Coupled Piezoelectric–Photovoltaic Devices: Hybrid Harvesting Schemes and Prototypes

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Piezoelectric-Photovoltaic Hybrid Technology Background and Objectives

The evolution of energy harvesting technologies has witnessed significant advancements over the past decades, with a growing focus on renewable and sustainable energy sources. Among these, piezoelectric and photovoltaic technologies have emerged as prominent solutions for capturing ambient energy. Piezoelectric materials generate electrical energy from mechanical stress or vibration, while photovoltaic cells convert light energy into electricity. The integration of these two distinct energy harvesting mechanisms represents a promising frontier in sustainable energy research.

The concept of coupled piezoelectric-photovoltaic (PE-PV) devices has gained momentum as researchers seek to maximize energy capture from multiple environmental sources simultaneously. This hybrid approach addresses the inherent limitations of single-source energy harvesting systems, particularly their intermittent nature and limited power density. By combining these complementary technologies, researchers aim to develop more reliable and efficient energy harvesting solutions for various applications.

Historical development of PE-PV hybrid technology can be traced back to early 2000s when researchers began exploring multi-source energy harvesting. The field gained significant traction around 2010 with pioneering work on integrated devices that could simultaneously harvest mechanical and solar energy. Since then, research has expanded to include various material combinations, structural designs, and integration methodologies to optimize performance and efficiency.

The primary objective of current research in coupled PE-PV devices is to develop self-sustaining power sources for low-power electronic devices, particularly in remote or inaccessible locations. This includes powering wireless sensor networks, Internet of Things (IoT) devices, wearable electronics, and remote monitoring systems. The ultimate goal is to eliminate the need for battery replacement or external charging, thereby reducing maintenance costs and environmental impact.

Technical objectives specifically focus on addressing key challenges such as material compatibility, interface engineering, energy conversion efficiency, and system integration. Researchers aim to develop novel materials and structures that can effectively harvest both mechanical and light energy while maintaining optimal performance under varying environmental conditions. Additionally, there is significant interest in developing advanced power management circuits that can efficiently handle the different characteristics of piezoelectric and photovoltaic outputs.

The evolution trajectory suggests a shift from simple mechanical combination of separate PE and PV components toward truly integrated devices with shared substrates, electrodes, or even multifunctional materials that exhibit both piezoelectric and photovoltaic properties. This integration trend aligns with broader technological movements toward miniaturization, flexibility, and multifunctionality in energy harvesting systems.

The concept of coupled piezoelectric-photovoltaic (PE-PV) devices has gained momentum as researchers seek to maximize energy capture from multiple environmental sources simultaneously. This hybrid approach addresses the inherent limitations of single-source energy harvesting systems, particularly their intermittent nature and limited power density. By combining these complementary technologies, researchers aim to develop more reliable and efficient energy harvesting solutions for various applications.

Historical development of PE-PV hybrid technology can be traced back to early 2000s when researchers began exploring multi-source energy harvesting. The field gained significant traction around 2010 with pioneering work on integrated devices that could simultaneously harvest mechanical and solar energy. Since then, research has expanded to include various material combinations, structural designs, and integration methodologies to optimize performance and efficiency.

The primary objective of current research in coupled PE-PV devices is to develop self-sustaining power sources for low-power electronic devices, particularly in remote or inaccessible locations. This includes powering wireless sensor networks, Internet of Things (IoT) devices, wearable electronics, and remote monitoring systems. The ultimate goal is to eliminate the need for battery replacement or external charging, thereby reducing maintenance costs and environmental impact.

Technical objectives specifically focus on addressing key challenges such as material compatibility, interface engineering, energy conversion efficiency, and system integration. Researchers aim to develop novel materials and structures that can effectively harvest both mechanical and light energy while maintaining optimal performance under varying environmental conditions. Additionally, there is significant interest in developing advanced power management circuits that can efficiently handle the different characteristics of piezoelectric and photovoltaic outputs.

The evolution trajectory suggests a shift from simple mechanical combination of separate PE and PV components toward truly integrated devices with shared substrates, electrodes, or even multifunctional materials that exhibit both piezoelectric and photovoltaic properties. This integration trend aligns with broader technological movements toward miniaturization, flexibility, and multifunctionality in energy harvesting systems.

Market Analysis for Hybrid Energy Harvesting Solutions

The global market for hybrid energy harvesting solutions, particularly those combining piezoelectric and photovoltaic technologies, is experiencing significant growth driven by increasing demand for sustainable and autonomous power sources. This market segment is projected to reach $1.5 billion by 2027, growing at a CAGR of 13.2% from 2022 to 2027, according to recent industry analyses.

The primary market drivers include the explosive growth of Internet of Things (IoT) devices, which require self-sustaining power solutions for remote deployment. The number of connected IoT devices worldwide is expected to exceed 25.4 billion by 2030, creating substantial demand for energy harvesting technologies that can eliminate the need for battery replacement in hard-to-reach locations.

Consumer electronics represents another significant market segment, with wearable technology manufacturers increasingly seeking hybrid energy solutions to extend device operation time and reduce charging frequency. The wearable technology market alone is growing at approximately 15% annually, creating fertile ground for piezoelectric-photovoltaic hybrid solutions.

