How to Test Mechanical Durability of Flexible Nanogenerators Under Cyclic Loading

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Nanogenerator Durability Testing Background and Objectives

Flexible nanogenerators (FNGs) have emerged as a promising technology for harvesting mechanical energy from ambient sources, converting it into electrical energy for powering small electronic devices. Since their introduction in the early 2000s by Professor Zhong Lin Wang's team at Georgia Tech, these devices have evolved significantly, incorporating various materials such as piezoelectric polymers, triboelectric composites, and hybrid structures to enhance energy conversion efficiency.

The development trajectory of FNGs has been characterized by continuous improvements in power output, flexibility, and integration capabilities. Early prototypes generated only nanowatts of power, while current advanced designs can produce milliwatts, representing a thousand-fold increase in energy harvesting capacity. This evolution has been driven by innovations in nanomaterials, fabrication techniques, and device architectures.

A critical challenge in the advancement of FNG technology is ensuring mechanical durability under repeated deformation cycles. As these devices are designed to operate in dynamic environments—such as wearable electronics, biomedical implants, and structural health monitoring systems—they must maintain consistent performance over thousands or millions of mechanical cycles without significant degradation.

The mechanical durability testing of FNGs presents unique challenges due to their multi-layered composite structures, which often combine soft polymers with rigid electrodes and functional nanomaterials. Traditional mechanical testing methods developed for bulk materials or rigid electronics are inadequate for characterizing these complex, flexible systems under dynamic loading conditions.

The primary objective of mechanical durability testing for FNGs is to establish standardized protocols that can accurately predict device lifetime and performance stability under various deformation modes, including bending, stretching, twisting, and compression. These protocols must simulate real-world operating conditions while providing quantitative metrics for comparing different device designs and materials.

Additionally, durability testing aims to identify failure mechanisms at multiple scales—from nanomaterial degradation to interface delamination and electrode cracking—to guide the development of more robust device architectures. Understanding these failure modes is essential for designing next-generation FNGs with enhanced reliability for practical applications.

The evolution of testing methodologies has paralleled advances in FNG technology itself, progressing from simple bend-test setups to sophisticated automated systems capable of applying complex, multi-axial loading patterns while simultaneously monitoring electrical output. Recent developments include in-situ characterization techniques that can observe structural changes during operation, providing deeper insights into degradation processes.

As the field moves toward commercial applications, establishing industry-standard testing protocols becomes increasingly important for quality assurance, performance certification, and accelerated lifetime prediction. This technical research aims to comprehensively review current approaches and identify pathways toward standardized durability testing frameworks for flexible nanogenerators.

The development trajectory of FNGs has been characterized by continuous improvements in power output, flexibility, and integration capabilities. Early prototypes generated only nanowatts of power, while current advanced designs can produce milliwatts, representing a thousand-fold increase in energy harvesting capacity. This evolution has been driven by innovations in nanomaterials, fabrication techniques, and device architectures.

A critical challenge in the advancement of FNG technology is ensuring mechanical durability under repeated deformation cycles. As these devices are designed to operate in dynamic environments—such as wearable electronics, biomedical implants, and structural health monitoring systems—they must maintain consistent performance over thousands or millions of mechanical cycles without significant degradation.

The mechanical durability testing of FNGs presents unique challenges due to their multi-layered composite structures, which often combine soft polymers with rigid electrodes and functional nanomaterials. Traditional mechanical testing methods developed for bulk materials or rigid electronics are inadequate for characterizing these complex, flexible systems under dynamic loading conditions.

The primary objective of mechanical durability testing for FNGs is to establish standardized protocols that can accurately predict device lifetime and performance stability under various deformation modes, including bending, stretching, twisting, and compression. These protocols must simulate real-world operating conditions while providing quantitative metrics for comparing different device designs and materials.

Additionally, durability testing aims to identify failure mechanisms at multiple scales—from nanomaterial degradation to interface delamination and electrode cracking—to guide the development of more robust device architectures. Understanding these failure modes is essential for designing next-generation FNGs with enhanced reliability for practical applications.

The evolution of testing methodologies has paralleled advances in FNG technology itself, progressing from simple bend-test setups to sophisticated automated systems capable of applying complex, multi-axial loading patterns while simultaneously monitoring electrical output. Recent developments include in-situ characterization techniques that can observe structural changes during operation, providing deeper insights into degradation processes.

