How to Suppress Fatigue in Flexible Piezoelectric Devices under Repeated Bending

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Piezoelectric Fatigue Background and Objectives

Flexible piezoelectric devices have emerged as a revolutionary technology in the field of energy harvesting and sensing applications over the past two decades. These devices convert mechanical energy into electrical energy through the piezoelectric effect, offering significant advantages in wearable electronics, biomedical implants, and self-powered systems. The evolution of this technology has been marked by continuous improvements in materials, fabrication techniques, and device architectures, transitioning from rigid ceramic-based piezoelectrics to highly flexible polymer-based and composite systems.

The development trajectory of flexible piezoelectric technology has been driven by the increasing demand for sustainable energy solutions and the miniaturization of electronic devices. Early piezoelectric materials like lead zirconate titanate (PZT) offered excellent performance but lacked flexibility. The introduction of polyvinylidene fluoride (PVDF) and its copolymers in the 1990s represented a significant breakthrough, enabling truly flexible piezoelectric devices. Recent advancements have focused on enhancing output performance through nanostructuring, composite formation, and novel fabrication techniques.

Despite these advancements, fatigue under repeated bending remains a critical challenge that severely limits the practical application and commercial viability of flexible piezoelectric devices. When subjected to cyclic mechanical deformation, these devices experience progressive degradation in performance, manifested as decreased output voltage, current, and overall energy conversion efficiency. This fatigue phenomenon stems from multiple factors including microstructural changes, crack propagation, delamination between layers, and degradation of electrode materials.

The technical objectives of this research are multifaceted and aim to address the fundamental limitations in flexible piezoelectric technology. Primary goals include developing comprehensive understanding of fatigue mechanisms at multiple scales (molecular, microstructural, and device level), establishing standardized testing protocols for evaluating fatigue resistance, and formulating effective strategies to mitigate fatigue effects. Additionally, we aim to design novel material systems and device architectures inherently resistant to fatigue-induced degradation.

The long-term vision extends beyond merely suppressing fatigue to creating "fatigue-proof" flexible piezoelectric systems capable of maintaining consistent performance over millions of bending cycles. This would enable transformative applications in perpetual energy harvesting, long-term implantable medical devices, and structural health monitoring systems. Achieving these objectives requires interdisciplinary approaches combining materials science, mechanical engineering, electrical engineering, and advanced manufacturing techniques.

Current research trends indicate growing interest in self-healing materials, strain-engineering approaches, and biomimetic designs inspired by natural systems that withstand repeated mechanical stress. The convergence of these approaches with emerging fabrication technologies presents promising pathways toward realizing the full potential of flexible piezoelectric devices in next-generation electronics and energy systems.

The development trajectory of flexible piezoelectric technology has been driven by the increasing demand for sustainable energy solutions and the miniaturization of electronic devices. Early piezoelectric materials like lead zirconate titanate (PZT) offered excellent performance but lacked flexibility. The introduction of polyvinylidene fluoride (PVDF) and its copolymers in the 1990s represented a significant breakthrough, enabling truly flexible piezoelectric devices. Recent advancements have focused on enhancing output performance through nanostructuring, composite formation, and novel fabrication techniques.

Despite these advancements, fatigue under repeated bending remains a critical challenge that severely limits the practical application and commercial viability of flexible piezoelectric devices. When subjected to cyclic mechanical deformation, these devices experience progressive degradation in performance, manifested as decreased output voltage, current, and overall energy conversion efficiency. This fatigue phenomenon stems from multiple factors including microstructural changes, crack propagation, delamination between layers, and degradation of electrode materials.

The technical objectives of this research are multifaceted and aim to address the fundamental limitations in flexible piezoelectric technology. Primary goals include developing comprehensive understanding of fatigue mechanisms at multiple scales (molecular, microstructural, and device level), establishing standardized testing protocols for evaluating fatigue resistance, and formulating effective strategies to mitigate fatigue effects. Additionally, we aim to design novel material systems and device architectures inherently resistant to fatigue-induced degradation.

The long-term vision extends beyond merely suppressing fatigue to creating "fatigue-proof" flexible piezoelectric systems capable of maintaining consistent performance over millions of bending cycles. This would enable transformative applications in perpetual energy harvesting, long-term implantable medical devices, and structural health monitoring systems. Achieving these objectives requires interdisciplinary approaches combining materials science, mechanical engineering, electrical engineering, and advanced manufacturing techniques.

