Insights into Laminar Flow and Thermal Management

JUL 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Fundamentals and Objectives

Laminar flow, a fundamental concept in fluid dynamics, is characterized by smooth, predictable fluid motion with parallel layers sliding past one another without mixing. This phenomenon plays a crucial role in various engineering applications, particularly in thermal management systems. The study of laminar flow has evolved significantly since its initial description by Osborne Reynolds in the late 19th century, with advancements in computational fluid dynamics and experimental techniques enhancing our understanding of its behavior and applications.

The primary objective in exploring laminar flow within the context of thermal management is to optimize heat transfer processes while minimizing energy consumption. By leveraging the predictable nature of laminar flow, engineers can design more efficient cooling systems for electronic devices, industrial processes, and renewable energy technologies. This approach is particularly relevant in an era where energy efficiency and sustainable practices are paramount.

Recent technological trends have pushed the boundaries of laminar flow applications, especially in microfluidics and nanofluidics. These fields exploit laminar flow characteristics to achieve precise control over fluid behavior at microscopic scales, enabling innovations in lab-on-a-chip devices, targeted drug delivery systems, and advanced heat exchangers. The integration of laminar flow principles with emerging materials and fabrication techniques has opened new avenues for thermal management solutions in compact and high-performance systems.

One of the key challenges in harnessing laminar flow for thermal management lies in maintaining flow stability under varying conditions. As systems become more complex and miniaturized, the transition from laminar to turbulent flow becomes a critical consideration. Researchers are actively exploring methods to extend the laminar flow regime and develop novel geometries that promote heat transfer while preserving laminar characteristics.

The intersection of laminar flow studies with advanced computational modeling has significantly accelerated progress in this field. High-fidelity simulations now allow for the optimization of flow channels and heat exchanger designs before physical prototyping, reducing development time and costs. These computational tools are increasingly incorporating machine learning algorithms to predict flow behavior and thermal performance under a wide range of operating conditions.

As we look towards future developments, the objectives for laminar flow in thermal management are multifaceted. They include enhancing heat transfer coefficients without inducing turbulence, developing adaptive flow control mechanisms for variable heat loads, and integrating smart materials that can modify flow characteristics in response to thermal demands. Additionally, there is a growing focus on bio-inspired designs that mimic natural laminar flow systems, such as the circulatory systems of plants and animals, to create more efficient and resilient thermal management solutions.

The primary objective in exploring laminar flow within the context of thermal management is to optimize heat transfer processes while minimizing energy consumption. By leveraging the predictable nature of laminar flow, engineers can design more efficient cooling systems for electronic devices, industrial processes, and renewable energy technologies. This approach is particularly relevant in an era where energy efficiency and sustainable practices are paramount.

Recent technological trends have pushed the boundaries of laminar flow applications, especially in microfluidics and nanofluidics. These fields exploit laminar flow characteristics to achieve precise control over fluid behavior at microscopic scales, enabling innovations in lab-on-a-chip devices, targeted drug delivery systems, and advanced heat exchangers. The integration of laminar flow principles with emerging materials and fabrication techniques has opened new avenues for thermal management solutions in compact and high-performance systems.

One of the key challenges in harnessing laminar flow for thermal management lies in maintaining flow stability under varying conditions. As systems become more complex and miniaturized, the transition from laminar to turbulent flow becomes a critical consideration. Researchers are actively exploring methods to extend the laminar flow regime and develop novel geometries that promote heat transfer while preserving laminar characteristics.

The intersection of laminar flow studies with advanced computational modeling has significantly accelerated progress in this field. High-fidelity simulations now allow for the optimization of flow channels and heat exchanger designs before physical prototyping, reducing development time and costs. These computational tools are increasingly incorporating machine learning algorithms to predict flow behavior and thermal performance under a wide range of operating conditions.

As we look towards future developments, the objectives for laminar flow in thermal management are multifaceted. They include enhancing heat transfer coefficients without inducing turbulence, developing adaptive flow control mechanisms for variable heat loads, and integrating smart materials that can modify flow characteristics in response to thermal demands. Additionally, there is a growing focus on bio-inspired designs that mimic natural laminar flow systems, such as the circulatory systems of plants and animals, to create more efficient and resilient thermal management solutions.

Market Demand Analysis for Thermal Management Solutions

The thermal management solutions market is experiencing significant growth driven by the increasing demand for efficient heat dissipation in various industries. As electronic devices become more compact and powerful, the need for effective thermal management solutions has become paramount. The market is primarily fueled by the rapid expansion of data centers, the automotive sector's shift towards electric vehicles, and the continuous advancement of consumer electronics.

In the data center industry, the rising adoption of cloud computing and the proliferation of big data analytics have led to a surge in high-performance computing systems. These systems generate substantial heat, necessitating advanced thermal management solutions to maintain optimal operating conditions and prevent equipment failure. The market for data center cooling solutions is expected to grow steadily as companies invest in expanding their digital infrastructure.

