High-Temperature Piezoelectric Nanogenerators: Ceramic Materials and Device Reliability

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High-Temperature Piezoelectric Technology Evolution and Objectives

Piezoelectric materials have been extensively studied since their discovery in the late 19th century, with significant advancements occurring during the mid-20th century through the development of lead zirconate titanate (PZT) ceramics. The evolution of high-temperature piezoelectric technology has been driven by increasing demands in harsh environment applications, particularly in aerospace, automotive, and industrial sectors where conventional piezoelectric materials fail due to temperature limitations.

Traditional piezoelectric materials like PZT typically lose their piezoelectric properties at temperatures above 200-300°C due to phase transitions and depolarization effects. This limitation has spurred research into alternative materials capable of maintaining piezoelectric functionality at elevated temperatures, with significant breakthroughs emerging in the past two decades.

The development trajectory has shifted from lead-based to lead-free compositions in response to environmental regulations and sustainability concerns. Notable milestones include the discovery of bismuth layer-structured ferroelectrics (BLSFs) in the 1990s, followed by the development of perovskite-structured materials with high Curie temperatures in the early 2000s. Recent advances in crystal engineering and doping strategies have further enhanced the thermal stability of piezoelectric properties.

Nanogenerator technology, pioneered by Wang et al. in 2006, represents a convergence of piezoelectric materials science and nanotechnology. The integration of high-temperature piezoelectric materials into nanogenerator architectures presents unique opportunities for energy harvesting in extreme environments, potentially enabling self-powered sensing systems in applications where conventional power sources are impractical.

The primary objectives of current research in high-temperature piezoelectric nanogenerators encompass several interconnected goals. First, developing ceramic materials with stable piezoelectric coefficients at temperatures exceeding 500°C while maintaining reasonable mechanical properties. Second, enhancing the power density and conversion efficiency of nanogenerators at elevated temperatures. Third, improving long-term reliability and fatigue resistance under thermal cycling conditions.

Additionally, researchers aim to establish standardized testing protocols for high-temperature piezoelectric performance evaluation, as current methodologies often yield inconsistent results across different laboratories. The field is also moving toward multifunctional devices that can simultaneously harvest energy and sense environmental parameters in high-temperature settings.

The ultimate technological goal is to create self-sustaining energy systems for harsh environment electronics, with particular emphasis on applications in deep-well drilling, jet engines, and nuclear facilities where conventional electronics and power sources face severe limitations.

Traditional piezoelectric materials like PZT typically lose their piezoelectric properties at temperatures above 200-300°C due to phase transitions and depolarization effects. This limitation has spurred research into alternative materials capable of maintaining piezoelectric functionality at elevated temperatures, with significant breakthroughs emerging in the past two decades.

The development trajectory has shifted from lead-based to lead-free compositions in response to environmental regulations and sustainability concerns. Notable milestones include the discovery of bismuth layer-structured ferroelectrics (BLSFs) in the 1990s, followed by the development of perovskite-structured materials with high Curie temperatures in the early 2000s. Recent advances in crystal engineering and doping strategies have further enhanced the thermal stability of piezoelectric properties.

Nanogenerator technology, pioneered by Wang et al. in 2006, represents a convergence of piezoelectric materials science and nanotechnology. The integration of high-temperature piezoelectric materials into nanogenerator architectures presents unique opportunities for energy harvesting in extreme environments, potentially enabling self-powered sensing systems in applications where conventional power sources are impractical.

The primary objectives of current research in high-temperature piezoelectric nanogenerators encompass several interconnected goals. First, developing ceramic materials with stable piezoelectric coefficients at temperatures exceeding 500°C while maintaining reasonable mechanical properties. Second, enhancing the power density and conversion efficiency of nanogenerators at elevated temperatures. Third, improving long-term reliability and fatigue resistance under thermal cycling conditions.

