Flexible Piezoelectric Nanogenerators: Substrate Engineering and Mechanical Endurance

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric Nanogenerator Evolution and Objectives

Piezoelectric nanogenerators (PENGs) have emerged as a revolutionary technology for harvesting mechanical energy from ambient environments since their inception in 2006 by Professor Zhong Lin Wang's team at Georgia Tech. These devices convert mechanical stimuli into electrical energy through the piezoelectric effect, where certain materials generate electric charges in response to applied mechanical stress. The evolution of PENGs has progressed through several distinct phases, from rigid ceramic-based structures to the current focus on flexible and stretchable configurations.

Initially, PENGs utilized zinc oxide nanowires on rigid substrates, demonstrating the fundamental concept but with limited practical applications due to their brittleness and low power output. The second generation saw the integration of thin-film piezoelectric materials like PZT (lead zirconate titanate) and PVDF (polyvinylidene fluoride), which improved energy conversion efficiency while maintaining some degree of flexibility.

The current technological frontier focuses on flexible piezoelectric nanogenerators that can conform to irregular surfaces and withstand repeated mechanical deformation without performance degradation. This advancement has been driven by innovations in substrate engineering, including the development of polymer-based flexible substrates, textile integration, and biodegradable platforms that expand application possibilities while addressing environmental concerns.

Market trends indicate a growing demand for self-powered wearable electronics, implantable medical devices, and IoT sensors, all of which benefit from flexible energy harvesting solutions. The global market for energy harvesting systems is projected to reach $1.3 billion by 2027, with piezoelectric devices representing a significant segment of this growth.

The primary objectives of current research in flexible PENGs center on three critical aspects: enhancing mechanical endurance through substrate engineering, improving energy conversion efficiency, and ensuring stable performance under various environmental conditions. Specifically, researchers aim to develop nanogenerators capable of withstanding over 10,000 bending cycles without significant performance degradation while maintaining power densities above 500 μW/cm².

Long-term technological goals include the seamless integration of flexible PENGs into smart textiles, biomedical implants, and structural health monitoring systems. This requires addressing challenges related to scalable manufacturing processes, encapsulation techniques for environmental protection, and hybrid energy harvesting approaches that combine piezoelectric with other mechanisms such as triboelectric or photovoltaic effects.

The convergence of nanotechnology, flexible electronics, and advanced materials science continues to drive innovation in this field, with interdisciplinary collaboration becoming increasingly important for overcoming current limitations and realizing the full potential of flexible piezoelectric nanogenerators in next-generation energy harvesting applications.

Initially, PENGs utilized zinc oxide nanowires on rigid substrates, demonstrating the fundamental concept but with limited practical applications due to their brittleness and low power output. The second generation saw the integration of thin-film piezoelectric materials like PZT (lead zirconate titanate) and PVDF (polyvinylidene fluoride), which improved energy conversion efficiency while maintaining some degree of flexibility.

The current technological frontier focuses on flexible piezoelectric nanogenerators that can conform to irregular surfaces and withstand repeated mechanical deformation without performance degradation. This advancement has been driven by innovations in substrate engineering, including the development of polymer-based flexible substrates, textile integration, and biodegradable platforms that expand application possibilities while addressing environmental concerns.

Market trends indicate a growing demand for self-powered wearable electronics, implantable medical devices, and IoT sensors, all of which benefit from flexible energy harvesting solutions. The global market for energy harvesting systems is projected to reach $1.3 billion by 2027, with piezoelectric devices representing a significant segment of this growth.

The primary objectives of current research in flexible PENGs center on three critical aspects: enhancing mechanical endurance through substrate engineering, improving energy conversion efficiency, and ensuring stable performance under various environmental conditions. Specifically, researchers aim to develop nanogenerators capable of withstanding over 10,000 bending cycles without significant performance degradation while maintaining power densities above 500 μW/cm².