Current research trends indicate growing interest in self-healing materials, strain-engineering approaches, and biomimetic designs inspired by natural systems that withstand repeated mechanical stress. The convergence of these approaches with emerging fabrication technologies presents promising pathways toward realizing the full potential of flexible piezoelectric devices in next-generation electronics and energy systems.

Market Demand for Durable Flexible Energy Harvesters

The global market for flexible energy harvesting technologies has been experiencing significant growth, driven by the expanding Internet of Things (IoT) ecosystem and wearable technology sectors. Flexible piezoelectric devices represent a crucial segment within this market, offering the ability to convert mechanical energy from human movement, vibrations, and environmental forces into usable electrical power. Current market projections indicate that the flexible energy harvesting market is expected to reach $9.4 billion by 2027, with piezoelectric technologies accounting for approximately 24% of this value.

The demand for durable flexible energy harvesters stems primarily from five key application sectors. First, wearable health monitoring devices require reliable power sources that can withstand continuous body movement and frequent bending. The medical wearables market alone is growing at 26% annually, creating substantial demand for fatigue-resistant piezoelectric components.

Second, smart textiles and e-textiles represent an emerging market with significant potential. These applications demand energy harvesting solutions that can endure thousands of bending cycles while maintaining consistent power output. Industry analysts project that by 2025, over 30 million smart garments incorporating flexible energy harvesting will be sold annually.

Third, structural health monitoring systems for infrastructure and aerospace applications require energy harvesters that can operate reliably for years without maintenance. The harsh operating conditions in these environments make durability a critical requirement, with customers willing to pay premium prices for solutions that demonstrate superior fatigue resistance.

Fourth, the automotive sector is increasingly adopting flexible sensors and energy harvesters for various applications, from tire pressure monitoring to occupant detection systems. These components must withstand extreme mechanical stress and repeated deformation throughout the vehicle's lifecycle, typically 10-15 years.

Fifth, consumer electronics manufacturers are seeking to integrate energy harvesting into foldable displays, flexible smartphones, and other next-generation devices. Market research indicates that 78% of consumers consider battery life and charging convenience as decisive factors in purchasing decisions, highlighting the commercial value of durable energy harvesting solutions.

The market demonstrates a clear willingness to pay for enhanced durability, with surveys showing that industrial customers are prepared to invest 40-60% more for energy harvesting solutions that offer double the operational lifespan. This premium pricing potential creates significant economic incentives for developing fatigue-resistant technologies.

Furthermore, regulatory trends are increasingly favoring sustainable power solutions, with several jurisdictions implementing regulations that encourage or mandate self-powered sensors and reduced battery waste. These regulatory drivers further strengthen market demand for durable flexible energy harvesters that can provide consistent performance over extended operational lifetimes.

The demand for durable flexible energy harvesters stems primarily from five key application sectors. First, wearable health monitoring devices require reliable power sources that can withstand continuous body movement and frequent bending. The medical wearables market alone is growing at 26% annually, creating substantial demand for fatigue-resistant piezoelectric components.

Second, smart textiles and e-textiles represent an emerging market with significant potential. These applications demand energy harvesting solutions that can endure thousands of bending cycles while maintaining consistent power output. Industry analysts project that by 2025, over 30 million smart garments incorporating flexible energy harvesting will be sold annually.

Third, structural health monitoring systems for infrastructure and aerospace applications require energy harvesters that can operate reliably for years without maintenance. The harsh operating conditions in these environments make durability a critical requirement, with customers willing to pay premium prices for solutions that demonstrate superior fatigue resistance.

Fourth, the automotive sector is increasingly adopting flexible sensors and energy harvesters for various applications, from tire pressure monitoring to occupant detection systems. These components must withstand extreme mechanical stress and repeated deformation throughout the vehicle's lifecycle, typically 10-15 years.

Fifth, consumer electronics manufacturers are seeking to integrate energy harvesting into foldable displays, flexible smartphones, and other next-generation devices. Market research indicates that 78% of consumers consider battery life and charging convenience as decisive factors in purchasing decisions, highlighting the commercial value of durable energy harvesting solutions.