The automotive sector, particularly the electric vehicle (EV) segment, represents another major driver for thermal management solutions. As EVs gain popularity, the demand for efficient battery thermal management systems has increased dramatically. These systems are crucial for maintaining battery performance, extending battery life, and ensuring passenger safety. The growing emphasis on fast charging technologies further amplifies the need for advanced thermal management in EVs.

Consumer electronics continue to be a significant market for thermal management solutions. With the trend towards thinner, more powerful devices, manufacturers face challenges in managing heat dissipation within limited spaces. This has led to increased demand for innovative cooling solutions, such as advanced heat spreaders, thermal interface materials, and miniaturized cooling systems.

The industrial sector also contributes substantially to the market demand for thermal management solutions. As manufacturing processes become more automated and rely heavily on electronic systems, the need for effective cooling solutions in industrial environments has grown. This includes applications in robotics, process control systems, and industrial IoT devices.

Emerging technologies such as 5G infrastructure and artificial intelligence (AI) hardware are creating new opportunities for thermal management solution providers. The deployment of 5G networks requires high-performance computing equipment that generates significant heat, while AI accelerators and specialized chips demand efficient cooling to maintain performance and reliability.

Geographically, the Asia-Pacific region is expected to witness the highest growth in demand for thermal management solutions, driven by the rapid industrialization, expanding electronics manufacturing sector, and increasing adoption of EVs in countries like China and India. North America and Europe also remain significant markets, particularly in sectors such as data centers, aerospace, and high-end consumer electronics.

In the data center industry, the rising adoption of cloud computing and the proliferation of big data analytics have led to a surge in high-performance computing systems. These systems generate substantial heat, necessitating advanced thermal management solutions to maintain optimal operating conditions and prevent equipment failure. The market for data center cooling solutions is expected to grow steadily as companies invest in expanding their digital infrastructure.

The automotive sector, particularly the electric vehicle (EV) segment, represents another major driver for thermal management solutions. As EVs gain popularity, the demand for efficient battery thermal management systems has increased dramatically. These systems are crucial for maintaining battery performance, extending battery life, and ensuring passenger safety. The growing emphasis on fast charging technologies further amplifies the need for advanced thermal management in EVs.

Consumer electronics continue to be a significant market for thermal management solutions. With the trend towards thinner, more powerful devices, manufacturers face challenges in managing heat dissipation within limited spaces. This has led to increased demand for innovative cooling solutions, such as advanced heat spreaders, thermal interface materials, and miniaturized cooling systems.

The industrial sector also contributes substantially to the market demand for thermal management solutions. As manufacturing processes become more automated and rely heavily on electronic systems, the need for effective cooling solutions in industrial environments has grown. This includes applications in robotics, process control systems, and industrial IoT devices.

Emerging technologies such as 5G infrastructure and artificial intelligence (AI) hardware are creating new opportunities for thermal management solution providers. The deployment of 5G networks requires high-performance computing equipment that generates significant heat, while AI accelerators and specialized chips demand efficient cooling to maintain performance and reliability.

Geographically, the Asia-Pacific region is expected to witness the highest growth in demand for thermal management solutions, driven by the rapid industrialization, expanding electronics manufacturing sector, and increasing adoption of EVs in countries like China and India. North America and Europe also remain significant markets, particularly in sectors such as data centers, aerospace, and high-end consumer electronics.

Current Challenges in Laminar Flow Control

Laminar flow control (LFC) remains a critical challenge in fluid dynamics and thermal management, with significant implications for various industries. Despite decades of research and development, several obstacles persist in achieving efficient and reliable laminar flow control systems.

One of the primary challenges is maintaining laminar flow over extended surfaces, particularly in aerospace applications. As the flow progresses along an aircraft's wing or fuselage, small disturbances can trigger a transition to turbulent flow, increasing drag and reducing overall efficiency. Developing robust methods to delay this transition and extend the laminar flow region is an ongoing area of research.

Another significant hurdle is the integration of LFC systems with existing structures and materials. Many LFC techniques require modifications to surface geometries or the incorporation of active control mechanisms, which can be challenging to implement without compromising structural integrity or adding excessive weight. This is particularly problematic in weight-sensitive applications such as aircraft design.

The complexity of real-world flow conditions poses another challenge. Laboratory experiments and computational simulations often struggle to accurately represent the full range of environmental factors that affect laminar flow in practical applications. Factors such as atmospheric turbulence, surface imperfections, and varying pressure gradients can significantly impact the effectiveness of LFC systems.

Energy efficiency remains a concern for active LFC methods. Techniques such as suction or blowing require power input, which must be carefully balanced against the potential drag reduction benefits. Developing more energy-efficient active control systems or improving passive LFC methods is crucial for widespread adoption.

Manufacturing precision presents another obstacle. Many LFC techniques rely on extremely smooth surfaces or precisely engineered microstructures. Achieving and maintaining the required level of surface quality in large-scale production can be technically challenging and economically prohibitive.