Long-term technological goals include the seamless integration of flexible PENGs into smart textiles, biomedical implants, and structural health monitoring systems. This requires addressing challenges related to scalable manufacturing processes, encapsulation techniques for environmental protection, and hybrid energy harvesting approaches that combine piezoelectric with other mechanisms such as triboelectric or photovoltaic effects.

The convergence of nanotechnology, flexible electronics, and advanced materials science continues to drive innovation in this field, with interdisciplinary collaboration becoming increasingly important for overcoming current limitations and realizing the full potential of flexible piezoelectric nanogenerators in next-generation energy harvesting applications.

Market Analysis for Flexible Energy Harvesting Solutions

The global market for flexible energy harvesting solutions has witnessed substantial growth in recent years, driven by increasing demand for sustainable power sources in wearable electronics, IoT devices, and self-powered sensors. The flexible piezoelectric nanogenerator (FPNG) segment specifically has emerged as a promising technology within this broader market, with a compound annual growth rate exceeding industry averages for conventional energy harvesting methods.

Consumer electronics represents the largest application segment for flexible piezoelectric nanogenerators, accounting for approximately one-third of the total market share. This dominance stems from the growing adoption of wearable technology and the need for compact, sustainable power sources that can conform to various form factors. Healthcare applications follow closely, with medical wearables and implantable devices creating significant demand for flexible energy harvesting solutions that can operate reliably within or on the human body.

Market research indicates that Asia-Pacific currently leads the global market for flexible energy harvesting technologies, with China, South Korea, and Japan serving as manufacturing and innovation hubs. North America and Europe maintain strong positions in research and development, particularly in advanced materials and substrate engineering for enhanced mechanical endurance of piezoelectric devices.

A key market driver is the expanding Internet of Things ecosystem, which is projected to connect billions of devices globally by 2025. This proliferation of connected devices creates substantial demand for self-powered sensors that can operate without battery replacement, particularly in remote or inaccessible locations. The automotive sector has also emerged as a rapidly growing application area, with flexible piezoelectric solutions being integrated into vehicle interiors for energy recovery from vibrations and passenger movements.

Consumer preference analysis reveals increasing demand for durable, long-lasting energy harvesting solutions, highlighting the critical importance of mechanical endurance in flexible piezoelectric technologies. Market surveys indicate that potential customers rank reliability and operational lifespan among their top three purchasing considerations, alongside energy conversion efficiency and cost.

The competitive landscape features both established electronics manufacturers and specialized startups focusing on advanced materials and fabrication techniques. Strategic partnerships between material science companies and electronics manufacturers have become increasingly common, creating integrated value chains that accelerate commercialization of flexible piezoelectric technologies with enhanced substrate properties and mechanical durability.

Market forecasts suggest that innovations in substrate engineering that successfully address mechanical endurance challenges could potentially double the addressable market for flexible piezoelectric nanogenerators within five years, particularly in applications requiring repeated bending, stretching, or compression cycles.

Consumer electronics represents the largest application segment for flexible piezoelectric nanogenerators, accounting for approximately one-third of the total market share. This dominance stems from the growing adoption of wearable technology and the need for compact, sustainable power sources that can conform to various form factors. Healthcare applications follow closely, with medical wearables and implantable devices creating significant demand for flexible energy harvesting solutions that can operate reliably within or on the human body.

Market research indicates that Asia-Pacific currently leads the global market for flexible energy harvesting technologies, with China, South Korea, and Japan serving as manufacturing and innovation hubs. North America and Europe maintain strong positions in research and development, particularly in advanced materials and substrate engineering for enhanced mechanical endurance of piezoelectric devices.

A key market driver is the expanding Internet of Things ecosystem, which is projected to connect billions of devices globally by 2025. This proliferation of connected devices creates substantial demand for self-powered sensors that can operate without battery replacement, particularly in remote or inaccessible locations. The automotive sector has also emerged as a rapidly growing application area, with flexible piezoelectric solutions being integrated into vehicle interiors for energy recovery from vibrations and passenger movements.