The market demonstrates a clear willingness to pay for enhanced durability, with surveys showing that industrial customers are prepared to invest 40-60% more for energy harvesting solutions that offer double the operational lifespan. This premium pricing potential creates significant economic incentives for developing fatigue-resistant technologies.

Furthermore, regulatory trends are increasingly favoring sustainable power solutions, with several jurisdictions implementing regulations that encourage or mandate self-powered sensors and reduced battery waste. These regulatory drivers further strengthen market demand for durable flexible energy harvesters that can provide consistent performance over extended operational lifetimes.

Technical Challenges in Piezoelectric Material Fatigue Resistance

Piezoelectric materials in flexible devices face significant fatigue challenges under repeated bending conditions, primarily due to the inherent brittleness of conventional piezoelectric ceramics such as PZT and BaTiO3. When subjected to cyclic mechanical deformation, these materials develop microcracks that propagate with continued stress, eventually leading to performance degradation and device failure. This fatigue phenomenon manifests as reduced voltage output, decreased sensitivity, and ultimately complete functional loss.

The mechanical mismatch between rigid piezoelectric elements and flexible substrates creates stress concentration points during bending cycles, accelerating fatigue progression. Research has shown that after just 1,000 bending cycles at moderate radii (5-10mm), conventional piezoelectric devices can lose up to 40% of their initial performance. This degradation rate increases exponentially with smaller bending radii and higher cycling frequencies.

Another significant challenge is the electrode-piezoelectric interface degradation. Repeated bending causes delamination between the electrode and active material, increasing contact resistance and reducing charge collection efficiency. This interface failure often precedes bulk material failure and represents a critical weak point in flexible piezoelectric systems.

Environmental factors further complicate fatigue resistance. Humidity accelerates crack propagation through stress corrosion mechanisms, while temperature fluctuations induce additional thermal stresses that compound mechanical fatigue effects. Studies indicate that operating in high humidity (>70% RH) can reduce fatigue life by up to 60% compared to controlled environments.

The polarization stability of piezoelectric materials presents another challenge. Mechanical stress can cause domain reorientation and depolarization, particularly in polymer-based piezoelectrics like PVDF. This leads to gradual loss of piezoelectric response even before physical material failure occurs. Research indicates that polarization degradation can begin after as few as 500 cycles in poorly designed systems.

Scale-dependent effects further complicate fatigue resistance in miniaturized devices. As dimensions decrease to micro and nanoscales, surface effects become increasingly dominant, altering fatigue mechanisms and often accelerating degradation. Nanoscale piezoelectric elements may exhibit different failure modes than their bulk counterparts, requiring specialized approaches to fatigue mitigation.

Current testing methodologies also present challenges, as accelerated life testing protocols often fail to accurately predict real-world performance. The complex interplay between mechanical, electrical, and environmental stressors creates failure modes that may not manifest during simplified laboratory testing, leading to unexpected field failures and reliability issues in commercial applications.

The mechanical mismatch between rigid piezoelectric elements and flexible substrates creates stress concentration points during bending cycles, accelerating fatigue progression. Research has shown that after just 1,000 bending cycles at moderate radii (5-10mm), conventional piezoelectric devices can lose up to 40% of their initial performance. This degradation rate increases exponentially with smaller bending radii and higher cycling frequencies.

Another significant challenge is the electrode-piezoelectric interface degradation. Repeated bending causes delamination between the electrode and active material, increasing contact resistance and reducing charge collection efficiency. This interface failure often precedes bulk material failure and represents a critical weak point in flexible piezoelectric systems.

Environmental factors further complicate fatigue resistance. Humidity accelerates crack propagation through stress corrosion mechanisms, while temperature fluctuations induce additional thermal stresses that compound mechanical fatigue effects. Studies indicate that operating in high humidity (>70% RH) can reduce fatigue life by up to 60% compared to controlled environments.

The polarization stability of piezoelectric materials presents another challenge. Mechanical stress can cause domain reorientation and depolarization, particularly in polymer-based piezoelectrics like PVDF. This leads to gradual loss of piezoelectric response even before physical material failure occurs. Research indicates that polarization degradation can begin after as few as 500 cycles in poorly designed systems.