Additionally, researchers aim to establish standardized testing protocols for high-temperature piezoelectric performance evaluation, as current methodologies often yield inconsistent results across different laboratories. The field is also moving toward multifunctional devices that can simultaneously harvest energy and sense environmental parameters in high-temperature settings.

The ultimate technological goal is to create self-sustaining energy systems for harsh environment electronics, with particular emphasis on applications in deep-well drilling, jet engines, and nuclear facilities where conventional electronics and power sources face severe limitations.

Market Analysis for High-Temperature Energy Harvesting Solutions

The high-temperature energy harvesting market is experiencing significant growth driven by increasing industrial automation and the expansion of harsh environment applications. Current market valuations indicate the global energy harvesting system market reached approximately $440 million in 2022, with projections suggesting a compound annual growth rate of 8.4% through 2030. Within this broader market, high-temperature energy harvesting solutions represent a specialized but rapidly expanding segment, particularly in industries such as aerospace, automotive, oil and gas, and industrial manufacturing.

The demand for high-temperature piezoelectric nanogenerators is primarily fueled by the need for self-powered sensors and monitoring systems in extreme environments where conventional power sources fail. Industries operating furnaces, turbines, and combustion engines require reliable power sources that can withstand temperatures exceeding 400°C. This market need is further amplified by the growing implementation of Industry 4.0 technologies, which require distributed sensing networks even in harsh operating conditions.

Geographically, North America and Europe currently lead the high-temperature energy harvesting market due to their advanced industrial bases and significant investments in research and development. However, the Asia-Pacific region is demonstrating the fastest growth rate, driven by rapid industrialization in countries like China, Japan, and South Korea, along with increasing adoption of IoT technologies in manufacturing sectors.

By application segment, industrial monitoring systems represent the largest market share for high-temperature piezoelectric nanogenerators, accounting for approximately 35% of the total market. Aerospace applications follow closely at 28%, with automotive applications representing about 20% of the market. The remaining market share is distributed among various applications including power generation, oil and gas, and defense.

Customer requirements in this market emphasize reliability, operational longevity, and consistent power output under extreme conditions. End-users are willing to pay premium prices for solutions that demonstrate proven performance at temperatures above 300°C, with minimal degradation over extended operational periods. The average selling price for high-temperature energy harvesting modules ranges from $200 to $1,500 depending on temperature rating, power output, and reliability specifications.

Market barriers include high development costs, technical challenges in material science, and the need for extensive validation testing. Despite these challenges, the market is expected to grow as industries increasingly seek autonomous power solutions for harsh environment applications. The transition toward more sustainable and maintenance-free industrial operations further supports the long-term growth trajectory of high-temperature energy harvesting technologies.

The demand for high-temperature piezoelectric nanogenerators is primarily fueled by the need for self-powered sensors and monitoring systems in extreme environments where conventional power sources fail. Industries operating furnaces, turbines, and combustion engines require reliable power sources that can withstand temperatures exceeding 400°C. This market need is further amplified by the growing implementation of Industry 4.0 technologies, which require distributed sensing networks even in harsh operating conditions.

Geographically, North America and Europe currently lead the high-temperature energy harvesting market due to their advanced industrial bases and significant investments in research and development. However, the Asia-Pacific region is demonstrating the fastest growth rate, driven by rapid industrialization in countries like China, Japan, and South Korea, along with increasing adoption of IoT technologies in manufacturing sectors.

By application segment, industrial monitoring systems represent the largest market share for high-temperature piezoelectric nanogenerators, accounting for approximately 35% of the total market. Aerospace applications follow closely at 28%, with automotive applications representing about 20% of the market. The remaining market share is distributed among various applications including power generation, oil and gas, and defense.

Customer requirements in this market emphasize reliability, operational longevity, and consistent power output under extreme conditions. End-users are willing to pay premium prices for solutions that demonstrate proven performance at temperatures above 300°C, with minimal degradation over extended operational periods. The average selling price for high-temperature energy harvesting modules ranges from $200 to $1,500 depending on temperature rating, power output, and reliability specifications.

