes.

In conclusion, the energy sector's demand for laminar flow technologies is multifaceted and growing, spanning across traditional fossil fuel industries, renewable energy generation, energy storage, and distribution systems. This trend is expected to continue as the industry seeks innovative solutions to address the challenges of energy efficiency, sustainability, and environmental compliance.

Technical Challenges

Laminar flow technology in the energy sector faces several significant technical challenges that hinder its widespread adoption and optimal performance. One of the primary obstacles is maintaining laminar flow conditions in complex geometries and at varying scales. As energy systems often involve intricate designs and diverse operational environments, achieving consistent laminar flow becomes increasingly difficult.

The transition from laminar to turbulent flow remains a critical issue, particularly in applications where energy efficiency is paramount. Predicting and controlling this transition point accurately across different fluid types, temperatures, and pressure conditions poses a substantial challenge. This unpredictability can lead to unexpected energy losses and reduced system performance.

Another major hurdle is the development of advanced materials and surface treatments that can promote and sustain laminar flow. While progress has been made in creating hydrophobic and superhydrophobic surfaces, their long-term durability and cost-effectiveness in large-scale energy applications remain problematic. The need for materials that can withstand harsh operating conditions while maintaining their flow-enhancing properties is a significant area of ongoing research.

The integration of laminar flow technologies with existing energy infrastructure presents its own set of challenges. Retrofitting older systems to incorporate laminar flow principles often requires substantial modifications, which can be both technically complex and economically prohibitive. This integration challenge is particularly acute in the renewable energy sector, where optimizing fluid dynamics in wind turbines and hydroelectric systems could yield significant efficiency gains.

Measurement and monitoring of laminar flow in real-time operational settings is another technical obstacle. Current sensing technologies often struggle to provide accurate, non-intrusive measurements without disrupting the very flow conditions they aim to monitor. The development of advanced, miniaturized sensors capable of real-time flow characterization without interfering with the flow itself is crucial for the effective implementation of laminar flow technologies.

The computational modeling of laminar flow, especially in complex, multi-phase systems common in energy applications, remains a significant challenge. While computational fluid dynamics (CFD) has made great strides, accurately simulating laminar flow behavior in realistic energy systems still requires immense computational resources and often relies on simplifying assumptions that may not fully capture real-world conditions.

Lastly, the challenge of scaling laminar flow technologies from laboratory demonstrations to industrial-scale energy applications is considerable. Many promising laminar flow concepts that show potential in controlled, small-scale experiments face significant hurdles when scaled up to meet the demands of large-scale energy production and distribution systems. Overcoming these scaling challenges requires innovative engineering solutions and often necessitates rethinking entire system designs to fully leverage the benefits of laminar flow.

The transition from laminar to turbulent flow remains a critical issue, particularly in applications where energy efficiency is paramount. Predicting and controlling this transition point accurately across different fluid types, temperatures, and pressure conditions poses a substantial challenge. This unpredictability can lead to unexpected energy losses and reduced system performance.

Another major hurdle is the development of advanced materials and surface treatments that can promote and sustain laminar flow. While progress has been made in creating hydrophobic and superhydrophobic surfaces, their long-term durability and cost-effectiveness in large-scale energy applications remain problematic. The need for materials that can withstand harsh operating conditions while maintaining their flow-enhancing properties is a significant area of ongoing research.

The integration of laminar flow technologies with existing energy infrastructure presents its own set of challenges. Retrofitting older systems to incorporate laminar flow principles often requires substantial modifications, which can be both technically complex and economically prohibitive. This integration challenge is particularly acute in the renewable energy sector, where optimizing fluid dynamics in wind turbines and hydroelectric systems could yield significant efficiency gains.

Measurement and monitoring of laminar flow in real-time operational settings is another technical obstacle. Current sensing technologies often struggle to provide accurate, non-intrusive measurements without disrupting the very flow conditions they aim to monitor. The development of advanced, miniaturized sensors capable of real-time flow characterization without interfering with the flow itself is crucial for the effective implementation of laminar flow technologies.

The computational modeling of laminar flow, especially in complex, multi-phase systems common in energy applications, remains a significant challenge. While computational fluid dynamics (CFD) has made great strides, accurately simulating laminar flow behavior in realistic energy systems still requires immense computational resources and often relies on simplifying assumptions that may not fully capture real-world conditions.

Lastly, the challenge of scaling laminar flow technologies from laboratory demonstrations to industrial-scale energy applications is considerable. Many promising laminar flow concepts that show potential in controlled, small-scale experiments face significant hurdles when scaled up to meet the demands of large-scale energy production and distribution systems. Overcoming these scaling challenges requires innovative engineering solutions and often necessitates rethinking entire system designs to fully leverage the benefits of laminar flow.

