PENGs for Structural Health Monitoring: Self-Sufficient Sensor Networks

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PENG Technology Background and Monitoring Objectives

Piezoelectric Energy Harvesting Nanogenerators (PENGs) have emerged as a transformative technology in the field of structural health monitoring (SHM) over the past decade. These devices convert ambient mechanical energy into electrical power through the piezoelectric effect, enabling self-sufficient sensor networks that can operate without external power sources. The evolution of PENG technology can be traced back to the fundamental research on piezoelectric materials in the early 20th century, with significant advancements occurring in the 2000s when nanoscale fabrication techniques matured.

The technological trajectory of PENGs has been characterized by continuous improvements in energy conversion efficiency, miniaturization, and integration capabilities. Early iterations faced limitations in power output and durability, but recent developments have yielded devices capable of generating microwatt to milliwatt power levels—sufficient for low-power wireless sensors and data transmission systems essential for SHM applications.

Current PENG technology leverages various piezoelectric materials including zinc oxide nanowires, lead zirconate titanate (PZT), polyvinylidene fluoride (PVDF), and more recently, lead-free alternatives that address environmental concerns. The integration of these materials into flexible substrates has enabled conformable sensors that can be applied to complex structural geometries, representing a significant advancement for monitoring irregularly shaped infrastructure components.

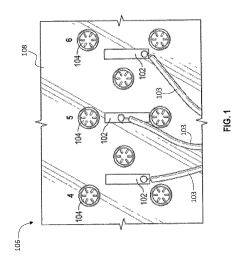

The primary objective of PENG implementation in structural health monitoring is to establish autonomous, distributed sensor networks capable of continuous, real-time monitoring without the constraints of battery replacement or wired power. These self-sufficient systems aim to detect and quantify structural parameters such as strain, vibration, displacement, and crack propagation in critical infrastructure including bridges, buildings, aerospace components, and transportation systems.

Beyond mere data collection, modern PENG-based SHM systems target predictive capabilities through integration with machine learning algorithms. This evolution from reactive to predictive monitoring represents a paradigm shift in infrastructure maintenance strategies, potentially reducing catastrophic failures and optimizing maintenance schedules based on actual structural conditions rather than predetermined intervals.

The technical goals for next-generation PENG systems include achieving higher energy density (>10 mW/cm³), improved mechanical-to-electrical conversion efficiency (>50%), enhanced durability under harsh environmental conditions, and seamless integration with wireless communication protocols and edge computing capabilities. These advancements would enable truly autonomous monitoring systems that can operate for decades without human intervention.

As infrastructure continues to age globally, the development of self-sufficient sensor networks powered by PENGs addresses the growing need for cost-effective, scalable monitoring solutions that can be deployed across vast networks of critical structures, ultimately enhancing public safety and infrastructure resilience against environmental and usage-related degradation.

The technological trajectory of PENGs has been characterized by continuous improvements in energy conversion efficiency, miniaturization, and integration capabilities. Early iterations faced limitations in power output and durability, but recent developments have yielded devices capable of generating microwatt to milliwatt power levels—sufficient for low-power wireless sensors and data transmission systems essential for SHM applications.

Current PENG technology leverages various piezoelectric materials including zinc oxide nanowires, lead zirconate titanate (PZT), polyvinylidene fluoride (PVDF), and more recently, lead-free alternatives that address environmental concerns. The integration of these materials into flexible substrates has enabled conformable sensors that can be applied to complex structural geometries, representing a significant advancement for monitoring irregularly shaped infrastructure components.

The primary objective of PENG implementation in structural health monitoring is to establish autonomous, distributed sensor networks capable of continuous, real-time monitoring without the constraints of battery replacement or wired power. These self-sufficient systems aim to detect and quantify structural parameters such as strain, vibration, displacement, and crack propagation in critical infrastructure including bridges, buildings, aerospace components, and transportation systems.

