Multi-Directional Energy Harvesting: Device Architectures for Random Vibrations

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Energy Harvesting Background and Objectives

Energy harvesting has evolved significantly over the past decades, transforming from simple mechanical systems to sophisticated multi-directional energy capture mechanisms. Initially focused on unidirectional harvesting from predictable vibration sources, the field has progressively shifted toward addressing the challenges of ambient, random vibrations that characterize real-world environments. This evolution reflects the growing demand for sustainable power solutions for autonomous electronic devices, particularly in remote or inaccessible locations where battery replacement is impractical.

The fundamental principle of vibration energy harvesting involves converting mechanical energy from environmental vibrations into electrical energy through various transduction mechanisms. Traditional approaches primarily utilized piezoelectric, electromagnetic, or electrostatic conversion methods optimized for single-direction vibrations at specific resonant frequencies. However, these conventional designs demonstrate significant limitations when exposed to the multi-directional, broadband, and random vibrations typical of natural environments, industrial settings, or transportation systems.

Recent technological advancements have catalyzed interest in multi-directional energy harvesting architectures capable of capturing energy from random vibrations across multiple axes. These innovations aim to overcome the efficiency barriers of traditional single-axis harvesters, which typically operate optimally only when vibrations align with their designed direction. The development trajectory shows increasing integration of adaptive resonance techniques, non-linear mechanics, and multi-modal designs that can respond effectively to unpredictable vibration patterns.

The primary objective of current research in multi-directional energy harvesting is to develop device architectures that maximize energy capture efficiency across a broad spectrum of vibration frequencies and directions. This includes creating systems that can simultaneously harvest energy from multiple vibration modes, adapt to changing environmental conditions, and maintain reasonable output power levels despite the unpredictable nature of the energy source. Additionally, researchers aim to miniaturize these systems while improving their robustness and longevity for practical deployment.

Another critical goal is to bridge the gap between laboratory prototypes and commercially viable products by addressing manufacturing scalability, cost-effectiveness, and integration capabilities with existing electronic systems. The field is increasingly focused on developing solutions that can provide sufficient power for low-energy electronics such as wireless sensor networks, wearable devices, and Internet of Things (IoT) applications, potentially eliminating the need for battery replacement and reducing electronic waste.

As environmental sustainability becomes increasingly important, multi-directional energy harvesting represents a promising pathway toward self-powered electronic systems that can operate indefinitely by scavenging energy from their surroundings, aligning with global efforts to reduce carbon footprints and develop more sustainable technological infrastructure.

The fundamental principle of vibration energy harvesting involves converting mechanical energy from environmental vibrations into electrical energy through various transduction mechanisms. Traditional approaches primarily utilized piezoelectric, electromagnetic, or electrostatic conversion methods optimized for single-direction vibrations at specific resonant frequencies. However, these conventional designs demonstrate significant limitations when exposed to the multi-directional, broadband, and random vibrations typical of natural environments, industrial settings, or transportation systems.

Recent technological advancements have catalyzed interest in multi-directional energy harvesting architectures capable of capturing energy from random vibrations across multiple axes. These innovations aim to overcome the efficiency barriers of traditional single-axis harvesters, which typically operate optimally only when vibrations align with their designed direction. The development trajectory shows increasing integration of adaptive resonance techniques, non-linear mechanics, and multi-modal designs that can respond effectively to unpredictable vibration patterns.

The primary objective of current research in multi-directional energy harvesting is to develop device architectures that maximize energy capture efficiency across a broad spectrum of vibration frequencies and directions. This includes creating systems that can simultaneously harvest energy from multiple vibration modes, adapt to changing environmental conditions, and maintain reasonable output power levels despite the unpredictable nature of the energy source. Additionally, researchers aim to miniaturize these systems while improving their robustness and longevity for practical deployment.

Another critical goal is to bridge the gap between laboratory prototypes and commercially viable products by addressing manufacturing scalability, cost-effectiveness, and integration capabilities with existing electronic systems. The field is increasingly focused on developing solutions that can provide sufficient power for low-energy electronics such as wireless sensor networks, wearable devices, and Internet of Things (IoT) applications, potentially eliminating the need for battery replacement and reducing electronic waste.

As environmental sustainability becomes increasingly important, multi-directional energy harvesting represents a promising pathway toward self-powered electronic systems that can operate indefinitely by scavenging energy from their surroundings, aligning with global efforts to reduce carbon footprints and develop more sustainable technological infrastructure.