Scale-dependent effects further complicate fatigue resistance in miniaturized devices. As dimensions decrease to micro and nanoscales, surface effects become increasingly dominant, altering fatigue mechanisms and often accelerating degradation. Nanoscale piezoelectric elements may exhibit different failure modes than their bulk counterparts, requiring specialized approaches to fatigue mitigation.

Current testing methodologies also present challenges, as accelerated life testing protocols often fail to accurately predict real-world performance. The complex interplay between mechanical, electrical, and environmental stressors creates failure modes that may not manifest during simplified laboratory testing, leading to unexpected field failures and reliability issues in commercial applications.

Current Fatigue Suppression Methods for Flexible Piezoelectrics

01 Materials for fatigue-resistant flexible piezoelectric devices

Various materials can be used to create flexible piezoelectric devices with enhanced fatigue resistance. These include specialized polymers, composite materials, and thin films that maintain piezoelectric properties while withstanding repeated bending and flexing. The selection of appropriate materials is crucial for extending the operational lifespan of flexible piezoelectric devices in applications requiring continuous mechanical deformation.- Materials for fatigue-resistant piezoelectric devices: Various materials can be used to create flexible piezoelectric devices with enhanced fatigue resistance. These include specialized polymers, composite materials, and novel piezoelectric materials that maintain their electrical properties under repeated mechanical stress. The selection of appropriate materials is crucial for developing devices that can withstand numerous bending cycles without performance degradation. These materials often feature optimized molecular structures that allow for flexibility while preserving piezoelectric properties.

- Structural designs to mitigate fatigue: Innovative structural designs can significantly improve the fatigue resistance of flexible piezoelectric devices. These designs include layered architectures, substrate optimization, and strategic placement of piezoelectric elements to distribute mechanical stress. By incorporating features such as strain-relieving structures, reinforcement layers, and flexible interconnects, these designs minimize localized stress concentrations that typically lead to fatigue failure. The geometry and arrangement of piezoelectric components play a critical role in extending device lifespan.

- Encapsulation and protection techniques: Effective encapsulation and protection methods are essential for preventing fatigue in flexible piezoelectric devices. These techniques include applying specialized protective coatings, using flexible encapsulants, and implementing moisture barriers that shield the piezoelectric elements from environmental factors while allowing mechanical flexibility. The encapsulation materials must maintain their protective properties during repeated flexing and should not impede the piezoelectric performance of the device. These protection systems often incorporate multiple layers with complementary protective functions.

- Testing and characterization of fatigue performance: Specialized testing methodologies have been developed to evaluate the fatigue performance of flexible piezoelectric devices. These include accelerated life testing, cyclic bending tests, and real-time monitoring of electrical output during mechanical cycling. Advanced characterization techniques such as in-situ microscopy and spectroscopic analysis help identify failure mechanisms and degradation pathways. These testing protocols are crucial for validating design improvements and predicting the operational lifespan of flexible piezoelectric devices under various usage conditions.

- Integration with flexible electronics: The integration of piezoelectric elements with flexible electronic components presents unique challenges for fatigue resistance. Solutions include developing compatible interconnection methods, flexible circuit designs, and hybrid integration approaches that accommodate the different mechanical properties of piezoelectric materials and electronic components. These integration strategies often employ stretchable conductors, flexible substrates, and novel bonding techniques that maintain electrical connectivity during repeated flexing. The co-design of the piezoelectric and electronic elements is essential for creating durable, multifunctional flexible devices.

02 Structural designs to mitigate fatigue in flexible piezoelectric devices

Innovative structural designs can significantly reduce fatigue in flexible piezoelectric devices. These designs include layered architectures, substrate reinforcement, strategic electrode placement, and mechanical stress distribution systems. By optimizing the physical configuration of the device components, mechanical stress can be more evenly distributed, reducing localized strain and extending the fatigue life of the overall device.Expand Specific Solutions03 Testing and evaluation methods for piezoelectric device fatigue

Specialized testing methodologies have been developed to evaluate the fatigue performance of flexible piezoelectric devices. These include accelerated life testing, cyclic loading tests, and real-time monitoring of electrical output during repeated deformation. These evaluation methods help in predicting device lifespan and identifying potential failure modes, allowing for improvements in design and material selection to enhance fatigue resistance.Expand Specific Solutions04 Encapsulation and protection techniques for fatigue reduction