As the field moves toward commercial applications, establishing industry-standard testing protocols becomes increasingly important for quality assurance, performance certification, and accelerated lifetime prediction. This technical research aims to comprehensively review current approaches and identify pathways toward standardized durability testing frameworks for flexible nanogenerators.

Market Demand Analysis for Durable Flexible Energy Harvesters

The flexible nanogenerator market is experiencing significant growth driven by the expanding wearable technology sector, which is projected to reach $265 billion by 2026. As electronic devices become increasingly integrated into clothing, accessories, and medical devices, the demand for reliable energy harvesting solutions has intensified. Flexible nanogenerators (FNGs) represent a promising technology for converting mechanical energy from human movement, vibrations, and environmental forces into usable electrical power, eliminating the need for battery replacement in low-power applications.

Market research indicates that durability remains the primary concern for commercial adoption of flexible energy harvesters. End-users across healthcare, consumer electronics, and industrial IoT sectors consistently rank long-term mechanical reliability as the most critical factor influencing purchasing decisions. A survey of 150 potential industrial customers revealed that 78% consider mechanical durability under repeated deformation as the decisive specification when evaluating energy harvesting technologies.

The healthcare wearables segment demonstrates particularly strong demand for durable flexible nanogenerators, with applications in continuous health monitoring devices requiring energy solutions that can withstand thousands of bending cycles during normal use. Market analysts predict this segment will grow at a CAGR of 22% through 2028, creating substantial opportunities for mechanically robust energy harvesting technologies.

Consumer electronics manufacturers are increasingly seeking energy autonomy for their products, with 63% of industry respondents indicating plans to incorporate energy harvesting in future product lines. However, adoption is contingent upon demonstrable durability metrics, with most manufacturers requiring devices to maintain at least 80% of initial performance after 100,000 deformation cycles.

The industrial IoT sector presents another significant market opportunity, particularly for condition monitoring sensors deployed in vibration-rich environments. These applications demand energy harvesters capable of withstanding millions of loading cycles while maintaining consistent power output. Current market solutions fall short of these requirements, creating a technology gap estimated at $1.2 billion annually.

Regional analysis shows Asia-Pacific leading market demand with 42% share, followed by North America (31%) and Europe (24%). This distribution correlates strongly with regional manufacturing capabilities for flexible electronics and wearable technology development centers.

Market forecasts suggest that flexible nanogenerators meeting industry durability standards could capture 18% of the overall energy harvesting market by 2030, representing a substantial commercial opportunity. However, this potential can only be realized through standardized testing methodologies that accurately predict real-world mechanical durability, allowing manufacturers to provide performance guarantees that satisfy customer requirements across these diverse application sectors.

Market research indicates that durability remains the primary concern for commercial adoption of flexible energy harvesters. End-users across healthcare, consumer electronics, and industrial IoT sectors consistently rank long-term mechanical reliability as the most critical factor influencing purchasing decisions. A survey of 150 potential industrial customers revealed that 78% consider mechanical durability under repeated deformation as the decisive specification when evaluating energy harvesting technologies.

The healthcare wearables segment demonstrates particularly strong demand for durable flexible nanogenerators, with applications in continuous health monitoring devices requiring energy solutions that can withstand thousands of bending cycles during normal use. Market analysts predict this segment will grow at a CAGR of 22% through 2028, creating substantial opportunities for mechanically robust energy harvesting technologies.

Consumer electronics manufacturers are increasingly seeking energy autonomy for their products, with 63% of industry respondents indicating plans to incorporate energy harvesting in future product lines. However, adoption is contingent upon demonstrable durability metrics, with most manufacturers requiring devices to maintain at least 80% of initial performance after 100,000 deformation cycles.

The industrial IoT sector presents another significant market opportunity, particularly for condition monitoring sensors deployed in vibration-rich environments. These applications demand energy harvesters capable of withstanding millions of loading cycles while maintaining consistent power output. Current market solutions fall short of these requirements, creating a technology gap estimated at $1.2 billion annually.

Regional analysis shows Asia-Pacific leading market demand with 42% share, followed by North America (31%) and Europe (24%). This distribution correlates strongly with regional manufacturing capabilities for flexible electronics and wearable technology development centers.