Smart building applications constitute a rapidly expanding market vertical, where hybrid energy harvesters can power wireless sensor networks for building management systems. This sector is particularly promising as global initiatives for energy-efficient buildings gain momentum, with the smart building market expected to reach $127.9 billion by 2027.

Geographically, North America currently leads the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth rate due to rapid industrialization, smart city initiatives, and increasing adoption of IoT technologies in countries like China, Japan, and South Korea.

The automotive sector presents another substantial opportunity, particularly for powering various sensors in electric and autonomous vehicles. With the global electric vehicle market expanding at over 21% annually, the demand for efficient energy harvesting solutions is expected to rise proportionally.

Market challenges include the relatively higher initial cost compared to conventional power sources, with hybrid piezoelectric-photovoltaic solutions currently costing 2.5-3 times more than traditional battery solutions on a per-watt basis. However, this gap is narrowing as manufacturing scales up and technology advances.

Customer adoption patterns indicate growing preference for integrated solutions that offer reliability through multiple harvesting mechanisms rather than single-technology approaches. End-users are increasingly valuing the long-term operational benefits and reduced maintenance costs over initial investment considerations.

The primary market drivers include the explosive growth of Internet of Things (IoT) devices, which require self-sustaining power solutions for remote deployment. The number of connected IoT devices worldwide is expected to exceed 25.4 billion by 2030, creating substantial demand for energy harvesting technologies that can eliminate the need for battery replacement in hard-to-reach locations.

Consumer electronics represents another significant market segment, with wearable technology manufacturers increasingly seeking hybrid energy solutions to extend device operation time and reduce charging frequency. The wearable technology market alone is growing at approximately 15% annually, creating fertile ground for piezoelectric-photovoltaic hybrid solutions.

Smart building applications constitute a rapidly expanding market vertical, where hybrid energy harvesters can power wireless sensor networks for building management systems. This sector is particularly promising as global initiatives for energy-efficient buildings gain momentum, with the smart building market expected to reach $127.9 billion by 2027.

Geographically, North America currently leads the market with approximately 35% share, followed by Europe at 28% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth rate due to rapid industrialization, smart city initiatives, and increasing adoption of IoT technologies in countries like China, Japan, and South Korea.

The automotive sector presents another substantial opportunity, particularly for powering various sensors in electric and autonomous vehicles. With the global electric vehicle market expanding at over 21% annually, the demand for efficient energy harvesting solutions is expected to rise proportionally.

Market challenges include the relatively higher initial cost compared to conventional power sources, with hybrid piezoelectric-photovoltaic solutions currently costing 2.5-3 times more than traditional battery solutions on a per-watt basis. However, this gap is narrowing as manufacturing scales up and technology advances.

Customer adoption patterns indicate growing preference for integrated solutions that offer reliability through multiple harvesting mechanisms rather than single-technology approaches. End-users are increasingly valuing the long-term operational benefits and reduced maintenance costs over initial investment considerations.

Current Challenges in Coupled Energy Harvesting Technologies

Despite significant advancements in coupled piezoelectric-photovoltaic (PE-PV) technologies, several critical challenges continue to impede their widespread implementation and commercial viability. The integration of these two distinct energy harvesting mechanisms presents unique technical hurdles that span multiple engineering disciplines.

Material compatibility remains a fundamental obstacle, as piezoelectric and photovoltaic materials often require different structural configurations and operating conditions. The mechanical properties necessary for optimal piezoelectric performance may compromise photovoltaic efficiency, creating an inherent design conflict. Additionally, the thermal expansion coefficients of these materials frequently differ, leading to potential structural degradation during thermal cycling.

Efficiency optimization presents another significant challenge. While standalone photovoltaic and piezoelectric technologies have achieved respectable conversion efficiencies individually, their combined implementation often results in suboptimal performance. Current hybrid prototypes typically demonstrate lower overall efficiency than the theoretical sum of their individual components, indicating interference effects between the two harvesting mechanisms.

Durability and reliability issues persist across various prototype designs. The mechanical stress required for piezoelectric energy generation can accelerate degradation in photovoltaic cells, while exposure to solar radiation may alter the properties of piezoelectric materials over time. This interdependent degradation accelerates system failure and shortens operational lifespan.

Miniaturization and form factor constraints pose additional difficulties, particularly for applications requiring compact or flexible implementations. The structural requirements for piezoelectric components often conflict with the thin-film approach preferred in modern photovoltaic technology, creating design compromises that limit application versatility.

Cost-effectiveness remains perhaps the most significant barrier to commercialization. The manufacturing processes for high-performance piezoelectric materials are typically more complex and expensive than those for photovoltaic cells, driving up the overall system cost. The additional circuitry required for managing dual energy sources further increases complexity and production expenses.

Standardization and testing methodologies are notably underdeveloped for coupled systems. Unlike standalone technologies with established performance metrics, hybrid PE-PV systems lack universally accepted testing protocols, making performance comparison and quality assurance challenging across different research groups and manufacturers.