The interaction between LFC systems and other aircraft systems, such as de-icing mechanisms or noise reduction technologies, introduces additional complexities. Ensuring that these various systems work harmoniously without compromising each other's performance is a multifaceted engineering challenge.

Lastly, the validation and certification of LFC systems for safety-critical applications, such as commercial aviation, remains a time-consuming and costly process. Demonstrating long-term reliability and performance under a wide range of operating conditions is essential but challenging, particularly given the subtle nature of laminar flow phenomena.

One of the primary challenges is maintaining laminar flow over extended surfaces, particularly in aerospace applications. As the flow progresses along an aircraft's wing or fuselage, small disturbances can trigger a transition to turbulent flow, increasing drag and reducing overall efficiency. Developing robust methods to delay this transition and extend the laminar flow region is an ongoing area of research.

Another significant hurdle is the integration of LFC systems with existing structures and materials. Many LFC techniques require modifications to surface geometries or the incorporation of active control mechanisms, which can be challenging to implement without compromising structural integrity or adding excessive weight. This is particularly problematic in weight-sensitive applications such as aircraft design.

The complexity of real-world flow conditions poses another challenge. Laboratory experiments and computational simulations often struggle to accurately represent the full range of environmental factors that affect laminar flow in practical applications. Factors such as atmospheric turbulence, surface imperfections, and varying pressure gradients can significantly impact the effectiveness of LFC systems.

Energy efficiency remains a concern for active LFC methods. Techniques such as suction or blowing require power input, which must be carefully balanced against the potential drag reduction benefits. Developing more energy-efficient active control systems or improving passive LFC methods is crucial for widespread adoption.

Manufacturing precision presents another obstacle. Many LFC techniques rely on extremely smooth surfaces or precisely engineered microstructures. Achieving and maintaining the required level of surface quality in large-scale production can be technically challenging and economically prohibitive.

The interaction between LFC systems and other aircraft systems, such as de-icing mechanisms or noise reduction technologies, introduces additional complexities. Ensuring that these various systems work harmoniously without compromising each other's performance is a multifaceted engineering challenge.

Lastly, the validation and certification of LFC systems for safety-critical applications, such as commercial aviation, remains a time-consuming and costly process. Demonstrating long-term reliability and performance under a wide range of operating conditions is essential but challenging, particularly given the subtle nature of laminar flow phenomena.

Existing Laminar Flow Control Techniques

01 Laminar flow cooling systems for electronic devices

Laminar flow cooling systems are designed to efficiently manage thermal issues in electronic devices. These systems utilize controlled airflow to create a laminar boundary layer over heat-generating components, enhancing heat dissipation. The design often incorporates specialized ducts, fans, and heat sinks to optimize cooling performance while minimizing turbulence and noise.- Laminar flow cooling systems for electronic devices: Laminar flow cooling systems are designed to efficiently manage thermal issues in electronic devices. These systems utilize controlled airflow to create a laminar flow pattern, which helps in dissipating heat more effectively from components. The design often includes strategically placed vents and channels to guide the airflow across heat-generating elements, ensuring optimal cooling performance.

- Thermal management in fluid handling systems: Laminar flow principles are applied in fluid handling systems to enhance thermal management. This approach involves designing flow paths and structures that maintain laminar flow characteristics, reducing turbulence and improving heat transfer efficiency. Such systems are particularly useful in applications where precise temperature control of fluids is crucial, such as in chemical processing or medical equipment.

- Laminar flow heat exchangers: Heat exchangers utilizing laminar flow principles are developed to maximize thermal transfer efficiency. These devices are designed to maintain laminar flow conditions, which allows for more predictable and controllable heat exchange processes. The laminar flow design helps in reducing pressure drops and improving overall system performance, making them suitable for various industrial and HVAC applications.

- Thermal management in aerospace applications: Laminar flow thermal management techniques are crucial in aerospace applications. These systems are designed to handle the extreme temperature variations encountered during flight. The use of laminar flow principles helps in creating more efficient cooling systems for aircraft components, engines, and electronic systems, contributing to improved performance and reliability in aerospace vehicles.

- Microfluidic thermal management systems: Microfluidic devices leverage laminar flow characteristics for precise thermal management at small scales. These systems are designed to control heat transfer in miniaturized environments, such as lab-on-a-chip devices or microelectronic cooling. The laminar flow in microchannels allows for efficient heat dissipation and temperature control, crucial for the performance of micro-scale devices and processes.