Beyond mere data collection, modern PENG-based SHM systems target predictive capabilities through integration with machine learning algorithms. This evolution from reactive to predictive monitoring represents a paradigm shift in infrastructure maintenance strategies, potentially reducing catastrophic failures and optimizing maintenance schedules based on actual structural conditions rather than predetermined intervals.

The technical goals for next-generation PENG systems include achieving higher energy density (>10 mW/cm³), improved mechanical-to-electrical conversion efficiency (>50%), enhanced durability under harsh environmental conditions, and seamless integration with wireless communication protocols and edge computing capabilities. These advancements would enable truly autonomous monitoring systems that can operate for decades without human intervention.

As infrastructure continues to age globally, the development of self-sufficient sensor networks powered by PENGs addresses the growing need for cost-effective, scalable monitoring solutions that can be deployed across vast networks of critical structures, ultimately enhancing public safety and infrastructure resilience against environmental and usage-related degradation.

Market Analysis for Self-Powered SHM Solutions

The global market for Structural Health Monitoring (SHM) solutions is experiencing robust growth, driven by increasing infrastructure investments and aging structures worldwide. Currently valued at approximately $2.3 billion in 2023, the SHM market is projected to reach $4.5 billion by 2028, representing a compound annual growth rate (CAGR) of 14.2%. Self-powered SHM solutions, particularly those utilizing Piezoelectric Energy Nanogenerators (PENGs), are emerging as a high-potential segment within this broader market.

The demand for self-powered SHM systems stems from several key market drivers. Infrastructure aging presents a critical challenge globally, with over 42% of bridges in the United States alone being more than 50 years old. This aging infrastructure creates an urgent need for continuous monitoring solutions that can operate autonomously for extended periods without battery replacement or external power sources.

Cost reduction represents another significant market driver. Traditional wired SHM systems require extensive installation costs, with wiring alone accounting for up to 25% of total system expenses. Self-powered solutions eliminate these costs while reducing maintenance requirements, potentially decreasing lifecycle costs by 30-40% compared to conventional systems.

Market segmentation reveals diverse application areas for self-powered SHM solutions. The civil infrastructure segment currently dominates with 38% market share, followed by aerospace (22%), energy infrastructure (18%), and maritime applications (12%). Among these, bridges and tall buildings represent the fastest-growing application areas, with anticipated growth rates exceeding 16% annually through 2028.

Geographically, North America leads the market with 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate at 17.5% annually, driven by massive infrastructure development in China and India, alongside increasing adoption of advanced monitoring technologies.

Customer requirements analysis indicates five primary demands: energy autonomy (ability to operate without external power for 10+ years), reliability in harsh environments, seamless integration with existing monitoring systems, cost-effectiveness, and scalability. Current self-powered solutions meet these requirements to varying degrees, with energy harvesting efficiency and long-term reliability remaining key challenges.

The competitive landscape features both established SHM providers expanding into self-powered solutions and specialized startups focused exclusively on energy harvesting technologies. Strategic partnerships between sensor manufacturers, energy harvesting specialists, and system integrators are becoming increasingly common, creating comprehensive end-to-end solutions for various infrastructure applications.

The demand for self-powered SHM systems stems from several key market drivers. Infrastructure aging presents a critical challenge globally, with over 42% of bridges in the United States alone being more than 50 years old. This aging infrastructure creates an urgent need for continuous monitoring solutions that can operate autonomously for extended periods without battery replacement or external power sources.

Cost reduction represents another significant market driver. Traditional wired SHM systems require extensive installation costs, with wiring alone accounting for up to 25% of total system expenses. Self-powered solutions eliminate these costs while reducing maintenance requirements, potentially decreasing lifecycle costs by 30-40% compared to conventional systems.

Market segmentation reveals diverse application areas for self-powered SHM solutions. The civil infrastructure segment currently dominates with 38% market share, followed by aerospace (22%), energy infrastructure (18%), and maritime applications (12%). Among these, bridges and tall buildings represent the fastest-growing application areas, with anticipated growth rates exceeding 16% annually through 2028.