Current Solutions

01 Laminar flow measurement and control systems

Various systems and methods for measuring and controlling laminar flow in different applications. These include optical systems for detecting flow characteristics, flow meters for precise measurements, and control mechanisms to maintain laminar flow conditions in diverse environments such as cleanrooms, fluid handling systems, and industrial processes.- Laminar flow measurement and control systems: Various systems and methods for measuring and controlling laminar flow in different applications. These include optical systems for detecting flow characteristics, flow control devices for maintaining laminar flow conditions, and sensors for monitoring flow parameters in real-time.

- Laminar flow in fluid handling devices: Designs and techniques for achieving laminar flow in fluid handling devices such as nozzles, valves, and pumps. This includes specialized geometries and flow path designs to promote smooth, non-turbulent fluid movement in various industrial and scientific applications.

- Laminar flow in aerodynamics and vehicle design: Applications of laminar flow principles in aerodynamics and vehicle design to reduce drag and improve efficiency. This includes surface treatments, shape optimizations, and flow control mechanisms for aircraft, automobiles, and other transportation vehicles.

- Laminar flow in environmental control systems: Utilization of laminar flow in environmental control systems for clean rooms, laboratories, and other controlled environments. This includes air handling units, filtration systems, and flow distribution designs to maintain sterile or particle-free conditions.

- Laminar flow in microfluidic and analytical devices: Implementation of laminar flow principles in microfluidic devices and analytical instruments for precise fluid control and manipulation. This includes lab-on-a-chip devices, flow cytometers, and other miniaturized systems for chemical and biological analysis.

02 Laminar flow in fluid delivery and spray systems

Innovations in fluid delivery and spray systems that utilize laminar flow principles to improve efficiency and performance. This includes nozzle designs, flow regulators, and spray pattern control mechanisms that maintain laminar flow characteristics for applications in agriculture, manufacturing, and consumer products.Expand Specific Solutions03 Laminar flow in air handling and ventilation systems

Advancements in air handling and ventilation systems that leverage laminar flow principles to enhance air quality, reduce turbulence, and improve energy efficiency. These innovations are applied in cleanrooms, HVAC systems, and specialized environments requiring precise air flow control.Expand Specific Solutions04 Laminar flow in fluid separation and filtration processes

Applications of laminar flow principles in fluid separation and filtration processes, including chromatography, membrane filtration, and particle separation. These technologies utilize laminar flow characteristics to improve separation efficiency, reduce contamination, and enhance overall process performance in various industries.Expand Specific Solutions05 Laminar flow in microfluidic and lab-on-a-chip devices

Utilization of laminar flow principles in the design and operation of microfluidic devices and lab-on-a-chip systems. These innovations enable precise control of fluid behavior at microscale levels, facilitating applications in biomedical research, diagnostics, and chemical analysis with improved accuracy and efficiency.Expand Specific Solutions

Industry Leaders

The laminar flow technology in the energy sector is currently in a growth phase, with increasing market size and evolving technological maturity. The competitive landscape is characterized by a mix of established players and innovative startups, each contributing to the advancement of laminar flow applications. Companies like Alfa Laval Corporate AB and Hayward Industries, Inc. are leveraging their expertise in fluid handling and flow control to develop more efficient laminar flow solutions. Meanwhile, research institutions such as the China Electric Power Research Institute Ltd. and Mitsubishi Electric Research Laboratories are pushing the boundaries of laminar flow technology, focusing on its potential in energy efficiency and renewable energy systems. As the market expands, we can expect to see more collaborations between industry leaders and research organizations to accelerate technological progress and commercial adoption.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has pioneered laminar flow solutions in heat exchangers and fluid handling systems for the energy sector. Their technology focuses on optimizing flow distribution and minimizing pressure drop in compact heat exchangers. Alfa Laval's patented AlfaNova fusion-bonded plate heat exchangers utilize a unique channel design that promotes laminar flow, enhancing heat transfer efficiency by up to 25% compared to traditional designs[4]. The company has also developed advanced computational models to predict and optimize laminar flow patterns in various energy applications, including renewable energy systems[5]. Their laminar flow technologies have been successfully applied in geothermal power plants and waste heat recovery systems, significantly improving overall system efficiency[6].

Strengths: Diverse application range across energy sectors, strong focus on sustainability, and proven track record in heat transfer technologies. Weaknesses: May face competition from specialized renewable energy technology providers.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has invested heavily in laminar flow research for power transmission and distribution systems. Their focus is on improving the efficiency of power transformers and cooling systems through advanced laminar flow designs. State Grid has developed innovative transformer oil circulation systems that maintain laminar flow conditions, reducing energy losses and extending equipment lifespan[10]. The company has also implemented laminar flow principles in the design of high-voltage direct current (HVDC) transmission systems, optimizing conductor cooling and increasing power transmission capacity[11]. State Grid's research extends to laminar flow applications in renewable energy integration, particularly in the cooling systems of large-scale solar inverters and wind turbine generators[12].