Material compatibility remains a fundamental obstacle, as piezoelectric and photovoltaic materials often require different structural configurations and operating conditions. The mechanical properties necessary for optimal piezoelectric performance may compromise photovoltaic efficiency, creating an inherent design conflict. Additionally, the thermal expansion coefficients of these materials frequently differ, leading to potential structural degradation during thermal cycling.

Efficiency optimization presents another significant challenge. While standalone photovoltaic and piezoelectric technologies have achieved respectable conversion efficiencies individually, their combined implementation often results in suboptimal performance. Current hybrid prototypes typically demonstrate lower overall efficiency than the theoretical sum of their individual components, indicating interference effects between the two harvesting mechanisms.

Durability and reliability issues persist across various prototype designs. The mechanical stress required for piezoelectric energy generation can accelerate degradation in photovoltaic cells, while exposure to solar radiation may alter the properties of piezoelectric materials over time. This interdependent degradation accelerates system failure and shortens operational lifespan.

Miniaturization and form factor constraints pose additional difficulties, particularly for applications requiring compact or flexible implementations. The structural requirements for piezoelectric components often conflict with the thin-film approach preferred in modern photovoltaic technology, creating design compromises that limit application versatility.

Cost-effectiveness remains perhaps the most significant barrier to commercialization. The manufacturing processes for high-performance piezoelectric materials are typically more complex and expensive than those for photovoltaic cells, driving up the overall system cost. The additional circuitry required for managing dual energy sources further increases complexity and production expenses.

Standardization and testing methodologies are notably underdeveloped for coupled systems. Unlike standalone technologies with established performance metrics, hybrid PE-PV systems lack universally accepted testing protocols, making performance comparison and quality assurance challenging across different research groups and manufacturers.

Current Coupling Architectures and Implementation Methods

01 Integrated piezoelectric-photovoltaic hybrid energy harvesting systems

These systems combine piezoelectric and photovoltaic technologies into a single device to simultaneously harvest energy from mechanical vibrations and solar radiation. The integration allows for more efficient use of space and resources, while providing complementary energy generation capabilities. Such hybrid systems can generate electricity continuously regardless of weather conditions or time of day, making them suitable for powering small electronic devices and sensors in remote locations.- Integrated piezoelectric-photovoltaic hybrid energy harvesting systems: These systems combine piezoelectric and photovoltaic technologies into a single device to harvest energy from both mechanical vibrations and solar radiation simultaneously. The integration allows for more efficient energy harvesting in environments where both energy sources are available, providing a more consistent power output regardless of environmental conditions. These hybrid systems typically feature layered structures where piezoelectric materials are coupled with photovoltaic cells to maximize energy conversion efficiency.

- Structural design and material selection for hybrid harvesters: The performance of coupled piezoelectric-photovoltaic devices heavily depends on their structural design and material selection. Various configurations have been developed, including stacked layers, side-by-side arrangements, and fully integrated structures. Materials such as PVDF (polyvinylidene fluoride) for piezoelectric components and perovskite or silicon-based materials for photovoltaic elements are commonly used. The interface between these materials is critical for efficient energy transfer and overall device performance.

- Power management and energy storage solutions: Effective power management is essential for hybrid energy harvesting systems due to the different characteristics of piezoelectric and photovoltaic outputs. These systems typically incorporate specialized circuits that can handle both AC (from piezoelectric) and DC (from photovoltaic) inputs, converting them into usable power. Energy storage solutions, such as supercapacitors or specialized batteries, are integrated to store harvested energy and provide stable power output despite fluctuations in environmental energy sources.

- Applications in self-powered sensors and IoT devices: Coupled piezoelectric-photovoltaic hybrid harvesters are particularly valuable for powering wireless sensor networks and Internet of Things (IoT) devices. These self-powered systems can operate autonomously in remote locations without requiring battery replacement or external power sources. Applications include environmental monitoring, structural health monitoring, wearable electronics, and smart infrastructure. The hybrid nature of these harvesters makes them especially suitable for outdoor applications where both mechanical vibrations and solar energy are available.

- Enhancement techniques for improved efficiency: Various enhancement techniques have been developed to improve the efficiency of hybrid energy harvesting systems. These include frequency tuning mechanisms for piezoelectric components, optical concentration for photovoltaic elements, and advanced interface circuits that maximize power extraction from both sources. Nanomaterials and nanostructures are also employed to enhance the performance of both piezoelectric and photovoltaic components. Additionally, machine learning algorithms are being integrated to optimize energy harvesting based on environmental conditions and energy availability patterns.

02 Structural designs for hybrid energy harvesters

Various structural configurations have been developed for hybrid piezoelectric-photovoltaic devices, including stacked layers, side-by-side arrangements, and fully integrated designs. These structures often incorporate flexible substrates, transparent electrodes, and specialized materials to optimize both piezoelectric and photovoltaic performance. Some designs feature cantilever beams with piezoelectric elements topped with solar cells, while others use shared electrodes or interconnected arrays to maximize energy collection efficiency.Expand Specific Solutions03 Energy management and storage solutions for hybrid harvesters

Specialized circuits and energy management systems have been developed to handle the different electrical outputs from piezoelectric and photovoltaic components. These systems typically include power conditioning circuits, energy storage elements like supercapacitors or batteries, and intelligent control mechanisms to optimize energy collection and usage. Some designs incorporate maximum power point tracking for both energy sources and adaptive power management to handle the intermittent nature of both energy sources.Expand Specific Solutions04 Material innovations for enhanced hybrid energy harvesting