02 Laminar flow thermal management in fluid systems

This approach focuses on maintaining laminar flow conditions in fluid-based thermal management systems. It involves careful design of fluid channels, flow rates, and heat exchanger surfaces to ensure smooth, non-turbulent flow. This method is particularly effective in applications requiring precise temperature control and efficient heat transfer, such as in industrial processes or advanced cooling systems.Expand Specific Solutions03 Laminar flow control for aerospace applications

Laminar flow control techniques are applied in aerospace engineering to reduce drag and improve thermal management on aircraft surfaces. This involves designing surfaces and implementing systems that maintain laminar airflow over wings and other critical areas. Such systems can include suction or blowing mechanisms to control the boundary layer, resulting in improved aerodynamic efficiency and heat distribution.Expand Specific Solutions04 Microfluidic devices utilizing laminar flow for thermal control

Microfluidic devices leverage laminar flow properties for precise thermal management in small-scale applications. These devices use carefully designed channels and flow patterns to control heat transfer at the microscale level. Applications include lab-on-a-chip devices, miniaturized cooling systems for electronics, and biomedical devices requiring accurate temperature regulation.Expand Specific Solutions05 Laminar flow heat exchangers for industrial processes

Laminar flow heat exchangers are designed for efficient thermal management in industrial processes. These systems optimize heat transfer by maintaining laminar flow conditions, reducing fouling and improving overall efficiency. They are particularly useful in applications requiring gentle handling of sensitive fluids or where turbulence must be minimized to maintain product quality or process stability.Expand Specific Solutions

Key Players in Thermal Management Industry

The field of laminar flow and thermal management is in a mature stage of development, with ongoing research and innovation driving incremental improvements. The market size is substantial, given its critical applications in various industries, including aerospace, automotive, and electronics. The technology's maturity is evident from the involvement of established players like Airbus Operations GmbH, GM Global Technology Operations LLC, and ASML Holding NV, which are leveraging laminar flow principles for enhanced thermal management in their respective domains. Universities such as Northeastern University and the University of Maryland are contributing to advancing the fundamental understanding and applications of this technology, indicating a healthy ecosystem of academic and industrial collaboration.

Airbus Operations GmbH

Technical Solution: Airbus Operations GmbH has developed advanced laminar flow control technologies for aircraft, focusing on Natural Laminar Flow (NLF) and Hybrid Laminar Flow Control (HLFC) systems. Their approach involves optimizing wing design to maintain laminar flow over larger portions of the wing surface, reducing drag by up to 10% [1]. For thermal management, they've implemented innovative heat exchanger designs in their aircraft, utilizing composite materials to enhance heat transfer efficiency while reducing weight. Their systems integrate sensors and adaptive control algorithms to optimize airflow and heat dissipation in real-time, improving overall aircraft performance and fuel efficiency [2].

Strengths: Cutting-edge aerodynamics expertise, extensive testing capabilities, and integration with aircraft systems. Weaknesses: High development costs and complexity in implementing laminar flow technologies across diverse aircraft models.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced thermal management systems for electric vehicles, focusing on battery cooling and cabin climate control. Their approach includes a patented battery cooling system that uses a refrigerant-based cooling circuit, allowing for rapid temperature reduction and more efficient heat dissipation [3]. For laminar flow, GM has implemented active grille shutters and underbody panels to optimize airflow around vehicles, reducing drag and improving fuel efficiency. Their thermal management strategy also incorporates heat pump technology for cabin heating, which is up to 300% more efficient than resistive heating in cold climates [4]. GM's systems use intelligent control algorithms to balance performance, efficiency, and comfort across various driving conditions.

Strengths: Integrated approach to vehicle thermal management, extensive experience in EV systems. Weaknesses: Complexity in balancing multiple thermal demands in electric vehicles, potential high costs for advanced cooling systems.

Innovative Approaches in Thermal Management

Laminar flow in carbon dioxide based chromatography

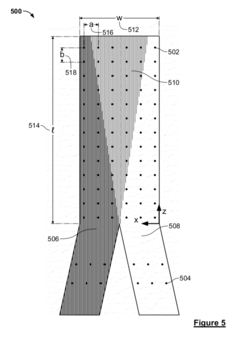

PatentWO2018203231A1

Innovation

- A method and system for developing laminar flow conditions in carbon dioxide based chromatography systems, involving the use of a pump, column, detector, and back pressure regulator connected by tubing, with temperature control mechanisms to maintain laminar flow by determining and adjusting the mobile phase composition, temperature, and flow rate based on laminar flow condition charts.