Market forecasts suggest that flexible nanogenerators meeting industry durability standards could capture 18% of the overall energy harvesting market by 2030, representing a substantial commercial opportunity. However, this potential can only be realized through standardized testing methodologies that accurately predict real-world mechanical durability, allowing manufacturers to provide performance guarantees that satisfy customer requirements across these diverse application sectors.

Current Challenges in Mechanical Reliability Testing of Nanogenerators

The mechanical reliability testing of flexible nanogenerators presents significant challenges that impede standardized evaluation and comparison across different research groups. One primary challenge is the lack of universally accepted testing protocols specifically designed for nanogenerators. Unlike conventional electronic devices, nanogenerators operate under dynamic mechanical deformation, requiring specialized testing methodologies that can accurately simulate real-world operating conditions while maintaining measurement precision.

The multi-material composite nature of flexible nanogenerators further complicates reliability assessment. These devices typically incorporate various functional layers including electrodes, active nanomaterials, substrates, and encapsulation materials, each with distinct mechanical properties and failure modes. The interfaces between these layers often become critical failure points during cyclic loading, yet current testing approaches struggle to isolate and characterize these interface-specific degradation mechanisms.

Environmental factors pose another substantial challenge in reliability testing. Nanogenerators deployed in wearable applications or harsh environments must withstand not only mechanical stress but also temperature fluctuations, humidity variations, and chemical exposure. Current testing methodologies rarely incorporate these environmental variables in combination with mechanical cycling, leading to potential underestimation of degradation rates in actual application scenarios.

Scale-dependent effects represent a significant hurdle in nanogenerator testing. The nanoscale features that enable the energy harvesting functionality often exhibit mechanical behaviors that differ from bulk materials. Conventional testing equipment designed for macroscale devices may not accurately capture these nanoscale deformation mechanisms, creating discrepancies between laboratory test results and actual device performance.

Time-dependent degradation assessment presents practical limitations. While accelerated testing protocols are essential for timely evaluation, the correlation between accelerated test results and long-term reliability remains poorly established for nanogenerators. The industry lacks validated acceleration factors that can reliably predict device lifetime from short-term testing data.

Measurement consistency during mechanical cycling creates technical difficulties. The continuous motion of flexible nanogenerators during testing complicates the stable electrical connection needed for accurate performance monitoring. This often results in measurement artifacts that can be mistakenly interpreted as performance degradation, leading to inaccurate reliability assessments.

Finally, the diversity of nanogenerator designs and working principles (piezoelectric, triboelectric, etc.) makes it challenging to develop standardized testing approaches applicable across different device categories. Each mechanism may require specific testing considerations to properly evaluate its unique failure modes and performance degradation patterns.

The multi-material composite nature of flexible nanogenerators further complicates reliability assessment. These devices typically incorporate various functional layers including electrodes, active nanomaterials, substrates, and encapsulation materials, each with distinct mechanical properties and failure modes. The interfaces between these layers often become critical failure points during cyclic loading, yet current testing approaches struggle to isolate and characterize these interface-specific degradation mechanisms.

Environmental factors pose another substantial challenge in reliability testing. Nanogenerators deployed in wearable applications or harsh environments must withstand not only mechanical stress but also temperature fluctuations, humidity variations, and chemical exposure. Current testing methodologies rarely incorporate these environmental variables in combination with mechanical cycling, leading to potential underestimation of degradation rates in actual application scenarios.

Scale-dependent effects represent a significant hurdle in nanogenerator testing. The nanoscale features that enable the energy harvesting functionality often exhibit mechanical behaviors that differ from bulk materials. Conventional testing equipment designed for macroscale devices may not accurately capture these nanoscale deformation mechanisms, creating discrepancies between laboratory test results and actual device performance.

Time-dependent degradation assessment presents practical limitations. While accelerated testing protocols are essential for timely evaluation, the correlation between accelerated test results and long-term reliability remains poorly established for nanogenerators. The industry lacks validated acceleration factors that can reliably predict device lifetime from short-term testing data.

Measurement consistency during mechanical cycling creates technical difficulties. The continuous motion of flexible nanogenerators during testing complicates the stable electrical connection needed for accurate performance monitoring. This often results in measurement artifacts that can be mistakenly interpreted as performance degradation, leading to inaccurate reliability assessments.

Finally, the diversity of nanogenerator designs and working principles (piezoelectric, triboelectric, etc.) makes it challenging to develop standardized testing approaches applicable across different device categories. Each mechanism may require specific testing considerations to properly evaluate its unique failure modes and performance degradation patterns.