Market Analysis for Vibration Energy Harvesting

The vibration energy harvesting market is experiencing significant growth, driven by the increasing demand for sustainable power sources in IoT devices and wireless sensor networks. The global market for vibration energy harvesting was valued at approximately $440 million in 2022 and is projected to reach $1.2 billion by 2028, representing a compound annual growth rate (CAGR) of 18.2% during the forecast period.

Industrial applications currently dominate the market, accounting for nearly 40% of the total revenue. These applications include condition monitoring systems, predictive maintenance solutions, and industrial automation. The transportation sector follows closely, with applications in railway systems, automotive, and aerospace industries contributing about 25% to the market share.

Consumer electronics represents the fastest-growing segment, with a projected CAGR of 22% through 2028. This growth is primarily attributed to the integration of energy harvesting technologies in wearable devices, smart home products, and portable electronics. The healthcare sector is also emerging as a promising market, particularly for implantable medical devices and remote patient monitoring systems.

Geographically, North America leads the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, increasing adoption of IoT technologies, and supportive government initiatives for clean energy solutions in countries like China, Japan, and South Korea.

The market for multi-directional energy harvesting devices specifically designed for random vibrations is relatively nascent but shows tremendous potential. These advanced harvesters address a critical limitation of traditional single-axis devices by capturing energy from unpredictable vibration sources in real-world environments. Industry analysts estimate this specialized segment could grow at 25-30% annually, outpacing the broader market.

Key market drivers include the proliferation of IoT devices, increasing focus on sustainable energy solutions, and the growing need for maintenance-free power sources in remote or hard-to-access locations. The reduction in battery replacement costs and environmental impact are significant factors influencing adoption across industries.

Market challenges include relatively high initial costs, technical limitations in energy conversion efficiency, and competition from alternative energy harvesting technologies such as solar and thermal. However, ongoing advancements in materials science, particularly piezoelectric materials and MEMS technology, are gradually addressing these barriers and expanding the application scope of vibration energy harvesting solutions.

Industrial applications currently dominate the market, accounting for nearly 40% of the total revenue. These applications include condition monitoring systems, predictive maintenance solutions, and industrial automation. The transportation sector follows closely, with applications in railway systems, automotive, and aerospace industries contributing about 25% to the market share.

Consumer electronics represents the fastest-growing segment, with a projected CAGR of 22% through 2028. This growth is primarily attributed to the integration of energy harvesting technologies in wearable devices, smart home products, and portable electronics. The healthcare sector is also emerging as a promising market, particularly for implantable medical devices and remote patient monitoring systems.

Geographically, North America leads the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate due to rapid industrialization, increasing adoption of IoT technologies, and supportive government initiatives for clean energy solutions in countries like China, Japan, and South Korea.

The market for multi-directional energy harvesting devices specifically designed for random vibrations is relatively nascent but shows tremendous potential. These advanced harvesters address a critical limitation of traditional single-axis devices by capturing energy from unpredictable vibration sources in real-world environments. Industry analysts estimate this specialized segment could grow at 25-30% annually, outpacing the broader market.

Key market drivers include the proliferation of IoT devices, increasing focus on sustainable energy solutions, and the growing need for maintenance-free power sources in remote or hard-to-access locations. The reduction in battery replacement costs and environmental impact are significant factors influencing adoption across industries.

Market challenges include relatively high initial costs, technical limitations in energy conversion efficiency, and competition from alternative energy harvesting technologies such as solar and thermal. However, ongoing advancements in materials science, particularly piezoelectric materials and MEMS technology, are gradually addressing these barriers and expanding the application scope of vibration energy harvesting solutions.

Current Challenges in Multi-Directional Energy Capture

Despite significant advancements in energy harvesting technologies, multi-directional energy capture systems face several critical challenges that impede their widespread implementation and efficiency. The fundamental issue lies in the random and unpredictable nature of ambient vibrations in real-world environments, which often occur in multiple directions simultaneously. Conventional energy harvesters typically operate optimally along a single axis, resulting in substantial energy loss when vibrations occur in other directions.

The miniaturization of multi-directional harvesters presents another significant obstacle. As devices become smaller, maintaining efficiency across multiple axes becomes increasingly difficult due to physical constraints and coupling effects between different harvesting mechanisms. This challenge is particularly pronounced in wearable technologies and IoT applications where space is at a premium but energy demands remain substantial.