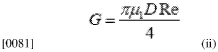

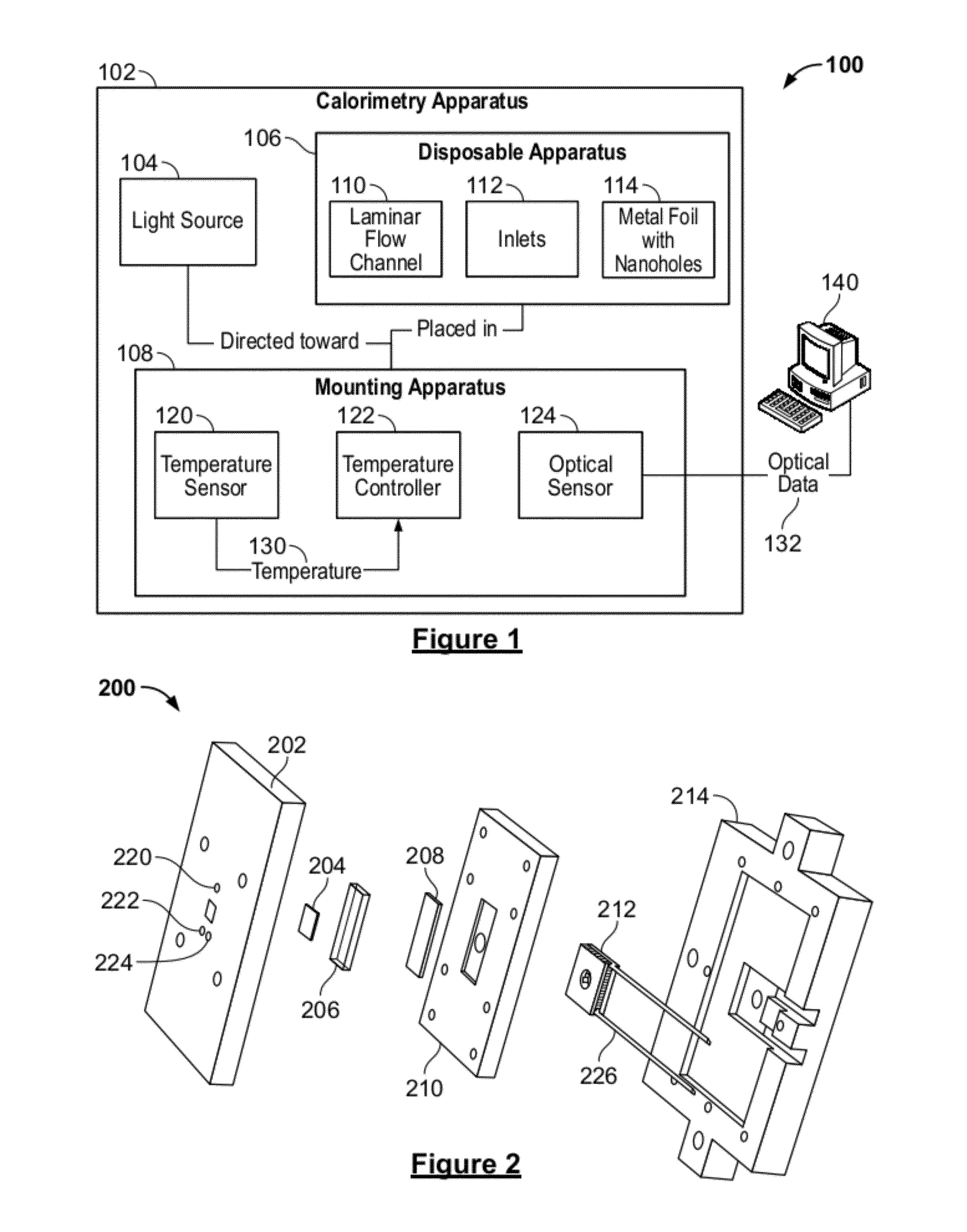

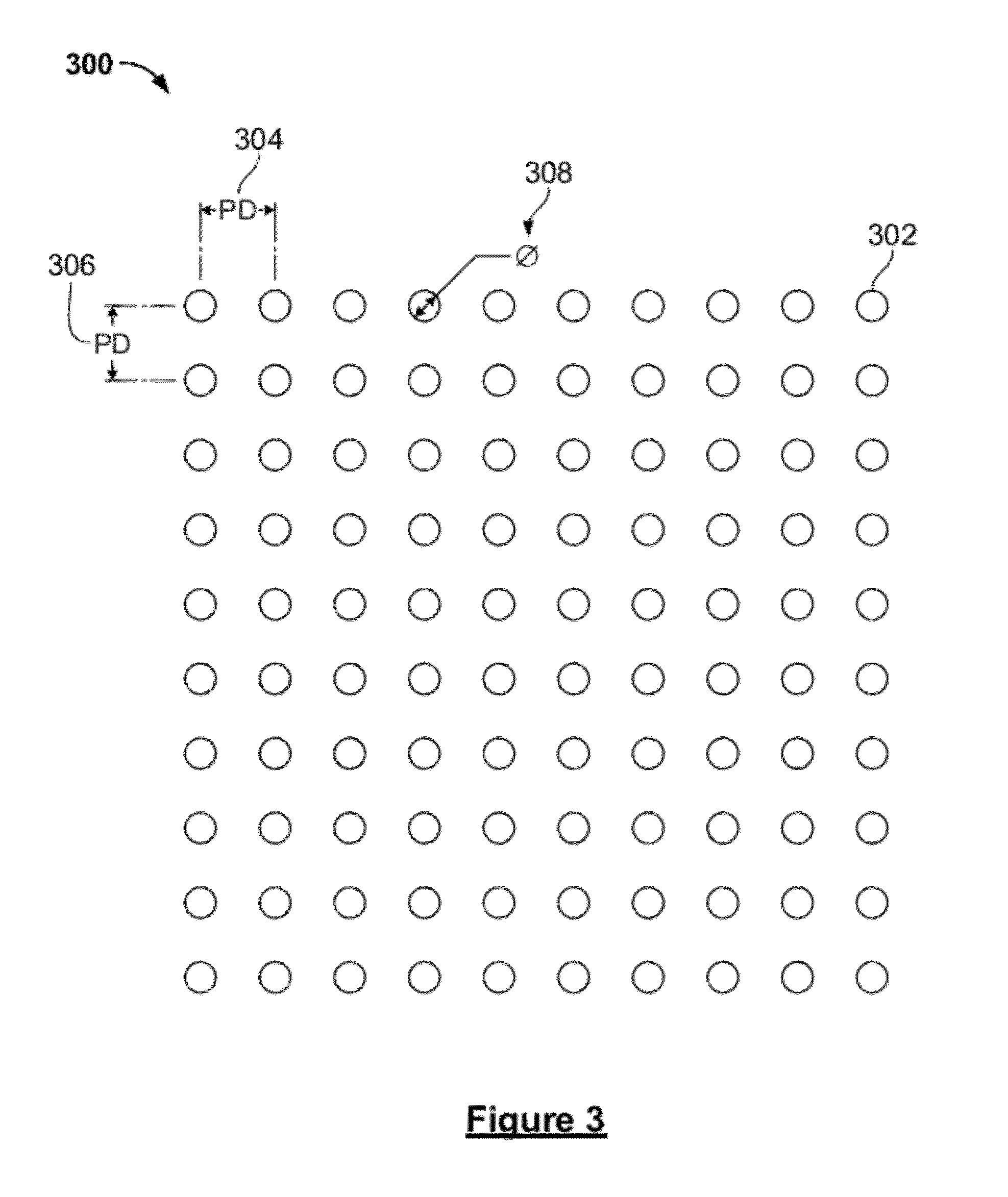

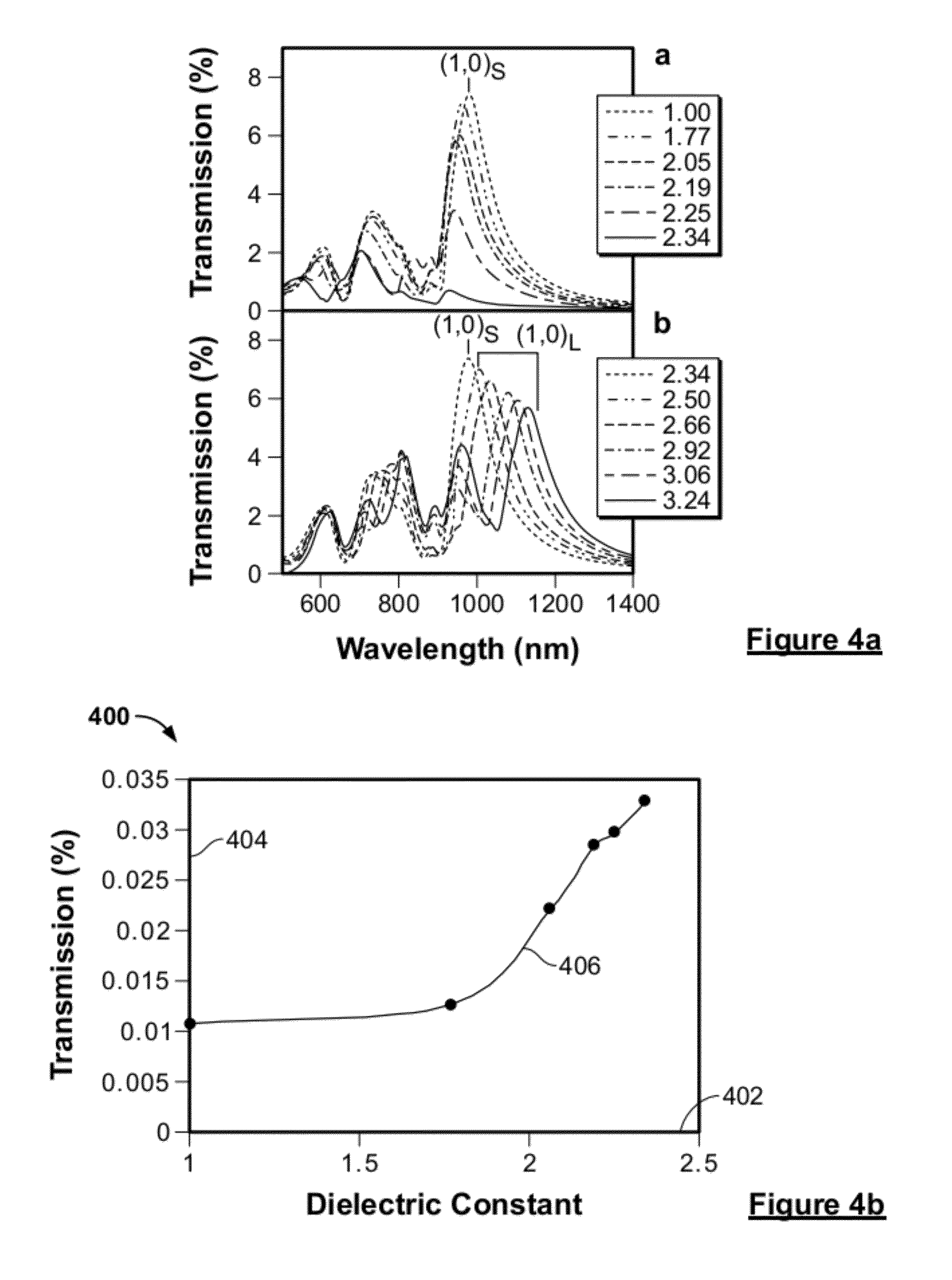

System and method for a microfluidic calorimeter

PatentActiveUS20120264224A1

Innovation

- A microfluidic calorimetry system utilizing microscale temperature sensors and nanohole arrays in a metal film to measure temperature changes in microfluidic laminar flow, allowing for precise calorimetry measurements with reduced reagent volumes and improved experimental efficiency.

Environmental Impact of Thermal Management Systems

The environmental impact of thermal management systems in laminar flow applications is a critical consideration in today's eco-conscious industrial landscape. These systems, while essential for maintaining optimal operating conditions in various processes, can have significant environmental implications if not properly designed and managed.

One of the primary environmental concerns associated with thermal management systems is energy consumption. Traditional cooling methods often rely heavily on electricity, contributing to increased carbon emissions and strain on power grids. However, advancements in laminar flow technology have led to more energy-efficient solutions. By optimizing fluid dynamics and heat transfer mechanisms, modern thermal management systems can achieve the same cooling effects with reduced energy input, thereby lowering their carbon footprint.

Water usage is another crucial environmental factor to consider. Many thermal management systems, particularly in industrial settings, require substantial amounts of water for cooling purposes. This can lead to water scarcity issues, especially in regions already facing water stress. Innovative approaches to water recycling and the implementation of closed-loop systems have shown promise in mitigating this impact, allowing for more sustainable water management practices.

