Exploring Silicone Rubber’s Contribution to Circular Economy

JUL 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Silicone Rubber Circular Economy Overview

Silicone rubber has emerged as a key player in the circular economy, offering unique properties that contribute to sustainable practices across various industries. This versatile material, known for its durability, flexibility, and resistance to extreme temperatures, is increasingly being recognized for its potential to reduce waste and promote resource efficiency.

In the context of the circular economy, silicone rubber stands out due to its long lifespan and recyclability. Unlike many traditional plastics, silicone rubber can maintain its structural integrity and performance characteristics over extended periods, reducing the need for frequent replacements. This longevity aligns with the circular economy principle of keeping products and materials in use for as long as possible.

The recyclability of silicone rubber further enhances its circular economy credentials. Advanced recycling technologies have been developed to process used silicone rubber products, allowing the material to be reintroduced into the production cycle. This closed-loop approach minimizes waste and reduces the demand for virgin raw materials, contributing to resource conservation.

Silicone rubber's contribution to the circular economy extends beyond its recyclability. Its unique properties enable the development of innovative products that support sustainability goals. For instance, silicone-based sealants and insulation materials improve energy efficiency in buildings, while silicone components in renewable energy systems enhance durability and performance.

The material's resistance to degradation also plays a crucial role in reducing environmental impact. Unlike some conventional plastics, silicone rubber does not break down into microplastics, mitigating pollution concerns in marine and terrestrial ecosystems. This characteristic aligns with the circular economy's aim to design out waste and pollution.

In the automotive and aerospace industries, silicone rubber components contribute to lightweight design, improving fuel efficiency and reducing emissions. The material's ability to withstand extreme conditions also extends the lifespan of critical parts, reducing the frequency of replacements and associated resource consumption.

As industries increasingly adopt circular economy principles, silicone rubber manufacturers are investing in research and development to further enhance the material's sustainability profile. Efforts are underway to improve recycling processes, develop bio-based silicone alternatives, and explore new applications that leverage the material's unique properties to support circular economy objectives.

In the context of the circular economy, silicone rubber stands out due to its long lifespan and recyclability. Unlike many traditional plastics, silicone rubber can maintain its structural integrity and performance characteristics over extended periods, reducing the need for frequent replacements. This longevity aligns with the circular economy principle of keeping products and materials in use for as long as possible.

The recyclability of silicone rubber further enhances its circular economy credentials. Advanced recycling technologies have been developed to process used silicone rubber products, allowing the material to be reintroduced into the production cycle. This closed-loop approach minimizes waste and reduces the demand for virgin raw materials, contributing to resource conservation.

Silicone rubber's contribution to the circular economy extends beyond its recyclability. Its unique properties enable the development of innovative products that support sustainability goals. For instance, silicone-based sealants and insulation materials improve energy efficiency in buildings, while silicone components in renewable energy systems enhance durability and performance.

The material's resistance to degradation also plays a crucial role in reducing environmental impact. Unlike some conventional plastics, silicone rubber does not break down into microplastics, mitigating pollution concerns in marine and terrestrial ecosystems. This characteristic aligns with the circular economy's aim to design out waste and pollution.

In the automotive and aerospace industries, silicone rubber components contribute to lightweight design, improving fuel efficiency and reducing emissions. The material's ability to withstand extreme conditions also extends the lifespan of critical parts, reducing the frequency of replacements and associated resource consumption.

As industries increasingly adopt circular economy principles, silicone rubber manufacturers are investing in research and development to further enhance the material's sustainability profile. Efforts are underway to improve recycling processes, develop bio-based silicone alternatives, and explore new applications that leverage the material's unique properties to support circular economy objectives.

Market Demand for Sustainable Silicone Products

The market demand for sustainable silicone products has been steadily increasing in recent years, driven by growing environmental awareness and stricter regulations on waste management and circular economy practices. Silicone rubber, known for its durability, versatility, and resistance to extreme temperatures, has long been a popular material in various industries. However, the traditional linear economy model of production and disposal has raised concerns about its environmental impact.