Geographically, North America leads the market with 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to witness the highest growth rate at 17.5% annually, driven by massive infrastructure development in China and India, alongside increasing adoption of advanced monitoring technologies.

Customer requirements analysis indicates five primary demands: energy autonomy (ability to operate without external power for 10+ years), reliability in harsh environments, seamless integration with existing monitoring systems, cost-effectiveness, and scalability. Current self-powered solutions meet these requirements to varying degrees, with energy harvesting efficiency and long-term reliability remaining key challenges.

The competitive landscape features both established SHM providers expanding into self-powered solutions and specialized startups focused exclusively on energy harvesting technologies. Strategic partnerships between sensor manufacturers, energy harvesting specialists, and system integrators are becoming increasingly common, creating comprehensive end-to-end solutions for various infrastructure applications.

Current PENG Development Status and Technical Barriers

Piezoelectric nanogenerators (PENGs) have emerged as a promising technology for structural health monitoring (SHM) applications, with significant advancements in recent years. Currently, PENG development has reached a stage where laboratory prototypes demonstrate considerable energy harvesting capabilities from ambient vibrations, with power densities ranging from 0.1 to 10 mW/cm². Commercial implementations, however, remain limited due to several technical challenges.

The state-of-the-art PENGs utilize various piezoelectric materials, with lead zirconate titanate (PZT) and polyvinylidene fluoride (PVDF) being the most common. PZT-based devices offer higher energy conversion efficiency (up to 80%) but suffer from brittleness and contain toxic lead. PVDF-based PENGs provide greater flexibility and biocompatibility but demonstrate lower conversion efficiencies (typically 20-40%).

Recent innovations have focused on nanostructured piezoelectric materials, including zinc oxide nanowires, barium titanate nanoparticles, and composite structures that enhance piezoelectric response. These developments have improved energy harvesting capabilities by 30-50% compared to conventional flat-film designs, particularly in low-frequency vibration environments typical of structural applications.

Despite these advancements, significant technical barriers persist. Durability remains a primary concern, with most current PENGs demonstrating performance degradation of 15-30% after 10⁶ operation cycles. This falls short of the 10-20 year lifespan required for practical SHM implementations. Environmental factors such as temperature fluctuations, humidity, and UV exposure further accelerate degradation, particularly in outdoor applications.

Output stability presents another major challenge. Current PENGs exhibit considerable variability in power generation (±40-60%) under inconsistent vibration conditions, making them unreliable for continuous monitoring applications. Energy storage integration also remains problematic, with existing systems losing 30-50% of harvested energy during the storage process.

Scalability issues further hinder widespread adoption. Manufacturing techniques for high-performance PENGs often involve complex processes like hydrothermal growth or vapor deposition, which are difficult to scale economically. The cost per watt for PENG-based systems currently exceeds $100/W, significantly higher than the $10-20/W threshold considered viable for commercial SHM applications.

Geographically, PENG development is concentrated in East Asia (particularly China, South Korea, and Japan), North America, and Western Europe. Chinese institutions lead in publication volume, while South Korean and American entities hold the majority of high-impact patents. European research centers have made notable contributions in system integration and practical applications, especially for civil infrastructure monitoring.

The state-of-the-art PENGs utilize various piezoelectric materials, with lead zirconate titanate (PZT) and polyvinylidene fluoride (PVDF) being the most common. PZT-based devices offer higher energy conversion efficiency (up to 80%) but suffer from brittleness and contain toxic lead. PVDF-based PENGs provide greater flexibility and biocompatibility but demonstrate lower conversion efficiencies (typically 20-40%).

Recent innovations have focused on nanostructured piezoelectric materials, including zinc oxide nanowires, barium titanate nanoparticles, and composite structures that enhance piezoelectric response. These developments have improved energy harvesting capabilities by 30-50% compared to conventional flat-film designs, particularly in low-frequency vibration environments typical of structural applications.