Market barriers include high development costs, technical challenges in material science, and the need for extensive validation testing. Despite these challenges, the market is expected to grow as industries increasingly seek autonomous power solutions for harsh environment applications. The transition toward more sustainable and maintenance-free industrial operations further supports the long-term growth trajectory of high-temperature energy harvesting technologies.

Current Challenges in High-Temperature Piezoelectric Materials

The development of high-temperature piezoelectric materials faces significant technical challenges that limit their widespread application in harsh environments. Current piezoelectric materials typically lose their functionality at elevated temperatures due to phase transitions, depolarization, and structural degradation. Traditional lead zirconate titanate (PZT) materials, which dominate the market, exhibit Curie temperatures around 350-400°C, beyond which they lose their piezoelectric properties completely.

Material stability represents a primary challenge, as most piezoelectric ceramics suffer from accelerated aging and performance degradation when operated near their temperature limits. Oxygen vacancies migration increases dramatically at high temperatures, leading to conductivity issues that compromise the electric field-induced strain necessary for energy harvesting applications. This conductivity increase results in leakage currents that reduce energy conversion efficiency and can ultimately lead to device failure.

Thermal cycling poses another significant obstacle, as repeated heating and cooling cycles induce mechanical stresses due to thermal expansion coefficient mismatches between different components in piezoelectric nanogenerators. These stresses often lead to microcracking, delamination at interfaces, and eventual mechanical failure of the entire device structure. The integration of high-temperature electrode materials that maintain good electrical contact with the piezoelectric element presents additional complications.

Chemical stability at elevated temperatures introduces further challenges, particularly in oxidizing or reducing atmospheres common in industrial applications. Many candidate materials for high-temperature piezoelectrics exhibit chemical reactions with surrounding components or atmospheric gases above 500°C, resulting in compositional changes that degrade piezoelectric performance over time. This degradation pathway is particularly problematic for long-term deployment scenarios.

Manufacturing reproducibility remains difficult for high-temperature piezoelectric materials. Specialized sintering processes required for high-temperature ceramics often result in variable grain structures and compositional inhomogeneities that affect performance consistency. The precise control of dopants, which are essential for enhancing temperature stability, becomes increasingly challenging as processing temperatures increase.

Interface engineering between the piezoelectric material and electrodes represents another critical challenge. At high temperatures, interdiffusion between layers accelerates, potentially creating unwanted phases at interfaces that compromise electrical connectivity and mechanical integrity. Additionally, many electrode materials that perform well at room temperature suffer from oxidation, evaporation, or other degradation mechanisms at elevated temperatures.

The fundamental understanding of piezoelectric mechanisms at high temperatures remains incomplete, hampering rational materials design. The complex interplay between crystal structure, domain dynamics, and defect chemistry at elevated temperatures is not fully characterized, making predictive modeling of material behavior difficult and slowing the development of improved materials.

Material stability represents a primary challenge, as most piezoelectric ceramics suffer from accelerated aging and performance degradation when operated near their temperature limits. Oxygen vacancies migration increases dramatically at high temperatures, leading to conductivity issues that compromise the electric field-induced strain necessary for energy harvesting applications. This conductivity increase results in leakage currents that reduce energy conversion efficiency and can ultimately lead to device failure.

Thermal cycling poses another significant obstacle, as repeated heating and cooling cycles induce mechanical stresses due to thermal expansion coefficient mismatches between different components in piezoelectric nanogenerators. These stresses often lead to microcracking, delamination at interfaces, and eventual mechanical failure of the entire device structure. The integration of high-temperature electrode materials that maintain good electrical contact with the piezoelectric element presents additional complications.

Chemical stability at elevated temperatures introduces further challenges, particularly in oxidizing or reducing atmospheres common in industrial applications. Many candidate materials for high-temperature piezoelectrics exhibit chemical reactions with surrounding components or atmospheric gases above 500°C, resulting in compositional changes that degrade piezoelectric performance over time. This degradation pathway is particularly problematic for long-term deployment scenarios.