Consumers and businesses alike are now seeking more sustainable alternatives, creating a significant market opportunity for eco-friendly silicone products. This demand is particularly strong in sectors such as construction, automotive, healthcare, and consumer goods. In the construction industry, there is a growing interest in sustainable building materials, including silicone-based sealants and adhesives that offer improved energy efficiency and longevity.

The automotive sector is another key driver of demand for sustainable silicone products. As the industry shifts towards electric vehicles and lightweight designs, there is an increased need for durable, heat-resistant, and recyclable silicone components. This trend aligns with the broader push for circular economy principles in the automotive supply chain.

In the healthcare industry, the demand for sustainable silicone products is fueled by the need for biocompatible, long-lasting medical devices and equipment. Hospitals and healthcare providers are increasingly prioritizing products that can be easily sterilized, reused, or recycled, reducing medical waste and environmental impact.

Consumer goods manufacturers are also responding to the growing demand for sustainable products. From kitchenware to personal care items, consumers are seeking silicone alternatives to single-use plastics and other environmentally harmful materials. This shift in consumer preferences is driving innovation in product design and manufacturing processes.

The market for sustainable silicone products is further bolstered by government initiatives and regulations promoting circular economy practices. Many countries have implemented policies to reduce waste, encourage recycling, and promote the use of sustainable materials. These regulatory frameworks are creating additional incentives for businesses to invest in sustainable silicone solutions.

As the circular economy concept gains traction, there is an increasing focus on developing closed-loop systems for silicone products. This includes innovations in recycling technologies, product design for disassembly, and the use of bio-based or recycled silicone materials. Companies that can offer these sustainable solutions are likely to gain a competitive edge in the market.

Consumers and businesses alike are now seeking more sustainable alternatives, creating a significant market opportunity for eco-friendly silicone products. This demand is particularly strong in sectors such as construction, automotive, healthcare, and consumer goods. In the construction industry, there is a growing interest in sustainable building materials, including silicone-based sealants and adhesives that offer improved energy efficiency and longevity.

The automotive sector is another key driver of demand for sustainable silicone products. As the industry shifts towards electric vehicles and lightweight designs, there is an increased need for durable, heat-resistant, and recyclable silicone components. This trend aligns with the broader push for circular economy principles in the automotive supply chain.

In the healthcare industry, the demand for sustainable silicone products is fueled by the need for biocompatible, long-lasting medical devices and equipment. Hospitals and healthcare providers are increasingly prioritizing products that can be easily sterilized, reused, or recycled, reducing medical waste and environmental impact.

Consumer goods manufacturers are also responding to the growing demand for sustainable products. From kitchenware to personal care items, consumers are seeking silicone alternatives to single-use plastics and other environmentally harmful materials. This shift in consumer preferences is driving innovation in product design and manufacturing processes.

The market for sustainable silicone products is further bolstered by government initiatives and regulations promoting circular economy practices. Many countries have implemented policies to reduce waste, encourage recycling, and promote the use of sustainable materials. These regulatory frameworks are creating additional incentives for businesses to invest in sustainable silicone solutions.

As the circular economy concept gains traction, there is an increasing focus on developing closed-loop systems for silicone products. This includes innovations in recycling technologies, product design for disassembly, and the use of bio-based or recycled silicone materials. Companies that can offer these sustainable solutions are likely to gain a competitive edge in the market.

Current Challenges in Silicone Rubber Recycling

Despite the numerous advantages of silicone rubber, its recycling presents significant challenges that hinder its full integration into the circular economy. One of the primary obstacles is the cross-linked structure of silicone rubber, which makes it difficult to break down and reprocess using conventional recycling methods. This inherent chemical stability, while beneficial for many applications, becomes a barrier when attempting to recycle the material.

The lack of established recycling infrastructure specifically designed for silicone rubber compounds the problem. Unlike more common plastics, silicone rubber requires specialized processes and equipment for effective recycling, which are not widely available in most recycling facilities. This gap in infrastructure leads to a significant portion of silicone rubber waste being directed to landfills or incineration, rather than being recycled.

Contamination is another major challenge in silicone rubber recycling. Silicone products often contain additives, fillers, or are bonded with other materials, making it difficult to separate and purify the silicone component. This contamination can compromise the quality and performance of recycled silicone, limiting its potential applications and market value.