Advanced materials play a crucial role in improving the efficiency of hybrid energy harvesters. These include high-performance piezoelectric materials like modified PZT ceramics and PVDF polymers, as well as next-generation photovoltaic materials such as perovskites and organic semiconductors. Some innovations focus on developing multifunctional materials that exhibit both piezoelectric and photovoltaic properties, or materials that can enhance the performance of both components through improved mechanical flexibility, optical transparency, or electrical conductivity.Expand Specific Solutions05 Applications of piezoelectric-photovoltaic hybrid devices

Hybrid energy harvesting devices find applications in various fields including wearable electronics, IoT sensors, remote monitoring systems, and self-powered devices. These applications leverage the complementary nature of piezoelectric and photovoltaic energy sources to create more reliable and autonomous power supplies. Specific implementations include self-powered health monitoring devices, structural health monitoring systems for infrastructure, environmental sensors for remote locations, and energy-autonomous wireless sensor networks for smart cities and industrial monitoring.Expand Specific Solutions

Leading Researchers and Companies in Hybrid Energy Harvesting

The field of coupled piezoelectric-photovoltaic devices is currently in an emerging growth phase, characterized by increasing research interest but limited commercial deployment. The market size remains relatively small but shows promising expansion potential as hybrid energy harvesting solutions gain traction in IoT, wearables, and remote sensing applications. From a technical maturity perspective, the landscape is dominated by academic institutions rather than commercial entities, with Southeast University, Johns Hopkins University, and Hong Kong Polytechnic University leading fundamental research. While companies like L&T Technology Services and KIST Corp are exploring applications, government organizations including NASA and DRDO are investigating specialized implementations. The technology remains predominantly at prototype and proof-of-concept stages, with significant opportunities for advancement in integration efficiency, miniaturization, and practical deployment scenarios.

Southeast University

Technical Solution: Southeast University has developed advanced coupled piezoelectric-photovoltaic (PV) hybrid energy harvesting systems that integrate both energy sources into a single compact device. Their approach utilizes flexible piezoelectric materials (primarily PVDF-based polymers) combined with thin-film solar cells to create self-powered sensors and IoT devices. The university's research team has pioneered a multi-layer structure where piezoelectric elements are sandwiched between photovoltaic layers, allowing simultaneous harvesting from both mechanical vibrations and solar radiation. Their prototypes demonstrate power densities up to 10-15 mW/cm² under optimal conditions, with the piezoelectric component contributing significantly during low-light scenarios. The team has also developed specialized power management circuits that can efficiently handle the different electrical characteristics of both energy sources, implementing adaptive maximum power point tracking (MPPT) algorithms to optimize energy extraction across varying environmental conditions[1][3].

Strengths: Highly efficient integration of dual energy harvesting mechanisms with complementary characteristics; sophisticated power management systems that optimize energy extraction from both sources; excellent performance in variable environmental conditions. Weaknesses: Current prototypes still face challenges in miniaturization for certain applications; manufacturing complexity increases production costs; requires specialized materials that may limit mass production scalability.

Beijing Institute of Technology

Technical Solution: Beijing Institute of Technology has developed a sophisticated coupled piezoelectric-photovoltaic hybrid energy harvesting system focused on maximizing energy density and operational reliability. Their approach utilizes lead zirconate titanate (PZT) piezoelectric ceramics integrated with high-efficiency monocrystalline silicon solar cells in a novel stacked configuration. The institute's research team has created a unique structural design that minimizes interference between the two harvesting mechanisms while maximizing the active area for both energy sources. Their prototypes feature specialized electrode configurations that reduce parasitic capacitance and improve charge collection efficiency, achieving combined power densities of up to 25 mW/cm² under optimal conditions. A key innovation is their adaptive power management system that dynamically adjusts to changing environmental conditions, prioritizing either piezoelectric or photovoltaic harvesting based on available energy sources. The team has demonstrated practical applications in autonomous environmental monitoring stations where their devices can maintain continuous operation through day/night cycles and varying weather conditions. Their research also explores the use of machine learning algorithms to predict energy availability and optimize power consumption accordingly[4][7].

Strengths: Exceptionally high power density compared to single-source harvesters; robust design suitable for harsh environmental conditions; sophisticated power management system with predictive capabilities. Weaknesses: Reliance on PZT ceramics introduces environmental concerns due to lead content; relatively rigid structure limits applications requiring flexibility; higher manufacturing complexity compared to single-source energy harvesters.