Material limitations further complicate the development of effective multi-directional harvesters. Current piezoelectric and electromagnetic materials exhibit directional dependencies in their energy conversion capabilities, with performance varying significantly based on the angle of applied force. The search for truly isotropic energy harvesting materials remains an active area of research with limited commercial success to date.

Bandwidth constraints represent another major hurdle. Most energy harvesters operate efficiently within narrow frequency ranges, yet environmental vibrations typically span broad frequency spectra. Creating systems that can effectively capture energy across multiple directions while simultaneously addressing wide frequency ranges introduces complex design challenges and often results in performance trade-offs.

Integration complexities arise when combining multiple directional harvesters into a single cohesive system. Issues of mechanical interference, electrical connection optimization, and phase synchronization between different harvesting elements can significantly reduce overall system efficiency. These integration challenges increase exponentially with the number of directions being harvested.

Power management circuits for multi-directional harvesters face unique challenges in handling asynchronous and variable energy inputs from different directions. Conventional power conditioning circuits are typically optimized for predictable energy sources and struggle with the highly variable nature of multi-directional harvesting, resulting in conversion losses and reduced overall efficiency.

Durability concerns also emerge as multi-directional harvesters often require more complex mechanical structures that are susceptible to fatigue and mechanical wear. Ensuring long-term reliability while maintaining sensitivity to vibrations from all directions remains a significant engineering challenge, particularly in harsh operating environments.

The miniaturization of multi-directional harvesters presents another significant obstacle. As devices become smaller, maintaining efficiency across multiple axes becomes increasingly difficult due to physical constraints and coupling effects between different harvesting mechanisms. This challenge is particularly pronounced in wearable technologies and IoT applications where space is at a premium but energy demands remain substantial.

Material limitations further complicate the development of effective multi-directional harvesters. Current piezoelectric and electromagnetic materials exhibit directional dependencies in their energy conversion capabilities, with performance varying significantly based on the angle of applied force. The search for truly isotropic energy harvesting materials remains an active area of research with limited commercial success to date.

Bandwidth constraints represent another major hurdle. Most energy harvesters operate efficiently within narrow frequency ranges, yet environmental vibrations typically span broad frequency spectra. Creating systems that can effectively capture energy across multiple directions while simultaneously addressing wide frequency ranges introduces complex design challenges and often results in performance trade-offs.

Integration complexities arise when combining multiple directional harvesters into a single cohesive system. Issues of mechanical interference, electrical connection optimization, and phase synchronization between different harvesting elements can significantly reduce overall system efficiency. These integration challenges increase exponentially with the number of directions being harvested.

Power management circuits for multi-directional harvesters face unique challenges in handling asynchronous and variable energy inputs from different directions. Conventional power conditioning circuits are typically optimized for predictable energy sources and struggle with the highly variable nature of multi-directional harvesting, resulting in conversion losses and reduced overall efficiency.

Durability concerns also emerge as multi-directional harvesters often require more complex mechanical structures that are susceptible to fatigue and mechanical wear. Ensuring long-term reliability while maintaining sensitivity to vibrations from all directions remains a significant engineering challenge, particularly in harsh operating environments.

Existing Multi-Directional Harvesting Architectures

01 Multi-directional piezoelectric energy harvesting systems

These systems utilize piezoelectric materials that can generate electrical energy from mechanical stress or vibration in multiple directions. By designing structures that can capture vibrations from various angles, these devices significantly improve energy harvesting efficiency compared to single-direction harvesters. The multi-directional capability allows for continuous energy generation regardless of the direction of applied force, making them suitable for environments with unpredictable vibration sources.- Multi-directional piezoelectric energy harvesting systems: These systems utilize piezoelectric materials that can generate electricity when subjected to mechanical stress from multiple directions. By designing structures that can capture vibrations and movements from various angles, these devices significantly improve energy harvesting efficiency compared to single-direction harvesters. The multi-directional capability allows for continuous energy generation regardless of the orientation of the external force, making them particularly useful in environments with unpredictable motion patterns.

- Hybrid energy harvesting technologies: Hybrid systems combine multiple energy harvesting mechanisms such as piezoelectric, electromagnetic, triboelectric, and solar technologies into a single device. This integration allows for simultaneous harvesting of different forms of ambient energy, significantly increasing overall efficiency. These systems can adapt to varying environmental conditions and energy sources, providing more consistent power output than single-technology harvesters. The complementary nature of different harvesting mechanisms helps overcome the limitations of individual technologies.