The energy-intensive nature of current silicone rubber recycling methods poses both economic and environmental challenges. Processes such as devulcanization or chemical breakdown require substantial energy inputs, potentially offsetting some of the environmental benefits of recycling. This energy requirement also impacts the economic viability of recycling operations, particularly when compared to the relatively low cost of virgin silicone materials.

Furthermore, the diverse range of silicone rubber formulations used across different industries complicates recycling efforts. Each formulation may require a slightly different recycling approach, making it challenging to develop standardized, efficient recycling processes that can handle a wide variety of silicone rubber waste streams.

The lack of regulatory frameworks and incentives specifically targeting silicone rubber recycling also hampers progress in this area. Without clear guidelines or economic incentives, manufacturers and consumers have little motivation to prioritize the recyclability of silicone products or invest in recycling technologies.

Lastly, there is a general lack of awareness and education about the recyclability of silicone rubber among consumers and even some industry professionals. This knowledge gap leads to improper disposal and missed opportunities for recycling, further exacerbating the challenges in establishing effective recycling systems for this material.

The lack of established recycling infrastructure specifically designed for silicone rubber compounds the problem. Unlike more common plastics, silicone rubber requires specialized processes and equipment for effective recycling, which are not widely available in most recycling facilities. This gap in infrastructure leads to a significant portion of silicone rubber waste being directed to landfills or incineration, rather than being recycled.

Contamination is another major challenge in silicone rubber recycling. Silicone products often contain additives, fillers, or are bonded with other materials, making it difficult to separate and purify the silicone component. This contamination can compromise the quality and performance of recycled silicone, limiting its potential applications and market value.

The energy-intensive nature of current silicone rubber recycling methods poses both economic and environmental challenges. Processes such as devulcanization or chemical breakdown require substantial energy inputs, potentially offsetting some of the environmental benefits of recycling. This energy requirement also impacts the economic viability of recycling operations, particularly when compared to the relatively low cost of virgin silicone materials.

Furthermore, the diverse range of silicone rubber formulations used across different industries complicates recycling efforts. Each formulation may require a slightly different recycling approach, making it challenging to develop standardized, efficient recycling processes that can handle a wide variety of silicone rubber waste streams.

The lack of regulatory frameworks and incentives specifically targeting silicone rubber recycling also hampers progress in this area. Without clear guidelines or economic incentives, manufacturers and consumers have little motivation to prioritize the recyclability of silicone products or invest in recycling technologies.

Lastly, there is a general lack of awareness and education about the recyclability of silicone rubber among consumers and even some industry professionals. This knowledge gap leads to improper disposal and missed opportunities for recycling, further exacerbating the challenges in establishing effective recycling systems for this material.

Existing Silicone Rubber Recycling Solutions

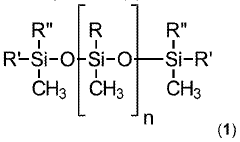

01 Composition and preparation of silicone rubber

Silicone rubber is typically composed of silicone polymers, fillers, and curing agents. The preparation process often involves mixing these components, shaping the mixture, and then curing it to form the final rubber product. Various additives can be incorporated to enhance specific properties such as strength, flexibility, or heat resistance.- Composition and formulation of silicone rubber: Silicone rubber compositions typically include silicone polymers, fillers, and curing agents. The formulation can be adjusted to achieve specific properties such as hardness, elasticity, and heat resistance. Various additives may be incorporated to enhance performance characteristics or processing behavior.

- Manufacturing processes for silicone rubber products: Different manufacturing techniques are employed to produce silicone rubber products, including molding, extrusion, and calendering. The choice of process depends on the desired shape and properties of the final product. Curing methods, such as heat curing or room temperature vulcanization, are crucial steps in the production process.

- Modifications and improvements to silicone rubber properties: Researchers continually work on enhancing silicone rubber properties through various modifications. This includes the development of new polymer structures, incorporation of novel fillers or reinforcing agents, and the use of specialized additives to improve specific characteristics such as tear strength, compression set, or chemical resistance.