Consumer preference analysis reveals increasing demand for durable, long-lasting energy harvesting solutions, highlighting the critical importance of mechanical endurance in flexible piezoelectric technologies. Market surveys indicate that potential customers rank reliability and operational lifespan among their top three purchasing considerations, alongside energy conversion efficiency and cost.

The competitive landscape features both established electronics manufacturers and specialized startups focusing on advanced materials and fabrication techniques. Strategic partnerships between material science companies and electronics manufacturers have become increasingly common, creating integrated value chains that accelerate commercialization of flexible piezoelectric technologies with enhanced substrate properties and mechanical durability.

Market forecasts suggest that innovations in substrate engineering that successfully address mechanical endurance challenges could potentially double the addressable market for flexible piezoelectric nanogenerators within five years, particularly in applications requiring repeated bending, stretching, or compression cycles.

Flexible Piezoelectric Technology: Status and Barriers

Flexible piezoelectric nanogenerators (FPNGs) have emerged as a promising technology for harvesting mechanical energy from ambient environments, with applications ranging from self-powered sensors to wearable electronics. However, the current state of this technology faces significant challenges that impede its widespread commercial adoption and practical implementation.

The global research landscape shows uneven development, with leading institutions concentrated in East Asia, North America, and Europe. China, South Korea, and the United States dominate patent filings and research publications in this field, creating a competitive but fragmented innovation ecosystem. This geographical distribution has led to varying technological approaches and standards, complicating industry-wide integration efforts.

From a technical perspective, several critical barriers persist. Substrate engineering remains a fundamental challenge, as the mechanical properties of the substrate directly impact the piezoelectric performance and durability of the devices. Current substrate materials often present a trade-off between flexibility and piezoelectric output, limiting optimal performance in real-world applications.

Mechanical endurance represents another significant hurdle. Most FPNGs demonstrate performance degradation after repeated deformation cycles, with efficiency typically declining by 15-30% after 10,000 cycles. This limitation severely restricts their application in scenarios requiring long-term reliability, such as implantable medical devices or structural health monitoring systems.

Output consistency poses an additional challenge, as environmental factors including temperature, humidity, and mechanical stress patterns significantly affect the electrical output of these nanogenerators. Current devices exhibit output variations of up to 40% under changing environmental conditions, making system integration and power management exceptionally difficult.

Manufacturing scalability remains problematic, with most high-performance FPNGs still produced using laboratory-scale techniques that are difficult to translate to mass production. The precision required for nanoscale piezoelectric structures conflicts with the cost and throughput demands of commercial manufacturing processes.

Material limitations further constrain development, as many high-performance piezoelectric materials contain lead or rare earth elements, raising environmental concerns and potential regulatory barriers. Alternative materials typically demonstrate 30-50% lower piezoelectric coefficients, creating a significant performance gap.

Integration challenges with existing electronic systems persist due to the inherently variable and unpredictable nature of the electrical output from FPNGs. Current power management circuits add complexity, cost, and energy losses to the overall system, reducing the net efficiency of energy harvesting solutions.

The global research landscape shows uneven development, with leading institutions concentrated in East Asia, North America, and Europe. China, South Korea, and the United States dominate patent filings and research publications in this field, creating a competitive but fragmented innovation ecosystem. This geographical distribution has led to varying technological approaches and standards, complicating industry-wide integration efforts.

From a technical perspective, several critical barriers persist. Substrate engineering remains a fundamental challenge, as the mechanical properties of the substrate directly impact the piezoelectric performance and durability of the devices. Current substrate materials often present a trade-off between flexibility and piezoelectric output, limiting optimal performance in real-world applications.

Mechanical endurance represents another significant hurdle. Most FPNGs demonstrate performance degradation after repeated deformation cycles, with efficiency typically declining by 15-30% after 10,000 cycles. This limitation severely restricts their application in scenarios requiring long-term reliability, such as implantable medical devices or structural health monitoring systems.