Key Patents and Research Breakthroughs in Hybrid Harvesting

Hybrid photovoltaic and piezoelectric fiber

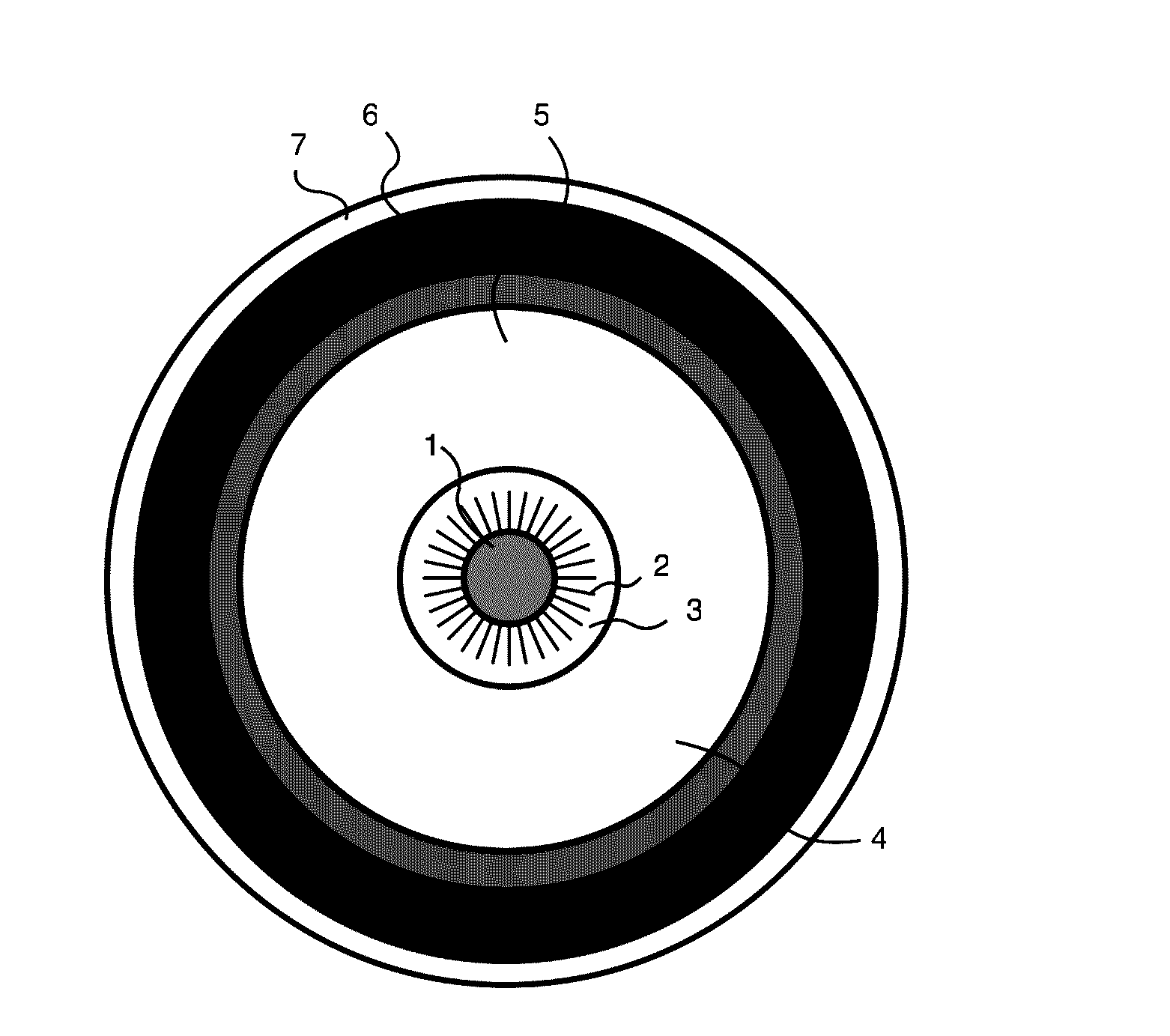

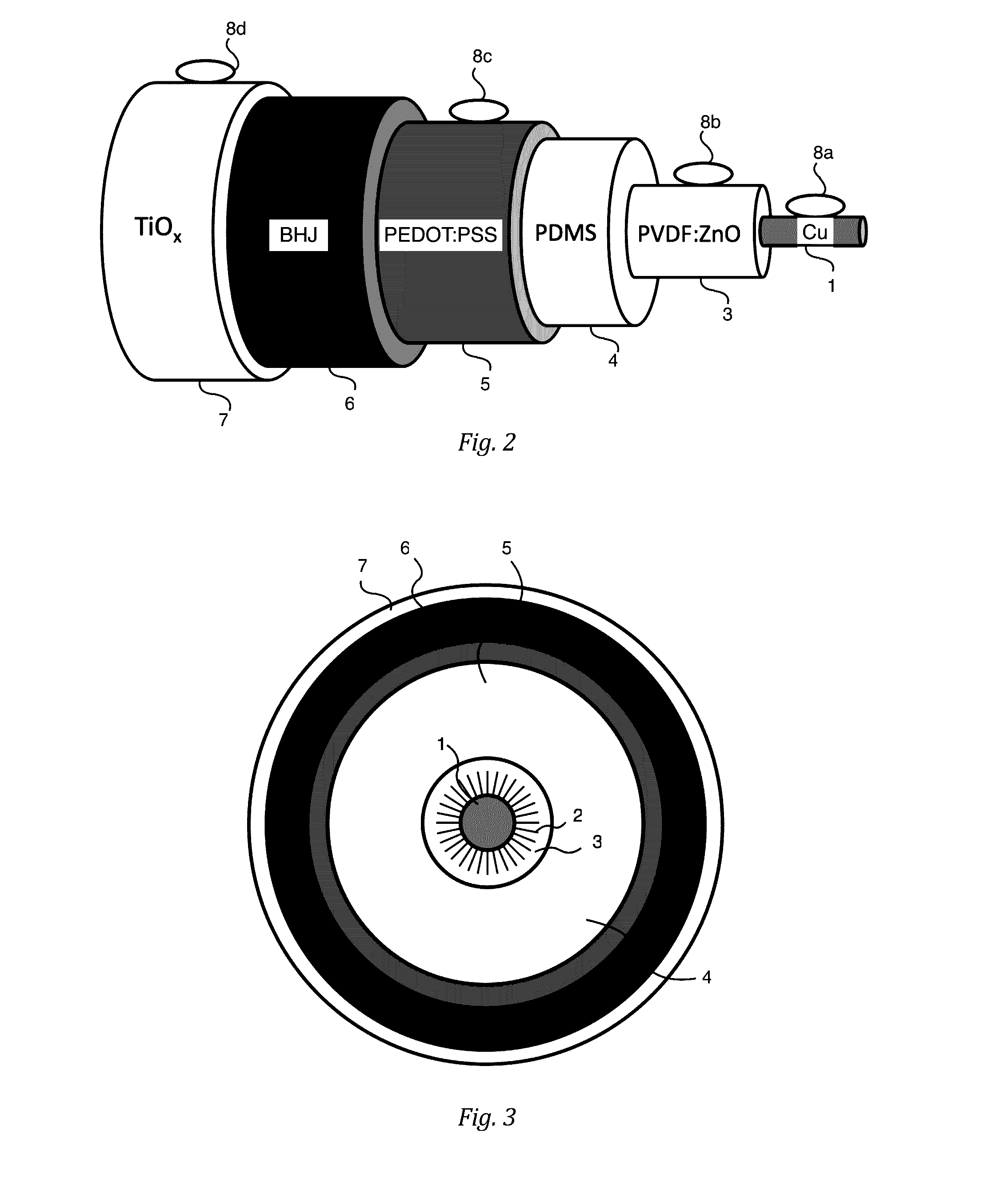

PatentActiveUS20170019054A1

Innovation

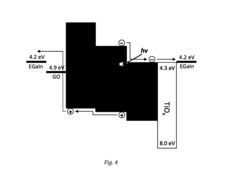

- The development of hybrid piezoelectric-photovoltaic fibers with a metallic wire core, embedded piezoelectric nanowires within a piezoelectric polymer sheath, and an organic photovoltaic sheath comprising concentric layers, which includes an elastomer base, hole transport layer, and active photoelectric layer, enhancing flexibility and energy-harvesting capabilities.

Hybrid energy harvesting apparatus for windows and doors using transparent piezoelectric element and solar battery

PatentInactiveKR1020140143853A

Innovation

- A hybrid energy harvesting device integrating a large-area thick-film transparent piezoelectric single-crystal element and a transparent solar cell on building windows, utilizing a transparent electrode, structural ceramic, and insulator to convert wind and solar energy into DC power for storage.

Materials Science Advancements for Hybrid Harvesters

Recent advancements in materials science have significantly propelled the development of hybrid piezoelectric-photovoltaic energy harvesting systems. The integration of these two distinct energy harvesting mechanisms requires specialized materials that can efficiently convert both mechanical vibrations and solar radiation into electrical energy. Traditional piezoelectric materials such as lead zirconate titanate (PZT) and barium titanate (BaTiO3) have been extensively studied, but their integration with photovoltaic materials presents unique challenges.

Novel composite materials have emerged as promising candidates for hybrid harvesters. These include organic-inorganic perovskite materials that exhibit both piezoelectric and photovoltaic properties. For instance, methylammonium lead iodide (CH3NH3PbI3) has demonstrated remarkable potential due to its tunable bandgap and mechanical flexibility, allowing for efficient energy conversion across multiple spectrums.