Manufacturing reproducibility remains difficult for high-temperature piezoelectric materials. Specialized sintering processes required for high-temperature ceramics often result in variable grain structures and compositional inhomogeneities that affect performance consistency. The precise control of dopants, which are essential for enhancing temperature stability, becomes increasingly challenging as processing temperatures increase.

Interface engineering between the piezoelectric material and electrodes represents another critical challenge. At high temperatures, interdiffusion between layers accelerates, potentially creating unwanted phases at interfaces that compromise electrical connectivity and mechanical integrity. Additionally, many electrode materials that perform well at room temperature suffer from oxidation, evaporation, or other degradation mechanisms at elevated temperatures.

The fundamental understanding of piezoelectric mechanisms at high temperatures remains incomplete, hampering rational materials design. The complex interplay between crystal structure, domain dynamics, and defect chemistry at elevated temperatures is not fully characterized, making predictive modeling of material behavior difficult and slowing the development of improved materials.

State-of-the-Art Ceramic Materials for High-Temperature Applications

01 Materials for high-temperature piezoelectric nanogenerators

Various materials are used in high-temperature piezoelectric nanogenerators to ensure reliability at elevated temperatures. These include specialized ceramics, composite materials, and doped piezoelectric materials that maintain their piezoelectric properties at high temperatures. The selection of appropriate materials is crucial for ensuring the device's performance and longevity under extreme thermal conditions.- High-temperature resistant piezoelectric materials: Development of piezoelectric materials that can maintain stability and performance at elevated temperatures is crucial for high-temperature nanogenerators. These materials include specialized ceramics, single crystals, and composite structures that exhibit minimal degradation of piezoelectric properties under thermal stress. The incorporation of certain dopants and structural modifications can enhance the Curie temperature and thermal stability, allowing the nanogenerators to operate reliably in harsh environments with temperatures exceeding 200°C.

- Thermal management and protection systems: Effective thermal management strategies are essential for maintaining the reliability of piezoelectric nanogenerators at high temperatures. These include heat dissipation structures, thermal isolation layers, and protective encapsulation materials that shield the active piezoelectric components from excessive heat. Advanced cooling mechanisms and temperature-responsive control systems can be integrated to prevent thermal runaway and ensure consistent performance during prolonged operation in high-temperature environments.

- Electrode and interconnection reliability: The reliability of electrodes and electrical interconnections is critical for high-temperature piezoelectric nanogenerators. Specialized electrode materials that resist oxidation, diffusion, and delamination at elevated temperatures are employed. These include noble metals, conductive ceramics, and high-temperature stable conductive composites. Advanced bonding techniques and interface engineering methods are implemented to maintain robust electrical connections and prevent performance degradation during thermal cycling and extended high-temperature operation.

- Structural design for thermal stability: Innovative structural designs are implemented to enhance the thermal stability and reliability of piezoelectric nanogenerators. These include multi-layered architectures with thermal expansion compensation layers, flexible substrates that accommodate thermal stress, and mechanically robust housing designs. Specialized nano-architectures and geometric configurations are developed to minimize thermal strain and maintain mechanical integrity during temperature fluctuations, ensuring consistent energy harvesting performance in high-temperature applications.

- Reliability testing and performance evaluation methods: Comprehensive testing methodologies are developed to evaluate the reliability of high-temperature piezoelectric nanogenerators. These include accelerated aging tests, thermal cycling protocols, and real-time monitoring systems that assess performance degradation under various thermal conditions. Advanced characterization techniques are employed to analyze failure mechanisms, material changes, and performance metrics during and after exposure to high temperatures. These testing frameworks enable the prediction of device lifetime and the optimization of designs for enhanced reliability in extreme thermal environments.