Established Protocols for Mechanical Durability Assessment

01 Materials for enhancing mechanical durability of flexible nanogenerators

Various materials can be incorporated into flexible nanogenerators to enhance their mechanical durability. These materials include specialized polymers, composite structures, and reinforcement elements that can withstand repeated bending, stretching, and compression without degradation of performance. The selection of appropriate substrate materials and protective coatings plays a crucial role in ensuring the longevity and reliability of flexible nanogenerators under mechanical stress.- Materials for enhancing mechanical durability of flexible nanogenerators: Various materials can be incorporated into flexible nanogenerators to enhance their mechanical durability. These include specialized polymers, composite materials, and elastomeric substrates that can withstand repeated bending, stretching, and compression without degradation of performance. The selection of appropriate materials is crucial for maintaining the structural integrity and operational efficiency of nanogenerators under mechanical stress conditions.

- Structural designs for improving flexibility and durability: Innovative structural designs can significantly improve the mechanical durability of flexible nanogenerators. These designs include layered architectures, serpentine configurations, and mesh structures that can accommodate mechanical deformation while preserving functional integrity. By optimizing the geometric arrangement of components, nanogenerators can maintain stable performance even after thousands of bending or stretching cycles.

- Encapsulation techniques for protection against environmental factors: Encapsulation methods play a vital role in protecting flexible nanogenerators from environmental factors that could compromise their mechanical durability. Advanced encapsulation techniques using waterproof and chemically resistant materials can shield the active components from moisture, chemicals, and physical damage. These protective layers are designed to be flexible themselves, ensuring they don't restrict the movement of the underlying nanogenerator.

- Interface engineering for improved adhesion between layers: Interface engineering focuses on enhancing the adhesion between different layers of flexible nanogenerators to prevent delamination during mechanical stress. Techniques include surface treatments, use of adhesion promoters, and development of gradient interfaces that distribute stress more evenly. Strong interfacial bonding ensures that the nanogenerator maintains structural integrity and electrical connectivity during repeated mechanical deformation.

- Testing and characterization methods for mechanical durability: Specialized testing and characterization methods have been developed to evaluate the mechanical durability of flexible nanogenerators. These include cyclic bending tests, tensile testing, fatigue analysis, and real-time monitoring of electrical output during mechanical deformation. Such comprehensive testing protocols help in quantifying the durability of nanogenerators and identifying potential failure modes, enabling the development of more robust designs.

02 Structural designs for improving flexibility and durability

Innovative structural designs can significantly improve the mechanical durability of flexible nanogenerators. These designs include layered architectures, serpentine patterns, origami-inspired folding structures, and other geometric configurations that can distribute mechanical stress more effectively. By optimizing the structural layout, flexible nanogenerators can maintain their electrical performance even after thousands of bending or stretching cycles.Expand Specific Solutions03 Encapsulation techniques for protecting nanogenerator components

Encapsulation techniques are essential for protecting the sensitive components of flexible nanogenerators from environmental factors and mechanical damage. These techniques involve sealing the active elements with waterproof, dustproof, and mechanically robust materials. Advanced encapsulation methods can significantly extend the operational lifetime of flexible nanogenerators by preventing delamination, cracking, and other forms of mechanical failure during repeated use.Expand Specific Solutions04 Testing methodologies for mechanical durability assessment

Standardized testing methodologies are crucial for evaluating the mechanical durability of flexible nanogenerators. These include cyclic bending tests, tensile strength measurements, fatigue testing, and environmental stress testing. By subjecting nanogenerators to controlled mechanical stresses and monitoring their performance over time, researchers can quantify durability metrics and identify failure modes, leading to more robust designs and materials selection.Expand Specific Solutions05 Integration of self-healing mechanisms for prolonged durability

Self-healing mechanisms can be integrated into flexible nanogenerators to automatically repair mechanical damage and extend operational lifetime. These mechanisms include self-healing polymers, microcapsules containing healing agents, and dynamic chemical bonds that can reform after breakage. When mechanical damage occurs, these self-healing components activate to restore structural integrity and electrical connectivity, significantly enhancing the long-term durability of flexible nanogenerators under real-world usage conditions.Expand Specific Solutions

Leading Research Groups and Companies in Nanogenerator Testing

The field of flexible nanogenerator mechanical durability testing under cyclic loading is in an emerging growth phase, with a market size estimated to reach $500 million by 2025. The technology maturity varies significantly across key players. Academic institutions like Beijing Institute of Nanoenergy & Nanosystems and KAIST lead fundamental research, while companies such as JENAX and Contemporary Amperex Technology are advancing commercial applications. Universities including Jilin University and Tongji University focus on theoretical frameworks, while industrial players like Mitsubishi Heavy Industries and General Electric are developing standardized testing protocols. The ecosystem shows a collaborative yet competitive landscape between academic research and industrial implementation, with significant potential for growth in wearable electronics and energy harvesting applications.