Despite these advancements, significant technical barriers persist. Durability remains a primary concern, with most current PENGs demonstrating performance degradation of 15-30% after 10⁶ operation cycles. This falls short of the 10-20 year lifespan required for practical SHM implementations. Environmental factors such as temperature fluctuations, humidity, and UV exposure further accelerate degradation, particularly in outdoor applications.

Output stability presents another major challenge. Current PENGs exhibit considerable variability in power generation (±40-60%) under inconsistent vibration conditions, making them unreliable for continuous monitoring applications. Energy storage integration also remains problematic, with existing systems losing 30-50% of harvested energy during the storage process.

Scalability issues further hinder widespread adoption. Manufacturing techniques for high-performance PENGs often involve complex processes like hydrothermal growth or vapor deposition, which are difficult to scale economically. The cost per watt for PENG-based systems currently exceeds $100/W, significantly higher than the $10-20/W threshold considered viable for commercial SHM applications.

Geographically, PENG development is concentrated in East Asia (particularly China, South Korea, and Japan), North America, and Western Europe. Chinese institutions lead in publication volume, while South Korean and American entities hold the majority of high-impact patents. European research centers have made notable contributions in system integration and practical applications, especially for civil infrastructure monitoring.

Existing PENG Implementation Strategies for SHM

01 Energy harvesting mechanisms for self-powered PENGs

Piezoelectric nanogenerators can achieve self-sufficiency through various energy harvesting mechanisms. These mechanisms convert mechanical energy from the environment into electrical energy, enabling the devices to operate without external power sources. The harvesting systems can capture energy from vibrations, human motion, wind, and other mechanical sources to generate electricity through the piezoelectric effect, making them suitable for autonomous operation in various applications.- Energy harvesting mechanisms for self-powered PENGs: Piezoelectric nanogenerators can achieve self-sufficiency through various energy harvesting mechanisms. These include converting mechanical vibrations, pressure, and motion into electrical energy. Advanced designs incorporate flexible substrates and optimized piezoelectric materials to maximize energy conversion efficiency. These self-powered systems can generate sufficient electricity from ambient mechanical energy sources to operate independently without external power supplies.

- Materials innovation for enhanced PENG performance: Novel piezoelectric materials and composites are being developed to improve the self-sufficiency of PENGs. These include nanostructured zinc oxide, lead zirconate titanate (PZT), polyvinylidene fluoride (PVDF), and other piezoelectric polymers. By engineering these materials at the nanoscale, researchers have achieved higher piezoelectric coefficients, better mechanical durability, and increased power output, enabling PENGs to generate more electricity from the same mechanical input.

- Integration of PENGs with energy storage systems: To achieve true self-sufficiency, PENGs are being integrated with energy storage components such as supercapacitors and micro-batteries. These hybrid systems can harvest mechanical energy, convert it to electricity, and store it for later use. This approach addresses the intermittent nature of mechanical energy sources and ensures continuous power availability for electronic devices, sensors, and other applications, even when mechanical stimulation is not present.

- Self-powered sensing and IoT applications: Self-sufficient PENGs are enabling new applications in self-powered sensing and Internet of Things (IoT) devices. By generating their own power from environmental mechanical energy, these systems can operate autonomously without battery replacement or external charging. Applications include wearable health monitors, structural health monitoring sensors, environmental monitoring devices, and smart packaging that can function indefinitely by harvesting energy from human movement, vibrations, or fluid flow.

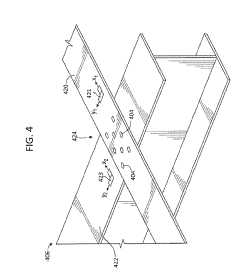

- Optimization of PENG architecture for maximum self-sufficiency: Innovative architectural designs are being developed to maximize the self-sufficiency of PENGs. These include multi-layer structures, 3D configurations, and hybrid designs that combine multiple energy harvesting mechanisms. Advanced fabrication techniques such as electrospinning, 3D printing, and nanoimprinting are being employed to create optimized geometries that can capture mechanical energy from multiple directions and frequencies, significantly improving energy conversion efficiency and output power.