The choice of coolants used in thermal management systems also plays a significant role in their environmental impact. Historically, some coolants contained harmful substances such as chlorofluorocarbons (CFCs), which contributed to ozone depletion. The phase-out of these substances has led to the development of more environmentally friendly alternatives. However, the production and disposal of these new coolants still require careful consideration to minimize their ecological footprint.

Noise pollution is an often-overlooked environmental aspect of thermal management systems. Large-scale cooling equipment can generate significant noise levels, potentially affecting local ecosystems and human communities. The application of laminar flow principles in system design has helped in reducing turbulence and, consequently, noise generation, leading to quieter and more environmentally harmonious operations.

The lifecycle impact of thermal management systems extends beyond their operational phase. The manufacturing of components, transportation, installation, and eventual decommissioning all contribute to the overall environmental footprint. Adopting a circular economy approach, with emphasis on recyclable materials and modular designs, can significantly reduce the end-of-life impact of these systems.

As industries strive for greater sustainability, the integration of renewable energy sources with thermal management systems is gaining traction. Solar-powered cooling systems and geothermal heat exchange are examples of how clean energy can be harnessed to power these essential processes, further reducing their environmental impact.

In conclusion, while thermal management systems are indispensable in many applications involving laminar flow, their environmental impact requires careful consideration and continuous improvement. Through technological advancements, sustainable design practices, and a holistic approach to system lifecycle management, the industry is moving towards more environmentally friendly thermal management solutions.