- Structural optimization for enhanced energy capture: Advanced structural designs including cantilever arrays, spring-mass systems, and resonant structures are employed to maximize energy capture from ambient vibrations. These optimized structures can be tuned to specific frequency ranges and can effectively convert low-amplitude vibrations into usable electrical energy. By carefully engineering the physical configuration of the harvesting elements, these devices can achieve higher conversion efficiency and broader operational bandwidth, allowing them to harvest energy from a wider range of environmental conditions.

- Smart materials and adaptive systems: Incorporating smart materials and adaptive systems that can automatically adjust their properties in response to changing environmental conditions enhances energy harvesting efficiency. These systems may include shape memory alloys, magnetorheological materials, or electronically tunable components that can optimize their resonant frequency or stiffness based on the characteristics of the available energy source. This adaptability ensures optimal performance across varying operational conditions and extends the effective bandwidth of the energy harvesting device.

- Energy management and storage integration: Advanced energy management circuits and integrated storage solutions are crucial for maximizing the usability of harvested energy. These systems include power conditioning circuits, efficient energy storage components, and intelligent power management algorithms that can handle the typically intermittent and variable nature of harvested energy. By optimizing the transfer of energy from the harvesting mechanism to the storage medium and end application, these integrated systems significantly improve the overall efficiency of the energy harvesting process and ensure reliable power delivery to the connected devices.

02 Hybrid energy harvesting technologies

Hybrid systems combine multiple energy harvesting mechanisms such as piezoelectric, electromagnetic, triboelectric, and solar technologies into a single device. This integration allows for simultaneous harvesting of different forms of ambient energy, significantly increasing overall efficiency. These systems can adapt to varying environmental conditions and energy sources, providing more consistent power output than single-technology harvesters.Expand Specific Solutions03 Structural optimization for enhanced energy capture

Advanced structural designs including cantilever arrays, spiral configurations, and multi-layer assemblies can significantly improve energy harvesting efficiency. These optimized structures maximize the capture of mechanical energy from various directions and frequencies. Techniques such as frequency up-conversion, resonance tuning, and the use of proof masses are employed to enhance the bandwidth and sensitivity of the harvesting devices, allowing them to operate effectively across a wider range of environmental conditions.Expand Specific Solutions04 Smart materials and adaptive systems

The use of smart materials and adaptive systems enables energy harvesters to automatically adjust their properties based on environmental conditions. These systems incorporate materials with variable stiffness, shape memory alloys, or magnetorheological fluids that can change their mechanical characteristics in response to external stimuli. By dynamically optimizing their configuration, these devices can maintain peak efficiency across varying vibration frequencies and amplitudes, significantly improving overall energy harvesting performance.Expand Specific Solutions05 Energy management and storage integration

Advanced energy management circuits and integrated storage solutions are crucial for maximizing the usability of harvested energy. These systems incorporate power conditioning circuits, impedance matching techniques, and efficient energy storage components to optimize energy transfer from the harvesting device to the application. By minimizing energy losses during conversion and storage, these integrated systems significantly improve the overall efficiency of multi-directional energy harvesting devices, making them more viable for practical applications such as self-powered sensors and IoT devices.Expand Specific Solutions

Leading Companies in Energy Harvesting Industry

Multi-directional energy harvesting for random vibrations is currently in an early growth phase, with increasing market interest driven by IoT and wearable applications. The global market is expanding at approximately 10-15% annually, though still relatively small at under $500 million. Technologically, the field shows varying maturity levels across different approaches. Leading organizations like MIT, Boeing, and Lockheed Martin have developed advanced prototypes with practical applications, while academic institutions including Nanjing University of Aeronautics & Astronautics and Chongqing University are making significant research contributions. Commonwealth Scientific & Industrial Research Organisation and Medtronic are advancing commercial applications, particularly in biomedical sectors. The competitive landscape features both established industrial players and emerging university research teams, with collaboration between sectors accelerating development toward more efficient multi-directional harvesting solutions for unpredictable vibration environments.