02 Structural design for thermal stability

The structural design of high-temperature piezoelectric nanogenerators plays a vital role in their reliability. Innovative designs incorporate thermal expansion compensation mechanisms, heat dissipation structures, and protective layers that shield the active piezoelectric components from thermal degradation. These structural considerations help maintain device performance and extend operational lifetime at elevated temperatures.Expand Specific Solutions03 Encapsulation and packaging techniques

Advanced encapsulation and packaging techniques are essential for protecting piezoelectric nanogenerators in high-temperature environments. These techniques include hermetic sealing, high-temperature resistant polymers, ceramic packaging, and specialized bonding methods that prevent thermal expansion mismatches. Proper encapsulation ensures device reliability by preventing contamination and mechanical damage while allowing efficient energy harvesting.Expand Specific Solutions04 Testing and reliability assessment methods

Specialized testing protocols and reliability assessment methods have been developed for high-temperature piezoelectric nanogenerators. These include accelerated aging tests, thermal cycling evaluations, performance degradation monitoring, and real-time reliability assessment techniques. These methods help predict device lifetime and identify potential failure modes under high-temperature operating conditions.Expand Specific Solutions05 Integration with electronic systems

The integration of high-temperature piezoelectric nanogenerators with electronic systems requires specialized interface circuits and energy management solutions. These include high-temperature compatible rectifiers, energy storage components, and signal conditioning circuits that can operate reliably at elevated temperatures. Proper integration ensures that the harvested energy is effectively utilized and the overall system maintains reliability in harsh thermal environments.Expand Specific Solutions

Leading Research Groups and Industrial Manufacturers Analysis

The high-temperature piezoelectric nanogenerator market is currently in its growth phase, characterized by increasing research activities and emerging commercial applications. The global market size is estimated to reach $350-400 million by 2027, driven by demand in harsh environment sensing, aerospace, and industrial automation. Leading players include established ceramic manufacturers like TDK Corp., Murata Manufacturing, and NGK Insulators, who leverage their expertise in piezoelectric materials. Research institutions such as Shanghai Institute of Ceramics and Beijing Institute of Nanoenergy & Nanosystems are advancing fundamental technology, while companies like CeramTec and Niterra are developing specialized applications. The technology is approaching commercial maturity, with reliability and scalability remaining key challenges for widespread industrial adoption.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: Shanghai Institute of Ceramics has developed high-temperature piezoelectric nanogenerators based on modified bismuth titanate (Bi4Ti3O12) and bismuth layered ferroelectric ceramics with specialized dopants that maintain piezoelectric properties at temperatures exceeding 650°C. Their approach incorporates a multi-layer structure with specialized high-temperature electrodes made of platinum-palladium alloys and protective ceramic coatings that prevent oxidation and degradation. The institute has pioneered a unique grain boundary engineering technique that enhances domain wall mobility at elevated temperatures, resulting in sustained piezoelectric coefficients (d33) of approximately 25-30 pC/N even at 700°C. Their devices utilize a specialized packaging system with alumina-based ceramic housing and high-temperature resistant connectors that maintain hermetic sealing under thermal cycling. The technology incorporates self-healing mechanisms through controlled microstructural design that allows for redistribution of internal stresses during thermal cycling, significantly improving device lifetime and reliability in harsh environments. These nanogenerators have been successfully tested in industrial settings including steel manufacturing facilities and power plants.

Strengths: Exceptional thermal stability with operational capability up to 700°C; excellent chemical resistance in oxidizing environments; long-term reliability with less than 15% degradation after 500 hours at high temperatures; compatible with standard ceramic processing techniques. Weaknesses: Lower power output compared to lead-based alternatives; relatively high internal impedance limiting current output; requires specialized high-temperature wiring and connection systems that add complexity to system integration.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed advanced high-temperature piezoelectric nanogenerators utilizing their proprietary sodium potassium niobate (KNN) ceramic formulations with specialized dopants that enhance thermal stability and piezoelectric response at elevated temperatures. Their technology employs a unique microstructural design featuring controlled grain size distribution and specialized grain boundary phases that maintain domain mobility at temperatures up to 650°C. NGK's approach incorporates specialized platinum-based interdigitated electrodes with proprietary adhesion layers that ensure reliable electrical contact during thermal cycling. The company has implemented a sophisticated packaging system using their advanced ceramic expertise, featuring alumina-zirconia composite housings with specialized high-temperature sealing glass that maintains hermeticity in harsh environments. Their nanogenerators utilize a resonant beam structure optimized through finite element analysis to maximize energy harvesting efficiency from low-amplitude vibrations typical in industrial settings. NGK has also developed specialized interface electronics with impedance matching circuits that optimize power extraction across varying temperature conditions. These devices have demonstrated stable performance with output voltages of 5-8V and power densities of approximately 0.7-1.0 mW/cm² at temperatures of 500-600°C, making them suitable for power plant monitoring, automotive exhaust systems, and industrial process control applications.