One of the primary environmental concerns associated with thermal management systems is energy consumption. Traditional cooling methods often rely heavily on electricity, contributing to increased carbon emissions and strain on power grids. However, advancements in laminar flow technology have led to more energy-efficient solutions. By optimizing fluid dynamics and heat transfer mechanisms, modern thermal management systems can achieve the same cooling effects with reduced energy input, thereby lowering their carbon footprint.

Water usage is another crucial environmental factor to consider. Many thermal management systems, particularly in industrial settings, require substantial amounts of water for cooling purposes. This can lead to water scarcity issues, especially in regions already facing water stress. Innovative approaches to water recycling and the implementation of closed-loop systems have shown promise in mitigating this impact, allowing for more sustainable water management practices.

The choice of coolants used in thermal management systems also plays a significant role in their environmental impact. Historically, some coolants contained harmful substances such as chlorofluorocarbons (CFCs), which contributed to ozone depletion. The phase-out of these substances has led to the development of more environmentally friendly alternatives. However, the production and disposal of these new coolants still require careful consideration to minimize their ecological footprint.

Noise pollution is an often-overlooked environmental aspect of thermal management systems. Large-scale cooling equipment can generate significant noise levels, potentially affecting local ecosystems and human communities. The application of laminar flow principles in system design has helped in reducing turbulence and, consequently, noise generation, leading to quieter and more environmentally harmonious operations.