- Applications of silicone rubber in various industries: Silicone rubber finds widespread use across multiple industries due to its unique properties. It is commonly used in medical devices, automotive parts, electrical insulation, consumer products, and construction materials. The material's biocompatibility, heat resistance, and durability make it suitable for diverse applications.

- Environmental and sustainability aspects of silicone rubber: As environmental concerns grow, there is increasing focus on the sustainability of silicone rubber. This includes research into biodegradable silicone formulations, recycling methods for silicone rubber products, and the development of eco-friendly production processes. The long lifespan and durability of silicone rubber products also contribute to their environmental profile.

02 Modification of silicone rubber properties

The properties of silicone rubber can be modified through the addition of specific compounds or by altering the polymer structure. This can include improving thermal stability, increasing electrical conductivity, enhancing mechanical strength, or adjusting the rubber's hardness. Such modifications allow for the customization of silicone rubber for various applications.Expand Specific Solutions03 Silicone rubber in medical and healthcare applications

Silicone rubber is widely used in medical and healthcare applications due to its biocompatibility, flexibility, and durability. It is used in various medical devices, implants, and prosthetics. The material can be formulated to meet specific requirements for medical use, such as being non-toxic, non-allergenic, and sterilizable.Expand Specific Solutions04 Silicone rubber in electronic and electrical applications

Silicone rubber finds extensive use in electronic and electrical applications due to its excellent insulating properties and resistance to extreme temperatures. It is used in the production of cables, connectors, keypads, and various other electronic components. The material can be formulated to provide specific electrical properties suitable for different electronic applications.Expand Specific Solutions05 Silicone rubber manufacturing processes

Various manufacturing processes are employed in the production of silicone rubber products. These can include injection molding, extrusion, compression molding, and liquid silicone rubber molding. Each process has its advantages and is suited to different types of products or production scales. Innovations in manufacturing techniques aim to improve efficiency, reduce costs, and enhance product quality.Expand Specific Solutions

Key Players in Silicone Circular Economy

The silicone rubber industry's contribution to the circular economy is in a developing stage, with growing market potential and increasing technological maturity. The market size is expanding as more industries recognize the recyclability and durability of silicone rubber products. Leading companies like Shin-Etsu Chemical, Dow Silicones, and Wacker Chemie are driving innovation in this field, focusing on developing more sustainable silicone rubber formulations and recycling processes. The technology is maturing, with advancements in recycling methods and the creation of bio-based silicones, though challenges remain in scaling these solutions. As environmental regulations tighten globally, the industry is poised for further growth and technological progress in circular economy applications.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed a novel silicone rubber recycling technology that contributes to the circular economy. Their process involves breaking down silicone rubber waste into its original components, which can then be used to produce new silicone products[1]. This method achieves a recycling rate of up to 90%, significantly reducing waste and conserving resources[2]. The company has also introduced bio-based silicone materials, derived partially from plant sources, reducing reliance on fossil fuels[3]. Additionally, Shin-Etsu has implemented energy-efficient manufacturing processes, reducing CO2 emissions in silicone production by approximately 30% compared to conventional methods[4].

Strengths: High recycling efficiency, reduced environmental impact, and innovative use of bio-based materials. Weaknesses: Potential high initial costs for implementing new recycling technologies and limited availability of bio-based raw materials.

Dow Silicones Corp.

Technical Solution: Dow Silicones has developed a comprehensive approach to incorporating silicone rubber into the circular economy. Their strategy includes designing products for durability and recyclability, implementing take-back programs for end-of-life silicone products, and investing in advanced recycling technologies[5]. The company has introduced a range of silicone elastomers with enhanced recyclability, allowing for easier separation and reprocessing of composite materials[6]. Dow has also developed a chemical recycling process for silicone rubber that can recover up to 80% of the original material, which can be used in new high-performance applications[7]. Furthermore, they have implemented a life cycle assessment approach to quantify the environmental impact of their silicone products, enabling more informed decision-making in product development and use[8].

Strengths: Comprehensive circular economy approach, advanced recycling technologies, and focus on product life cycle assessment. Weaknesses: Potential challenges in scaling up recycling infrastructure and ensuring consistent quality of recycled materials.