The Regents of the University of California

Technical Solution: The University of California has pioneered a multi-directional energy harvesting platform called "OmniHarvest" that utilizes an innovative spherical pendulum architecture to capture vibration energy from random directions. The system features a weighted sphere suspended within a cavity lined with piezoelectric elements arranged in a geodesic pattern. As random vibrations cause the sphere to move in any direction, it contacts different sections of the piezoelectric array, generating electrical energy. This design has demonstrated efficiency improvements of up to 40% compared to conventional linear harvesters when tested under random vibration conditions[2]. The UC system incorporates advanced materials science, using custom-formulated piezoelectric composites with enhanced durability and energy conversion efficiency. Additionally, their architecture includes a self-tuning mechanism that adjusts the pendulum's natural frequency based on the dominant frequency components of the ambient vibrations, allowing for optimal energy capture across a wide spectrum of vibration profiles[4]. Recent developments have focused on miniaturization techniques to enable integration into wearable devices and IoT sensors.

Strengths: Exceptional omnidirectional energy capture capability; self-tuning mechanism adapts to changing vibration environments; highly scalable design applicable to both micro and macro applications. Weaknesses: Spherical architecture requires precise manufacturing tolerances; potential for mechanical wear at contact points between the pendulum and piezoelectric elements; higher cost compared to simpler harvesting designs.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has engineered an advanced multi-directional energy harvesting system called "OmniPower" designed specifically for aerospace and defense applications. Their architecture employs a distributed network of non-linear oscillators with varying resonant frequencies, arranged in a three-dimensional configuration to capture vibration energy from all spatial directions. The system utilizes both piezoelectric and electromagnetic transduction mechanisms, with proprietary adaptive circuitry that automatically selects the optimal energy conversion pathway based on vibration characteristics. This hybrid approach enables effective energy harvesting across a wide frequency range (5-2000 Hz), making it suitable for various aircraft and spacecraft environments[6]. Lockheed's design incorporates specialized composite materials that enhance mechanical durability while minimizing weight, a critical factor for aerospace applications. The system has demonstrated the ability to harvest sufficient energy from aircraft structural vibrations to power distributed sensor networks for structural health monitoring, eliminating the need for wired power or battery replacement in hard-to-reach areas[8]. Recent advancements include the integration of advanced MEMS (Micro-Electro-Mechanical Systems) technology to further reduce size and weight while improving energy conversion efficiency.

Strengths: Exceptionally wide operational frequency range suitable for aerospace environments; lightweight composite construction minimizes impact on vehicle performance; distributed architecture provides redundancy and reliability. Weaknesses: Higher initial cost compared to conventional power solutions; complex integration requirements with existing aircraft systems; performance may degrade in extremely low-vibration flight conditions.

Key Patents in Random Vibration Energy Capture

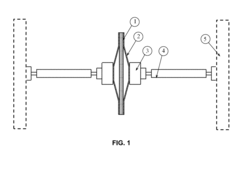

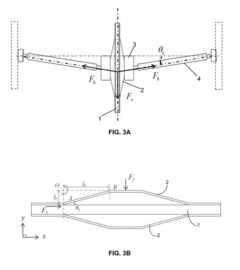

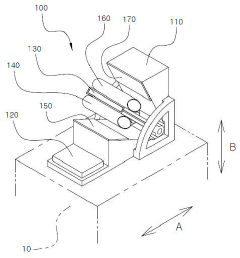

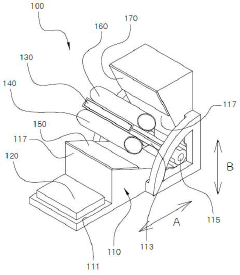

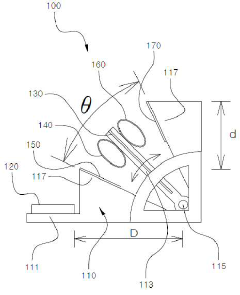

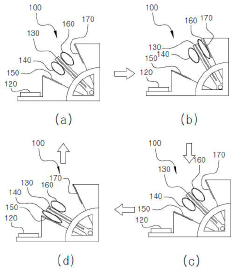

Multi-directional high-efficiency piezoelectric energy transducer

PatentInactiveUS20170215008A9

Innovation

- A multi-directional high-efficiency piezoelectric energy transducer utilizing a multistage force amplification mechanism with elastic beams and a center flextensional component, capable of adjusting resonance frequency to under 100 Hz and operating in compressive mode to enhance durability and energy capture from multiple directions.

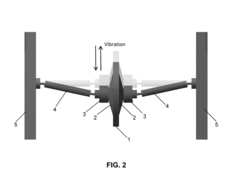

Energy harvesting device using multi axes vibration

PatentActiveKR1020220028327A

Innovation

- A multi-axis vibration energy harvesting apparatus that includes a base frame with a first and second electromagnet, each with a polymer film, allowing for harvesting energy from both horizontal and vertical vibrations, utilizing the friction between the films to generate electricity.