Strengths: Extensive power grid infrastructure, significant R&D resources, and ability to implement technologies at a massive scale. Weaknesses: Potential bureaucratic challenges in rapid technology adoption, and focus primarily on electrical power systems may limit application in other energy sectors.

Key Innovations

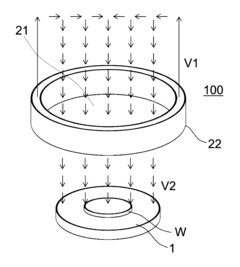

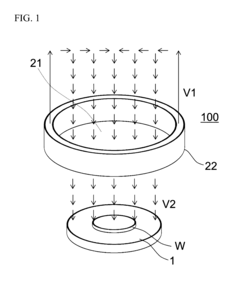

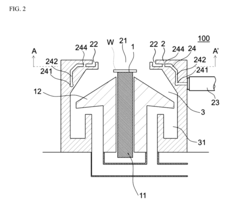

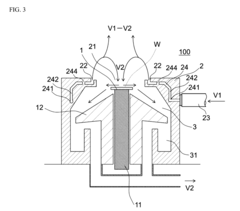

Columnar laminar flow generation device and method for generating columnar laminar flows

PatentActiveUS20170072438A1

Innovation

- A columnar laminar flow generation device that focuses gas blow-out and suction within a localized columnar area, allowing for adjustable flow velocity and reduced gas usage by positioning a gas blow-out port vertically within an opening and a corresponding suction path, thereby generating laminar flows only where needed, with a feed pipe filter for purification.

Laminar mixing apparatus and methods

PatentInactiveEP1412065A2

Innovation

- The use of microfluidic channels with strategically designed grooves or protrusions oriented at angles relative to the principal flow direction creates a transverse or helical flow component, enhancing mixing by increasing the effective diffusion area and promoting chaotic flows, even at low Reynolds numbers.

Environmental Impact

The adoption of laminar flow technologies in the energy sector presents significant environmental implications that warrant careful consideration. One of the primary benefits is the potential for substantial energy savings across various applications. By reducing turbulence and promoting smoother fluid flow, laminar flow systems can significantly decrease energy consumption in pumping and transportation processes. This reduction in energy usage directly translates to lower greenhouse gas emissions, contributing to global efforts to mitigate climate change.

In the context of renewable energy, laminar flow principles are being applied to improve the efficiency of wind turbines. By optimizing blade designs to maintain laminar flow over larger surface areas, wind turbines can capture more energy from the wind while reducing noise pollution. This not only enhances the environmental sustainability of wind energy but also addresses concerns about the impact of wind farms on local ecosystems and communities.

The oil and gas industry, traditionally associated with significant environmental challenges, is also benefiting from laminar flow technologies. In pipeline operations, maintaining laminar flow conditions can reduce friction losses, leading to decreased energy requirements for fluid transport. This optimization not only improves operational efficiency but also minimizes the risk of leaks and spills, thereby reducing potential environmental contamination.

In water treatment and desalination processes, laminar flow principles are being leveraged to enhance membrane filtration technologies. By ensuring stable, laminar flow conditions across membrane surfaces, these systems can achieve higher filtration efficiencies with lower energy inputs. This advancement is particularly crucial in addressing global water scarcity issues, offering more sustainable solutions for clean water production.

However, the environmental benefits of laminar flow technologies must be balanced against potential drawbacks. The manufacturing and implementation of specialized equipment designed to maintain laminar flow conditions may involve energy-intensive processes and materials. A comprehensive life cycle assessment is necessary to ensure that the environmental gains from operational efficiencies outweigh the impacts of production and installation.

Moreover, in some natural ecosystems, the introduction of artificial laminar flow conditions could disrupt natural turbulent flows that are essential for nutrient distribution and aquatic life. Therefore, careful ecological studies must accompany the implementation of laminar flow technologies in sensitive environmental areas to prevent unintended consequences on biodiversity and ecosystem health.

In the context of renewable energy, laminar flow principles are being applied to improve the efficiency of wind turbines. By optimizing blade designs to maintain laminar flow over larger surface areas, wind turbines can capture more energy from the wind while reducing noise pollution. This not only enhances the environmental sustainability of wind energy but also addresses concerns about the impact of wind farms on local ecosystems and communities.

The oil and gas industry, traditionally associated with significant environmental challenges, is also benefiting from laminar flow technologies. In pipeline operations, maintaining laminar flow conditions can reduce friction losses, leading to decreased energy requirements for fluid transport. This optimization not only improves operational efficiency but also minimizes the risk of leaks and spills, thereby reducing potential environmental contamination.