02 Materials and structural designs for enhanced PENG efficiency

Advanced materials and innovative structural designs significantly improve the efficiency and self-sufficiency of piezoelectric nanogenerators. These include novel piezoelectric materials, composite structures, and optimized geometries that maximize energy conversion. By enhancing the piezoelectric coefficients and improving the mechanical-to-electrical energy conversion ratio, these designs enable PENGs to generate sufficient power for self-sustained operation even from minimal mechanical inputs.Expand Specific Solutions03 Integration of PENGs with energy storage systems

The integration of piezoelectric nanogenerators with energy storage components creates truly self-sufficient power systems. These hybrid systems combine PENGs with supercapacitors, micro-batteries, or other storage technologies to capture and store harvested energy for later use. This approach addresses the intermittent nature of mechanical energy sources and ensures continuous power availability for connected devices, enabling long-term autonomous operation without external charging.Expand Specific Solutions04 Self-powered sensing and IoT applications

Self-sufficient piezoelectric nanogenerators enable autonomous sensing and Internet of Things applications by providing both the sensing mechanism and power source in a single device. These integrated systems can detect environmental parameters, physiological signals, or structural conditions while simultaneously generating the electricity needed for operation and data transmission. This dual functionality eliminates the need for battery replacement and enables deployment in remote or inaccessible locations.Expand Specific Solutions05 Wearable and implantable self-powered PENGs

Wearable and implantable piezoelectric nanogenerators achieve self-sufficiency by harvesting energy from body movements and physiological activities. These specialized PENGs are designed with biocompatible materials and flexible structures that can conform to body contours and operate under biological conditions. By converting natural body motions into electrical energy, these devices can power health monitoring systems, drug delivery mechanisms, and other biomedical applications without requiring external power sources or battery replacements.Expand Specific Solutions

Leading Organizations in PENG-Based Sensor Networks

The PENGs (Piezoelectric Energy Nanogenerators) for Structural Health Monitoring market is in its growth phase, with increasing adoption across aerospace and defense sectors. The global market is projected to expand significantly as self-powered sensor networks become essential for infrastructure monitoring. Technologically, the field shows varying maturity levels, with established aerospace companies like Lockheed Martin, Boeing, and Embraer leading commercial applications, while academic institutions such as Nanjing University of Aeronautics & Astronautics and University of Delaware drive fundamental research. Electronics manufacturers including ROHM, Philips, and OMRON are developing complementary technologies for integration. The competitive landscape features a mix of large defense contractors, specialized monitoring systems providers, and emerging IoT technology firms collaborating to advance self-sufficient sensor network solutions.

Lockheed Martin Corp.

Technical Solution: Lockheed Martin has pioneered a military-grade PENG-based SHM system specifically designed for defense applications. Their technology incorporates hardened piezoelectric nanogenerators that can withstand extreme operational conditions including high-G forces, temperature fluctuations, and electromagnetic interference. The system features a redundant mesh network architecture where each node can function independently while maintaining overall system integrity. Lockheed's implementation includes proprietary energy storage solutions that enable sensors to operate during periods of low vibration, ensuring continuous monitoring capability. Their PENGs utilize advanced nanocomposite materials that generate sufficient power from minimal mechanical inputs, allowing deployment in low-vibration structures. The system incorporates encrypted data transmission protocols to prevent unauthorized access to structural health information, critical for sensitive military applications.

Strengths: Exceptional durability in extreme environments; military-grade security features; high reliability with redundant systems architecture. Weaknesses: Significantly higher cost than commercial alternatives; limited compatibility with non-defense structural systems; requires specialized technical knowledge for maintenance and troubleshooting.