Strengths: Exceptional long-term reliability with less than 12% performance degradation after 1000 hours at high temperatures; excellent chemical resistance in corrosive environments; lead-free composition meeting environmental regulations; leverages NGK's established expertise in advanced ceramics manufacturing. Weaknesses: Lower output power compared to some competing technologies; requires precise mounting to optimize mechanical energy coupling; relatively high internal impedance limiting current output capabilities; more expensive than conventional room-temperature piezoelectric generators.

Critical Patents and Research on Temperature-Resistant Nanogenerators

High temperature piezoelectric ceramics

PatentInactiveUS8518291B2

Innovation

- Development of piezoelectric ceramics based on the Bi(Zn1/2Zr1/2)O3—BiScO3—PbTiO3 (BZZ-BS-PT) formulation with tailored weight ratios, processed through mixing, calcination, forming, and sintering, to achieve high Curie temperatures and large piezoelectric coefficients, maintaining stability up to 400°C.

High temperature piezoelectric ceramic material of bisco3-pbtio3, chemically designed to operate in high power conditions and procedure to obtain such ceramic materia.

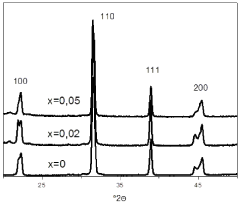

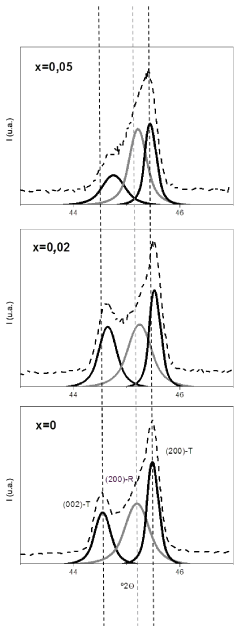

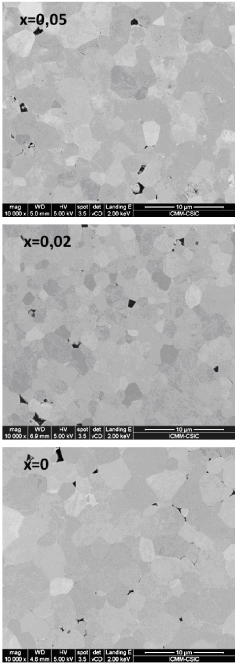

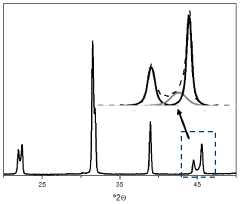

PatentInactiveES2628027A1

Innovation

- A piezoelectric ceramic material with the formula Bi0,36Pb0,64Sc0,36-xMnxTi0,64O3, where x ranges from 0.02 to 0.05, incorporating a point defect to reduce dielectric and mechanical losses, achieved through mechanochemical activation of nanocrystalline powders and controlled sintering, maintaining a dense and homogeneous microstructure.

Material Degradation Mechanisms at Elevated Temperatures

Piezoelectric ceramic materials undergo several critical degradation mechanisms when exposed to elevated temperatures, significantly impacting the performance and reliability of high-temperature nanogenerators. The primary degradation pathway involves phase transitions that occur as temperatures approach or exceed the Curie point of the material. For materials like PZT (lead zirconate titanate), this transition from ferroelectric to paraelectric phase results in complete loss of piezoelectric properties, rendering the device non-functional.