Output consistency poses an additional challenge, as environmental factors including temperature, humidity, and mechanical stress patterns significantly affect the electrical output of these nanogenerators. Current devices exhibit output variations of up to 40% under changing environmental conditions, making system integration and power management exceptionally difficult.

Manufacturing scalability remains problematic, with most high-performance FPNGs still produced using laboratory-scale techniques that are difficult to translate to mass production. The precision required for nanoscale piezoelectric structures conflicts with the cost and throughput demands of commercial manufacturing processes.

Material limitations further constrain development, as many high-performance piezoelectric materials contain lead or rare earth elements, raising environmental concerns and potential regulatory barriers. Alternative materials typically demonstrate 30-50% lower piezoelectric coefficients, creating a significant performance gap.

Integration challenges with existing electronic systems persist due to the inherently variable and unpredictable nature of the electrical output from FPNGs. Current power management circuits add complexity, cost, and energy losses to the overall system, reducing the net efficiency of energy harvesting solutions.

Current Substrate Engineering Approaches for Flexibility

01 Materials for enhancing mechanical endurance in flexible piezoelectric nanogenerators

Various materials can be incorporated into flexible piezoelectric nanogenerators to enhance their mechanical endurance. These materials include polymer composites, carbon-based materials, and specialized substrate materials that can withstand repeated bending, stretching, and compression without degrading performance. The selection of appropriate materials is crucial for maintaining the electrical output and structural integrity of the nanogenerators under continuous mechanical stress.- Materials for enhancing mechanical endurance in flexible piezoelectric nanogenerators: Various materials can be incorporated into flexible piezoelectric nanogenerators to enhance their mechanical endurance. These materials include polymer composites, carbon-based materials, and specialized elastomers that can withstand repeated bending, stretching, and compression without degradation of performance. The selection of appropriate substrate materials and protective coatings plays a crucial role in ensuring long-term mechanical stability under continuous operation conditions.

- Structural designs for improving durability of flexible nanogenerators: Innovative structural designs can significantly improve the mechanical endurance of flexible piezoelectric nanogenerators. These designs include layered architectures, sandwich structures, and strategic placement of strain-relief features that distribute mechanical stress more evenly. Incorporating flexible interconnects between rigid components and using geometric patterns that accommodate deformation can prevent mechanical failure during repeated bending or stretching cycles.

- Testing methodologies for mechanical endurance evaluation: Specialized testing methodologies have been developed to evaluate the mechanical endurance of flexible piezoelectric nanogenerators. These include cyclic bending tests, tensile strength measurements, fatigue testing under various environmental conditions, and real-time monitoring of electrical output during mechanical stress. Accelerated aging tests help predict long-term performance and identify potential failure modes under continuous operation.

- Interface engineering for enhanced mechanical stability: Interface engineering between different components of flexible piezoelectric nanogenerators is critical for mechanical endurance. Techniques such as surface functionalization, gradient interfaces, and chemical bonding optimization can significantly improve adhesion between layers and prevent delamination during repeated mechanical deformation. Proper interface design ensures efficient stress transfer while maintaining electrical connectivity throughout the device lifetime.

- Self-healing mechanisms for prolonged operational lifetime: Self-healing mechanisms incorporated into flexible piezoelectric nanogenerators can automatically repair microcracks and damage caused by mechanical stress, significantly extending operational lifetime. These mechanisms include microcapsules containing healing agents, dynamic chemical bonds that can reform after breaking, and stimuli-responsive materials that activate repair processes when damage occurs. Such self-healing capabilities ensure sustained performance even after thousands of deformation cycles.