Encapsulation and protective coating technologies play a crucial role in enhancing the fatigue resistance of flexible piezoelectric devices. These techniques include polymer encapsulation, hermetic sealing, and specialized protective layers that shield the active piezoelectric elements from environmental factors while allowing mechanical flexibility. Proper encapsulation can significantly extend device lifespan by preventing moisture ingress, mechanical damage, and electrical degradation.Expand Specific Solutions05 Applications of fatigue-resistant flexible piezoelectric devices

Fatigue-resistant flexible piezoelectric devices find applications in various fields including wearable electronics, energy harvesting, biomedical implants, and structural health monitoring. These applications leverage the devices' ability to withstand repeated mechanical deformation while maintaining consistent electrical output. The development of fatigue-resistant designs has enabled long-term deployment in challenging environments where continuous flexing occurs.Expand Specific Solutions

Leading Companies and Research Institutions in Flexible Electronics

The flexible piezoelectric device fatigue suppression market is currently in a growth phase, with increasing demand driven by wearable technology and IoT applications. The market is projected to expand significantly as these devices become integral to energy harvesting systems. Technologically, the field shows varying maturity levels across players. Industry leaders like Murata Manufacturing and Kyocera have established advanced manufacturing capabilities for durable piezoelectric components, while companies such as TDK Electronics and Canon are developing innovative materials to enhance flexibility and longevity. Academic institutions including Tsinghua University and Michigan State University are pioneering fundamental research in fatigue mechanisms. Automotive manufacturers like Toyota and Honda are exploring applications in vehicle sensing systems, indicating cross-industry adoption potential.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed a comprehensive approach to suppress fatigue in flexible piezoelectric devices through their proprietary multi-layer ceramic capacitor (MLCC) technology. Their solution incorporates a flexible polymer substrate with optimized thickness and elasticity properties that distribute bending stress more evenly. The piezoelectric elements are embedded in a specialized matrix using their "sheet lamination process" which creates microscopic stress-relief structures between layers. Additionally, Murata employs nano-engineered electrode materials with high flexibility and conductivity that maintain electrical performance under repeated deformation. Their devices incorporate self-healing mechanisms where minor cracks in the piezoelectric material can be repaired through localized heating during operation. Murata's approach also includes specialized encapsulation techniques that protect against environmental factors while maintaining flexibility, significantly extending device lifespan under continuous bending conditions.

Strengths: Industry-leading expertise in piezoelectric materials manufacturing; established mass production capabilities; comprehensive material science research facilities. Weaknesses: Higher production costs compared to conventional rigid piezoelectric devices; some solutions may be limited to specific application environments.

Huazhong University of Science & Technology

Technical Solution: Huazhong University has developed a groundbreaking approach to fatigue suppression in flexible piezoelectric devices through their research on "stress-adaptive microstructures." Their solution incorporates a biomimetic design inspired by natural materials like bamboo, creating hierarchical structures that distribute mechanical stress across multiple scales. The university's research team has engineered specialized grain boundary modifications in piezoelectric ceramics that inhibit crack propagation under cyclic loading. Their approach includes a novel electrode design using liquid metal alloys contained in microchannels that maintain electrical connectivity even under extreme deformation. Additionally, they've developed a self-reinforcing composite structure where initial bending actually strengthens certain molecular bonds through mechanochemical reactions, creating a material that becomes more resistant to fatigue with use. Their manufacturing process employs precision-controlled laser sintering that creates predetermined "safe failure" zones that absorb mechanical energy without compromising overall device functionality.

Strengths: Cutting-edge fundamental research capabilities; innovative biomimetic design approaches; strong collaboration with Chinese manufacturing sector. Weaknesses: Less established commercialization pathway compared to industry players; potential challenges in scaling laboratory techniques to mass production.