Oxidation processes accelerate dramatically at high temperatures, particularly affecting electrode materials and their interfaces with piezoelectric ceramics. This oxidation creates resistive layers that impede charge transfer, reducing the overall electrical output of nanogenerators. In multi-component ceramic systems, differential thermal expansion between constituent phases induces mechanical stress, leading to microcrack formation and propagation throughout the material structure.

Ionic diffusion becomes pronounced at elevated temperatures, with mobile species like oxygen vacancies and metal cations migrating across grain boundaries. This migration alters local stoichiometry and electrical properties, creating compositional gradients that degrade piezoelectric response over time. The rate of this diffusion follows Arrhenius behavior, approximately doubling with every 10°C increase in operating temperature.

Domain wall motion, essential for piezoelectric response, becomes increasingly irreversible at high temperatures. This phenomenon, known as domain wall pinning, occurs when point defects accumulate at domain boundaries, restricting their mobility and diminishing the material's piezoelectric coefficient. Experimental data indicates up to 40% reduction in d33 coefficient after extended exposure to temperatures above 200°C.

Grain boundary degradation represents another critical failure mechanism, as intergranular regions often contain secondary phases with lower melting points than the primary ceramic. These regions soften or melt at elevated temperatures, compromising mechanical integrity and creating electrical leakage paths. Electron microscopy studies have revealed significant morphological changes at grain boundaries after thermal cycling between room temperature and 400°C.

Chemical decomposition of certain piezoelectric compositions occurs at extreme temperatures, particularly for materials containing volatile components like lead or bismuth. This decomposition alters surface chemistry and creates porosity that further accelerates degradation through increased surface area exposure. Advanced ceramic compositions incorporating stabilizing dopants like lanthanum or niobium have demonstrated improved resistance to these decomposition mechanisms, extending operational temperature ranges by up to 150°C compared to conventional formulations.

Oxidation processes accelerate dramatically at high temperatures, particularly affecting electrode materials and their interfaces with piezoelectric ceramics. This oxidation creates resistive layers that impede charge transfer, reducing the overall electrical output of nanogenerators. In multi-component ceramic systems, differential thermal expansion between constituent phases induces mechanical stress, leading to microcrack formation and propagation throughout the material structure.

Ionic diffusion becomes pronounced at elevated temperatures, with mobile species like oxygen vacancies and metal cations migrating across grain boundaries. This migration alters local stoichiometry and electrical properties, creating compositional gradients that degrade piezoelectric response over time. The rate of this diffusion follows Arrhenius behavior, approximately doubling with every 10°C increase in operating temperature.

Domain wall motion, essential for piezoelectric response, becomes increasingly irreversible at high temperatures. This phenomenon, known as domain wall pinning, occurs when point defects accumulate at domain boundaries, restricting their mobility and diminishing the material's piezoelectric coefficient. Experimental data indicates up to 40% reduction in d33 coefficient after extended exposure to temperatures above 200°C.

Grain boundary degradation represents another critical failure mechanism, as intergranular regions often contain secondary phases with lower melting points than the primary ceramic. These regions soften or melt at elevated temperatures, compromising mechanical integrity and creating electrical leakage paths. Electron microscopy studies have revealed significant morphological changes at grain boundaries after thermal cycling between room temperature and 400°C.

Chemical decomposition of certain piezoelectric compositions occurs at extreme temperatures, particularly for materials containing volatile components like lead or bismuth. This decomposition alters surface chemistry and creates porosity that further accelerates degradation through increased surface area exposure. Advanced ceramic compositions incorporating stabilizing dopants like lanthanum or niobium have demonstrated improved resistance to these decomposition mechanisms, extending operational temperature ranges by up to 150°C compared to conventional formulations.