02 Structural designs for improved durability

Innovative structural designs can significantly improve the mechanical endurance of flexible piezoelectric nanogenerators. These designs include layered architectures, sandwich structures, and strategic placement of strain-relief features that distribute mechanical stress more evenly. By optimizing the physical configuration of the nanogenerator components, these designs minimize damage from repeated deformation and extend operational lifetime under dynamic conditions.Expand Specific Solutions03 Encapsulation techniques for environmental protection

Effective encapsulation techniques are essential for protecting flexible piezoelectric nanogenerators from environmental factors that could compromise their mechanical endurance. These techniques include the application of protective coatings, hermetic sealing methods, and specialized packaging that shields the active components from moisture, dust, and chemical contaminants while maintaining flexibility. Proper encapsulation significantly extends the operational lifetime of nanogenerators in real-world applications.Expand Specific Solutions04 Testing and characterization methods for mechanical endurance

Standardized testing and characterization methods are crucial for evaluating the mechanical endurance of flexible piezoelectric nanogenerators. These methods include cyclic bending tests, fatigue analysis, accelerated aging protocols, and real-time monitoring of electrical output during mechanical stress. Advanced analytical techniques help identify failure mechanisms and provide valuable data for improving design and material selection to enhance long-term durability.Expand Specific Solutions05 Integration of self-healing mechanisms

The incorporation of self-healing mechanisms represents an innovative approach to extending the mechanical endurance of flexible piezoelectric nanogenerators. These mechanisms include self-healing polymers, microcapsules containing healing agents, and dynamic chemical bonds that can repair microcracks and structural damage caused by repeated mechanical deformation. Self-healing capabilities allow nanogenerators to recover from mechanical damage autonomously, significantly improving their operational lifespan and reliability in applications requiring continuous mechanical stress.Expand Specific Solutions

Leading Researchers and Companies in Nanogenerator Field

The flexible piezoelectric nanogenerator market is currently in an early growth phase, characterized by rapid technological advancement and expanding applications. Market size is projected to increase significantly due to rising demand for self-powered electronics and wearable devices. In terms of technical maturity, leading research institutions like Korea Advanced Institute of Science & Technology, Beijing Institute of Nanoenergy & Nanosystems, and Georgia Tech Research Corp. are pioneering substrate engineering innovations, while companies such as Samsung Electronics and Kolon Industries are focusing on improving mechanical endurance for commercial viability. The competitive landscape features strong collaboration between academic institutions (Peking University, Xiamen University) and industrial players, with significant regional clusters in East Asia, North America, and Europe driving innovation in flexible energy harvesting technologies.

Korea Advanced Institute of Science & Technology

Technical Solution: Korea Advanced Institute of Science & Technology (KAIST) has developed an advanced flexible piezoelectric nanogenerator platform based on their proprietary "strain-engineered substrate" technology. Their approach utilizes a composite substrate architecture consisting of a core elastomeric layer sandwiched between engineered strain distribution layers. This design effectively minimizes localized strain concentrations during bending, significantly enhancing mechanical durability. KAIST's PENGs incorporate lead-free piezoelectric materials (primarily modified BaTiO3 nanoparticles) embedded in a flexible polymer matrix with controlled crystallographic orientation to maximize piezoelectric response. Their substrate engineering includes surface functionalization techniques that create strong covalent bonds between the piezoelectric elements and substrate, preventing delamination during repeated mechanical cycling. Testing has demonstrated sustained performance over 500,000 bending cycles with less than 15% output degradation. Additionally, KAIST has pioneered a novel "strain-isolation layer" that protects the active piezoelectric components from excessive deformation while still allowing efficient energy harvesting from normal operational movements.

Strengths: Excellent mechanical durability with proven long-term stability; environmentally friendly lead-free piezoelectric materials; sophisticated strain engineering that optimizes energy harvesting while protecting device integrity. Weaknesses: Lower power density compared to lead-based piezoelectric systems; more complex fabrication process requiring precise control of multiple layers; potential challenges in scaling up production while maintaining performance consistency.