Innovative Approaches to Silicone Upcycling

Article useful for circular economy and comprising a silicone elastomer with peelable and clean-releasing properties

PatentWO2021154961A1

Innovation

- A curable liquid silicone composition comprising specific ratios of alkenyl group-containing organopolysiloxane, diorganohydrogensiloxy-terminated polydiorganosiloxane, and organosilicon crosslinker, allowing for a cured silicone elastomer with adhesive properties that can be easily and cleanly peeled off from substrates using human force, with a peel force range of 1.5N to 23N, facilitating repair and recycling.

A process for the recycling of silicone rubber using digestive cracking method

PatentInactiveIN1204MUM2007A

Innovation

- A process using an acid-base tandem catalyst system in combination with non-polar solvents for the digestion and thermal cracking of filled silicone scrap at reduced temperatures and pressures, allowing for the recovery of cyclosiloxane monomers from filled silicone scrap.

Environmental Impact Assessment

The environmental impact assessment of silicone rubber in the context of circular economy reveals both positive and negative aspects. On the positive side, silicone rubber's durability and longevity contribute significantly to resource conservation. Its ability to withstand extreme temperatures, UV radiation, and chemical exposure allows for extended product lifespans, reducing the need for frequent replacements and thereby minimizing waste generation.

Furthermore, silicone rubber's versatility enables its use in various applications, including renewable energy technologies such as solar panels and wind turbines. This indirect contribution to clean energy production helps mitigate greenhouse gas emissions and combat climate change. Additionally, silicone rubber's low thermal conductivity properties make it an excellent insulation material, improving energy efficiency in buildings and industrial processes.

However, the production of silicone rubber does have environmental drawbacks. The manufacturing process requires significant energy inputs and involves the use of potentially harmful chemicals. The extraction of silica, a primary raw material for silicone production, can lead to habitat disruption and soil erosion if not managed responsibly.

End-of-life management of silicone rubber products presents challenges in the circular economy framework. While silicone rubber is theoretically recyclable, the current infrastructure for collection and processing is limited. Many silicone products end up in landfills or incineration facilities, contributing to waste accumulation and potential environmental contamination.

Water pollution is another concern associated with silicone rubber. Microparticles of silicone can leach into aquatic ecosystems, potentially affecting marine life and entering the food chain. The long-term effects of these microparticles on ecosystems and human health are still being studied.

Despite these challenges, ongoing research and development in silicone rubber technology are focusing on improving its environmental profile. Efforts are being made to develop bio-based silicones, enhance recycling processes, and create more sustainable production methods. These advancements aim to align silicone rubber more closely with circular economy principles, minimizing its environmental footprint while maximizing its beneficial properties.

In conclusion, the environmental impact of silicone rubber in the circular economy context is multifaceted. While its durability and versatility offer significant environmental benefits, challenges remain in production processes and end-of-life management. Continued innovation and improved lifecycle management strategies are crucial to fully realizing silicone rubber's potential as a sustainable material in the circular economy.

Furthermore, silicone rubber's versatility enables its use in various applications, including renewable energy technologies such as solar panels and wind turbines. This indirect contribution to clean energy production helps mitigate greenhouse gas emissions and combat climate change. Additionally, silicone rubber's low thermal conductivity properties make it an excellent insulation material, improving energy efficiency in buildings and industrial processes.

However, the production of silicone rubber does have environmental drawbacks. The manufacturing process requires significant energy inputs and involves the use of potentially harmful chemicals. The extraction of silica, a primary raw material for silicone production, can lead to habitat disruption and soil erosion if not managed responsibly.

End-of-life management of silicone rubber products presents challenges in the circular economy framework. While silicone rubber is theoretically recyclable, the current infrastructure for collection and processing is limited. Many silicone products end up in landfills or incineration facilities, contributing to waste accumulation and potential environmental contamination.

Water pollution is another concern associated with silicone rubber. Microparticles of silicone can leach into aquatic ecosystems, potentially affecting marine life and entering the food chain. The long-term effects of these microparticles on ecosystems and human health are still being studied.