Key Patents and Research on Piezoelectric Fatigue Mitigation

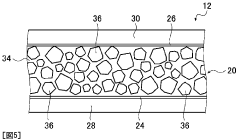

Member for flexible element and manufacturing method thereof

PatentActiveUS9510445B2

Innovation

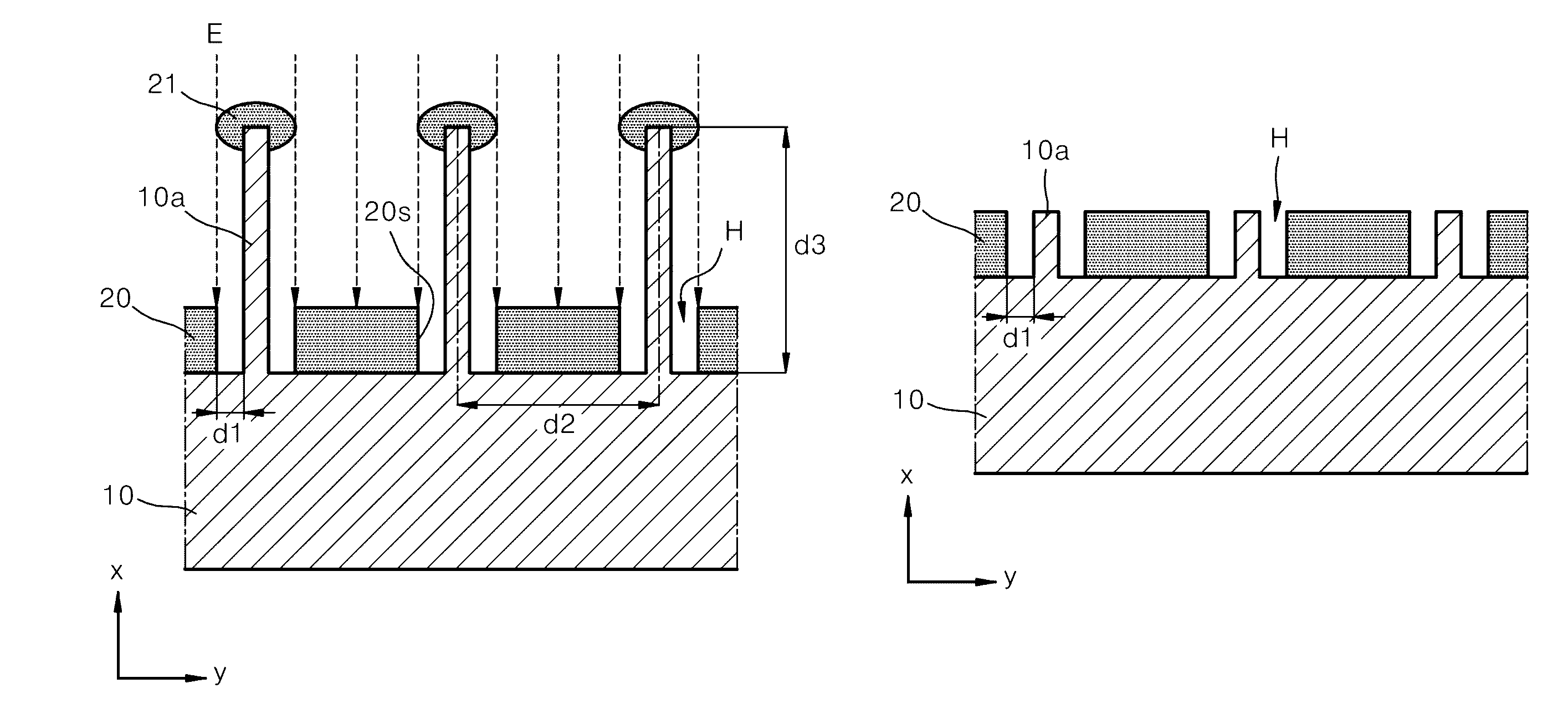

- A metal electrode with a nanostructure featuring nanoholes and nanopillars on a polyimide substrate, where the nanopillars penetrate through nanoholes and the metal electrode is composed of copper, enhancing fatigue resistance by distributing stress and blunting crack tips.

Piezoelectric element, and electro-acoustic converter

PatentWO2023157532A1

Innovation

- A piezoelectric element with multiple layers of polymer composite piezoelectric films, featuring notches in intermediate layers to enhance bending resistance and maintain high stretching force, is developed, allowing for attachment to bendable diaphragms without compromising sound pressure.

Materials Science Approaches to Enhance Mechanical Durability

Materials science offers significant pathways to enhance the mechanical durability of flexible piezoelectric devices subjected to repeated bending. The fundamental challenge lies in the inherent brittleness of many piezoelectric materials, particularly ceramics like PZT (lead zirconate titanate), which exhibit excellent electromechanical properties but poor flexibility.