Beijing Institute of Nanoenergy & Nanosystems

Technical Solution: Beijing Institute of Nanoenergy & Nanosystems (BINN) has pioneered flexible piezoelectric nanogenerators (PENGs) using innovative substrate engineering approaches. Their flagship technology involves the development of ultra-thin polymer substrates with engineered micro/nano-structures that enhance mechanical flexibility while maintaining high energy conversion efficiency. BINN has created PENGs based on PVDF (polyvinylidene fluoride) nanofibers embedded in flexible polymer matrices that can withstand over 100,000 bending cycles without significant performance degradation. Their proprietary "sandwich structure" design incorporates protective layers that shield the active piezoelectric materials from environmental factors while allowing efficient strain transfer. Recent advancements include the development of self-healing substrates that can recover from mechanical damage, significantly extending device lifetime in real-world applications. BINN has also pioneered composite substrates with gradient mechanical properties that distribute strain more evenly, reducing stress concentration and enhancing durability under repeated deformation.

Strengths: Superior mechanical endurance with documented performance stability over 100,000+ bending cycles; innovative self-healing substrate technology that extends operational lifetime; comprehensive expertise in both material synthesis and device integration. Weaknesses: Higher manufacturing complexity compared to conventional approaches; potential scalability challenges for mass production; relatively higher cost due to specialized materials and processing techniques.

Key Patents in Mechanical Endurance Enhancement

Flexible nanogenerator and method for manufacturing same

PatentWO2015122727A1

Innovation

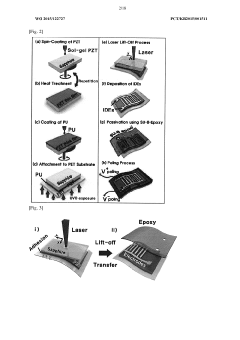

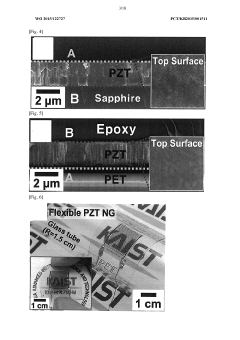

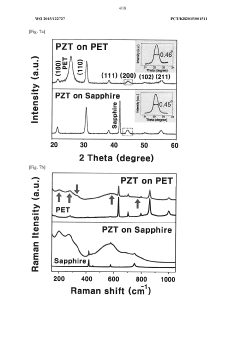

- A flexible nanogenerator manufacturing method involving a laser lift-off process to stack piezoelectric material layers on a transparent sacrificial substrate, transferring them to a flexible substrate, and forming electrodes, while using a passivation layer to enhance performance and durability.

Method for manufacturing flexible nanogenerator and flexible nanogenerator manufactured thereby

PatentWO2012047071A2

Innovation

- A method for manufacturing a flexible nanogenerator involves stacking a piezoelectric element layer on a sacrificial substrate, crystallizing it, and transferring it to a flexible substrate, with electrodes exposed and connected to form a connected electrode line, allowing for efficient energy harvesting from mechanical stress like body movements.

Materials Science Advancements for Flexible Electronics

The evolution of flexible electronics has been fundamentally driven by breakthroughs in materials science. Traditional rigid electronic substrates like silicon and glass have given way to flexible polymers such as polyimide, polyethylene terephthalate (PET), and polydimethylsiloxane (PDMS), enabling the development of bendable, stretchable, and even foldable electronic devices. These substrate materials provide the necessary mechanical properties while maintaining electronic functionality under deformation.

Recent advancements in substrate engineering have focused on improving the interface between flexible substrates and functional electronic materials. Researchers have developed novel surface treatment techniques that enhance adhesion while maintaining flexibility. Plasma treatment, chemical functionalization, and nanoscale texturing have emerged as effective methods to modify substrate surfaces without compromising their mechanical properties.

Nanocomposite materials represent another significant advancement, incorporating nanomaterials such as graphene, carbon nanotubes, and metal nanowires into polymer matrices. These composites offer superior electrical conductivity while maintaining excellent flexibility and stretchability. For piezoelectric nanogenerators specifically, nanocomposite substrates can enhance energy harvesting efficiency by optimizing the mechanical-to-electrical energy conversion process.