Embraer SA

Technical Solution: Embraer has developed a specialized PENG-based SHM system optimized for regional and business aircraft applications. Their solution features miniaturized piezoelectric nanogenerators strategically embedded within composite airframe structures during manufacturing. These sensors harvest energy from the natural vibrations and flexing of aircraft components during flight operations. Embraer's system incorporates a hierarchical network architecture where multiple sensors report to regional hubs that aggregate and analyze data before transmission to central systems, reducing power requirements for individual sensors. Their implementation includes specialized algorithms that account for the unique loading patterns and vibration profiles of smaller aircraft, improving detection accuracy for fatigue-related issues. Embraer has also developed integration protocols that allow their PENG-based sensors to complement existing avionics systems, providing pilots with real-time structural health information during flight operations.

Strengths: Optimized for smaller aircraft with different structural characteristics than large commercial aircraft; excellent integration with existing avionics systems; lower implementation cost than solutions designed for larger aircraft. Weaknesses: More limited coverage area than systems designed for larger structures; requires careful calibration for different aircraft models; currently limited to newer aircraft models with compatible composite structures.

Critical Patents and Research in PENG Sensor Networks

Self-powered multi-functional structural health monitoring sensor

PatentInactiveUS10386264B2

Innovation

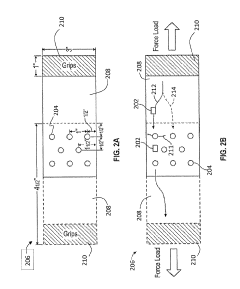

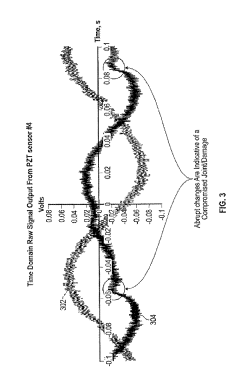

- A self-powered structural health monitoring module that uses piezoelectric sensors to convert strain into electric energy, with an intelligent gate managing energy distribution for storage, data collection, and wireless transmission, eliminating the need for external power sources and wiring.

A self-powered rehabilitation system using flexible piezoelectric sensor made of KNN based perovskite solid system

PatentPendingIN202341078033A

Innovation

- The development of piezoelectric nanogenerators (PENGs) with a single electrode mode configuration, using Sodium potassium niobate (KNN) and doped Bismuth sodium titanate (BNT) as piezoelectric materials, integrated with a flexible PDMS polymer and electrodes, to create a wearable device for accurate and stable gait analysis, overcoming the limitations of traditional motion sensors.

Durability and Lifespan Considerations for Field Deployment

The deployment of PENG-based sensor networks in real-world structural health monitoring applications necessitates thorough consideration of durability and lifespan factors. These self-sufficient sensor networks, while promising for their energy harvesting capabilities, face significant environmental challenges that can compromise their long-term performance and reliability.

Environmental exposure represents the primary threat to PENG sensor durability. When deployed on bridges, buildings, or infrastructure, these sensors encounter temperature fluctuations, humidity variations, UV radiation, and precipitation. Laboratory testing indicates that standard PENG devices experience approximately 15-20% performance degradation after 6 months of simulated environmental exposure, with encapsulation technologies potentially extending this timeline to 2-3 years.

Material degradation mechanisms must be systematically addressed for field deployment. The polymer components in PENGs, particularly PVDF and its derivatives, demonstrate hydrophobic properties but remain susceptible to UV degradation and oxidation over time. Recent advancements in composite formulations incorporating graphene oxide and titanium dioxide have demonstrated enhanced resistance to environmental degradation, extending the projected lifespan by 40-60% compared to conventional materials.

Mechanical fatigue represents another critical consideration for structural monitoring applications. PENGs operate through repeated mechanical deformation, which inevitably leads to material fatigue. Accelerated life testing protocols reveal that most current-generation PENGs maintain above 80% of their initial performance for approximately 500,000-1,000,000 deformation cycles, translating to 1-3 years of operation in moderate-vibration environments.