In water treatment and desalination processes, laminar flow principles are being leveraged to enhance membrane filtration technologies. By ensuring stable, laminar flow conditions across membrane surfaces, these systems can achieve higher filtration efficiencies with lower energy inputs. This advancement is particularly crucial in addressing global water scarcity issues, offering more sustainable solutions for clean water production.

However, the environmental benefits of laminar flow technologies must be balanced against potential drawbacks. The manufacturing and implementation of specialized equipment designed to maintain laminar flow conditions may involve energy-intensive processes and materials. A comprehensive life cycle assessment is necessary to ensure that the environmental gains from operational efficiencies outweigh the impacts of production and installation.

Moreover, in some natural ecosystems, the introduction of artificial laminar flow conditions could disrupt natural turbulent flows that are essential for nutrient distribution and aquatic life. Therefore, careful ecological studies must accompany the implementation of laminar flow technologies in sensitive environmental areas to prevent unintended consequences on biodiversity and ecosystem health.

Economic Implications

The economic implications of laminar flow trends in the energy sector are far-reaching and multifaceted. As this technology continues to evolve, it presents significant opportunities for cost reduction and efficiency improvements across various energy applications.

In the oil and gas industry, laminar flow technologies can lead to substantial savings in pipeline operations. By optimizing fluid dynamics, companies can reduce pumping costs and minimize energy losses due to friction. This translates to lower operational expenses and improved profit margins for energy companies. Additionally, the enhanced flow control can extend the lifespan of pipeline infrastructure, reducing long-term capital expenditures.

For renewable energy sectors, particularly in wind and hydroelectric power generation, advancements in laminar flow research can boost overall system efficiency. Wind turbine designs incorporating laminar flow principles can increase energy capture, potentially lowering the levelized cost of electricity (LCOE) for wind farms. Similarly, in hydroelectric systems, optimized flow patterns can improve turbine performance, leading to higher power output and increased revenue generation.

The adoption of laminar flow technologies in the energy sector also has broader economic implications for related industries. Manufacturers of fluid handling equipment, such as pumps and valves, may see increased demand for products designed to maintain laminar flow conditions. This could stimulate growth in the manufacturing sector and create new job opportunities in research, development, and production.

Furthermore, the energy savings achieved through laminar flow applications can contribute to national and global efforts to reduce carbon emissions. As countries implement stricter environmental regulations and carbon pricing mechanisms, energy companies leveraging laminar flow technologies may gain a competitive advantage. This could reshape market dynamics and influence investment patterns in the energy sector.

The economic benefits of laminar flow trends extend to end-users as well. Improved energy efficiency in production and transportation can lead to more stable energy prices for consumers. In industrial processes, the application of laminar flow principles can result in higher product quality and reduced waste, enhancing overall economic productivity.

As research in laminar flow continues to advance, it is likely to spur innovation in adjacent fields, such as materials science and computational fluid dynamics. This cross-pollination of ideas and technologies can create new economic opportunities and potentially lead to the emergence of entirely new industries or business models within the energy sector.

In the oil and gas industry, laminar flow technologies can lead to substantial savings in pipeline operations. By optimizing fluid dynamics, companies can reduce pumping costs and minimize energy losses due to friction. This translates to lower operational expenses and improved profit margins for energy companies. Additionally, the enhanced flow control can extend the lifespan of pipeline infrastructure, reducing long-term capital expenditures.

For renewable energy sectors, particularly in wind and hydroelectric power generation, advancements in laminar flow research can boost overall system efficiency. Wind turbine designs incorporating laminar flow principles can increase energy capture, potentially lowering the levelized cost of electricity (LCOE) for wind farms. Similarly, in hydroelectric systems, optimized flow patterns can improve turbine performance, leading to higher power output and increased revenue generation.

The adoption of laminar flow technologies in the energy sector also has broader economic implications for related industries. Manufacturers of fluid handling equipment, such as pumps and valves, may see increased demand for products designed to maintain laminar flow conditions. This could stimulate growth in the manufacturing sector and create new job opportunities in research, development, and production.

Furthermore, the energy savings achieved through laminar flow applications can contribute to national and global efforts to reduce carbon emissions. As countries implement stricter environmental regulations and carbon pricing mechanisms, energy companies leveraging laminar flow technologies may gain a competitive advantage. This could reshape market dynamics and influence investment patterns in the energy sector.

The economic benefits of laminar flow trends extend to end-users as well. Improved energy efficiency in production and transportation can lead to more stable energy prices for consumers. In industrial processes, the application of laminar flow principles can result in higher product quality and reduced waste, enhancing overall economic productivity.

As research in laminar flow continues to advance, it is likely to spur innovation in adjacent fields, such as materials science and computational fluid dynamics. This cross-pollination of ideas and technologies can create new economic opportunities and potentially lead to the emergence of entirely new industries or business models within the energy sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!