Self-healing materials have emerged as a promising solution to the mechanical endurance challenges in flexible electronics. These materials can autonomously repair damage from repeated bending, stretching, or folding, significantly extending device lifespan. Incorporating microcapsules containing healing agents or using reversible chemical bonds has shown promising results in maintaining electrical connectivity after mechanical damage.

Biomimetic approaches have also influenced materials development, with researchers drawing inspiration from natural structures like plant leaves or insect wings. These biological systems demonstrate remarkable combinations of flexibility and durability that can be emulated in synthetic materials. For example, hierarchical structures mimicking the architecture of natural tissues can distribute mechanical stress more effectively, preventing localized damage.

The integration of 2D materials like MXenes and transition metal dichalcogenides (TMDs) with flexible substrates has opened new possibilities for ultrathin, highly flexible electronic systems. These atomically thin materials offer exceptional electrical properties while being inherently flexible, making them ideal components for next-generation flexible piezoelectric nanogenerators with enhanced mechanical endurance.

Advances in printing technologies have enabled the direct deposition of functional materials onto flexible substrates, allowing for scalable manufacturing processes. Techniques such as inkjet printing, screen printing, and roll-to-roll processing can now deposit piezoelectric materials with precise control over thickness and pattern geometry, optimizing both electrical output and mechanical durability.

Recent advancements in substrate engineering have focused on improving the interface between flexible substrates and functional electronic materials. Researchers have developed novel surface treatment techniques that enhance adhesion while maintaining flexibility. Plasma treatment, chemical functionalization, and nanoscale texturing have emerged as effective methods to modify substrate surfaces without compromising their mechanical properties.

Nanocomposite materials represent another significant advancement, incorporating nanomaterials such as graphene, carbon nanotubes, and metal nanowires into polymer matrices. These composites offer superior electrical conductivity while maintaining excellent flexibility and stretchability. For piezoelectric nanogenerators specifically, nanocomposite substrates can enhance energy harvesting efficiency by optimizing the mechanical-to-electrical energy conversion process.

Self-healing materials have emerged as a promising solution to the mechanical endurance challenges in flexible electronics. These materials can autonomously repair damage from repeated bending, stretching, or folding, significantly extending device lifespan. Incorporating microcapsules containing healing agents or using reversible chemical bonds has shown promising results in maintaining electrical connectivity after mechanical damage.

Biomimetic approaches have also influenced materials development, with researchers drawing inspiration from natural structures like plant leaves or insect wings. These biological systems demonstrate remarkable combinations of flexibility and durability that can be emulated in synthetic materials. For example, hierarchical structures mimicking the architecture of natural tissues can distribute mechanical stress more effectively, preventing localized damage.

The integration of 2D materials like MXenes and transition metal dichalcogenides (TMDs) with flexible substrates has opened new possibilities for ultrathin, highly flexible electronic systems. These atomically thin materials offer exceptional electrical properties while being inherently flexible, making them ideal components for next-generation flexible piezoelectric nanogenerators with enhanced mechanical endurance.

Advances in printing technologies have enabled the direct deposition of functional materials onto flexible substrates, allowing for scalable manufacturing processes. Techniques such as inkjet printing, screen printing, and roll-to-roll processing can now deposit piezoelectric materials with precise control over thickness and pattern geometry, optimizing both electrical output and mechanical durability.

Environmental Impact and Sustainability Considerations

The development of Flexible Piezoelectric Nanogenerators (FPNGs) presents significant environmental implications that warrant careful consideration in their design, manufacturing, and end-of-life management. These devices offer promising sustainable energy harvesting capabilities, potentially reducing dependence on conventional power sources and associated carbon emissions. By converting ambient mechanical energy into electrical power, FPNGs contribute to the growing field of self-powered electronics, which can decrease battery consumption and electronic waste.

Material selection for FPNGs carries substantial environmental consequences. Traditional piezoelectric materials often contain lead-based compounds such as lead zirconate titanate (PZT), which pose serious environmental and health hazards. Recent research has focused on developing lead-free alternatives like zinc oxide (ZnO), barium titanate (BaTiO3), and polyvinylidene fluoride (PVDF), which demonstrate lower environmental toxicity while maintaining acceptable performance characteristics.