Encapsulation strategies have emerged as essential for field deployment success. Multi-layer approaches utilizing hydrophobic polymers (PDMS, parylene) combined with rigid protective casings have demonstrated significant improvements in sensor longevity. Field trials in bridge monitoring applications show that properly encapsulated PENG sensors maintain operational status for 24-36 months without maintenance, compared to 6-12 months for inadequately protected devices.

Maintenance requirements and replacement schedules must be incorporated into deployment planning. Current best practices suggest inspection intervals of 6-12 months for PENG sensor networks, with modular design approaches facilitating component replacement rather than complete system overhaul. The development of self-diagnostic capabilities within these networks, capable of reporting degradation metrics, represents a promising direction for optimizing maintenance schedules.

Cost-benefit analysis of durability enhancements indicates that investments in advanced encapsulation and material technologies typically increase initial deployment costs by 30-45% while extending operational lifespan by 200-300%, resulting in favorable lifetime cost structures for infrastructure monitoring applications with expected service periods exceeding five years.

Environmental exposure represents the primary threat to PENG sensor durability. When deployed on bridges, buildings, or infrastructure, these sensors encounter temperature fluctuations, humidity variations, UV radiation, and precipitation. Laboratory testing indicates that standard PENG devices experience approximately 15-20% performance degradation after 6 months of simulated environmental exposure, with encapsulation technologies potentially extending this timeline to 2-3 years.

Material degradation mechanisms must be systematically addressed for field deployment. The polymer components in PENGs, particularly PVDF and its derivatives, demonstrate hydrophobic properties but remain susceptible to UV degradation and oxidation over time. Recent advancements in composite formulations incorporating graphene oxide and titanium dioxide have demonstrated enhanced resistance to environmental degradation, extending the projected lifespan by 40-60% compared to conventional materials.

Mechanical fatigue represents another critical consideration for structural monitoring applications. PENGs operate through repeated mechanical deformation, which inevitably leads to material fatigue. Accelerated life testing protocols reveal that most current-generation PENGs maintain above 80% of their initial performance for approximately 500,000-1,000,000 deformation cycles, translating to 1-3 years of operation in moderate-vibration environments.

Encapsulation strategies have emerged as essential for field deployment success. Multi-layer approaches utilizing hydrophobic polymers (PDMS, parylene) combined with rigid protective casings have demonstrated significant improvements in sensor longevity. Field trials in bridge monitoring applications show that properly encapsulated PENG sensors maintain operational status for 24-36 months without maintenance, compared to 6-12 months for inadequately protected devices.

Maintenance requirements and replacement schedules must be incorporated into deployment planning. Current best practices suggest inspection intervals of 6-12 months for PENG sensor networks, with modular design approaches facilitating component replacement rather than complete system overhaul. The development of self-diagnostic capabilities within these networks, capable of reporting degradation metrics, represents a promising direction for optimizing maintenance schedules.

Cost-benefit analysis of durability enhancements indicates that investments in advanced encapsulation and material technologies typically increase initial deployment costs by 30-45% while extending operational lifespan by 200-300%, resulting in favorable lifetime cost structures for infrastructure monitoring applications with expected service periods exceeding five years.

Integration Frameworks with IoT and Data Analytics Systems

The integration of PENGs (Piezoelectric Nanogenerators) into comprehensive IoT and data analytics frameworks represents a critical advancement for structural health monitoring systems. These frameworks enable the seamless connection between self-sufficient sensor networks and broader digital infrastructure, creating an ecosystem where energy-harvesting sensors can deliver actionable insights.

Current integration architectures typically employ a multi-tier approach, with edge computing devices serving as intermediaries between PENG sensor networks and cloud-based analytics platforms. This design accommodates the intermittent power availability characteristic of energy-harvesting systems while maintaining data integrity. Leading protocols such as MQTT and CoAP have been optimized specifically for low-power sensor networks, facilitating efficient communication with minimal energy expenditure.