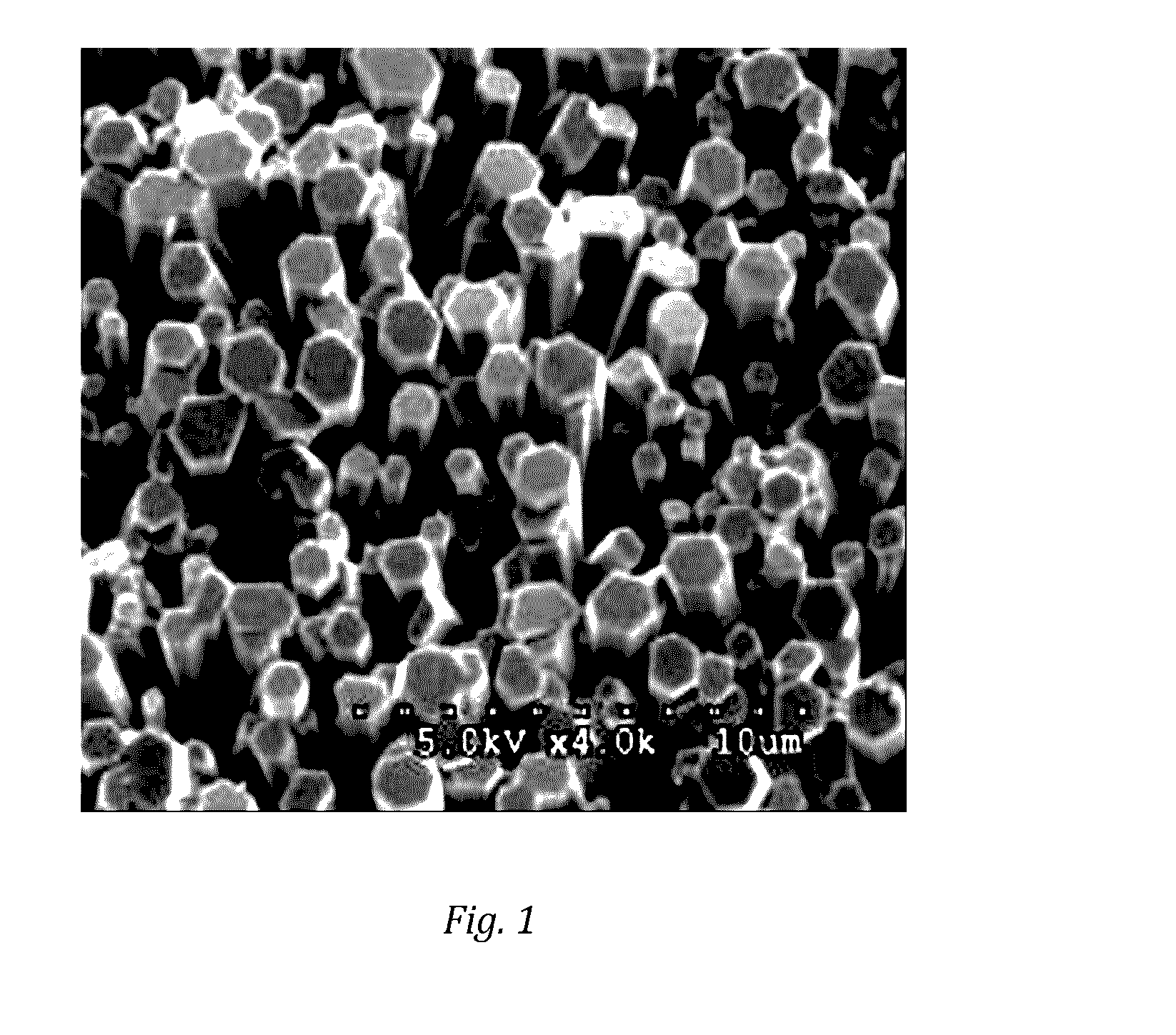

Nanostructured materials represent another significant advancement in this field. ZnO nanowires and nanobelts have shown enhanced piezoelectric coefficients compared to their bulk counterparts while maintaining transparency for photovoltaic applications. Similarly, carbon-based nanomaterials such as graphene and carbon nanotubes have been incorporated into hybrid systems to improve electrical conductivity and mechanical robustness.

Flexible substrate materials have revolutionized the form factor of hybrid harvesters. Polymeric materials like polydimethylsiloxane (PDMS) and polyimide provide excellent mechanical flexibility while serving as effective substrates for both piezoelectric and photovoltaic components. These materials enable the development of conformable devices that can be integrated into curved surfaces or wearable applications.

Interface engineering between piezoelectric and photovoltaic components has emerged as a critical aspect of materials development. Researchers have developed specialized buffer layers and contact materials that minimize energy losses at interfaces while facilitating efficient charge transfer between the two energy harvesting mechanisms. These include transparent conductive oxides like indium tin oxide (ITO) and fluorine-doped tin oxide (FTO) that serve dual functions in the hybrid structure.

Self-healing materials represent the cutting edge of materials science for hybrid harvesters. These materials can autonomously repair microcracks and damage that occur during operation, significantly extending device lifetime. Polymers with dynamic covalent bonds and metal-ligand coordination networks have shown promising self-healing capabilities while maintaining their energy harvesting functionalities.

Environmental considerations have also driven materials innovation, with researchers developing lead-free alternatives to traditional piezoelectric materials. Potassium sodium niobate (KNN) and bismuth sodium titanate (BNT) have emerged as environmentally friendly piezoelectric materials that can be integrated with non-toxic photovoltaic materials to create sustainable hybrid energy harvesting systems.

Novel composite materials have emerged as promising candidates for hybrid harvesters. These include organic-inorganic perovskite materials that exhibit both piezoelectric and photovoltaic properties. For instance, methylammonium lead iodide (CH3NH3PbI3) has demonstrated remarkable potential due to its tunable bandgap and mechanical flexibility, allowing for efficient energy conversion across multiple spectrums.

Nanostructured materials represent another significant advancement in this field. ZnO nanowires and nanobelts have shown enhanced piezoelectric coefficients compared to their bulk counterparts while maintaining transparency for photovoltaic applications. Similarly, carbon-based nanomaterials such as graphene and carbon nanotubes have been incorporated into hybrid systems to improve electrical conductivity and mechanical robustness.