Despite these challenges, ongoing research and development in silicone rubber technology are focusing on improving its environmental profile. Efforts are being made to develop bio-based silicones, enhance recycling processes, and create more sustainable production methods. These advancements aim to align silicone rubber more closely with circular economy principles, minimizing its environmental footprint while maximizing its beneficial properties.

In conclusion, the environmental impact of silicone rubber in the circular economy context is multifaceted. While its durability and versatility offer significant environmental benefits, challenges remain in production processes and end-of-life management. Continued innovation and improved lifecycle management strategies are crucial to fully realizing silicone rubber's potential as a sustainable material in the circular economy.

Policy Frameworks for Silicone Recycling

Policy frameworks for silicone recycling are crucial in promoting the circular economy for silicone rubber materials. These frameworks establish the regulatory environment and incentives necessary to encourage the development and implementation of recycling technologies and practices.

At the national level, several countries have introduced legislation to support silicone recycling. For instance, the European Union's Waste Framework Directive sets targets for recycling and recovery of various materials, including silicone rubber. This directive has been instrumental in driving research and investment in silicone recycling technologies across EU member states.

In the United States, while there is no federal legislation specifically targeting silicone recycling, some states have implemented their own policies. California's Electronic Waste Recycling Act, for example, includes provisions that can be applied to silicone-containing electronic components, encouraging their proper disposal and recycling.

Japan has taken a proactive approach with its Home Appliance Recycling Law, which mandates the recycling of certain household appliances. This law indirectly promotes the recycling of silicone rubber components found in these appliances, contributing to the overall circular economy for silicone materials.

At the industry level, voluntary initiatives and standards have emerged to fill gaps in government regulations. The Global Silicones Council, an international organization representing silicone manufacturers, has developed guidelines for the responsible use and disposal of silicone products. These guidelines, while not legally binding, provide a framework for best practices in silicone recycling.

Some countries have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. These programs have been particularly effective in encouraging the development of recycling technologies for complex products containing silicone components.

To further support silicone recycling, many jurisdictions have introduced financial incentives. These may include tax breaks for companies investing in recycling technologies, grants for research and development in silicone recycling, or subsidies for recycling facilities that process silicone waste.

Despite these efforts, there remains a need for more comprehensive and harmonized policy frameworks for silicone recycling. Many existing policies focus on specific product categories or industries, leaving gaps in coverage for other silicone applications. Additionally, the lack of standardized recycling processes and quality standards for recycled silicone materials presents challenges for widespread adoption.

At the national level, several countries have introduced legislation to support silicone recycling. For instance, the European Union's Waste Framework Directive sets targets for recycling and recovery of various materials, including silicone rubber. This directive has been instrumental in driving research and investment in silicone recycling technologies across EU member states.

In the United States, while there is no federal legislation specifically targeting silicone recycling, some states have implemented their own policies. California's Electronic Waste Recycling Act, for example, includes provisions that can be applied to silicone-containing electronic components, encouraging their proper disposal and recycling.

Japan has taken a proactive approach with its Home Appliance Recycling Law, which mandates the recycling of certain household appliances. This law indirectly promotes the recycling of silicone rubber components found in these appliances, contributing to the overall circular economy for silicone materials.

At the industry level, voluntary initiatives and standards have emerged to fill gaps in government regulations. The Global Silicones Council, an international organization representing silicone manufacturers, has developed guidelines for the responsible use and disposal of silicone products. These guidelines, while not legally binding, provide a framework for best practices in silicone recycling.

Some countries have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. These programs have been particularly effective in encouraging the development of recycling technologies for complex products containing silicone components.

To further support silicone recycling, many jurisdictions have introduced financial incentives. These may include tax breaks for companies investing in recycling technologies, grants for research and development in silicone recycling, or subsidies for recycling facilities that process silicone waste.

Despite these efforts, there remains a need for more comprehensive and harmonized policy frameworks for silicone recycling. Many existing policies focus on specific product categories or industries, leaving gaps in coverage for other silicone applications. Additionally, the lack of standardized recycling processes and quality standards for recycled silicone materials presents challenges for widespread adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!