Composite material approaches represent one of the most promising strategies. By integrating piezoelectric materials with elastic polymers such as PDMS (polydimethylsiloxane) or PVDF (polyvinylidene fluoride), researchers have developed structures that can withstand substantial mechanical deformation while maintaining electrical performance. These composites distribute stress more effectively, preventing catastrophic failure during bending cycles.

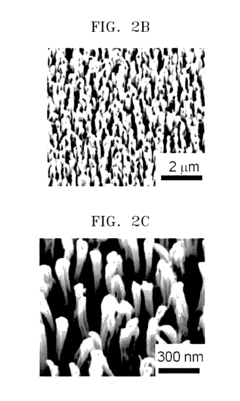

Nanostructuring has emerged as another critical approach. Piezoelectric nanowires, nanofibers, and nanoparticles embedded in flexible matrices demonstrate superior fatigue resistance compared to their bulk counterparts. The reduced dimensions allow for greater strain accommodation without crack propagation, significantly extending device lifetime under cyclic loading conditions.

Surface treatment and interface engineering techniques have shown remarkable effectiveness in enhancing mechanical durability. Methods such as chemical functionalization, plasma treatment, and the application of coupling agents improve adhesion between piezoelectric elements and substrate materials, preventing delamination during repeated bending. These treatments create stronger chemical bonds at interfaces where mechanical failure typically initiates.

Novel material architectures, including kirigami and origami-inspired designs, provide another avenue for enhancing durability. These structures incorporate strategic cuts or folds that effectively convert bending strain into stretching or rotation, reducing localized stress concentrations that lead to fatigue failure. Such biomimetic approaches have demonstrated up to 300% improvement in bending cycle endurance.

Self-healing materials represent the cutting edge of durability enhancement. Incorporating microcapsules containing healing agents or utilizing reversible chemical bonds enables piezoelectric devices to autonomously repair microcracks formed during bending cycles. Although still in early development stages, self-healing piezoelectric composites have shown the potential to restore up to 80% of performance after mechanical damage.

Strain engineering through the precise control of crystallographic orientation in piezoelectric thin films has also proven effective. By aligning crystal domains perpendicular to the primary bending axis, researchers have created structures that can accommodate greater strain without fracture, extending fatigue life by orders of magnitude compared to randomly oriented films.

Composite material approaches represent one of the most promising strategies. By integrating piezoelectric materials with elastic polymers such as PDMS (polydimethylsiloxane) or PVDF (polyvinylidene fluoride), researchers have developed structures that can withstand substantial mechanical deformation while maintaining electrical performance. These composites distribute stress more effectively, preventing catastrophic failure during bending cycles.

Nanostructuring has emerged as another critical approach. Piezoelectric nanowires, nanofibers, and nanoparticles embedded in flexible matrices demonstrate superior fatigue resistance compared to their bulk counterparts. The reduced dimensions allow for greater strain accommodation without crack propagation, significantly extending device lifetime under cyclic loading conditions.

Surface treatment and interface engineering techniques have shown remarkable effectiveness in enhancing mechanical durability. Methods such as chemical functionalization, plasma treatment, and the application of coupling agents improve adhesion between piezoelectric elements and substrate materials, preventing delamination during repeated bending. These treatments create stronger chemical bonds at interfaces where mechanical failure typically initiates.

Novel material architectures, including kirigami and origami-inspired designs, provide another avenue for enhancing durability. These structures incorporate strategic cuts or folds that effectively convert bending strain into stretching or rotation, reducing localized stress concentrations that lead to fatigue failure. Such biomimetic approaches have demonstrated up to 300% improvement in bending cycle endurance.

Self-healing materials represent the cutting edge of durability enhancement. Incorporating microcapsules containing healing agents or utilizing reversible chemical bonds enables piezoelectric devices to autonomously repair microcracks formed during bending cycles. Although still in early development stages, self-healing piezoelectric composites have shown the potential to restore up to 80% of performance after mechanical damage.

Strain engineering through the precise control of crystallographic orientation in piezoelectric thin films has also proven effective. By aligning crystal domains perpendicular to the primary bending axis, researchers have created structures that can accommodate greater strain without fracture, extending fatigue life by orders of magnitude compared to randomly oriented films.