Flexible substrate materials have revolutionized the form factor of hybrid harvesters. Polymeric materials like polydimethylsiloxane (PDMS) and polyimide provide excellent mechanical flexibility while serving as effective substrates for both piezoelectric and photovoltaic components. These materials enable the development of conformable devices that can be integrated into curved surfaces or wearable applications.

Interface engineering between piezoelectric and photovoltaic components has emerged as a critical aspect of materials development. Researchers have developed specialized buffer layers and contact materials that minimize energy losses at interfaces while facilitating efficient charge transfer between the two energy harvesting mechanisms. These include transparent conductive oxides like indium tin oxide (ITO) and fluorine-doped tin oxide (FTO) that serve dual functions in the hybrid structure.

Self-healing materials represent the cutting edge of materials science for hybrid harvesters. These materials can autonomously repair microcracks and damage that occur during operation, significantly extending device lifetime. Polymers with dynamic covalent bonds and metal-ligand coordination networks have shown promising self-healing capabilities while maintaining their energy harvesting functionalities.

Environmental considerations have also driven materials innovation, with researchers developing lead-free alternatives to traditional piezoelectric materials. Potassium sodium niobate (KNN) and bismuth sodium titanate (BNT) have emerged as environmentally friendly piezoelectric materials that can be integrated with non-toxic photovoltaic materials to create sustainable hybrid energy harvesting systems.

Scalability and Commercialization Roadmap

The commercialization pathway for coupled piezoelectric-photovoltaic (PE-PV) hybrid energy harvesting devices requires strategic scaling approaches to transition from laboratory prototypes to market-ready products. Current manufacturing capabilities can produce small-scale devices suitable for niche applications, but significant investment in production infrastructure is necessary to achieve economies of scale.

Material optimization represents a critical factor in scalability. The development of cost-effective piezoelectric materials with reduced reliance on rare elements like lead zirconate titanate (PZT) will enable broader manufacturing adoption. Similarly, advancements in flexible photovoltaic materials that maintain efficiency while allowing for varied form factors will accelerate commercial viability.

Manufacturing process innovation presents both challenges and opportunities. Roll-to-roll processing techniques show promise for continuous production of flexible hybrid harvesters, potentially reducing unit costs by 40-60% at scale. Automated assembly methods for integrating the piezoelectric and photovoltaic components require further refinement to ensure consistent performance across mass-produced units.

Market entry strategies should initially target high-value applications where the unique advantages of hybrid energy harvesting justify premium pricing. The Internet of Things (IoT) sensor market, valued at $12.7 billion in 2022 and projected to reach $35.2 billion by 2028, represents an ideal entry point. Remote environmental monitoring, structural health monitoring, and wearable health devices offer immediate commercialization opportunities.

Regulatory considerations and certification requirements vary significantly across global markets. Obtaining UL, CE, and other regional certifications will be necessary for widespread adoption. Environmental compliance, particularly regarding end-of-life recycling of piezoelectric materials containing lead, must be addressed through sustainable design approaches.

Investment requirements follow a staged approach, with approximately $2-5 million needed for advanced prototype development and initial pilot production. Scaling to commercial manufacturing volumes will require $10-25 million in capital expenditure, depending on production capacity targets and automation levels.

Strategic partnerships with established electronics manufacturers and system integrators will accelerate market penetration. Licensing technology to existing manufacturers may provide faster commercialization pathways than building dedicated production facilities. Joint development agreements with end-users in target industries can provide valuable feedback loops for product refinement while securing early adoption commitments.

Material optimization represents a critical factor in scalability. The development of cost-effective piezoelectric materials with reduced reliance on rare elements like lead zirconate titanate (PZT) will enable broader manufacturing adoption. Similarly, advancements in flexible photovoltaic materials that maintain efficiency while allowing for varied form factors will accelerate commercial viability.

Manufacturing process innovation presents both challenges and opportunities. Roll-to-roll processing techniques show promise for continuous production of flexible hybrid harvesters, potentially reducing unit costs by 40-60% at scale. Automated assembly methods for integrating the piezoelectric and photovoltaic components require further refinement to ensure consistent performance across mass-produced units.

Market entry strategies should initially target high-value applications where the unique advantages of hybrid energy harvesting justify premium pricing. The Internet of Things (IoT) sensor market, valued at $12.7 billion in 2022 and projected to reach $35.2 billion by 2028, represents an ideal entry point. Remote environmental monitoring, structural health monitoring, and wearable health devices offer immediate commercialization opportunities.

Regulatory considerations and certification requirements vary significantly across global markets. Obtaining UL, CE, and other regional certifications will be necessary for widespread adoption. Environmental compliance, particularly regarding end-of-life recycling of piezoelectric materials containing lead, must be addressed through sustainable design approaches.

Investment requirements follow a staged approach, with approximately $2-5 million needed for advanced prototype development and initial pilot production. Scaling to commercial manufacturing volumes will require $10-25 million in capital expenditure, depending on production capacity targets and automation levels.

Strategic partnerships with established electronics manufacturers and system integrators will accelerate market penetration. Licensing technology to existing manufacturers may provide faster commercialization pathways than building dedicated production facilities. Joint development agreements with end-users in target industries can provide valuable feedback loops for product refinement while securing early adoption commitments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!