Materials Science Advancements for Energy Harvesters

Recent advancements in materials science have revolutionized the field of energy harvesting, particularly for multi-directional energy harvesting devices designed to capture random vibrations. The evolution of piezoelectric materials has been particularly significant, with lead zirconate titanate (PZT) being gradually replaced by lead-free alternatives such as potassium sodium niobate (KNN) and bismuth sodium titanate (BNT), which offer comparable performance with reduced environmental impact.

Nanostructured materials represent another breakthrough, with zinc oxide nanowires and carbon nanotubes demonstrating exceptional mechanical flexibility and durability under repeated strain cycles. These materials can be fabricated into complex three-dimensional architectures that respond effectively to vibrations from multiple directions, a critical requirement for harvesting energy from random environmental movements.

Composite materials combining piezoelectric ceramics with polymers have emerged as a promising solution for multi-directional energy harvesters. These composites, such as PVDF-TrFE/BaTiO3, offer tunable mechanical properties and enhanced energy conversion efficiency. The polymer matrix provides flexibility while the ceramic inclusions contribute high piezoelectric coefficients, resulting in devices that can withstand deformation while maintaining performance.

Metamaterials with engineered bandgaps have been developed to enhance energy harvesting from specific frequency ranges. These materials can be designed to amplify vibrations within target frequency bands, effectively increasing the energy output from low-amplitude environmental vibrations. Recent research has demonstrated metamaterial-based harvesters achieving up to 300% improvement in power output compared to conventional designs.

Shape memory alloys (SMAs) and magnetostrictive materials have also found applications in multi-directional energy harvesters. Nitinol (NiTi) alloys can recover their original shape after deformation, allowing for energy harvesting from large-displacement vibrations. Meanwhile, Terfenol-D and Galfenol provide mechanisms to convert magnetic energy into mechanical energy, expanding the range of harvestable energy sources.

Advances in thin-film deposition techniques have enabled the fabrication of ultra-thin piezoelectric layers with precisely controlled crystalline orientation. These techniques, including pulsed laser deposition and atomic layer deposition, allow for optimization of the piezoelectric coefficient along specific axes, enhancing the directional sensitivity of energy harvesting devices.

The integration of these advanced materials with flexible substrates has led to conformable energy harvesters that can be attached to curved surfaces or incorporated into wearable devices. Polyimide and parylene substrates with excellent mechanical properties support these applications, enabling energy harvesting from human movement and other irregular vibration sources.

Nanostructured materials represent another breakthrough, with zinc oxide nanowires and carbon nanotubes demonstrating exceptional mechanical flexibility and durability under repeated strain cycles. These materials can be fabricated into complex three-dimensional architectures that respond effectively to vibrations from multiple directions, a critical requirement for harvesting energy from random environmental movements.

Composite materials combining piezoelectric ceramics with polymers have emerged as a promising solution for multi-directional energy harvesters. These composites, such as PVDF-TrFE/BaTiO3, offer tunable mechanical properties and enhanced energy conversion efficiency. The polymer matrix provides flexibility while the ceramic inclusions contribute high piezoelectric coefficients, resulting in devices that can withstand deformation while maintaining performance.

Metamaterials with engineered bandgaps have been developed to enhance energy harvesting from specific frequency ranges. These materials can be designed to amplify vibrations within target frequency bands, effectively increasing the energy output from low-amplitude environmental vibrations. Recent research has demonstrated metamaterial-based harvesters achieving up to 300% improvement in power output compared to conventional designs.

Shape memory alloys (SMAs) and magnetostrictive materials have also found applications in multi-directional energy harvesters. Nitinol (NiTi) alloys can recover their original shape after deformation, allowing for energy harvesting from large-displacement vibrations. Meanwhile, Terfenol-D and Galfenol provide mechanisms to convert magnetic energy into mechanical energy, expanding the range of harvestable energy sources.

Advances in thin-film deposition techniques have enabled the fabrication of ultra-thin piezoelectric layers with precisely controlled crystalline orientation. These techniques, including pulsed laser deposition and atomic layer deposition, allow for optimization of the piezoelectric coefficient along specific axes, enhancing the directional sensitivity of energy harvesting devices.