Data preprocessing at the edge represents a significant optimization in these frameworks. By implementing lightweight algorithms directly at the sensor node or nearby edge devices, the system can filter irrelevant data and compress transmissions, thereby reducing communication overhead and extending operational lifetimes of self-powered networks. This approach is particularly valuable for PENG implementations where energy budgets remain constrained despite harvesting capabilities.

Several commercial platforms have emerged to support PENG integration, including IBM Watson IoT, Microsoft Azure IoT, and specialized offerings from companies like Advantech and Libelium. These platforms provide standardized APIs and software development kits that simplify the incorporation of energy-harvesting sensors into existing monitoring infrastructure. The standardization efforts by organizations such as the Industrial Internet Consortium have further accelerated integration capabilities.

Machine learning frameworks adapted for structural health monitoring represent another crucial component of these integration systems. Specialized algorithms capable of operating with intermittent or irregular data streams have been developed to accommodate the unique characteristics of PENG-powered sensors. These algorithms can identify structural anomalies even when working with discontinuous monitoring data, leveraging temporal patterns and contextual information to maintain analytical accuracy.

Security considerations present unique challenges in PENG-based systems due to their energy constraints. Lightweight encryption protocols and authentication mechanisms designed specifically for energy-harvesting applications have emerged, balancing security requirements with operational limitations. These solutions typically implement selective encryption strategies that prioritize critical data while minimizing computational overhead.

The integration landscape continues to evolve toward more autonomous systems that can self-configure and adapt to changing environmental conditions. Future frameworks will likely incorporate digital twin technologies that maintain virtual representations of monitored structures, enabling more sophisticated predictive maintenance capabilities while optimizing the deployment of limited energy resources across self-sufficient sensor networks.

Current integration architectures typically employ a multi-tier approach, with edge computing devices serving as intermediaries between PENG sensor networks and cloud-based analytics platforms. This design accommodates the intermittent power availability characteristic of energy-harvesting systems while maintaining data integrity. Leading protocols such as MQTT and CoAP have been optimized specifically for low-power sensor networks, facilitating efficient communication with minimal energy expenditure.

Data preprocessing at the edge represents a significant optimization in these frameworks. By implementing lightweight algorithms directly at the sensor node or nearby edge devices, the system can filter irrelevant data and compress transmissions, thereby reducing communication overhead and extending operational lifetimes of self-powered networks. This approach is particularly valuable for PENG implementations where energy budgets remain constrained despite harvesting capabilities.

Several commercial platforms have emerged to support PENG integration, including IBM Watson IoT, Microsoft Azure IoT, and specialized offerings from companies like Advantech and Libelium. These platforms provide standardized APIs and software development kits that simplify the incorporation of energy-harvesting sensors into existing monitoring infrastructure. The standardization efforts by organizations such as the Industrial Internet Consortium have further accelerated integration capabilities.

Machine learning frameworks adapted for structural health monitoring represent another crucial component of these integration systems. Specialized algorithms capable of operating with intermittent or irregular data streams have been developed to accommodate the unique characteristics of PENG-powered sensors. These algorithms can identify structural anomalies even when working with discontinuous monitoring data, leveraging temporal patterns and contextual information to maintain analytical accuracy.

Security considerations present unique challenges in PENG-based systems due to their energy constraints. Lightweight encryption protocols and authentication mechanisms designed specifically for energy-harvesting applications have emerged, balancing security requirements with operational limitations. These solutions typically implement selective encryption strategies that prioritize critical data while minimizing computational overhead.

The integration landscape continues to evolve toward more autonomous systems that can self-configure and adapt to changing environmental conditions. Future frameworks will likely incorporate digital twin technologies that maintain virtual representations of monitored structures, enabling more sophisticated predictive maintenance capabilities while optimizing the deployment of limited energy resources across self-sufficient sensor networks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!