The substrate materials used in FPNGs also present environmental considerations. Polymer-based substrates like polyethylene terephthalate (PET) and polyimide offer flexibility but derive from petroleum resources and may not be readily biodegradable. Emerging research into bio-based substrates, including cellulose derivatives and biodegradable polymers, shows promise for reducing the environmental footprint of these devices while potentially enhancing their mechanical endurance.

Manufacturing processes for FPNGs typically involve chemical treatments, high-temperature processing, and specialized equipment that consume significant energy and resources. Life cycle assessments indicate that the environmental benefits of energy harvesting during operation must be weighed against the ecological costs of production. Innovations in green manufacturing techniques, such as low-temperature solution processing and additive manufacturing, are gradually reducing these impacts.

The durability and mechanical endurance of FPNGs directly influence their sustainability profile. Devices with longer operational lifespans distribute their initial environmental manufacturing costs over extended periods of use. Engineering approaches that enhance mechanical robustness—such as encapsulation techniques, strain-distributing designs, and self-healing materials—not only improve performance but also reduce replacement frequency and associated waste generation.

End-of-life considerations for FPNGs remain underdeveloped in current research. Recyclability challenges arise from the composite nature of these devices, which often integrate multiple materials that are difficult to separate. Design for disassembly and material recovery represents an important frontier for future development, potentially enabling closed-loop material systems that minimize environmental impact throughout the product lifecycle.

Water consumption and potential contamination during manufacturing present additional environmental concerns. Fabrication processes often require ultrapure water and various chemical solutions that must be properly managed to prevent ecosystem damage. Implementing water recycling systems and developing water-efficient manufacturing protocols can significantly reduce this environmental burden.

Material selection for FPNGs carries substantial environmental consequences. Traditional piezoelectric materials often contain lead-based compounds such as lead zirconate titanate (PZT), which pose serious environmental and health hazards. Recent research has focused on developing lead-free alternatives like zinc oxide (ZnO), barium titanate (BaTiO3), and polyvinylidene fluoride (PVDF), which demonstrate lower environmental toxicity while maintaining acceptable performance characteristics.

The substrate materials used in FPNGs also present environmental considerations. Polymer-based substrates like polyethylene terephthalate (PET) and polyimide offer flexibility but derive from petroleum resources and may not be readily biodegradable. Emerging research into bio-based substrates, including cellulose derivatives and biodegradable polymers, shows promise for reducing the environmental footprint of these devices while potentially enhancing their mechanical endurance.

Manufacturing processes for FPNGs typically involve chemical treatments, high-temperature processing, and specialized equipment that consume significant energy and resources. Life cycle assessments indicate that the environmental benefits of energy harvesting during operation must be weighed against the ecological costs of production. Innovations in green manufacturing techniques, such as low-temperature solution processing and additive manufacturing, are gradually reducing these impacts.

The durability and mechanical endurance of FPNGs directly influence their sustainability profile. Devices with longer operational lifespans distribute their initial environmental manufacturing costs over extended periods of use. Engineering approaches that enhance mechanical robustness—such as encapsulation techniques, strain-distributing designs, and self-healing materials—not only improve performance but also reduce replacement frequency and associated waste generation.

End-of-life considerations for FPNGs remain underdeveloped in current research. Recyclability challenges arise from the composite nature of these devices, which often integrate multiple materials that are difficult to separate. Design for disassembly and material recovery represents an important frontier for future development, potentially enabling closed-loop material systems that minimize environmental impact throughout the product lifecycle.

Water consumption and potential contamination during manufacturing present additional environmental concerns. Fabrication processes often require ultrapure water and various chemical solutions that must be properly managed to prevent ecosystem damage. Implementing water recycling systems and developing water-efficient manufacturing protocols can significantly reduce this environmental burden.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!