Reliability Testing Standards for Flexible Electronic Devices

Reliability testing standards for flexible electronic devices have become increasingly critical as these technologies transition from laboratory prototypes to commercial applications. For flexible piezoelectric devices specifically, standardized testing protocols are essential to evaluate their durability under repeated bending conditions. Currently, several international organizations including IEC (International Electrotechnical Commission), ASTM International, and IEEE have developed preliminary standards that address aspects of flexible electronics reliability.

The IEC 62951 series represents one of the most comprehensive frameworks, with specific sections dedicated to flexible and stretchable electronic systems. These standards outline testing methodologies for mechanical durability, including cyclic bending tests with controlled parameters such as bending radius, frequency, and environmental conditions. For piezoelectric devices, IEC 62830-8 provides additional guidance on performance characterization under mechanical deformation.

ASTM F3089 establishes testing protocols for determining mechanical properties of flexible substrates, which serves as a foundation for evaluating the structural integrity of flexible piezoelectric devices. This standard specifies methods for measuring flexural endurance and resistance to cracking under repeated bending stress.

Testing parameters typically include bending radius (ranging from 1mm to 10mm), cycling frequency (0.5Hz to 10Hz), temperature conditions (-20°C to 85°C), and humidity levels (10% to 95% RH). These parameters must be carefully controlled to ensure reproducible results across different testing facilities and device types.

Accelerated life testing represents another crucial aspect of reliability standards. These protocols subject devices to intensified stress conditions to predict long-term performance in shorter testing periods. For flexible piezoelectric devices, this often involves increased bending frequencies and environmental cycling to simulate years of operation within weeks of testing.

Failure criteria are explicitly defined within these standards, with common metrics including: reduction in piezoelectric output below 80% of initial value, visible cracking or delamination, significant drift in resonant frequency, and increased electrical impedance. These quantitative benchmarks enable objective assessment of device durability.

Recent developments in reliability standards have begun incorporating in-situ monitoring techniques, allowing real-time observation of performance degradation during cycling tests. This approach provides valuable insights into failure mechanisms and progression patterns that static before-and-after measurements cannot capture.

Despite these advances, standardization efforts specifically targeting flexible piezoelectric devices remain incomplete. Current standards often require adaptation from related fields such as flexible displays or sensors, highlighting the need for more specialized protocols that address the unique failure modes of piezoelectric materials under repeated mechanical stress.

The IEC 62951 series represents one of the most comprehensive frameworks, with specific sections dedicated to flexible and stretchable electronic systems. These standards outline testing methodologies for mechanical durability, including cyclic bending tests with controlled parameters such as bending radius, frequency, and environmental conditions. For piezoelectric devices, IEC 62830-8 provides additional guidance on performance characterization under mechanical deformation.

ASTM F3089 establishes testing protocols for determining mechanical properties of flexible substrates, which serves as a foundation for evaluating the structural integrity of flexible piezoelectric devices. This standard specifies methods for measuring flexural endurance and resistance to cracking under repeated bending stress.

Testing parameters typically include bending radius (ranging from 1mm to 10mm), cycling frequency (0.5Hz to 10Hz), temperature conditions (-20°C to 85°C), and humidity levels (10% to 95% RH). These parameters must be carefully controlled to ensure reproducible results across different testing facilities and device types.

Accelerated life testing represents another crucial aspect of reliability standards. These protocols subject devices to intensified stress conditions to predict long-term performance in shorter testing periods. For flexible piezoelectric devices, this often involves increased bending frequencies and environmental cycling to simulate years of operation within weeks of testing.

Failure criteria are explicitly defined within these standards, with common metrics including: reduction in piezoelectric output below 80% of initial value, visible cracking or delamination, significant drift in resonant frequency, and increased electrical impedance. These quantitative benchmarks enable objective assessment of device durability.

Recent developments in reliability standards have begun incorporating in-situ monitoring techniques, allowing real-time observation of performance degradation during cycling tests. This approach provides valuable insights into failure mechanisms and progression patterns that static before-and-after measurements cannot capture.

Despite these advances, standardization efforts specifically targeting flexible piezoelectric devices remain incomplete. Current standards often require adaptation from related fields such as flexible displays or sensors, highlighting the need for more specialized protocols that address the unique failure modes of piezoelectric materials under repeated mechanical stress.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!