Standardization and Testing Protocols for Device Reliability

The standardization and testing protocols for high-temperature piezoelectric nanogenerators represent a critical yet underdeveloped area that requires immediate attention from the research community and industry stakeholders. Currently, there exists significant variability in how device reliability is assessed across different research groups, making direct comparisons between studies challenging and hindering technological advancement.

A comprehensive standardization framework should address multiple dimensions of device reliability testing. Temperature cycling tests must evaluate performance under repeated thermal stress conditions, with standardized protocols specifying heating/cooling rates, dwell times at extreme temperatures, and minimum cycle counts (typically 1000+ cycles for industrial applications). These protocols should align with established standards such as JEDEC JESD22-A104 while incorporating modifications specific to piezoelectric nanogenerator requirements.

Mechanical durability testing represents another crucial aspect, particularly for devices intended for harsh environments. Standardized vibration testing should include defined frequencies, amplitudes, and durations that simulate real-world conditions. For impact resistance, controlled drop tests with specified heights and impact surfaces would provide comparable reliability metrics across different device designs.

Long-term stability assessment protocols must standardize environmental exposure conditions, including humidity levels, chemical environments, and radiation exposure where applicable. Accelerated aging tests should follow established methodologies with clearly defined acceleration factors to enable meaningful lifetime predictions.

Electrical performance characterization requires standardized measurement conditions, including consistent load resistances, measurement frequencies, and environmental parameters. Output metrics should be uniformly reported as power density (mW/cm²), energy conversion efficiency, and voltage stability over time rather than peak values alone.

Several international organizations have begun addressing these standardization needs, including IEEE's Working Group on Energy Harvesting and the International Electrotechnical Commission (IEC). However, specific standards for high-temperature piezoelectric nanogenerators remain in nascent stages. The development of these standards would benefit from collaborative efforts between academic institutions, national laboratories, and industry partners.

Implementation of these standardized protocols would significantly enhance the reliability assessment of high-temperature piezoelectric nanogenerators, accelerate technology maturation, and facilitate more meaningful benchmarking across different material systems and device architectures. This standardization represents a necessary step toward commercial viability and widespread adoption of these promising energy harvesting technologies.

A comprehensive standardization framework should address multiple dimensions of device reliability testing. Temperature cycling tests must evaluate performance under repeated thermal stress conditions, with standardized protocols specifying heating/cooling rates, dwell times at extreme temperatures, and minimum cycle counts (typically 1000+ cycles for industrial applications). These protocols should align with established standards such as JEDEC JESD22-A104 while incorporating modifications specific to piezoelectric nanogenerator requirements.

Mechanical durability testing represents another crucial aspect, particularly for devices intended for harsh environments. Standardized vibration testing should include defined frequencies, amplitudes, and durations that simulate real-world conditions. For impact resistance, controlled drop tests with specified heights and impact surfaces would provide comparable reliability metrics across different device designs.

Long-term stability assessment protocols must standardize environmental exposure conditions, including humidity levels, chemical environments, and radiation exposure where applicable. Accelerated aging tests should follow established methodologies with clearly defined acceleration factors to enable meaningful lifetime predictions.

Electrical performance characterization requires standardized measurement conditions, including consistent load resistances, measurement frequencies, and environmental parameters. Output metrics should be uniformly reported as power density (mW/cm²), energy conversion efficiency, and voltage stability over time rather than peak values alone.

Several international organizations have begun addressing these standardization needs, including IEEE's Working Group on Energy Harvesting and the International Electrotechnical Commission (IEC). However, specific standards for high-temperature piezoelectric nanogenerators remain in nascent stages. The development of these standards would benefit from collaborative efforts between academic institutions, national laboratories, and industry partners.

Implementation of these standardized protocols would significantly enhance the reliability assessment of high-temperature piezoelectric nanogenerators, accelerate technology maturation, and facilitate more meaningful benchmarking across different material systems and device architectures. This standardization represents a necessary step toward commercial viability and widespread adoption of these promising energy harvesting technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!