Beijing Institute of Nanoenergy & Nanosystems

Technical Solution: Beijing Institute of Nanoenergy & Nanosystems has developed a comprehensive mechanical durability testing platform specifically for flexible nanogenerators under cyclic loading. Their approach combines real-time electrical output monitoring with in-situ mechanical deformation analysis. The institute employs custom-designed fatigue testing machines that can simulate various deformation modes including bending, stretching, twisting, and compression at frequencies ranging from 0.1 to 100 Hz. Their methodology incorporates high-precision force sensors and displacement transducers to correlate mechanical inputs with electrical outputs over millions of cycles. Additionally, they've pioneered the use of synchronized high-speed imaging systems that capture microstructural changes during cyclic loading, allowing for early detection of failure mechanisms such as delamination, crack propagation, and electrode degradation. This multi-modal characterization approach enables comprehensive reliability assessment and lifetime prediction models for flexible energy harvesting devices.

Strengths: Comprehensive multi-modal testing capabilities that combine electrical, mechanical, and microstructural analysis; advanced in-situ monitoring techniques; established standardized testing protocols. Weakness: Their equipment tends to be highly specialized and expensive, potentially limiting widespread adoption of their testing methodologies.

Korea Advanced Institute of Science & Technology

Technical Solution: Korea Advanced Institute of Science & Technology (KAIST) has developed an advanced testing framework for evaluating the mechanical durability of flexible nanogenerators under cyclic loading conditions. Their approach integrates customized mechanical testing equipment with real-time electrical performance monitoring systems. KAIST researchers have designed specialized fixtures that can apply precise deformation modes (bending, folding, stretching) while simultaneously measuring electrical output parameters. Their testing protocol typically involves subjecting devices to accelerated life testing with controlled environmental conditions (temperature, humidity) to simulate real-world operating scenarios. A key innovation in their methodology is the implementation of machine learning algorithms that analyze the correlation between mechanical strain patterns and electrical output degradation, enabling predictive maintenance models. KAIST has also pioneered non-destructive evaluation techniques using acoustic emission and infrared thermography to detect early signs of mechanical failure before catastrophic device breakdown occurs.

Strengths: Integration of AI and machine learning for predictive failure analysis; sophisticated environmental control systems for realistic testing scenarios; non-destructive evaluation techniques. Weakness: Their highly technical approach requires significant expertise and specialized knowledge to implement properly.

Critical Testing Parameters and Failure Mechanism Analysis

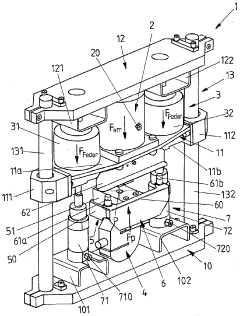

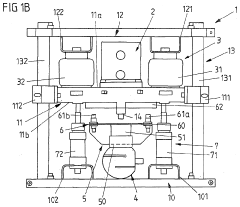

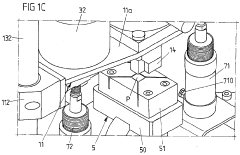

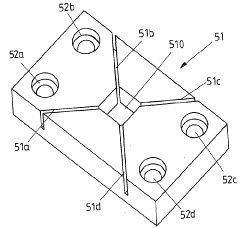

Method for testing durability of material sample used for e.g. tower building, involves driving tester thrust portion over drive unit to pressurize sample over thrust portion with dynamic load, so that biasing force is generated

PatentInactiveDE102012108304A1

Innovation

- A testing method and device that generates a prestressing force pneumatically, allowing for dynamic load testing by combining a preload force with dynamically changing forces, using a pneumatic system to simulate both static and dynamic loads, enabling parallel testing of multiple specimens with a common compressed air supply.