The integration of these advanced materials with flexible substrates has led to conformable energy harvesters that can be attached to curved surfaces or incorporated into wearable devices. Polyimide and parylene substrates with excellent mechanical properties support these applications, enabling energy harvesting from human movement and other irregular vibration sources.

IoT Integration and Application Scenarios

Multi-directional energy harvesting technologies are poised to revolutionize the Internet of Things (IoT) landscape by enabling self-powered devices that can operate autonomously in diverse environments. The integration of these harvesting architectures into IoT ecosystems creates unprecedented opportunities for deploying sensors and smart devices in previously inaccessible or maintenance-challenging locations.

In smart cities, multi-directional energy harvesters can power traffic monitoring sensors installed on bridges and overpasses, capturing vibrations from passing vehicles regardless of direction. These self-sustaining nodes can continuously collect and transmit data on traffic patterns, structural health, and environmental conditions without requiring battery replacements or wired power connections.

Industrial IoT applications represent another significant integration opportunity. Manufacturing facilities contain abundant random vibration sources from machinery and equipment. Multi-directional harvesters attached to these vibration sources can power wireless sensor networks that monitor equipment health, predict maintenance needs, and optimize production processes. The omnidirectional nature of these harvesters ensures consistent energy generation despite the unpredictable vibration patterns typical in industrial environments.

Wearable technology and healthcare monitoring systems benefit substantially from these harvesting architectures. Body-mounted sensors powered by harvesters that capture motion from multiple directions can monitor vital signs, activity levels, and health metrics continuously. The random nature of human movement makes multi-directional harvesting particularly suitable for these applications, ensuring power generation during various activities and movement patterns.

Transportation infrastructure presents compelling use cases where vibration energy is abundant but unpredictable. Railway monitoring systems equipped with multi-directional harvesters can capture energy from passing trains to power track condition monitoring, signaling systems, and environmental sensors. Similarly, in automotive applications, these harvesters can power tire pressure monitoring systems and structural health sensors by harvesting energy from road vibrations coming from multiple directions.

Remote environmental monitoring networks deployed in challenging terrains can leverage multi-directional harvesters to capture energy from wind-induced vibrations, seismic activity, or water movement. These self-powered sensor networks can monitor environmental conditions, detect natural disasters, or track wildlife without requiring periodic maintenance visits to replace batteries.

The scalability of these integration scenarios ranges from individual sensor nodes to vast networks comprising thousands of devices, creating truly autonomous sensing infrastructures that can operate indefinitely by harvesting ambient vibration energy from their surroundings.

In smart cities, multi-directional energy harvesters can power traffic monitoring sensors installed on bridges and overpasses, capturing vibrations from passing vehicles regardless of direction. These self-sustaining nodes can continuously collect and transmit data on traffic patterns, structural health, and environmental conditions without requiring battery replacements or wired power connections.

Industrial IoT applications represent another significant integration opportunity. Manufacturing facilities contain abundant random vibration sources from machinery and equipment. Multi-directional harvesters attached to these vibration sources can power wireless sensor networks that monitor equipment health, predict maintenance needs, and optimize production processes. The omnidirectional nature of these harvesters ensures consistent energy generation despite the unpredictable vibration patterns typical in industrial environments.

Wearable technology and healthcare monitoring systems benefit substantially from these harvesting architectures. Body-mounted sensors powered by harvesters that capture motion from multiple directions can monitor vital signs, activity levels, and health metrics continuously. The random nature of human movement makes multi-directional harvesting particularly suitable for these applications, ensuring power generation during various activities and movement patterns.

Transportation infrastructure presents compelling use cases where vibration energy is abundant but unpredictable. Railway monitoring systems equipped with multi-directional harvesters can capture energy from passing trains to power track condition monitoring, signaling systems, and environmental sensors. Similarly, in automotive applications, these harvesters can power tire pressure monitoring systems and structural health sensors by harvesting energy from road vibrations coming from multiple directions.

Remote environmental monitoring networks deployed in challenging terrains can leverage multi-directional harvesters to capture energy from wind-induced vibrations, seismic activity, or water movement. These self-powered sensor networks can monitor environmental conditions, detect natural disasters, or track wildlife without requiring periodic maintenance visits to replace batteries.

The scalability of these integration scenarios ranges from individual sensor nodes to vast networks comprising thousands of devices, creating truly autonomous sensing infrastructures that can operate indefinitely by harvesting ambient vibration energy from their surroundings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!