The lifecycle impact of thermal management systems extends beyond their operational phase. The manufacturing of components, transportation, installation, and eventual decommissioning all contribute to the overall environmental footprint. Adopting a circular economy approach, with emphasis on recyclable materials and modular designs, can significantly reduce the end-of-life impact of these systems.

As industries strive for greater sustainability, the integration of renewable energy sources with thermal management systems is gaining traction. Solar-powered cooling systems and geothermal heat exchange are examples of how clean energy can be harnessed to power these essential processes, further reducing their environmental impact.

In conclusion, while thermal management systems are indispensable in many applications involving laminar flow, their environmental impact requires careful consideration and continuous improvement. Through technological advancements, sustainable design practices, and a holistic approach to system lifecycle management, the industry is moving towards more environmentally friendly thermal management solutions.

Cost-Benefit Analysis of Laminar Flow Implementation

Implementing laminar flow technology in thermal management systems requires a comprehensive cost-benefit analysis to determine its economic viability and long-term advantages. The initial investment for laminar flow systems can be substantial, encompassing specialized equipment, redesigned components, and advanced control systems. However, these upfront costs must be weighed against the potential long-term benefits.

One of the primary advantages of laminar flow is its ability to significantly enhance heat transfer efficiency. This improved thermal management can lead to reduced energy consumption in cooling systems, potentially resulting in substantial operational cost savings over time. For industries with high cooling demands, such as data centers or manufacturing facilities, these energy savings can translate into a considerable reduction in overall operating expenses.

Additionally, laminar flow systems often require less maintenance compared to turbulent flow systems. The smoother, more predictable flow patterns result in reduced wear and tear on system components, potentially extending their lifespan and decreasing maintenance and replacement costs. This factor should be carefully considered when calculating the total cost of ownership over the system's lifetime.

The implementation of laminar flow can also lead to improved product quality in certain manufacturing processes. For industries where precise temperature control is crucial, such as semiconductor fabrication or pharmaceutical production, the enhanced thermal management capabilities of laminar flow systems can result in higher yields and reduced waste. These quality improvements can contribute significantly to the overall financial benefits of the technology.

However, it's important to note that the benefits of laminar flow may vary depending on the specific application and industry. In some cases, the performance improvements may not justify the increased complexity and cost of implementation. A thorough analysis of the specific use case, including factors such as required flow rates, temperature differentials, and system scale, is essential to accurately assess the cost-benefit ratio.

Furthermore, regulatory considerations and potential future energy price fluctuations should be factored into the analysis. As environmental regulations become more stringent, the energy efficiency gains from laminar flow systems may become increasingly valuable. Conversely, if energy prices were to decrease significantly, the financial benefits of reduced energy consumption would be diminished.

In conclusion, while the implementation of laminar flow technology for thermal management can offer substantial benefits in terms of energy efficiency, maintenance reduction, and product quality, a detailed cost-benefit analysis is crucial. This analysis should consider not only the immediate financial implications but also long-term operational savings, potential regulatory changes, and industry-specific factors to make an informed decision on its implementation.

One of the primary advantages of laminar flow is its ability to significantly enhance heat transfer efficiency. This improved thermal management can lead to reduced energy consumption in cooling systems, potentially resulting in substantial operational cost savings over time. For industries with high cooling demands, such as data centers or manufacturing facilities, these energy savings can translate into a considerable reduction in overall operating expenses.

Additionally, laminar flow systems often require less maintenance compared to turbulent flow systems. The smoother, more predictable flow patterns result in reduced wear and tear on system components, potentially extending their lifespan and decreasing maintenance and replacement costs. This factor should be carefully considered when calculating the total cost of ownership over the system's lifetime.

The implementation of laminar flow can also lead to improved product quality in certain manufacturing processes. For industries where precise temperature control is crucial, such as semiconductor fabrication or pharmaceutical production, the enhanced thermal management capabilities of laminar flow systems can result in higher yields and reduced waste. These quality improvements can contribute significantly to the overall financial benefits of the technology.

However, it's important to note that the benefits of laminar flow may vary depending on the specific application and industry. In some cases, the performance improvements may not justify the increased complexity and cost of implementation. A thorough analysis of the specific use case, including factors such as required flow rates, temperature differentials, and system scale, is essential to accurately assess the cost-benefit ratio.

Furthermore, regulatory considerations and potential future energy price fluctuations should be factored into the analysis. As environmental regulations become more stringent, the energy efficiency gains from laminar flow systems may become increasingly valuable. Conversely, if energy prices were to decrease significantly, the financial benefits of reduced energy consumption would be diminished.

In conclusion, while the implementation of laminar flow technology for thermal management can offer substantial benefits in terms of energy efficiency, maintenance reduction, and product quality, a detailed cost-benefit analysis is crucial. This analysis should consider not only the immediate financial implications but also long-term operational savings, potential regulatory changes, and industry-specific factors to make an informed decision on its implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!