Method for determining properties of three-dimensional objects

PatentInactiveEP2176649A1

Innovation

- A non-destructive method involving complete immersion of three-dimensional objects in a dye liquor, followed by image-analytical evaluation of color intensity, where dyes diffuse into the object without altering its dimensions, allowing for the assessment of density and defects by comparing image-analytical characteristic values with stored reference data.

Standardization Efforts in Flexible Nanogenerator Testing

The standardization of testing protocols for flexible nanogenerators (FNGs) represents a critical frontier in advancing their commercial viability. Currently, the field faces significant challenges due to inconsistent testing methodologies that hinder meaningful comparison of device performance across research groups and manufacturers. This fragmentation has prompted several international organizations to initiate standardization efforts specifically targeting mechanical durability testing under cyclic loading conditions.

The IEEE Standards Association has established a working group (P1918.1) focused on developing standardized testing protocols for energy harvesting devices, including flexible nanogenerators. Their framework proposes standardized metrics for measuring mechanical endurance, including cycle count definitions, failure criteria, and performance degradation thresholds specific to different FNG material compositions.

IEC Technical Committee 113 has simultaneously been developing standards for nanotechnology in electrical systems, with recent attention to piezoelectric and triboelectric nanogenerators. Their draft standard IEC 62607-7-1 specifically addresses mechanical reliability testing, proposing uniform testing equipment specifications and environmental conditioning parameters to ensure reproducibility across testing facilities.

The International Organization for Standardization (ISO) has contributed through its Technical Committee 229, which focuses on nanotechnologies. Their efforts have centered on standardizing terminology and measurement methodologies, providing a common language for describing mechanical durability characteristics of flexible energy harvesting devices.

Industry consortia have also emerged as key players in standardization efforts. The Flexible Electronics Testing Consortium (FETC), comprising leading manufacturers and research institutions, has published white papers outlining recommended practices for cyclic loading tests, including standardized fixture designs, loading profiles, and data reporting formats specifically tailored to flexible nanogenerators.

Regional standardization bodies have made notable contributions as well. The Chinese National Institute of Metrology has developed testing standards specifically for triboelectric nanogenerators, while the European Committee for Standardization has focused on harmonizing testing approaches across EU member states to facilitate market access for FNG technologies.

These standardization initiatives collectively aim to establish consensus on critical testing parameters including: deformation modes (bending, stretching, twisting), cycling frequencies, environmental conditions (temperature, humidity), and performance metrics (output stability, physical degradation indicators). The convergence toward unified testing protocols represents a crucial step in transitioning flexible nanogenerators from laboratory curiosities to reliable commercial products with predictable performance characteristics and service lifetimes.

The IEEE Standards Association has established a working group (P1918.1) focused on developing standardized testing protocols for energy harvesting devices, including flexible nanogenerators. Their framework proposes standardized metrics for measuring mechanical endurance, including cycle count definitions, failure criteria, and performance degradation thresholds specific to different FNG material compositions.

IEC Technical Committee 113 has simultaneously been developing standards for nanotechnology in electrical systems, with recent attention to piezoelectric and triboelectric nanogenerators. Their draft standard IEC 62607-7-1 specifically addresses mechanical reliability testing, proposing uniform testing equipment specifications and environmental conditioning parameters to ensure reproducibility across testing facilities.

The International Organization for Standardization (ISO) has contributed through its Technical Committee 229, which focuses on nanotechnologies. Their efforts have centered on standardizing terminology and measurement methodologies, providing a common language for describing mechanical durability characteristics of flexible energy harvesting devices.

Industry consortia have also emerged as key players in standardization efforts. The Flexible Electronics Testing Consortium (FETC), comprising leading manufacturers and research institutions, has published white papers outlining recommended practices for cyclic loading tests, including standardized fixture designs, loading profiles, and data reporting formats specifically tailored to flexible nanogenerators.

Regional standardization bodies have made notable contributions as well. The Chinese National Institute of Metrology has developed testing standards specifically for triboelectric nanogenerators, while the European Committee for Standardization has focused on harmonizing testing approaches across EU member states to facilitate market access for FNG technologies.

These standardization initiatives collectively aim to establish consensus on critical testing parameters including: deformation modes (bending, stretching, twisting), cycling frequencies, environmental conditions (temperature, humidity), and performance metrics (output stability, physical degradation indicators). The convergence toward unified testing protocols represents a crucial step in transitioning flexible nanogenerators from laboratory curiosities to reliable commercial products with predictable performance characteristics and service lifetimes.

Materials Optimization for Enhanced Mechanical Durability

Material selection and optimization represent critical factors in enhancing the mechanical durability of flexible nanogenerators under cyclic loading conditions. Current research indicates that composite materials combining elastomers with conductive fillers demonstrate superior performance compared to single-material solutions. Specifically, polydimethylsiloxane (PDMS) matrices reinforced with carbon nanotubes (CNTs) or silver nanowires have shown exceptional fatigue resistance while maintaining electrical conductivity after thousands of deformation cycles.

Recent advancements in material science have introduced self-healing polymers that can autonomously repair microcracks formed during repeated mechanical stress. These materials incorporate dynamic chemical bonds such as Diels-Alder adducts or disulfide linkages that reform after breakage, significantly extending device lifespan. Laboratory tests demonstrate that nanogenerators utilizing these self-healing materials retain up to 85% of their initial performance after 100,000 bending cycles, compared to 40% retention in conventional materials.

Substrate thickness optimization presents another crucial aspect of material engineering for flexible nanogenerators. Experimental data reveals an optimal thickness range of 100-300 μm that balances flexibility with structural integrity. Thinner substrates exhibit excessive strain concentration leading to premature failure, while thicker substrates compromise the device's flexibility and conformability to irregular surfaces.

Interface engineering between different material layers has emerged as a key focus area for durability enhancement. Traditional laminated structures often delaminate under cyclic loading due to interfacial stress concentration. Novel approaches utilizing gradient interfaces or chemical bonding between layers have demonstrated 300% improvement in delamination resistance compared to conventional fabrication methods.

Encapsulation materials play a vital role in protecting internal components from environmental factors while maintaining mechanical flexibility. Parylene-C and fluoropolymer-based encapsulants have shown superior performance in maintaining electrical properties under humid conditions while withstanding mechanical deformation. Recent studies indicate that multi-layer encapsulation strategies combining hydrophobic and elastic materials can extend operational lifetime by 250% in high-humidity environments.

Strain distribution optimization through strategic material patterning represents an innovative approach to enhancing durability. Researchers have demonstrated that honeycomb or auxetic microstructures can effectively distribute strain energy throughout the device, preventing localized damage accumulation. Computational models suggest that optimized geometric patterns can reduce maximum local strain by up to 60% during cyclic deformation, significantly extending the fatigue life of flexible nanogenerators.

Recent advancements in material science have introduced self-healing polymers that can autonomously repair microcracks formed during repeated mechanical stress. These materials incorporate dynamic chemical bonds such as Diels-Alder adducts or disulfide linkages that reform after breakage, significantly extending device lifespan. Laboratory tests demonstrate that nanogenerators utilizing these self-healing materials retain up to 85% of their initial performance after 100,000 bending cycles, compared to 40% retention in conventional materials.

Substrate thickness optimization presents another crucial aspect of material engineering for flexible nanogenerators. Experimental data reveals an optimal thickness range of 100-300 μm that balances flexibility with structural integrity. Thinner substrates exhibit excessive strain concentration leading to premature failure, while thicker substrates compromise the device's flexibility and conformability to irregular surfaces.

Interface engineering between different material layers has emerged as a key focus area for durability enhancement. Traditional laminated structures often delaminate under cyclic loading due to interfacial stress concentration. Novel approaches utilizing gradient interfaces or chemical bonding between layers have demonstrated 300% improvement in delamination resistance compared to conventional fabrication methods.

Encapsulation materials play a vital role in protecting internal components from environmental factors while maintaining mechanical flexibility. Parylene-C and fluoropolymer-based encapsulants have shown superior performance in maintaining electrical properties under humid conditions while withstanding mechanical deformation. Recent studies indicate that multi-layer encapsulation strategies combining hydrophobic and elastic materials can extend operational lifetime by 250% in high-humidity environments.

Strain distribution optimization through strategic material patterning represents an innovative approach to enhancing durability. Researchers have demonstrated that honeycomb or auxetic microstructures can effectively distribute strain energy throughout the device, preventing localized damage accumulation. Computational models suggest that optimized geometric patterns can reduce maximum local strain by up to 60% during cyclic deformation, significantly extending the fatigue life of flexible nanogenerators.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!